Halogen-free inflaming-retarding high impact polystyrene resin

A flame-retardant high-impact polystyrene and polystyrene resin technology, applied in the field of halogen-free flame-retardant high-impact polystyrene resin, can solve problems such as loss of processing performance and increase in cost, avoiding migration and accelerating extinction High flame and flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

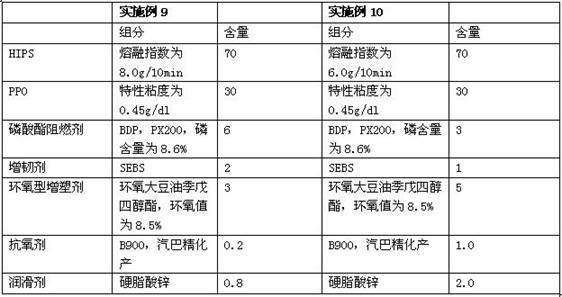

[0034] The components of the halogen-free flame-retardant high-impact polystyrene resin involved in Examples 1-9 and the weight content of each component are shown in Tables 1-5 below. The preparation method of the halogen-free flame-retardant high-impact polystyrene resin Proceed as follows:

[0035] (a) get each component by weight parts;

[0036] (b) After fully mixing high-impact polystyrene resin, polyphenylene ether, phosphate flame retardant, toughening agent, epoxy plasticizer, antioxidant, and lubricant in a high-speed mixer, The metering device is fed into the twin-screw extruder, and the temperature of the twin-screw extruder is controlled at 170-200°C. Under the conveying, shearing and mixing of the screw, the material is melted and compounded, and finally extruded, drawn, Cooling and pelletizing steps to obtain the halogen-free flame-retardant high-impact polystyrene resin.

[0037] Table 1

[0038]

[0039] Table 2

[0040]

[0041] table 3

[0042] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com