Production method of epoxidized fatty acid methyl ester/epoxidized soybean oil

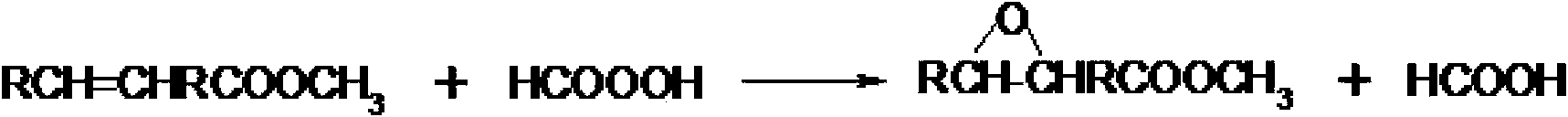

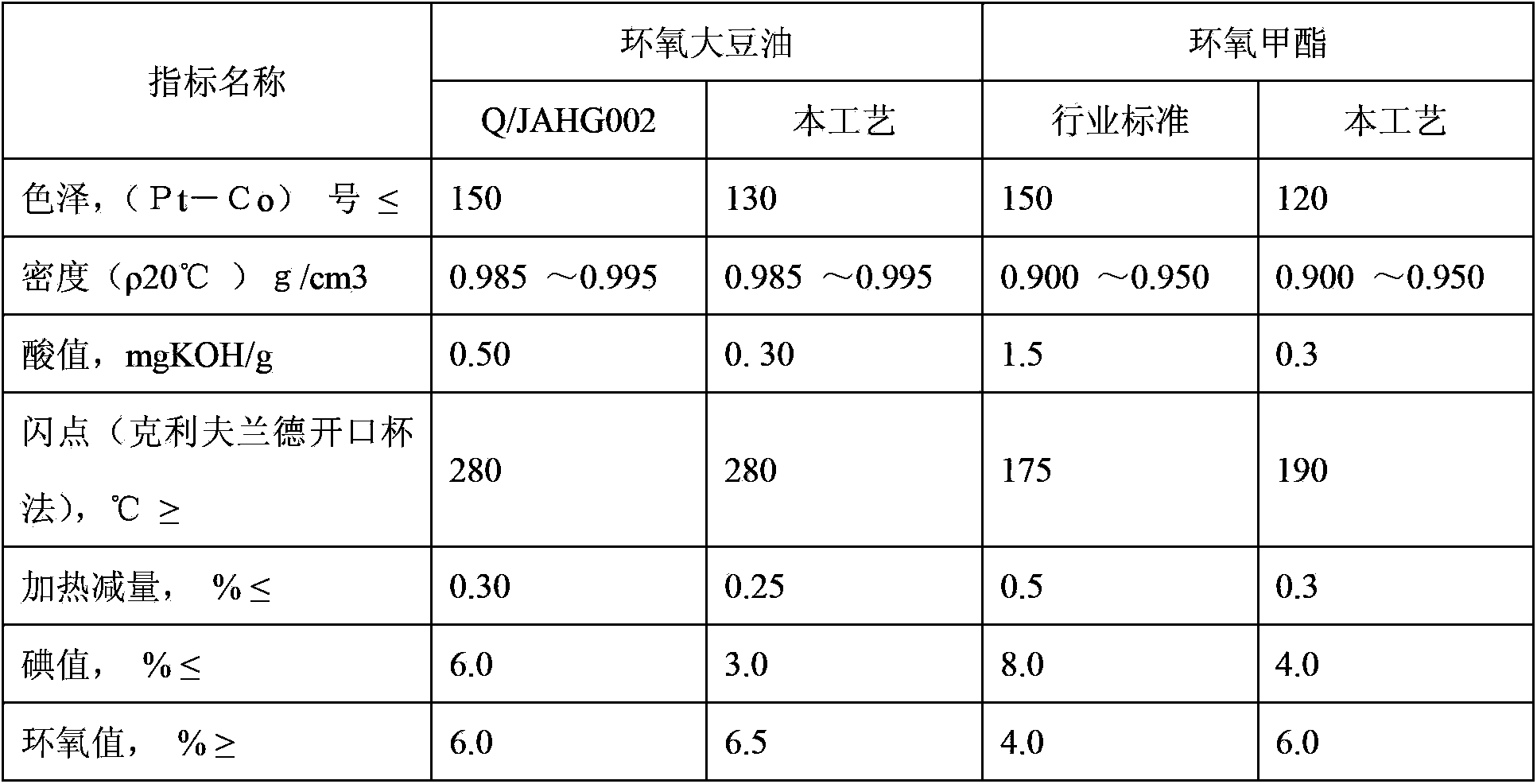

A technology of epoxidized fatty acid methyl ester and epoxidized soybean oil, which is applied in the production of fatty acid, chemical modification of fatty acid, etc., can solve the problems of many side reactions, yellowish color difference of products, low epoxy value of products, etc., and achieves color improvement, The effect of increasing the epoxy value and shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Take 5 cubic meters of soybean oil, 200 kg of formic acid, and 2 cubic meters of hydrogen peroxide with a concentration of 70% and preheat it to 88°C in a tank; 3 Add the preheated soybean oil, formic acid and hydrogen peroxide at the speed of 25mm at the same time into the pipeline reactor with an inner diameter of 25mm to react for 20 minutes, and then re-feed for continuous reaction production.

Embodiment 2

[0021] (1) Take 5 cubic meters of soybean oil, 200 kg of formic acid, and 2 cubic meters of hydrogen peroxide with a concentration of 70% and preheat it to 90°C in a tank; 3 Add the preheated soybean oil, formic acid and hydrogen peroxide at the speed of 25mm at the same time into the pipeline reactor with an inner diameter of 25mm to react for 10 minutes, and then re-feed for continuous reaction production.

Embodiment 3

[0023] (1) Take 5 cubic meters of fatty acid methyl ester, 200 kg of formic acid, and 2 cubic meters of hydrogen peroxide with a concentration of 70% and preheat it to 92°C in a tank; 3 Add the preheated fatty acid methyl ester, formic acid and hydrogen peroxide at the speed of 50mm at the same time into the pipeline reactor with an inner diameter of 50mm to react for 15 minutes, and then re-feed for continuous reaction production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com