Ca-Zn composite stabilizer for PVC (polyvinyl chloride) cables and preparation method of Ca-Zn composite stabilizer

A calcium-zinc composite and stabilizer technology, used in circuits, electrical components, plastic/resin/wax insulators, etc., which can solve the problems of large dielectric loss of PVC, increased maintenance costs, and less auxiliary heat stabilizer used alone.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

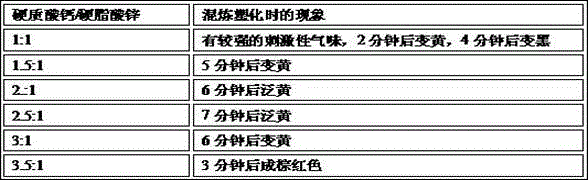

[0038] A calcium-zinc composite stabilizer for PVC cables, made of the following raw materials in parts by weight: 45 parts of calcium stearate, 15 parts of zinc stearate, 10 parts of dibutyl tin maleate, 10 parts of hydrotalcite, 5 parts of polyethylene wax, 25 parts of composite calcium carbonate, 3 parts of pentaerythritol diester, 10 parts of epoxy rubber tree oil;

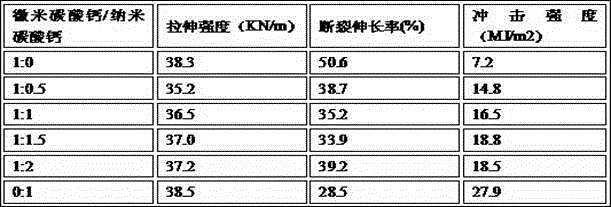

[0039] Described composite calcium carbonate is 1:1 by weight ratio by micron calcium carbonate and nanometer calcium carbonate

[0040] The above-mentioned production method comprises the following steps:

[0041] (1) Purchasing each raw material by weight for use;

[0042] (2) Synthesis of hydrotalcite: Add a certain amount of magnesium nitrate and aluminum nitrate into water to prepare a salt solution, in which the concentration of magnesium nitrate is 0.85mol / L, and the concentration of aluminum nitrate is 0.4mol / L. Add a certain amount of sodium carbonate and sodium hydroxide to water at 40°C to prepare...

Embodiment 2

[0047]A calcium-zinc composite stabilizer for PVC cables, made of the following raw materials in parts by weight: 50 parts of calcium stearate, 20 parts of zinc stearate, 11 parts of dibutyltin maleate, 12 parts of hydrotalcite, oxidized polystyrene 7 parts of ethylene wax, 12 parts of micron calcium carbonate, 15.5 parts of nano calcium carbonate, 4 parts of pentaerythritol diester, 13 parts of epoxy rubber tree oil.

[0048] The preparation method is the same as in Example 1.

Embodiment 3

[0050] A calcium-zinc composite stabilizer for PVC cables is made of the following raw materials in parts by weight: 65 parts of calcium stearate, 25 parts of zinc stearate, 12 parts of dibutyl tin maleate, 15 parts of hydrotalcite, oxidized polystyrene 10 parts of ethylene wax, 30 parts of complex calcium carbonate, 6 parts of pentaerythritol diester, 15 parts of epoxy rubber tree oil;

[0051] The composite calcium carbonate consists of micron calcium carbonate and nano calcium carbonate in a weight ratio of 1:1.5.

[0052] The preparation method is the same as in Example 1.

[0053] The vibration-milling equipment used in the present invention is common equipment in the field, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com