A kind of multi-color vacuum coating and its processing technology

A technology of vacuum coating and processing technology, applied in vacuum evaporation coating, metal material coating process, sputtering coating and other directions, can solve the problems of inability to meet the requirements of use, inability to coat multiple layers, multi-color color patterns, etc. Achieve good anti-counterfeiting effect, good plating and printing effect, clear and accurate pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

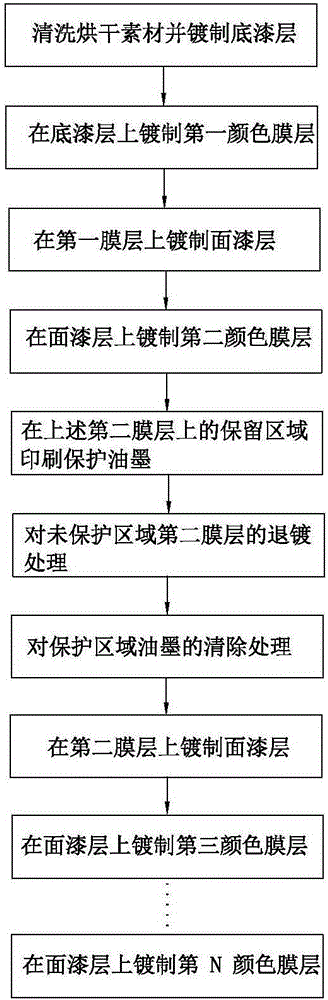

[0036] A multi-color vacuum coating process, comprising the following steps:

[0037] a. Material primer coating: wash and dry the material 1 to be coated to obtain a clean material 1, and print a layer of material 1 primer on the surface of the material 1 by vacuum coating.

[0038] b. Plating the first color film layer 3: using the coating material to vacuum-plate the first color film layer 3 on the surface of the primer of the material 1 .

[0039] c. Plating top paint layer 4: vacuum plating top paint layer 4 on the surface of the first color film layer 3 .

[0040] d. Plating the second color film layer 5: using the coating material to vacuum-plate the second color film layer 5 on the surface of the first top paint layer 4 .

[0041] e. Protective ink printing: Select the area to be reserved on the surface of the second color film layer 5, and print protective ink in this area by pad printing. The protective ink in this embodiment is Shenzhen Wanjiayuan Chemical Industry...

Embodiment 2

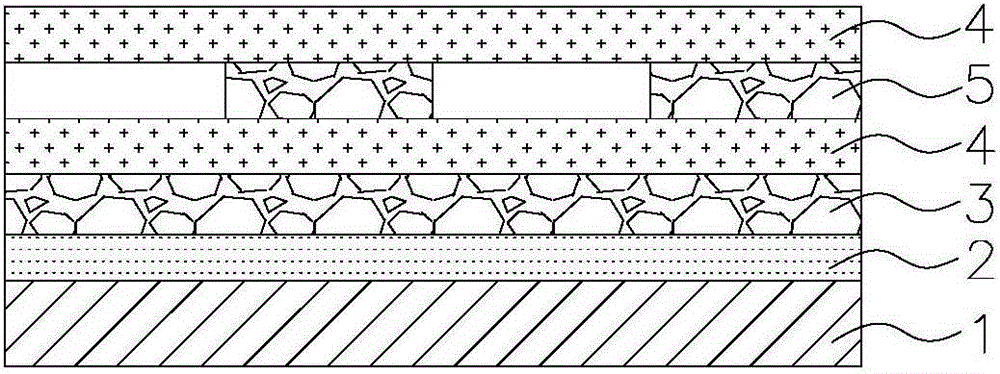

[0047] The difference between this embodiment and Embodiment 1 is that step i is also included after the step h: according to the method of steps d~h, the opaque third color film layer and topcoat layer 4 are sequentially plated, and further, continuously Step i is repeated to sequentially obtain opaque film layers of the fourth color to the Nth color film layer. The first color film layer 3 to the Nth color film layer of the present invention overlap in sequence, and a topcoat layer 4 is arranged between the first color film layer 3 to the Nth color film layer, and the topcoat layer can be determined according to actual needs Layer 4 is colorless or transparent.

[0048] The multi-color vacuum coating of the present embodiment comprises a material layer, a primer layer 2 printed on the surface of the material 1 layer, and a multi-layer coating layer sequentially arranged above the primer layer 2, and each coating layer is provided with The topcoat layer 4, preferably, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com