Hyperbranched water-based polyurethane coating and preparation method thereof

A technology of water-based polyurethane and hyperbranched polyester, which is applied in the direction of polyurea/polyurethane coatings and coatings, and can solve the problems of poor water resistance, solvent resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

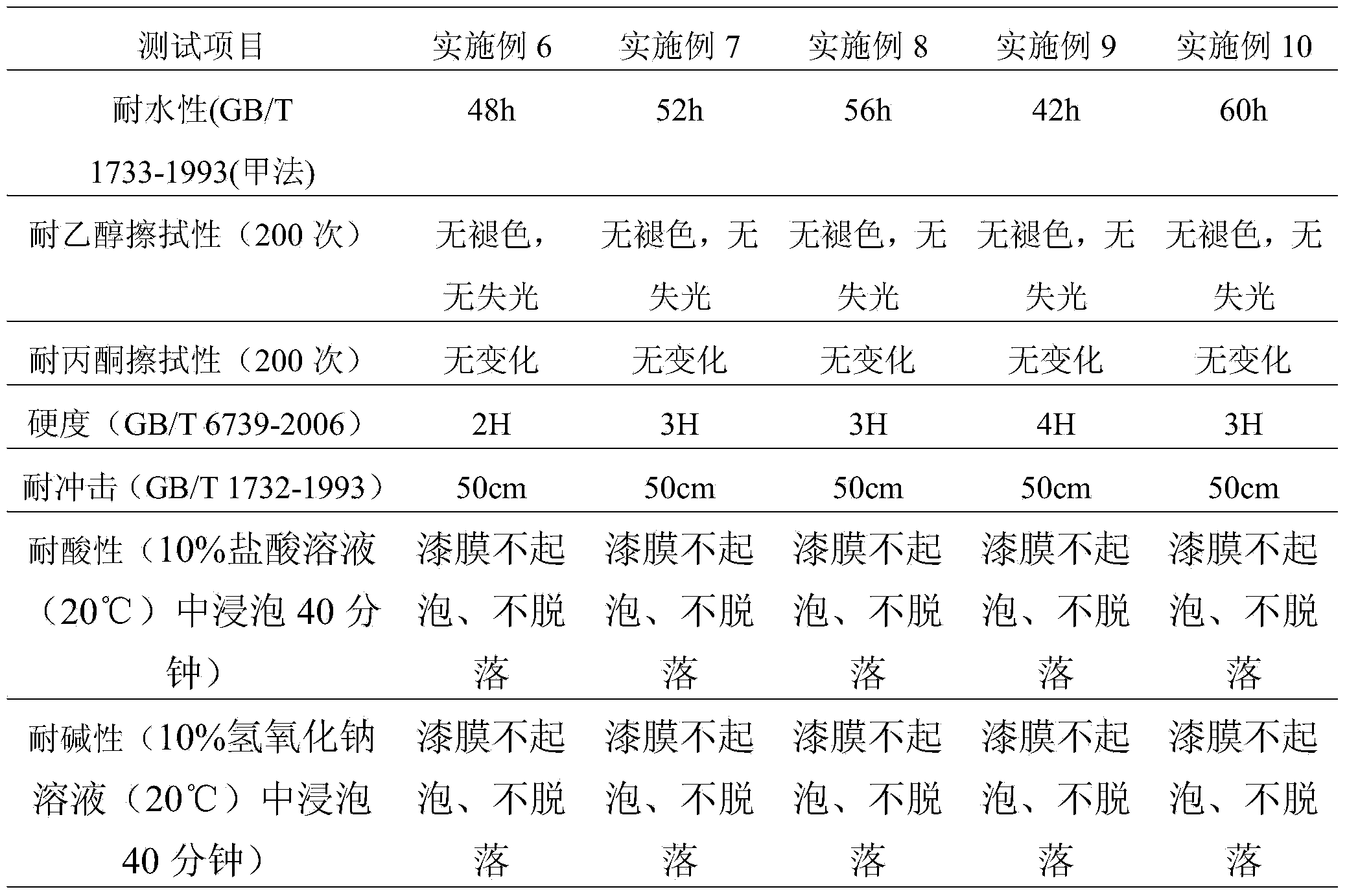

Examples

preparation example Construction

[0027] The preparation method of hyperbranched waterborne polyurethane of the present invention preferably comprises as follows:

[0028] Step 1: Hyperbranched Polyester Boltorn TM H40, anhydrous stannous chloride catalyst, antioxidant and maleic anhydride react to obtain modified hyperbranched waterborne polyurethane;

[0029] Step 2: reacting the modified hyperbranched waterborne polyurethane obtained in step 1 with diisocyanate to obtain the first intermediate;

[0030] Step 3: reacting the first intermediate obtained in step 2 with a small molecule chain extender to obtain a second intermediate;

[0031] Step 4: reacting the second intermediate obtained in Step 3 with diaminosulfonate to obtain hyperbranched waterborne polyurethane.

[0032] Hyperbranched polyester Boltorn of the present invention TM H40 refers to the fourth-generation hyperbranched polyester Boltorn produced by Perstorp, Sweden. TM H40, which contains 64 hydroxyl groups in the molecule, reacts with th...

Embodiment 1

[0046] Add 450g of hyperbranched polyester Boltorn in the reaction vessel TM H40 and 1300g xylene, the temperature is raised to 110°C, stirred for 20min, after heating to dissolve completely, add 0.23g of anhydrous stannous chloride catalyst and 0.01g of antioxidant 1010, then add 80g of maleic anhydride, and heat up to 145°C, react for 2 hours, remove xylene under 0.098MPa pressure, and obtain modified hyperbranched waterborne polyurethane;

[0047] Under the protection of nitrogen, add 350g modified hyperbranched water-based polyurethane to the reaction vessel, raise the temperature to 100°C, and remove water under reduced pressure for 2 hours under 0.098MPa pressure, then drop the temperature to 70°C, add 160g acetone, and 165g of 1,6-hexamethylene diisocyanate was added dropwise at a speed of min, and after the dropwise addition was completed, the reaction was continued for 2 hours to obtain the first intermediate;

[0048] Add 120ml of acetone to the reaction vessel to r...

Embodiment 2

[0051] In reaction vessel, add the hyperbranched polyester Boltorn of 820g TM H40 and 1650g xylene, the temperature is raised to 135°C, stirred for 35min, after heating to dissolve completely, add 0.55g anhydrous stannous chloride catalyst and 0.03g antioxidant 1010, then, add 170g maleic anhydride, heat up to 160°C, reacted for 3.5 hours, and removed xylene under a pressure of 0.098MPa to obtain a modified hyperbranched waterborne polyurethane;

[0052] Under the protection of nitrogen, add 672g of modified hyperbranched water-based polyurethane to the reaction vessel, raise the temperature to 120°C, and remove water under reduced pressure for 2 hours under the pressure of 0.098MPa, then drop the temperature to 85°C, add 240g of acetone, and Add 238g of dicyclohexylmethane diisocyanate dropwise at a speed of min, and after the dropwise addition, continue to react for 4 hours to obtain the first intermediate;

[0053] Add 200ml of acetone to the reaction vessel to reduce the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com