Method for filtering and removing rubber from rubber seed oil by utilizing high-efficiency membrane

A rubber seed oil and high-efficiency membrane technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problem of easy removal of other beneficial trace components, achieve thorough removal of polyisoprene, improve membrane efficiency, and filter efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

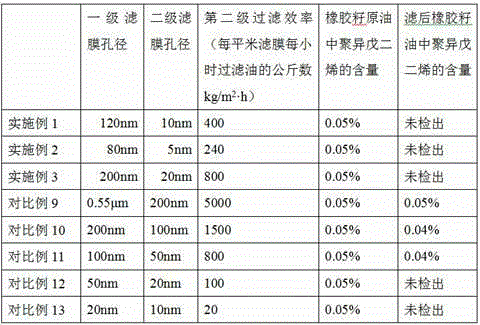

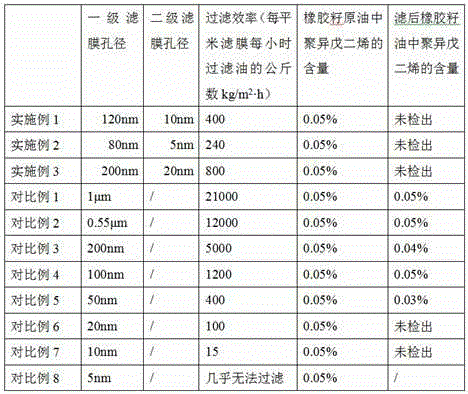

Embodiment 1

[0016] Heat 1kg of rubber seed crude oil to 30°C, then pass through a ceramic filter membrane with a pore size of 120nm at a pressure of 0.5MPa, and control the filtration rate to 5000kg / m 2 h; then heat the filtered rubber seed crude oil to 50°C, pass through a ceramic filter membrane with a pore size of 10nm at a pressure of 2MPa, and control the filtration rate to 400kg / m 2 h, the filtered rubber seed oil has been freed of polyisoprene.

[0017] No polyisoprene molecules were detected in the obtained rubber seed oil.

Embodiment 2

[0019] Heat 1kg of rubber seed crude oil to 20°C, then pass through a ceramic filter membrane with a pore size of 80nm at a pressure of 0.1MPa, and control the filtration rate to 3200kg / m 2 h; then heat the filtered rubber seed crude oil to 80°C, pass through a ceramic filter membrane with a pore size of 5nm at a pressure of 10MPa, and control the filtration rate to 2000kg / m 2 h, the filtered rubber seed oil has been freed of polyisoprene.

[0020] No polyisoprene molecules were detected in the obtained rubber seed oil.

Embodiment 3

[0022] Heat 1kg of rubber seed crude oil to 80°C, then pass through a ceramic filter membrane with a pore size of 200nm at a pressure of 10MPa, and control the filtration rate to 400kg / m 2 h; then heat the filtered rubber seed crude oil to 20°C, pass through a ceramic filter membrane with a pore size of 30nm at a pressure of 0.1MPa, and control the filtration rate to 5000kg / m 2 h, the filtered rubber seed oil has been freed of polyisoprene.

[0023] No polyisoprene molecules were detected in the obtained rubber seed oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com