A drilling fluid with chemical reverse osmosis function

A technology of reverse osmosis and drilling fluid, which is applied in the field of water-based drilling fluid and drilling fluid for oil drilling, and can solve problems such as rock instability and collapse on the well wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

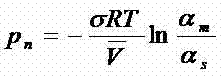

Image

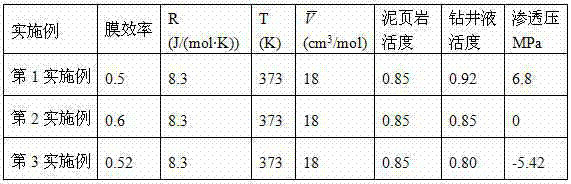

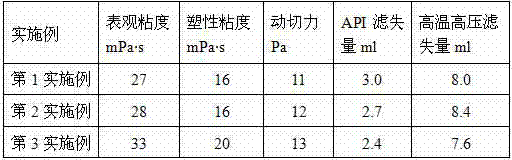

Examples

Embodiment 1

[0046] A drilling fluid with chemical reverse osmosis function includes the following components in mass percentage:

[0047] 2.0 parts of bentonite;

[0048] 0.2 parts of sodium hydroxide;

[0049] 0.5 part of polyanionic cellulose;

[0050] 3.0 parts of temperature-resistant and salt-resistant fluid loss reducer, made by mixing sulfonated phenolic resin, lignite resin, and potassium humate at room temperature. The ratio of sulfonated phenolic resin: lignite resin: potassium humate is 2:1:3.

[0051] 1.0 parts of nano-micron emulsified plugging agent, prepared by mixing emulsified paraffin wax, styrene-butadiene latex, and acrylate emulsion at a temperature of 80°C and stirring at a high speed of 10,000 rpm for 20 minutes; emulsified paraffin wax: styrene-butadiene latex: acrylate The ratio of the emulsion is 3:2:5.

[0052] 1.0 parts of nano-blocking agent, prepared by mixing nano-calcium carbonate, nano-silica, and nano-montmorillonite at normal temperature, the ratio of...

Embodiment 2

[0059] A drilling fluid with chemical reverse osmosis function includes the following components in mass percentage:

[0060] 2.0 parts of bentonite;

[0061] 0.2 parts of sodium hydroxide;

[0062] 0.5 part of polyanionic cellulose;

[0063] 1.0 parts of temperature-resistant and salt-resistant fluid loss reducer, which is prepared by mixing sulfonated phenolic resin, lignite resin, and potassium humate at room temperature. The ratio of sulfonated phenolic resin: lignite resin: potassium humate is 2.5: 1.5: 4.

[0064] 2.0 parts of nano-micron emulsified plugging agent, prepared by mixing emulsified paraffin wax, styrene-butadiene latex, and acrylate emulsion at a temperature of 80°C and stirring at a high speed of 10,000 rpm for 20 minutes; emulsified paraffin wax: styrene-butadiene latex: acrylate The ratio of the emulsion is 4:3:6.

[0065] 1.0 parts of nano-blocking agent, prepared by mixing nano-calcium carbonate, nano-silica, and nano-montmorillonite at room temperat...

Embodiment 3

[0072] A drilling fluid with chemical reverse osmosis function includes the following components in mass percentage:

[0073] 2.0 parts of bentonite;

[0074] 0.2 parts of sodium hydroxide;

[0075] 0.5 part of polyanionic cellulose;

[0076] 3.0 parts of temperature-resistant and salt-resistant fluid loss reducer, made by mixing sulfonated phenolic resin, lignite resin, and potassium humate at room temperature. The ratio of sulfonated phenolic resin: lignite resin: potassium humate is 3:2:5.

[0077] 3.0 parts of nano-micron emulsified plugging agent, prepared by mixing emulsified paraffin wax, styrene-butadiene latex, and acrylate emulsion at a temperature of 80°C and stirring at a high speed of 10,000 rpm for 20 minutes; emulsified paraffin wax: styrene-butadiene latex: acrylate The ratio of the emulsion is 5:4:7.

[0078] 2.0 parts of nano-blocking agent, prepared by mixing nano-calcium carbonate, nano-silica, and nano-montmorillonite at room temperature, the ratio of n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com