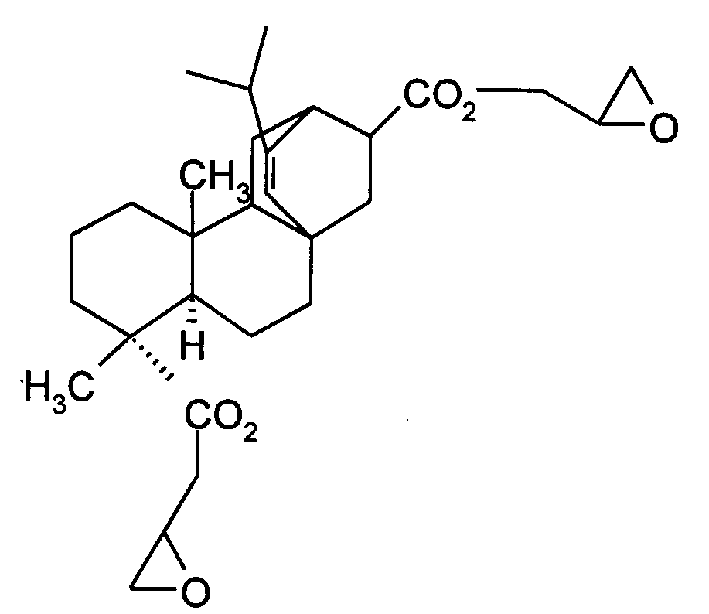

Propylenyl pimaric acid diglycidic ester and its epoxy resin and their preparation

A technology of diglycidyl ester and propylene pimaric acid, applied in the directions of water-based dispersants, etc., achieves the effects of broad application prospects, simple preparation method and high epoxy value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of Propylene Pimaric Acid Diglycidyl Ester:

[0027] In a 100ml reactor, add 3.74g (10mmol) of propylene pimaric acid, 1.87g (20mmol) of epichlorohydrin and 3.74g (27mmol) of potassium carbonate, and 0.0187g (0.07mmol) of 18-crown-6 ether, 80ml of acetone , heated to 55-60°C to reflux, and reacted for 60 hours. After cooling, the solvent was removed under reduced pressure with a rotary evaporator. Add 15ml of toluene to dissolve, wash with distilled water several times, vibrate, stand still, separate layers, and then use silver nitrate to check that there is no chloride ion in the water layer. Collect the toluene layer, dry it over anhydrous magnesium sulfate, remove the solvent with a rotary evaporator, and dry it in vacuum at 80°C for 3 to 4 hours to obtain a yellow viscous resin with an epoxy value of 0.38 and a chlorine content of 0.036% (molar content); After recrystallization from alkane and acetone, diglycidyl propylene pimarate was obtained as a wh...

Embodiment 2

[0029] Preparation of Propylene Pimaric Acid Diglycidyl Ester:

[0030] In the 100ml reactor, add 3.74g (10mmol) propylene pimaric acid, 2.24g (24mmol) epichlorohydrin and 4.11g (30mmol) potassium bicarbonate, and 0.075g (0.28mmol) tetrabutylammonium bromide, 70ml of acetone was heated to reflux at 55-60°C and reacted for 70 hours. After cooling, the solvent was removed under reduced pressure with a rotary evaporator. Add 20ml of toluene to dissolve, wash with distilled water several times, vibrate, stand still, and separate layers, then use silver nitrate to check that there is no chloride ion in the water layer. Collect the toluene layer, dry it over anhydrous magnesium sulfate, remove the solvent with a rotary evaporator, and dry it in vacuum at 80°C for 3 to 4 hours to obtain a yellow viscous resin with an epoxy value of 0.385 and a chlorine content of 0.042% (molar content); After recrystallization with acetone, propylene pimaric acid diglycidyl ester is obtained as a w...

Embodiment 3

[0032] Preparation of Propylene Pimaric Acid Diglycidyl Ester:

[0033] In a 100ml reactor, add 3.74g (10mmol) of acrylpimaric acid, 3.0g (32mmol) of epichlorohydrin and 4.49g (34mmol) of potassium carbonate, and 0.15g (0.56mmol) of 18-crown-6 ether, 60ml Butanone, heated to 75-80°C, reacted for 80 hours. After cooling, the solvent was removed under reduced pressure with a rotary evaporator. Add 20ml of toluene to dissolve, wash with distilled water several times, vibrate, stand still, and separate layers, then use silver nitrate to check that there is no chloride ion in the water layer. Collect the toluene layer, dry it over anhydrous magnesium sulfate, remove the solvent with a rotary evaporator, and dry it in vacuum at 80°C for 3 to 4 hours to obtain a yellow viscous resin with an epoxy value of 0.39 and a chlorine content of 0.03% (molar content); column chromatography After recrystallization with n-hexane and acetone, propylene pimarate diglycidyl ester was obtained as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com