Application of rubber tree seed oil and preparation method of rubber tree seed oil

A technology of rubber tree seed oil and rubber seeds, which is applied in cosmetic preparations, preparations for skin care, and oil/fat refining, etc., can solve the problem of low content of natural antioxidant substances, large changes in peroxide value, and content of unsaturated fatty acids. High problems, to achieve the effect of fast absorption, strong permeability and strong antioxidant function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

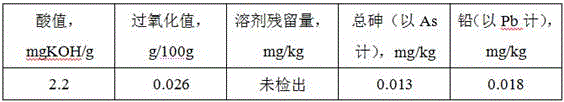

[0038] The application of rubber tree seed oil in skin care products, wherein, rubber tree seed oil is made through the following steps:

[0039] (1) Raw material screening: Screen fresh rubber seeds to remove impurities and moldy rubber seeds in fresh rubber seeds;

[0040] (2) Drying of raw materials: Dry the rubber seeds screened in step (1) at 60°C for 3 hours until the moisture content is 8.5%;

[0041] (3) Shelling of rubber seeds: send the rubber seeds in step (2) to the shelling equipment for mechanical breaking to separate the shells and kernels, and take the rubber seeds;

[0042] (4) Cold pressing: The rubber seed kernel obtained in step (3) is cold pressed at 90°C to extract oil, and then the rubber seed oil cake obtained after the first cold pressing is pressed according to the mass ratio of rubber seed oil cake: rubber seed kernel = 1:5 After mixing with the rubber seed kernels obtained in step (3), carry out secondary cold pressing to extract oil. This operatio...

Embodiment 2

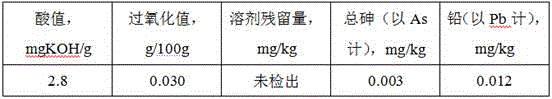

[0049] The application of rubber tree seed oil in skin care products, wherein, rubber tree seed oil is made through the following steps:

[0050] (1) Raw material screening: Screen fresh rubber seeds to remove impurities and moldy rubber seeds in fresh rubber seeds;

[0051] (2) Drying of raw materials: Dry the rubber seeds screened in step (1) at 57°C for 4 hours to a moisture content of 8.3%;

[0052] (3) Shelling of rubber seeds: send the rubber seeds in step (2) to the shelling equipment for mechanical breaking to separate the shells and kernels, and take the rubber seeds;

[0053] (4) Cold pressing: The rubber seed kernel obtained in step (3) is cold pressed at 78°C to extract oil, and then the rubber seed oil cake obtained after the first cold pressing is pressed according to the mass ratio of rubber seed oil cake: rubber seed kernel = 1:5 After mixing with the rubber seed kernels obtained in step (3), carry out secondary cold pressing to extract oil. This operation can...

Embodiment 3

[0061] The application of rubber tree seed oil in skin care products, wherein, rubber tree seed oil is made through the following steps:

[0062] (1) Raw material screening: Screen fresh rubber seeds to remove impurities and moldy rubber seeds in fresh rubber seeds;

[0063] (2) Drying of raw materials: Dry the rubber seeds screened in step (1) at 48°C for 6 hours until the moisture content is 8%;

[0064] (3) Shelling of rubber seeds: send the rubber seeds in step (2) to the shelling equipment for mechanical breaking to separate the shells and kernels, and take the rubber seeds;

[0065] (4) Cold pressing: The rubber seed kernel obtained in step (3) is cold pressed at 65°C to extract oil, and then the rubber seed oil cake obtained after the first cold pressing is pressed according to the mass ratio of rubber seed oil cake: rubber seed kernel = 1:5 After mixing with the rubber seed kernels obtained in step (3), carry out secondary cold pressing to extract oil. This operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com