Method and apparatus for removing rubber from rubber seed oil

A rubber seed oil and rubber seed technology, applied in the field of rubber seed oil derubberization, can solve the problems of rubber seed oil peroxide value increase, damage to oil quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

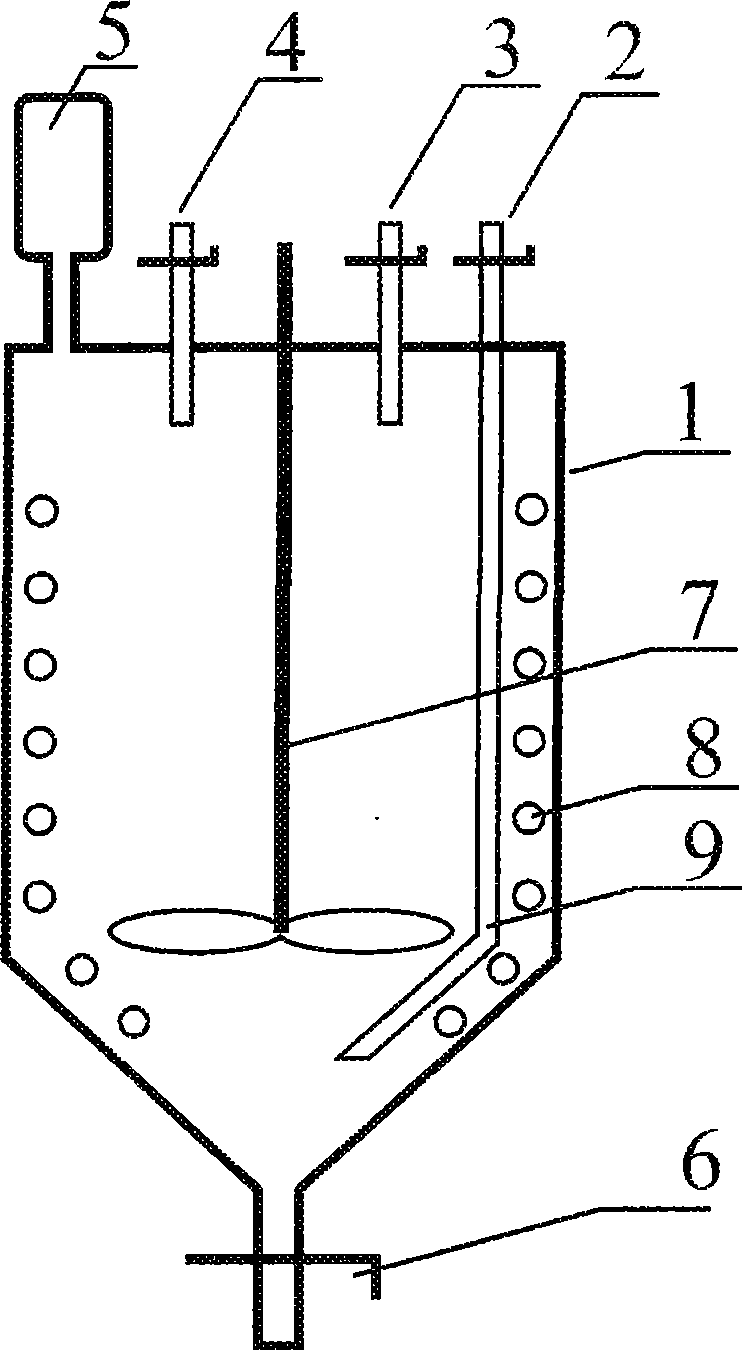

[0022] The composition and connection method of the rubber sinking tank (1) specially used for rubber seed oil derubberization of the present invention are as follows: the main body of the device is a closed tank body (1); the tank body (1) is provided with two The inlet and two outlets with valves are: rubber seed crude oil inlet and valve (3), derubber agent inlet and valve (4), rubber discharge port and valve (6), derubber agent-rubber seed oil mixing Solution outlet and valve (2), wherein there is a pipeline (9) in the tank body (1) to connect the derubber agent-rubber seed oil mixed solution outlet (2) to the bottom of the tank body; the tank body (1) is also provided with 3 auxiliary devices, namely derubberizing agent condensation reflux device (5), mechanical stirring device (7), heating coil (8).

Embodiment 2

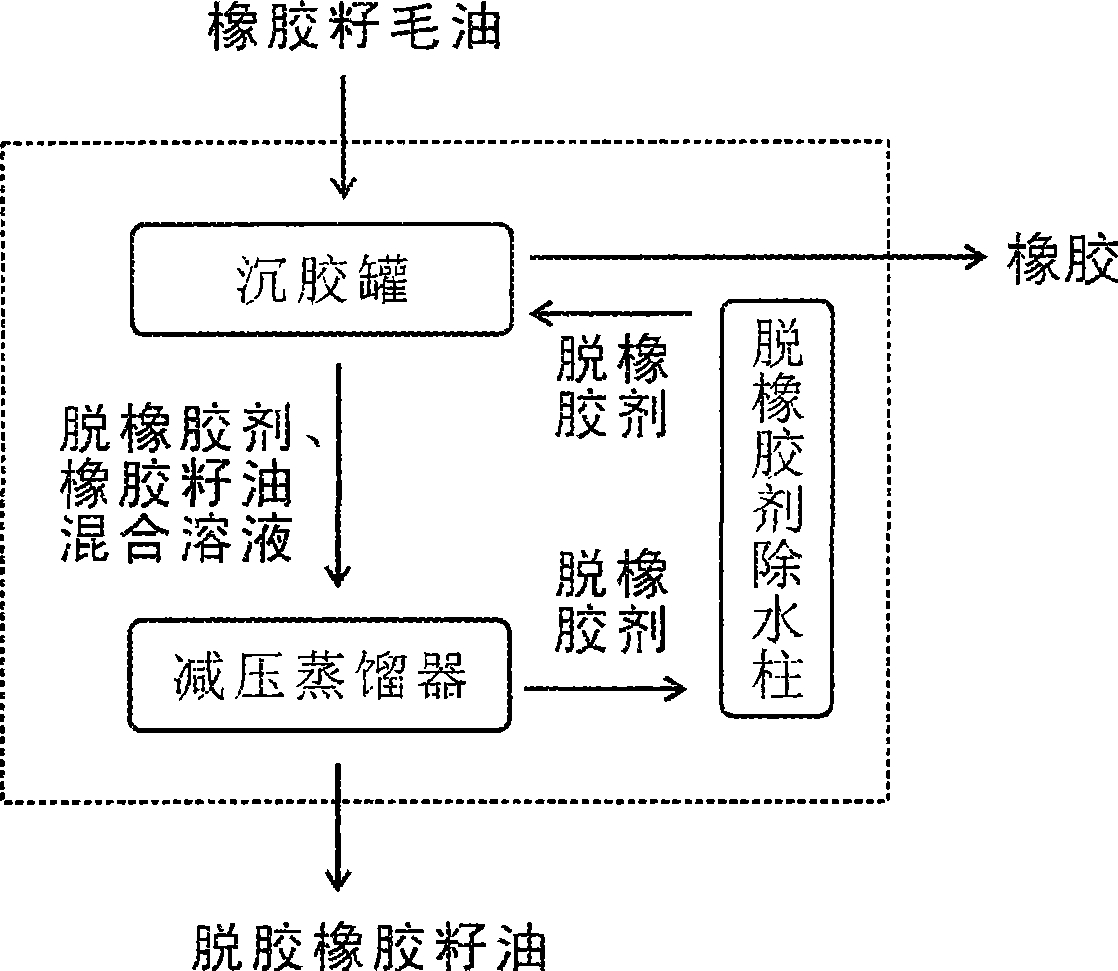

[0024] Carry out the steps of the method for rubber seed oil derubberization in the sinking tank (1) that is specially used for rubber seed oil derubberization of the present invention of embodiment 1: the derubberizing agent that injects from the degumming agent inlet (4) and from rubber seed The crude rubber seed oil injected into the crude oil inlet (3) is injected into the sinking tank (1) at a ratio of 1:1-1:1.5 (volume ratio), and stirred and mixed by the stirring device (7) for 5 minutes, while heating the coil (8) Heat the mixed solution to 50-60°C, and then let it stand for 40-60 minutes. At this time, the rubber aggregates, precipitates, and adheres to the tank wall of the sinking tank; after that, the rubber seed oil-derubberizing agent solution passes through the pipeline (9), from the outlet (2) is pumped to the vacuum distiller; at 80-90 ° C, vacuum distillation under a pressure of 0.01MPa, reclaim the derubberizing agent, and obtain the rubber seed oil for derubb...

Embodiment 3

[0026] Get 540 liters of derubberizing agent that contains acetone 99%, and 800 liters (728 kilograms) of the rubber seed crude oil of squeezing, pour into sinking rubber tank (1), be heated to 55 ℃, stir 10 revolutions per minute, stir 5 minutes, then Let stand for 60 minutes. Afterwards, the derubberizing agent-rubber seed oil mixed solution was taken out, and vacuum distillation was carried out at 80° C. and 0.01 MPa to obtain 778 liters (708 kg) of derubberizing oil and 20 kg of rubber-rubber seed oil paste. The rubber seed oil after derubberization will not be drawn, and when heated to 280°C, the color of the oil will not turn black, and no carbon fiber will be precipitated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com