A kind of epoxy resin based on gallic acid and its preparation method and application

A technology of gallic acid and epoxy resin, applied in the direction of epoxy resin glue, epoxy resin coating, adhesive type, etc., to achieve broad application prospects, good mechanical and thermal properties, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Mix 100 grams of gallic acid and 500 grams of epichlorohydrin, raise the temperature to 100°C, add 10 grams of tetramethylammonium chloride, react at 100°C for 5 hours, then cool down to 30°C, then add 25 grams of sodium hydroxide and 60 g of distilled water to form a reaction system, and continue to react at 30°C for 2h. After the reaction system was lowered to room temperature, it was washed with 200 mL of deionized water each time for a total of 4 times, and then the solvent was removed by a rotary evaporator, and vacuum-dried at 50° C. for 12 hours to obtain 60 grams of gallic acid-based epoxy resin.

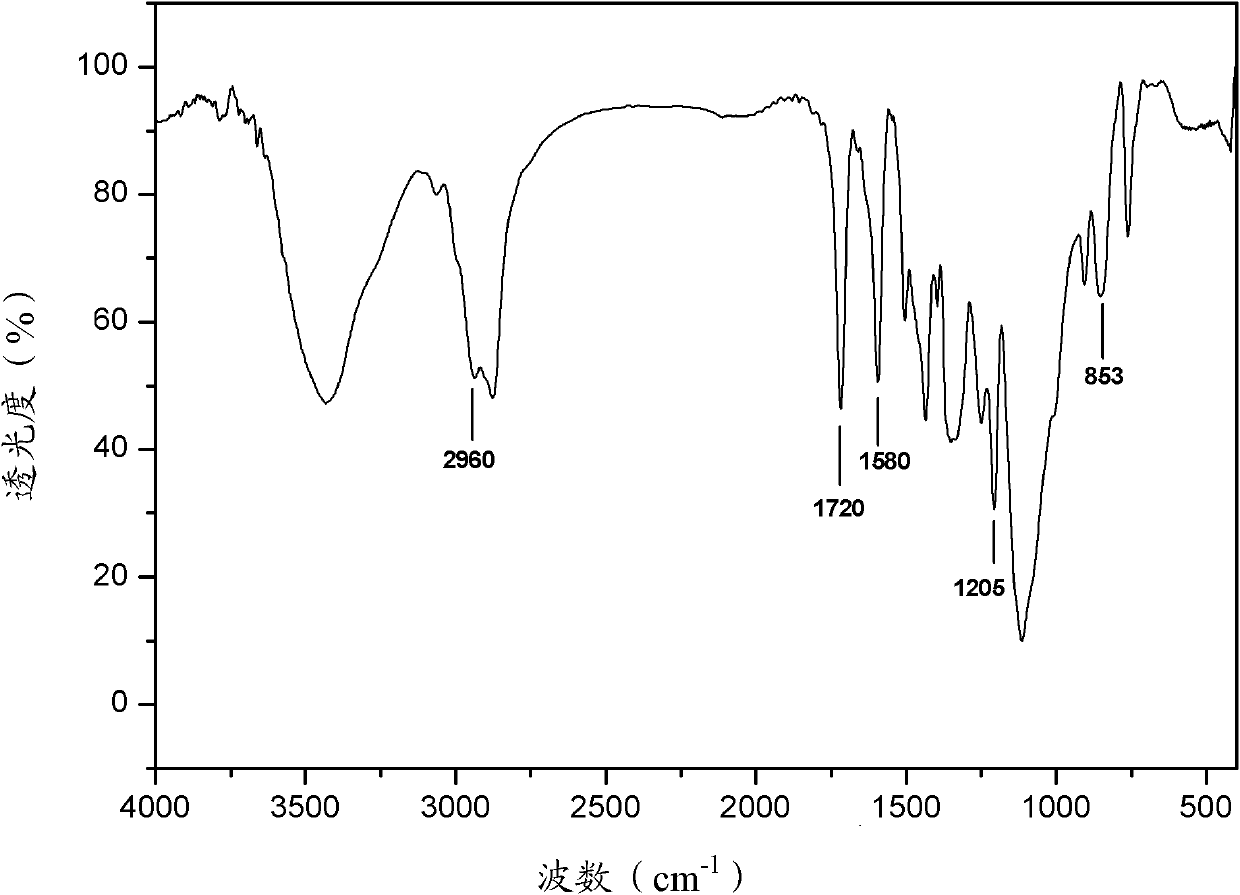

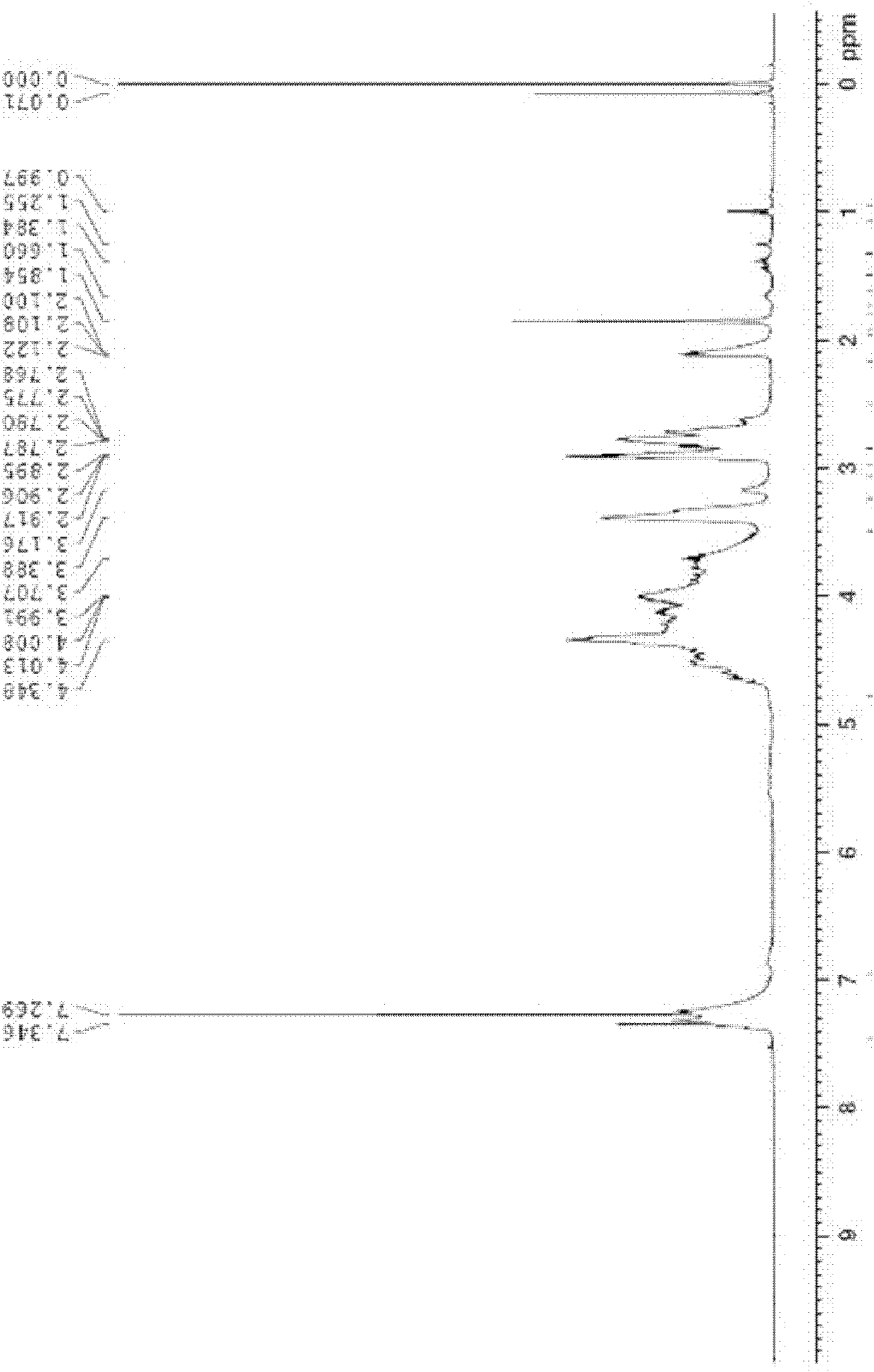

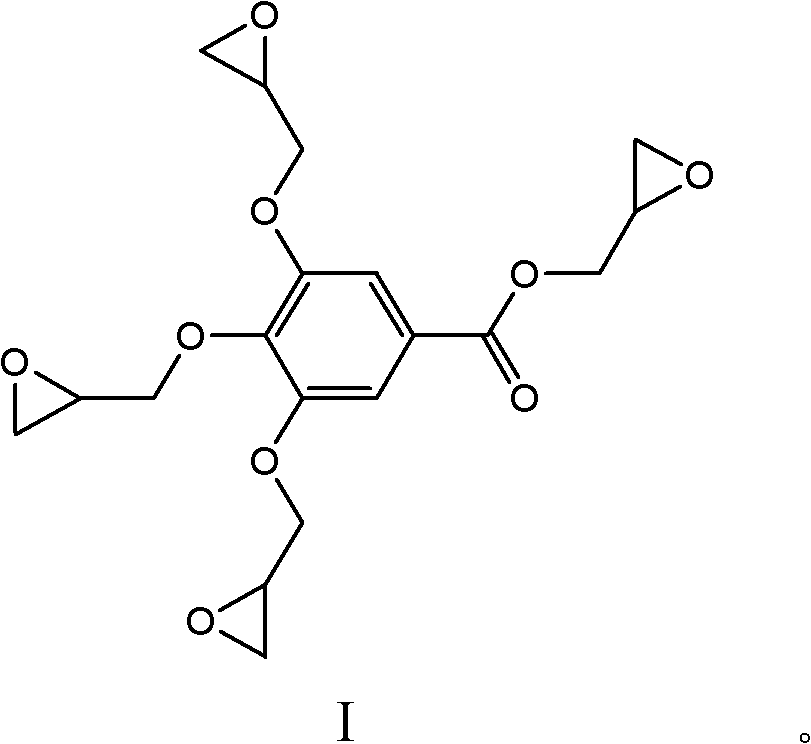

[0037] The above-mentioned epoxy resin based on gallic acid is carried out structural identification, and the infrared spectrogram is as follows figure 1 shown. The identification result is: there is 2960cm in the infrared spectrum -1 、1720cm -1 、1580cm -1 、1205cm -1 、1080cm -1 、853cm -1 and other characteristic absorption peaks; hydrogen nuclear magnetic reson...

Embodiment 2

[0041] Mix 100 grams of gallic acid and 700 grams of epibromohydrin, raise the temperature to 110°C, add 20 grams of octadecyltrimethylammonium bromide, react at 110°C for 2 hours, then cool down to 30°C, then add 30 grams of hydrogen Potassium oxide and 60 grams of distilled water form a reaction system, and the reaction is continued at 30° C. for 3 hours. After the reaction system was lowered to room temperature, it was washed with 200 mL of deionized water each time for a total of 4 times, and then the solvent was removed by a rotary evaporator, and vacuum-dried at 50° C. for 12 hours to obtain 80 grams of epoxy resin based on gallic acid.

[0042] The structure of the epoxy resin based on gallic acid obtained above was identified, and the identification result was basically the same as that in Example 1. The measured epoxy value is 0.6 epoxy equivalent / 100 grams of resin. 100 parts by weight of epoxy resin based on gallic acid and 46 parts by weight of hexahydrophthalic a...

Embodiment 3

[0044] 100 grams of gallic acid, 300 grams of epibromohydrin and 300 grams of epichlorohydrin were mixed, the temperature was raised to 120°C, 6 grams of octadecyltrimethylammonium bromide and 12 grams of hexamethylenetetraammonium were added, After reacting at 120°C for 4 hours, the temperature was lowered to 30°C, and then 10 grams of potassium hydroxide, 8 grams of magnesium hydroxide and 60 grams of distilled water were added to form a reaction system, and the reaction was continued at 30°C for 4 hours. After the reaction system was lowered to room temperature, it was washed with 200 mL of deionized water each time for a total of 4 times, and then the solvent was removed by a rotary evaporator, and vacuum-dried at 50° C. for 12 hours to obtain 68 grams of gallic acid-based epoxy resin.

[0045] The gallic acid-based epoxy resin obtained above was identified, and the identification result was basically the same as that in Example 1. The measured epoxy value is 0.53 epoxy eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com