Cashew nut shell oil-modified phenolic resin and preparation method for cashew nut shell oil polyether polyol prepared from same

A technology of polyether polyol and cashew nut shell oil, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as unfavorable production and on-site construction, high toxicity, high viscosity of polyether polyol, etc., and achieve excellent mechanical properties, Moderate functionality, good alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

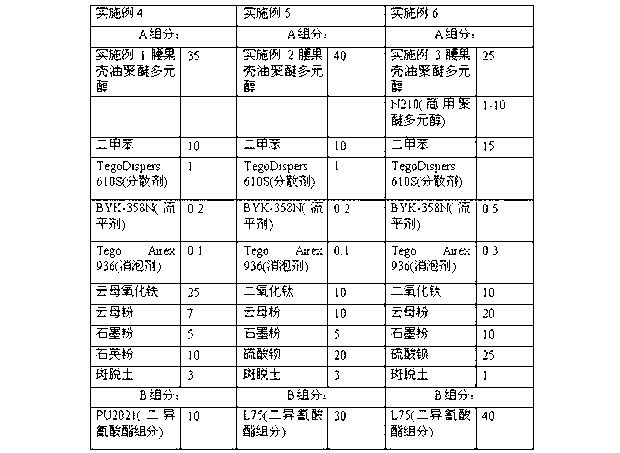

Examples

Embodiment 1

[0030] A cashew nut shell liquid polyether polyol, its raw material is composed of the following components: 300g cashew nut shell liquid (1.0 mol), 18g paraformaldehyde (0.6 mol), 1.8g oxalic acid, 101.2 g (1.15 mol) of ethylene carbonate, 6 g triethylamine.

[0031] Its preparation method comprises the following steps:

[0032] 1) Add cashew nut shell oil and oxalic acid in sequence to the four-necked reaction flask, preheat to 60°C, then add paraformaldehyde in batches under stirring, while controlling the system temperature at 60-70°C, wait until the oxalic acid and paraformaldehyde are completely dissolve, get a solution;

[0033] 2) Heat the solution to 80°C for 5 h, then heat up to 80°C and vacuum dehydrate for 1.5 h (vacuum degree 35 mmHg) to obtain cashew nut shell oil modified phenolic resin, yield ≥ 95%, viscosity 505 cp25°C, pH =3.4;

[0034] 3) Add ethylene carbonate to the modified phenolic resin of cashew nut shell oil, mix well, then add triethylamine, mix w...

Embodiment 2

[0036] A cashew nut shell oil polyether polyol, its raw material is composed of the following components: 300g cashew nut shell oil (1.0 mol), 2.4g sulfuric acid aqueous solution (mass concentration 77%), 64.8g formaldehyde aqueous solution (mass concentration 37%, 0.8mol ), 132.6 g (1.3 mol) of propylene carbonate, and 8 g of triethylamine.

[0037] Its preparation method comprises the following steps:

[0038] 1) Add cashew nut shell oil and sulfuric acid aqueous solution in sequence to the four-necked reaction flask, preheat to 60°C, then add formaldehyde aqueous solution dropwise under stirring, while controlling the system temperature at 60-70°C, and wait until the formaldehyde is completely dissolved to obtain a solution;

[0039] 2) Heat the solution to 90°C for 6 h, then heat up to 70°C and vacuum dehydrate for 4 h (vacuum degree 10 mmHg), to obtain cashew nut shell oil modified phenolic resin, yield ≥ 95%, viscosity 715cp25°C, pH= 3.2;

[0040] 3) Add propylene carb...

Embodiment 3

[0042] A polyether polyol, the raw material of which consists of the following components: 300g of cashew nut shell liquid (1.0 mol), 1.3g of sulfuric acid aqueous solution (mass concentration 77%), 12g of paraformaldehyde (0.4mol), 142.8g of propylene carbonate ( 1.4mol), 10 g imidazole.

[0043] Its preparation method comprises the following steps:

[0044] 1) Add cashew nut shell oil and sulfuric acid aqueous solution in turn to the four-necked reaction flask, preheat to 60°C, then add paraformaldehyde in batches under stirring, while controlling the system temperature at 60-70°C, until the paraformaldehyde is completely dissolved , to get a solution;

[0045]2) Heat the solution to 100°C for 1 h, then heat up to 90°C for 1 h in vacuum dehydration (vacuum degree 40 mmHg), to obtain cashew nut shell oil modified phenolic resin, yield ≥ 95%, viscosity 351cp25°C, pH= 3.4;

[0046] 3) Add propylene carbonate to the modified phenolic resin of cashew nut shell oil, mix well, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com