Oil-resistant high-temperature-resistant seal gasket rubber for cylinders and preparation method thereof

A kind of sealing gasket and high temperature resistance technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of difficult rubber application, achieve good high temperature resistance, good flame retardancy, and improve the effect of friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] An oil-resistant and high-temperature-resistant sealing gasket rubber compound for cylinders, which is prepared from the following raw materials in parts by weight (kg): nitrile rubber 70, fluorosilicone rubber 40, novolac resin 5, methyl hydrogen silicone oil 7, tall Oil diethanolamide 13, magnesium hydroxide 12, magnesium dimethacrylate 4, diisopropyl peroxydicarbonate 2, calcium stearate 5, ammonium persulfate 1, nano calcium silicate 20, dibutyl naphthalene sulfonate Sodium Acid 3, Hydroxyapatite Whiskers 10, Trimethylolpropane 7, Epoxy Rubber Seed Oil 6, N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane 4, Silica 6. 3-Dimethylaminopropylamine 2. Sulfur 1.

[0016] A method for preparing an oil-resistant and high-temperature-resistant sealing gasket compound for a cylinder, comprising the following steps:

[0017] (1) Put nitrile rubber and fluorosilicone rubber in an internal mixer for 60-80 seconds, then add novolac resin, methyl hydrogen silicone oil, calcium s...

Embodiment 2

[0021] An oil-resistant and high-temperature-resistant sealing gasket rubber compound for cylinders, which is prepared from the following raw materials in parts by weight (kg): nitrile rubber 80, fluorosilicone rubber 50, novolac resin 6.5, methyl hydrogen silicone oil 8, tall Oil diethanolamide 14.5, magnesium hydroxide 14, magnesium dimethacrylate 5, diisopropyl peroxydicarbonate 3, calcium stearate 6, ammonium persulfate 2, nano calcium silicate 25, dibutyl naphthalene sulfonate Sodium phosphate 4, hydroxyapatite whisker 12, trimethylolpropane 8, epoxy rubber seed oil 6.5, N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane 5, white carbon black 7.5, 3-dimethylaminopropylamine 3, sulfur 2.

[0022] The preparation method is the same as in Example 1.

Embodiment 3

[0024] An oil-resistant and high-temperature-resistant sealing gasket rubber compound for a cylinder, which is prepared from the following raw materials in parts by weight (kg): nitrile rubber 90, fluorosilicone rubber 60, novolac resin 8, methyl hydrogen silicone oil 9, tall Oil diethanolamide 6, magnesium hydroxide 16, magnesium dimethacrylate 6, diisopropyl peroxydicarbonate 4, calcium stearate 7, ammonium persulfate 3, nano calcium silicate 30, dibutyl naphthalene sulfonate Sodium phosphate 5, hydroxyapatite whisker 14, trimethylolpropane 9, epoxy rubber seed oil 7, N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane 6, white carbon black 9. 3-Dimethylaminopropylamine 4. Sulfur 3.

[0025] The preparation method is the same as in Example 1.

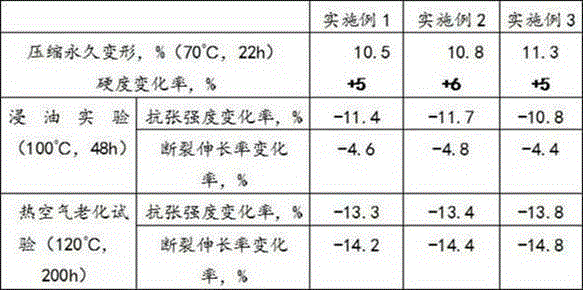

[0026] The performance testing results of the oil-resistant and high-temperature-resistant sealing gasket compound for the cylinder prepared in the above-mentioned embodiments 1-3 are shown in the following table:

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com