Transparent hardened film for in-mold decoration

A technology of in-mold decoration and hardening film, which is applied in the direction of chemical instruments and methods, coatings, layered products, etc., can solve the problems of insufficient hardness, etc., to overcome the reduction of molding tensile properties and excellent molding tensile properties , the effect of good forming tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

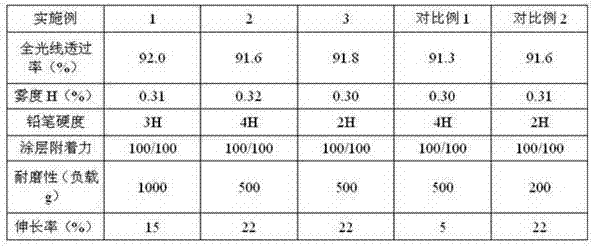

Examples

Embodiment 1

[0048] The hardened coating layer of this embodiment is made by the following components by weight after being cured by ultraviolet light:

[0049] 6147 15

[0050] 6130B-80 20

[0051] U8605 5

[0052] 184 10

[0053] EFKA3772 0.01

[0054] Ethyl acetate 49.99

[0055] The preparation method is as follows:

[0056] To 15 parts by weight of hexafunctional aliphatic urethane acrylate prepolymer (produced by Changxing Chemical Materials Co., Ltd., trade name: 6147, functionality: 6), 20 parts by weight of trifunctional aliphatic urethane acrylate prepolymer (Changxing Produced by Chemical Materials Co., Ltd., trade name: 6130B-80, functionality: 3) and 5 parts by weight of organic-inorganic hybrid material (produced by Taiwan Lida Chemical Co., Ltd., trade name: U8605) mixture, while adding 0.01 wt. Parts of acrylic leveling agent (produced by Efka Auxiliary Company of the Netherlands, trade name: EFKA3772), 10 parts by weight of photoinitiator 1-hydroxycyclohexyl phenyl k...

Embodiment 2

[0058] The hardened coating layer of this embodiment is made by the following components by weight after being cured by ultraviolet light:

[0059] U900 20

[0060] W300 5

[0061] 601A-35 7

[0062] 184 5

[0063] EFKA3299 0.1

[0064] Butyl acetate 62.9

[0065] The preparation method is as follows:

[0066] To 20 parts by weight of hexafunctional aliphatic urethane acrylate prepolymer (produced by Bayer, Germany, trade name: U900, functionality: 6), 5 parts by weight of difunctional aliphatic urethane acrylate prepolymer (Guangzhou Wuxing Produced by Material Company, trade name: W300, functionality: 2) and 7 parts by weight of organic-inorganic hybrid material (produced by Changxing Chemical Co., Ltd., trade name: 601A-35), while adding 0.1 parts by weight of organosiloxane Alkane leveling agent (produced by Efka Auxiliary Company of the Netherlands, trade name: EFKA3299), 5 parts by weight of photoinitiator 1-hydroxycyclohexyl phenyl ketone (produced by Changzhou Hu...

Embodiment 3

[0068] The hardened coating layer of this embodiment is made by the following components in parts by weight after being cured by ultraviolet light: EB220 30

[0069] W300 14

[0070] U-0933-63 10

[0071] 1173 8

[0072] EFKA3299 0.5

[0073] Butyl acetate 37.5

[0074] The preparation method is as follows:

[0075] To 30 parts by weight of hexafunctional aromatic urethane acrylate prepolymer (produced by Cytec, trade name: EB220, functionality: 6), 14 parts by weight of difunctional aliphatic urethane acrylate prepolymer (Guangzhou Wuxing Produced by Material Company, trade name: W300, functionality: 2) and 10 parts by weight of organic-inorganic hybrid material (produced by Suzhou Lihua Resin Co., Ltd., trade name: U-0933-63), while adding 0.5 parts by weight Parts of organosiloxane leveling agent (produced by Efka Auxiliaries in the Netherlands, trade name: EFKA3299), 8 parts by weight of photoinitiator 2-hydroxy-methylphenylpropane-1-one (Changzhou Huati Chemical Co.,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com