Preparation method of microbial oil-based epoxide

A microbial oil and oxide technology, applied in the direction of organic chemistry, can solve the problems of limited application, high production cost, low epoxy value, etc., and achieve low production cost, high epoxy value, and low residual iodine value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

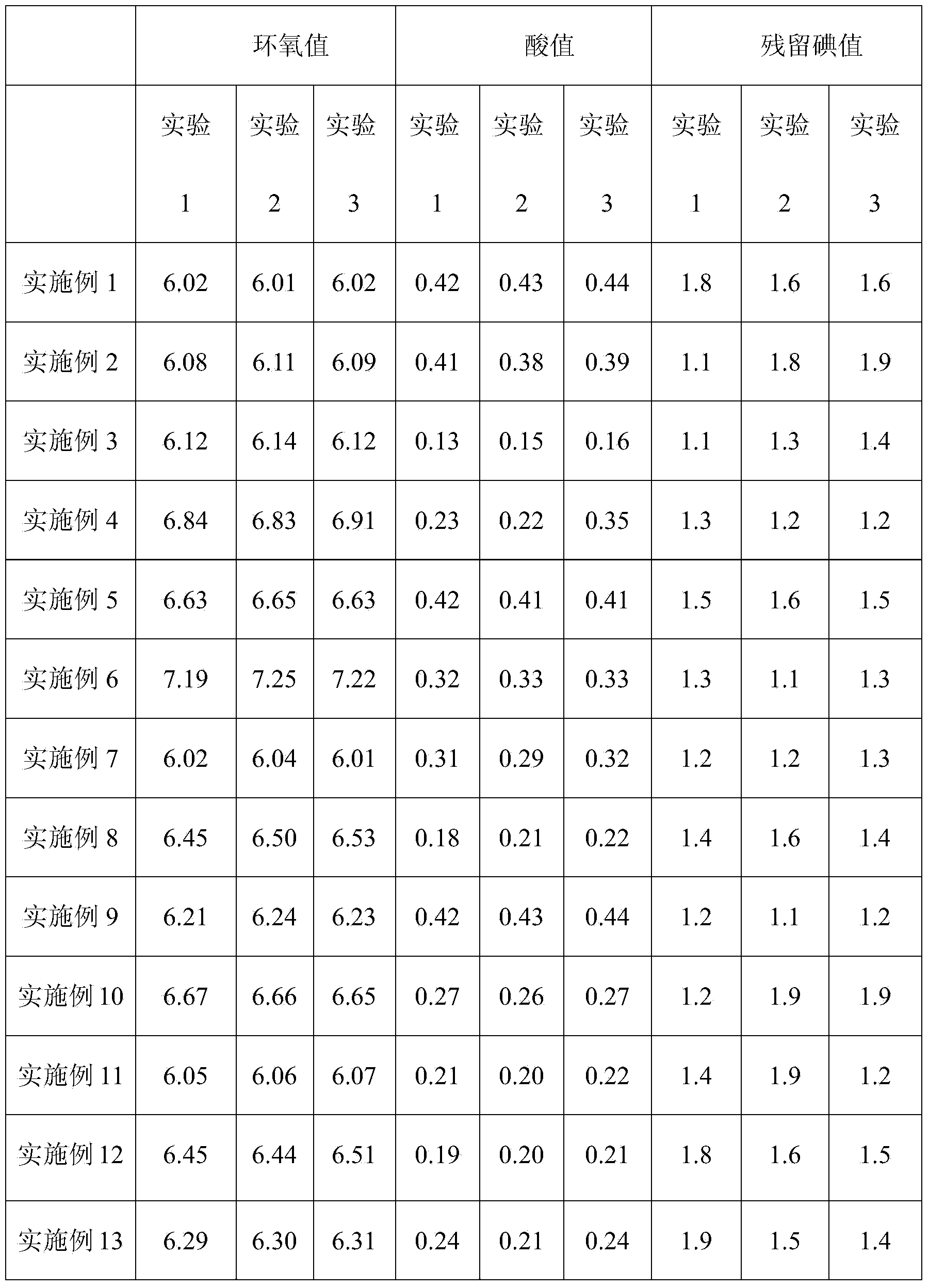

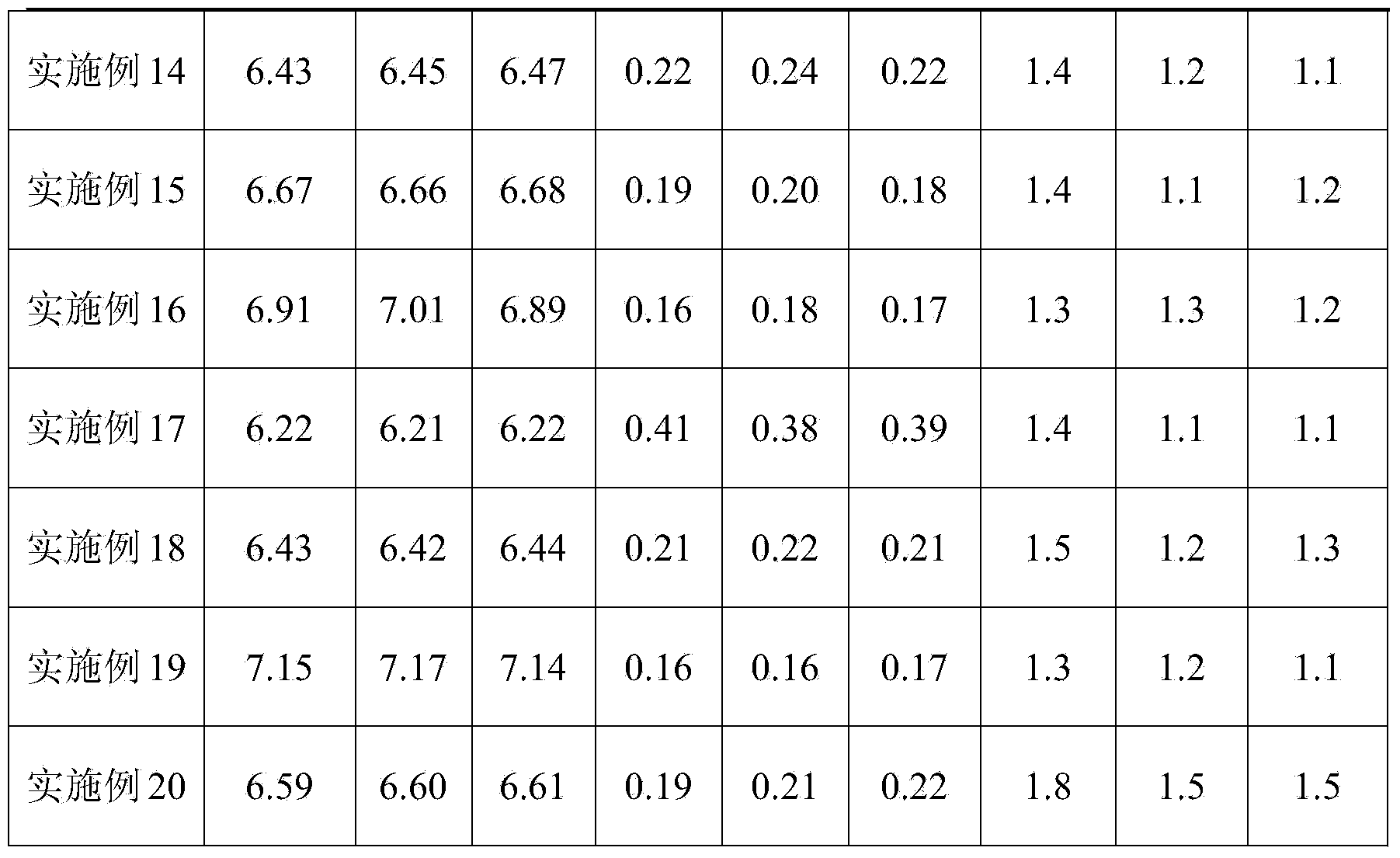

Examples

Embodiment 1

[0026] A kind of preparation of microbial grease base epoxide product, get 10g microbial grease (iodine value 80); Formic acid 0.5g; Catalyst concentrated sulfuric acid 0.5g; Add in the reactor, water-bath heating, be warming up to 40 ℃, then stir and drop slowly Add 6g of sodium peroxide, and react for 4 hours after the sodium peroxide is completely added; after the reaction, wash the crude product with hot distilled water at 50-60°C, and then use a dilute alkali solution with a concentration of 0.1-0.3mol / l for alkali washing , and finally wash with distilled water to make the solution neutral; the washed product is distilled and dehydrated under reduced pressure to obtain microbial oil-based epoxide.

Embodiment 2

[0028] Referring to Example 1, the differences are: 1.3 g of acetic acid, 0.2 g of concentrated sulfuric acid as a catalyst; 65° C. of reaction temperature; 15 g of peracetic acid; and 8 hours of reaction time.

Embodiment 3

[0030] Referring to Example 1, the differences are: 2 g of formic acid, the catalyst is a mixture of 0.1 g of concentrated sulfuric acid and 0.1 g of hydrochloric acid; 7 g of hydrogen peroxide; the reaction temperature is 80° C.; the reaction time is 7 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com