Electrode composite material of flexible supercapacitor and preparation method of electrode composite material

A technology of supercapacitors and composite materials, applied in the field of energy storage materials, can solve the problems of insufficient storage capacity of flexible supercapacitors, and achieve the effects of good flexibility, convenient operation and good energy storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

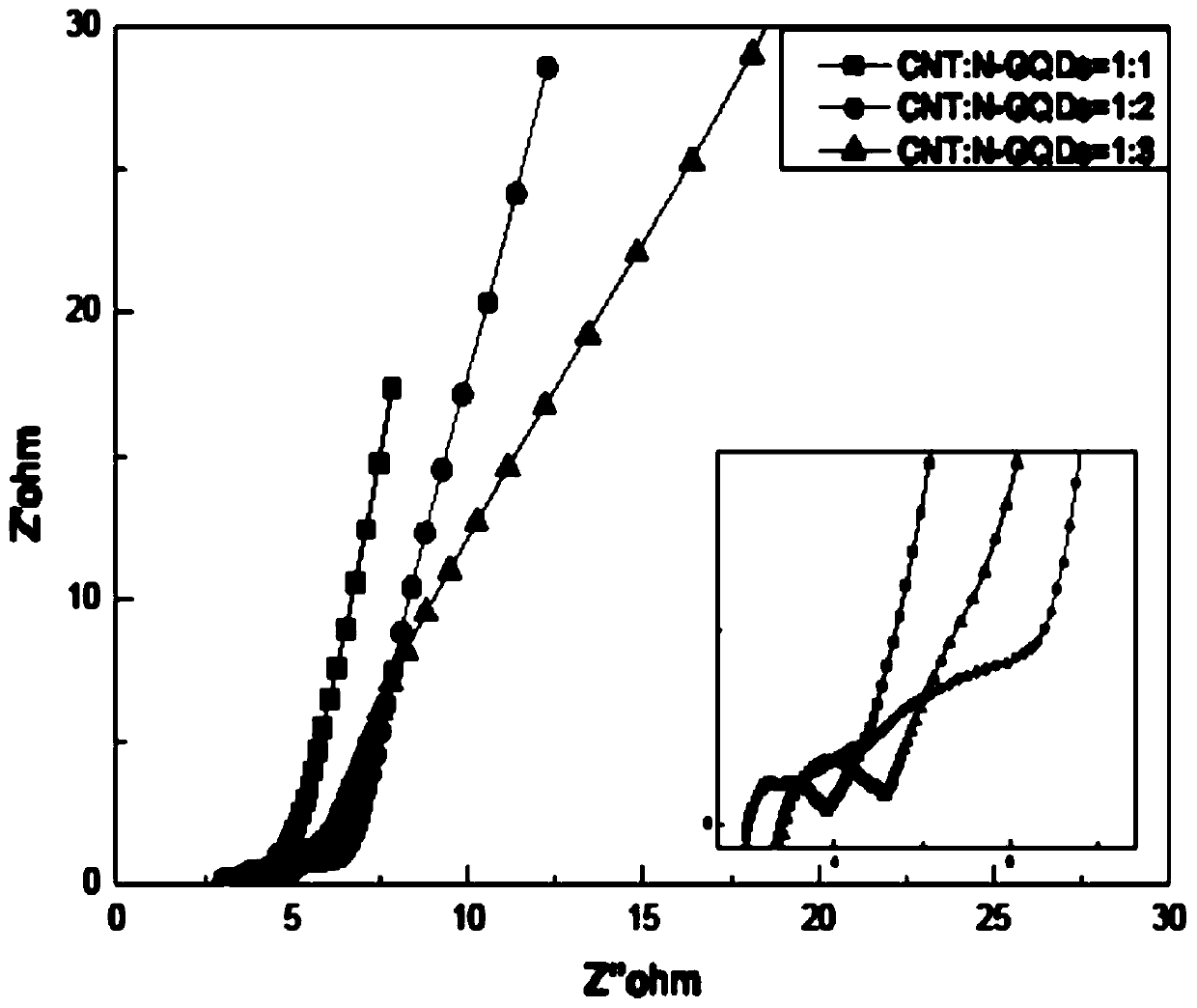

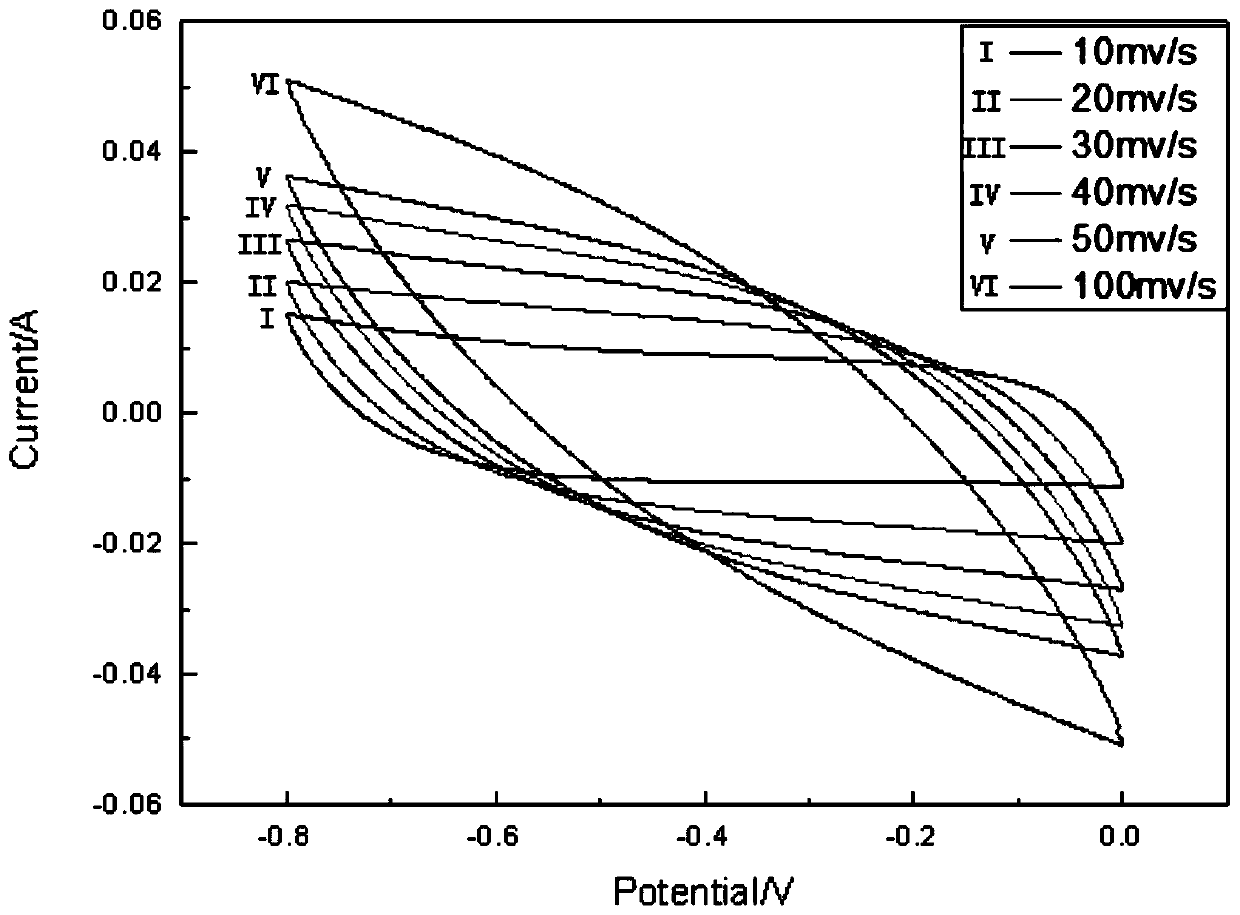

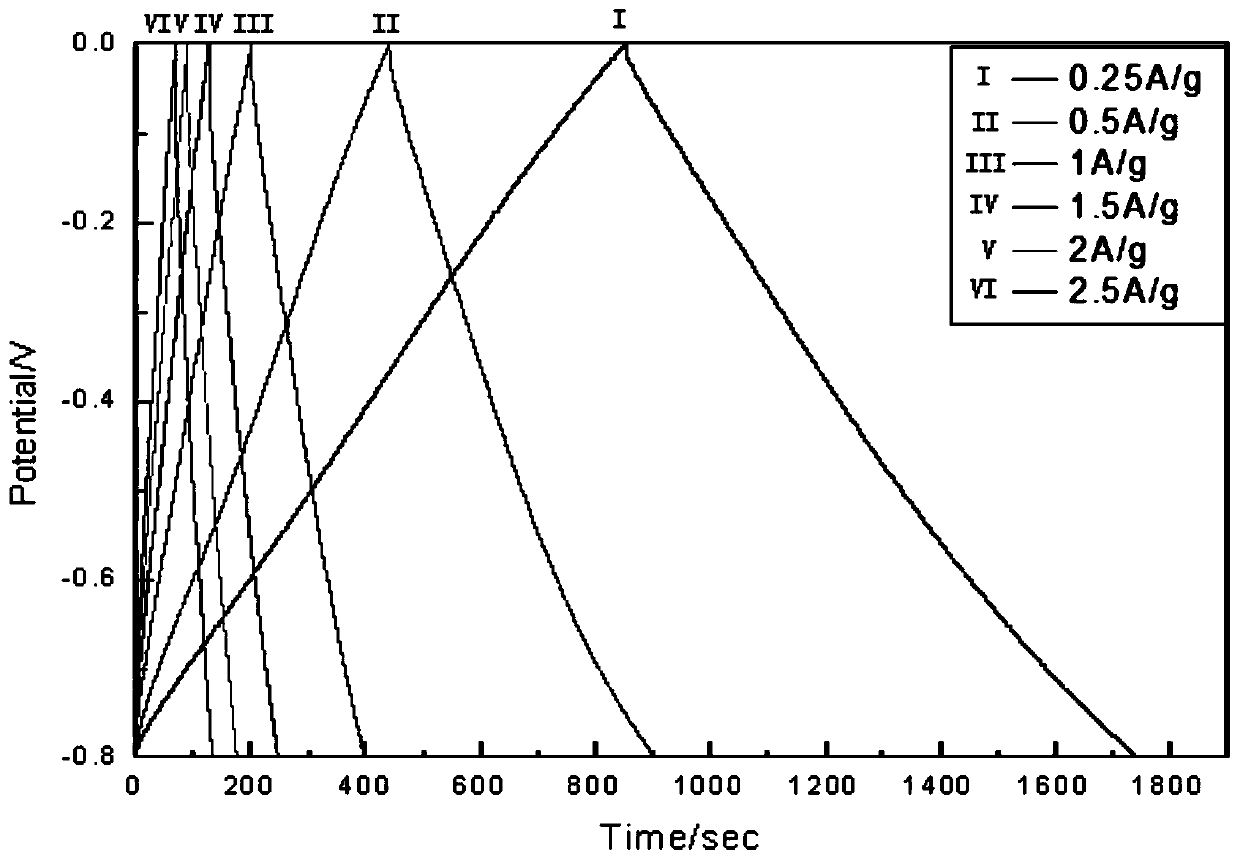

[0054] An electrode composite material for a flexible supercapacitor, which is MoS prepared by self-growing molybdenum disulfide nanosheets, nitrogen-doped graphene quantum dots, and helical carbon nanotubes on carbon cloth pretreated with nitric acid by a one-step hydrothermal method 2 / N-GQDs / HCNTs ternary composites.

[0055] A preparation method for an electrode composite material of a flexible supercapacitor, comprising the following steps:

[0056] S1. Nitric acid pretreatment of carbon cloth

[0057] Soak the carbon cloth in 68wt% nitric acid for 12 hours to make the carbon cloth reach a hydrophilic effect, then wash it alternately with ethanol and acetone for 3 times, and set aside;

[0058] S2. Preparation of nitrogen-doped graphene quantum dots

[0059] Weigh 1.05g of citric acid and 1.2g of urea and dissolve them in 24mL of deionized water, stir for 10min, transfer them to a 50mL reaction kettle, react at 160°C for 8h, naturally cool to room temperature, and wash ...

Embodiment 2

[0066] An electrode composite material for a flexible supercapacitor, which is MoS prepared by self-growing molybdenum disulfide nanosheets, nitrogen-doped graphene quantum dots, and helical carbon nanotubes on carbon cloth pretreated with nitric acid by a one-step hydrothermal method 2 / N-GQDs / HCNTs ternary composites.

[0067] A preparation method for an electrode composite material of a flexible supercapacitor, comprising the following steps:

[0068] S1. Nitric acid pretreatment of carbon cloth

[0069] Soak the carbon cloth in 65wt% nitric acid for 8 hours to make the carbon cloth reach the hydrophilic effect, then alternately wash twice with ethanol and acetone, and set aside;

[0070] S2. Preparation of nitrogen-doped graphene quantum dots

[0071] Weigh 1.05g of citric acid and 1.26g of urea, dissolve them in 23mL of deionized water, stir for 10min, transfer them to a 50mL reaction kettle, react at 180°C for 6h, naturally cool to room temperature, and wash repeatedly...

Embodiment 3

[0078] An electrode composite material for a flexible supercapacitor, which is MoS prepared by self-growing molybdenum disulfide nanosheets, nitrogen-doped graphene quantum dots, and helical carbon nanotubes on carbon cloth pretreated with nitric acid by a one-step hydrothermal method 2 / N-GQDs / HCNTs ternary composites.

[0079] A preparation method for an electrode composite material of a flexible supercapacitor, comprising the following steps:

[0080] S1. Nitric acid pretreatment of carbon cloth

[0081] Soak the carbon cloth in 70wt% nitric acid for 10 hours to make the carbon cloth reach a hydrophilic effect, then wash it alternately with ethanol and acetone for 3 times, and set aside;

[0082] S2. Preparation of nitrogen-doped graphene quantum dots

[0083] Weigh 1.05g of citric acid and 1.37g of urea and dissolve them in 21mL of deionized water, stir for 10min, transfer them to a 50mL reaction kettle, react at 170°C for 10h, naturally cool to room temperature, and was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com