Chromium-free high-solid-content double-component epoxy primer and preparation method thereof

An epoxy primer, two-component technology, applied in the direction of epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve problems such as carcinogenicity, achieve excellent machine oil resistance, simple preparation method, and excellent salt spray resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

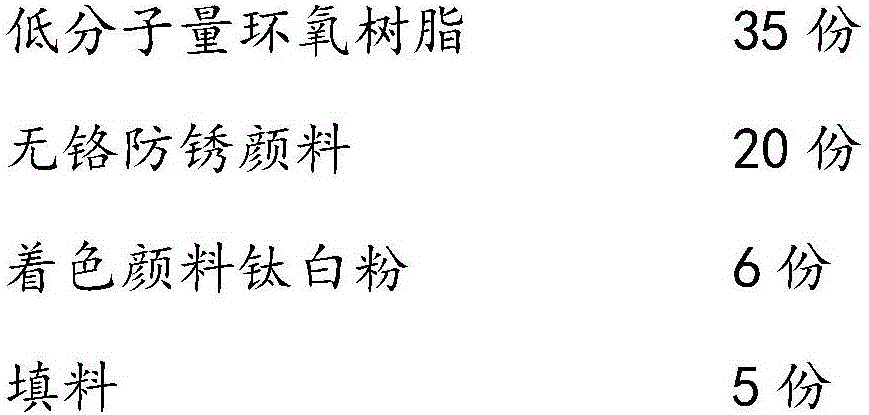

Embodiment 1

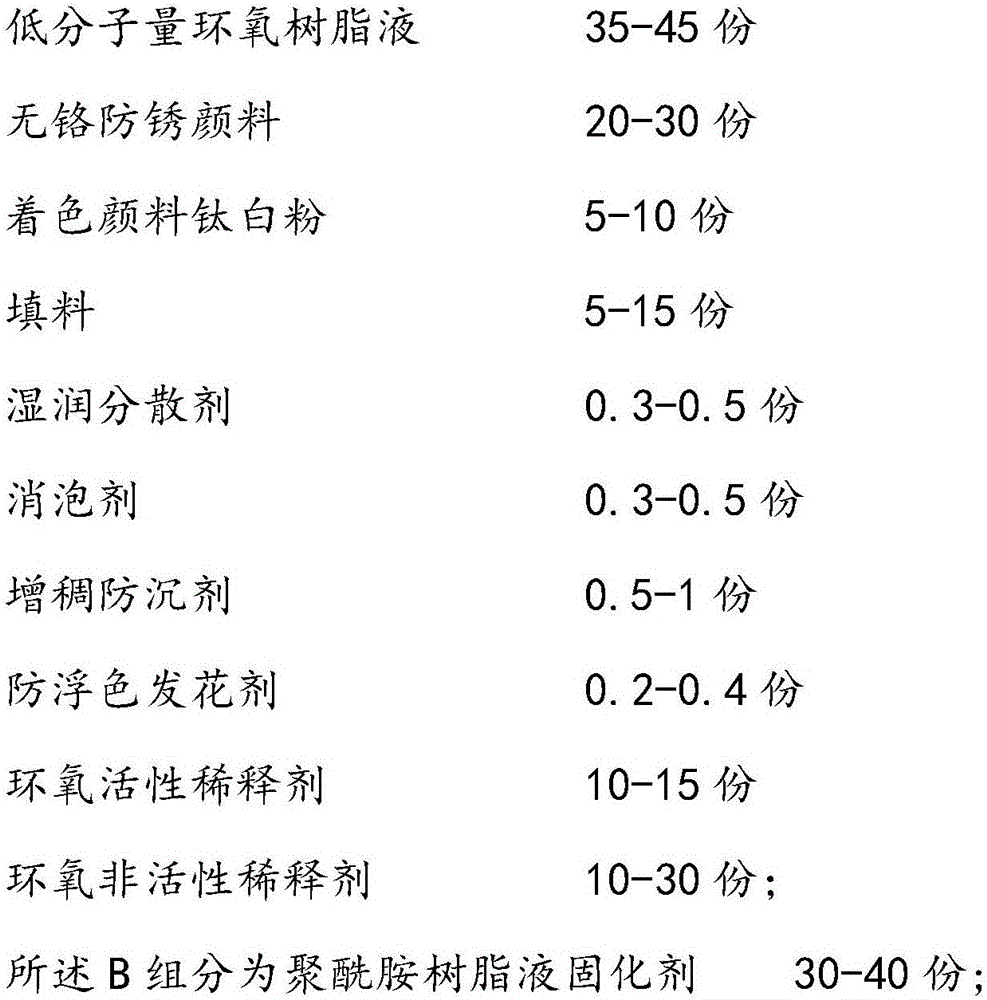

[0031] A chromium-free high-solid two-component epoxy primer, which is composed of A component and B component, and the A component is composed of the following components, in parts by weight:

[0032]

[0033]

[0034] The preparation method of described chromium-free high solid two-component epoxy primer, concrete steps are as follows:

[0035] Ⅰ. Preparation of component A:

[0036] (1) Add 1 / 2 of low molecular weight epoxy resin, wetting and dispersing agent, defoaming agent, anti-floating and anti-flooding agent, thickening and anti-settling agent, and non-reactive diluent into the stirring container in turn according to the formula amount and stir evenly, 600 -800 rpm for 10 minutes at medium speed, then add chrome-free anti-rust pigments, coloring pigments and fillers in turn at 1200-1600 rpm for 10 minutes at high speed;

[0037] (2) Add the mixed slurry into the grinder and grind until the fineness reaches below 40 μm, then pour it into the paint mixing tank; ...

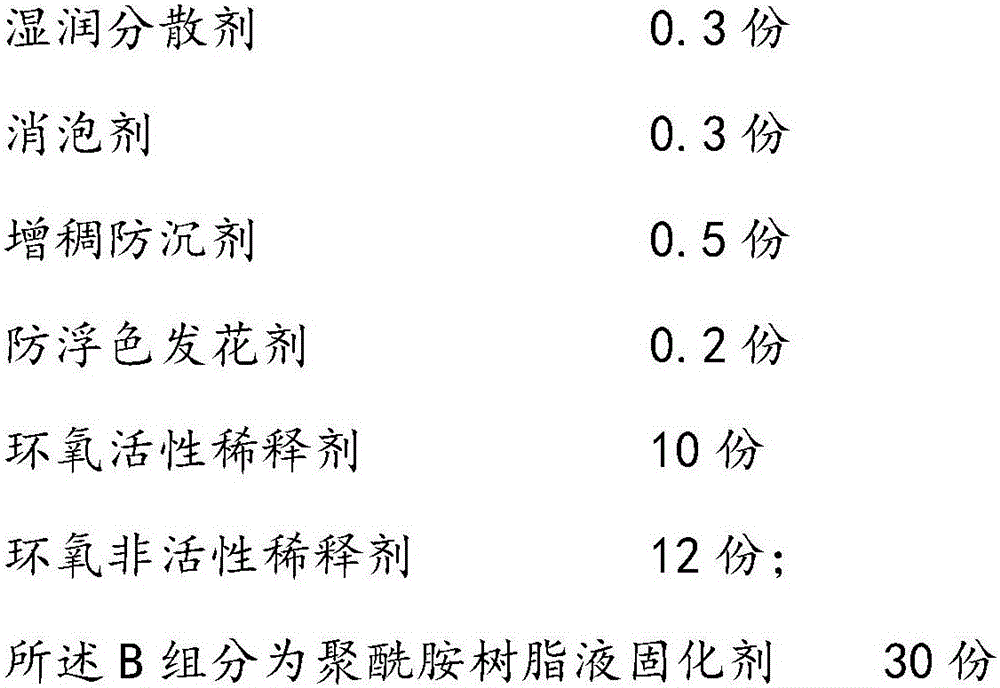

Embodiment 2

[0041]

[0042]

[0043] The preparation method of the above-mentioned chromium-free high solid two-component epoxy primer is according to the preparation method described in Example 1.

Embodiment 3

[0045]

[0046] The preparation method of the above-mentioned chromium-free high solid two-component epoxy primer is according to the preparation method described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com