Winding machine

A winding machine and winding technology, which is used in coil manufacturing, electrical components, transportation of filamentous materials, etc., can solve the problems of uneven wire diameter and difficulty in avoiding random wires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

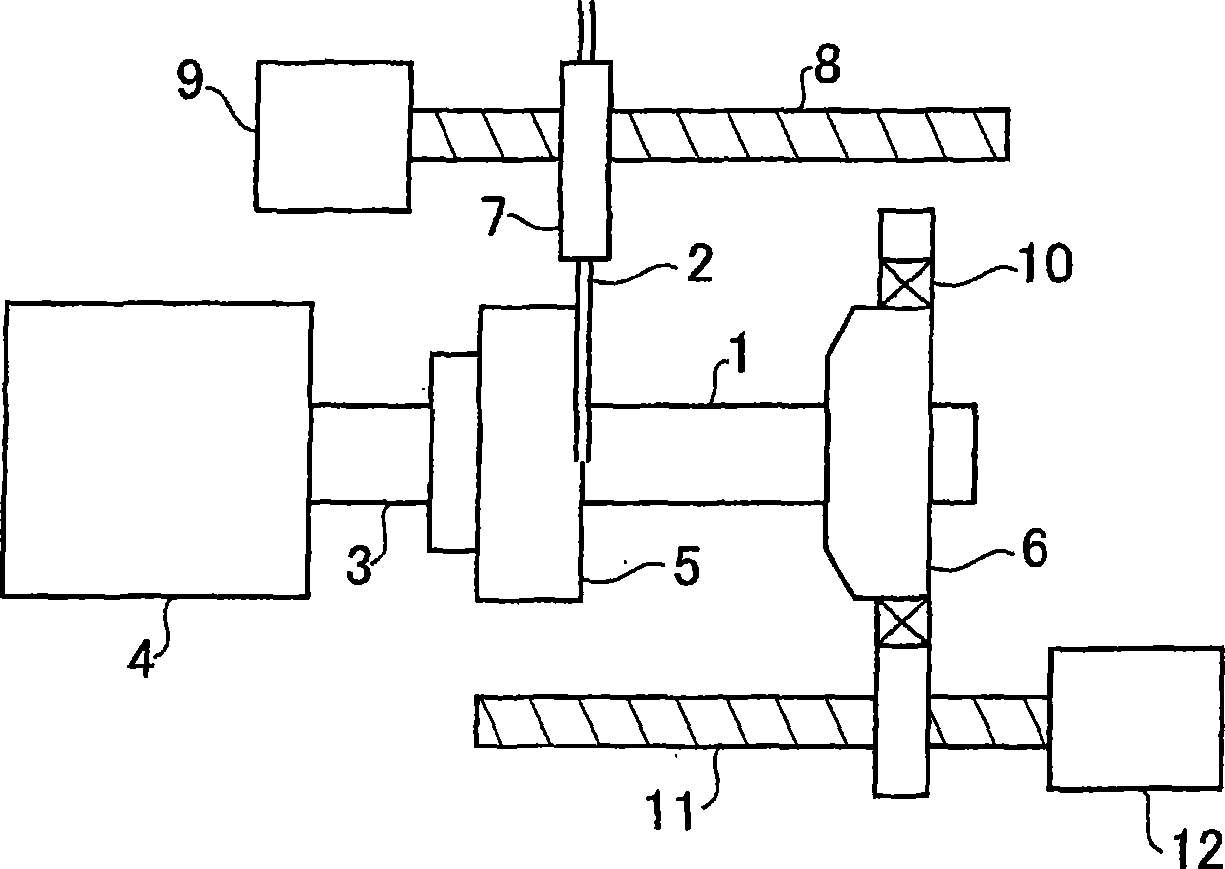

[0042] Hereinafter, the present invention will be described in detail with reference to embodiments of the drawings. figure 1 It is the winding machine of embodiment example. A winding machine having a movable flange 6 is known (for example, refer to JP-A-58-116712). Briefly, here, the wire 2 supplied by the wire supply mechanism 7 is wound on the winding mandrel 1 to form a multi-layer wound air-core coil.

[0043] The wire supply mechanism 7 moves in parallel with respect to the winding mandrel 1 through the feed screw 8 . The feed screw 8 is driven by a motor 9 . The winding mandrel 1 is fixed on the main shaft 3 and driven by the main shaft motor 4 to rotate. A fixed flange 5 and a movable flange 6 are disposed on the winding mandrel 1 . The movable flange 6 is engaged with the feed screw 11 through the bearing 10 . The feed screw 11 is driven by a motor 12 to move the movable flange 6 on the winding mandrel 1 .

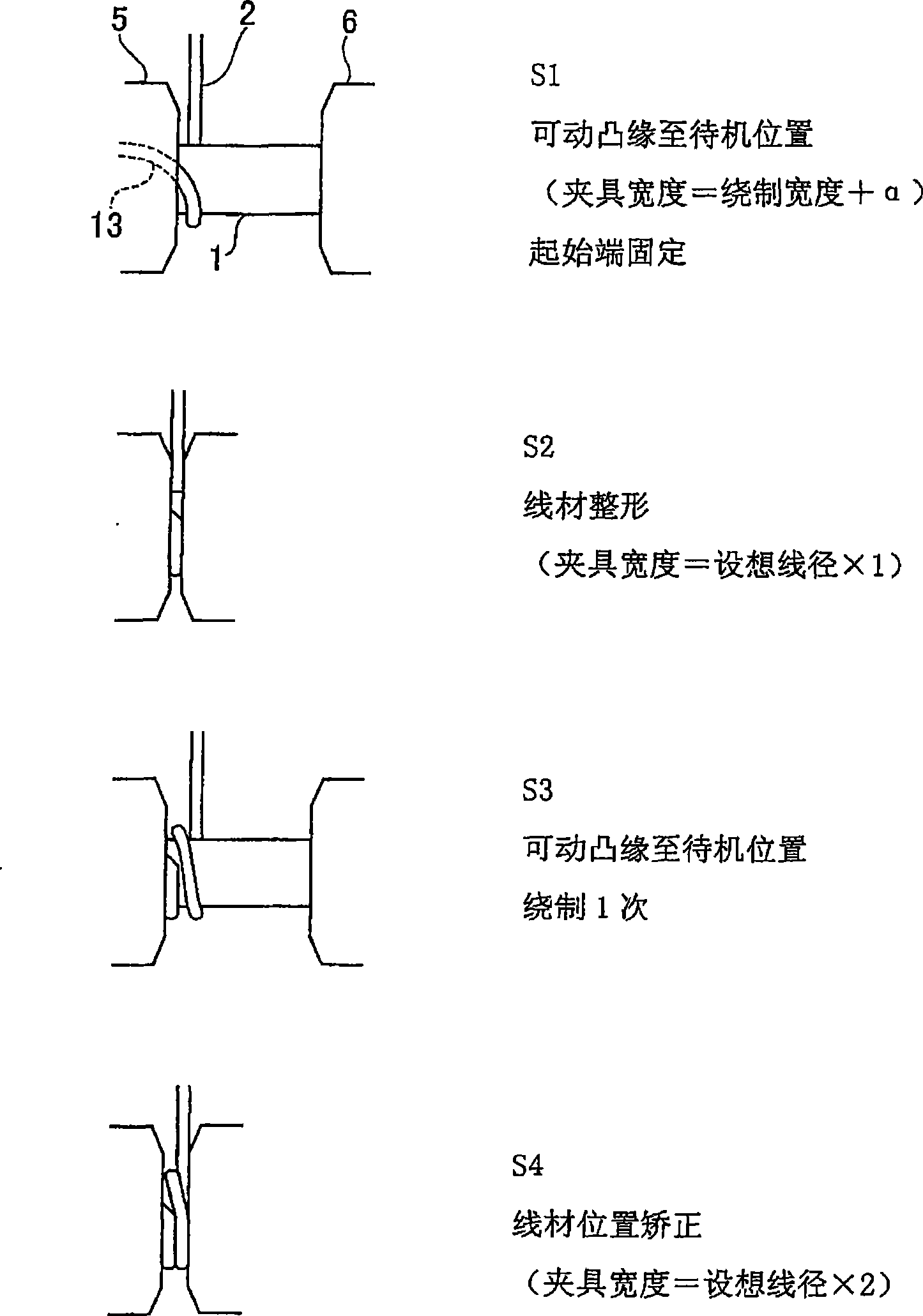

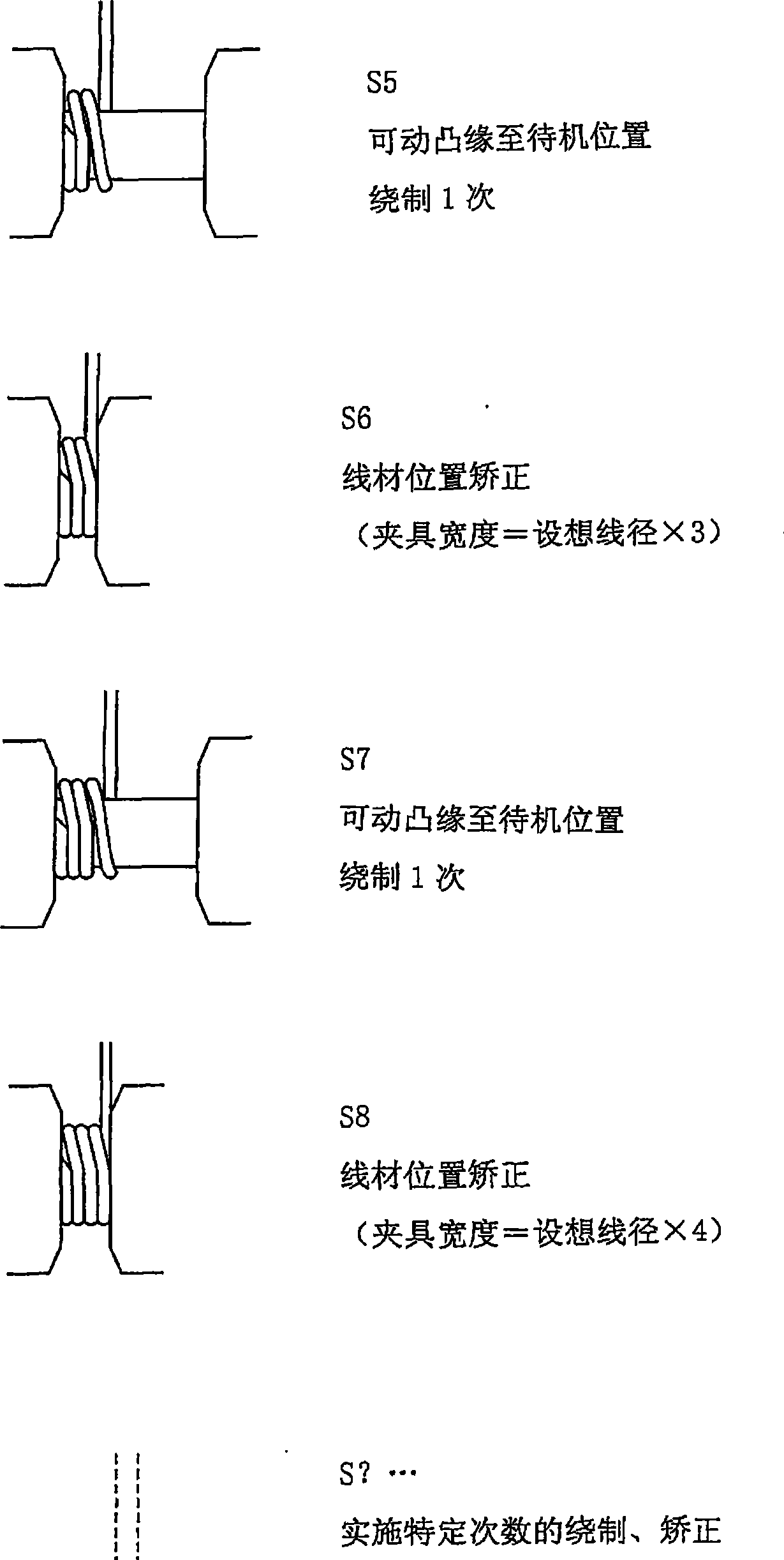

[0044] The winding steps of this winding machine are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com