Production method for collecting fluorite-contained tailings from rubber seed oil

A technology for rubber seed oil and fluorite tailings, applied in solid separation, flotation and other directions, can solve the problems of unable to obtain fluorite concentrate, unable to recycle, increase energy consumption, etc., to ensure the quality and yield, The effect of reducing production costs and simplifying the pharmaceutical system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

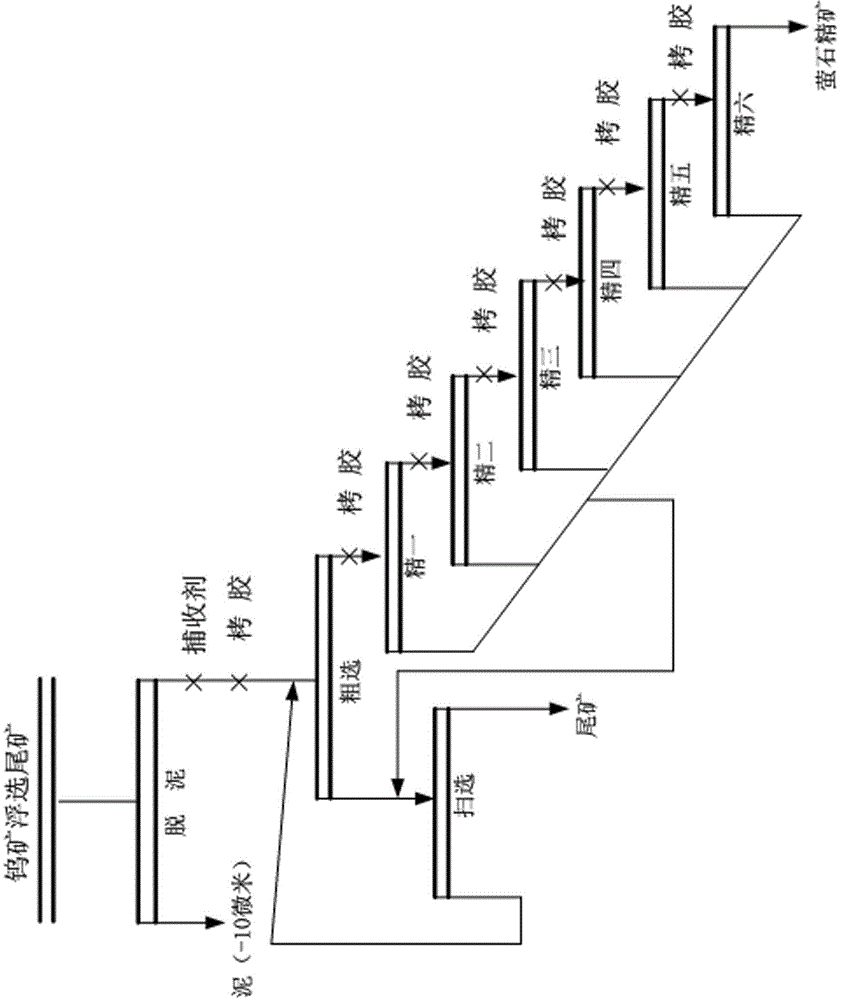

Image

Examples

Embodiment 1

[0034] The raw materials of this embodiment consist of 60 kg of saponified rubber seed oil, 3 kg of tributyl phosphate, 2 kg of Tween 80, 1 kg of sodium cetyl sulfonate, and 34 kg of water.

[0035] Preparation method: Add the above-mentioned substances in the stirring tank in sequence, under normal pressure, control the temperature of the stirring tank at 70-80°C, stir for 40-60 minutes and cool down to prepare low-temperature-resistant fatty acid saponification Receiver.

Embodiment 2

[0037] The raw materials of this embodiment consist of 67 kg of saponified rubber seed oil, 4 kg of tributyl phosphate, 2 kg of Tween 80, 2 kg of sodium cetyl sulfonate, and 25 kg of water.

[0038] Preparation method: Add the above-mentioned substances in the stirring tank in sequence, under normal pressure, control the temperature of the stirring tank at 70-80°C, stir for 40-60 minutes and cool down to prepare low-temperature-resistant fatty acid saponification Receiver.

[0039] The anti-low temperature type fatty acid saponification collector of the present invention can be used after being formulated into an aqueous solution with a concentration of 2-5%.

[0040] In a tungsten ore flotation plant in a high-altitude area in Yunnan, the annual slurry temperature is 5-25 degrees Celsius, and CaF in tungsten ore flotation tailings 2 Grade 19.63%, Ca 2 CO 3 The content reaches 50.16%. Due to the use of traditional collectors such as oleic acid and sodium oleate, the requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com