Method for preparing rubber seed oil through subcritical extraction

A rubber seed oil and subcritical technology, which is applied in the direction of fat oil/fat production, fat oil/fat refining, and fat generation, can solve the problems of poor safety in large-scale production, large equipment investment and energy consumption, and large investment in supercritical equipment. , achieve the effect of shortening the production cycle, reducing high cost and low boiling point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: this subcritical extraction prepares the method for rubber seed oil, concrete operations are as follows:

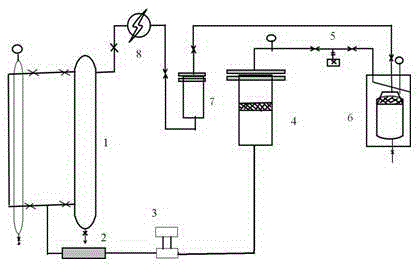

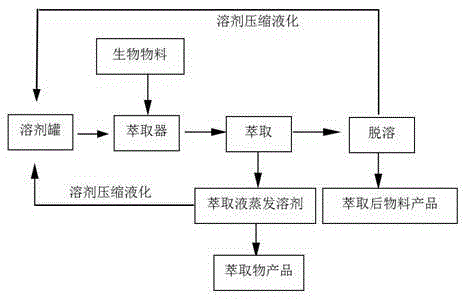

[0021] (1) Shelling the rubber seeds to obtain the rubber seed kernels, drying the rubber seeds at 70°C, and crushing the rubber seeds to obtain rubber seed powder; take 300g of rubber seed powder and place it in the extraction tank 4 of the subcritical extraction equipment and close it For the extraction tank, turn on the vacuum pump 3 to pump the extraction tank 4 to a vacuum state, turn off the vacuum pump 3, and use the pressure difference between the solvent tank 1 and the pipeline to pass the butane in the solvent tank through the solvent filter 2 and enter the extraction tank. Ratio 1:1.5, the heating device wrapped outside the extraction tank controls the temperature, the extraction temperature is 35°C, the pressure is 0.41Mpa, the number of extractions is 2 times, and the extraction time is 35 minutes;

[0022] (2) After the extraction is com...

Embodiment 2

[0025] Embodiment 2: this subcritical extraction prepares the method for rubber seed oil, concrete operations are as follows:

[0026] (1) After rubber seeds are shelled to obtain rubber seeds, the rubber seeds are dried at 70°C and crushed to obtain rubber seed powder; 300g of rubber seed powder is placed in an extraction tank of a subcritical extraction equipment and added with butane. The liquid ratio is 1:2.5, the extraction temperature is 30°C, the pressure is 0.35Mpa, the extraction time is 1 time, and the extraction time is 55 minutes;

[0027] (2) After the extraction is completed, the extract is introduced into the separation tank through the pressure control valve, and the pressure control valve is switched to evacuate until the pressure is zero to continuously vaporize and separate the solvent butane;

[0028] (3) After separation in step (2), it is liquefied after being compressed and condensed, and the liquid butane flows back to the solvent tank for continued use...

Embodiment 3

[0030] Embodiment 3: this subcritical extraction prepares the method for rubber seed oil, concrete operations are as follows:

[0031] (1) After the rubber seeds are shelled, the rubber seed kernels are obtained, which are dried and crushed at 70°C, and the rubber seed powder obtained is 300g of the rubber seed powder, which is placed in the extraction tank of the subcritical extraction equipment and added with butane. Ratio 1:3, extraction temperature 45°C, pressure 0.6Mpa, continuous extraction 3 times, each extraction time is 25 minutes;

[0032] (2) After the extraction is completed, the extract is introduced into the separation tank through the pressure control valve, and the pressure control valve is switched to evacuate until the pressure is zero to continuously vaporize and separate the solvent butane;

[0033] (3) In step (2), the solvent is liquefied after being compressed and condensed, and the liquid butane flows back to the solvent tank for continued use;

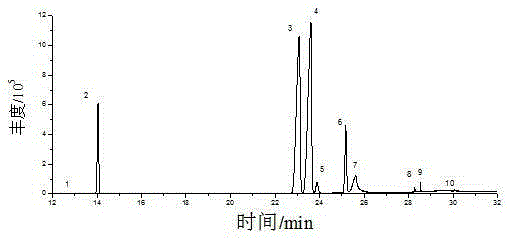

[0034...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com