Patents

Literature

87results about How to "Dense network structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hyperbranched water-based polyurethane coating and preparation method thereof

ActiveCN103450792AGood storage stabilityHigh functionalityPolyurea/polyurethane coatingsWater basedHyperbranched polyester

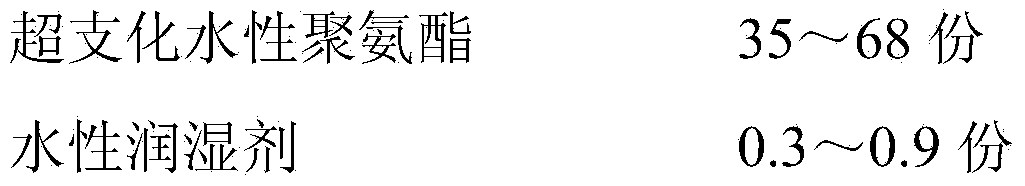

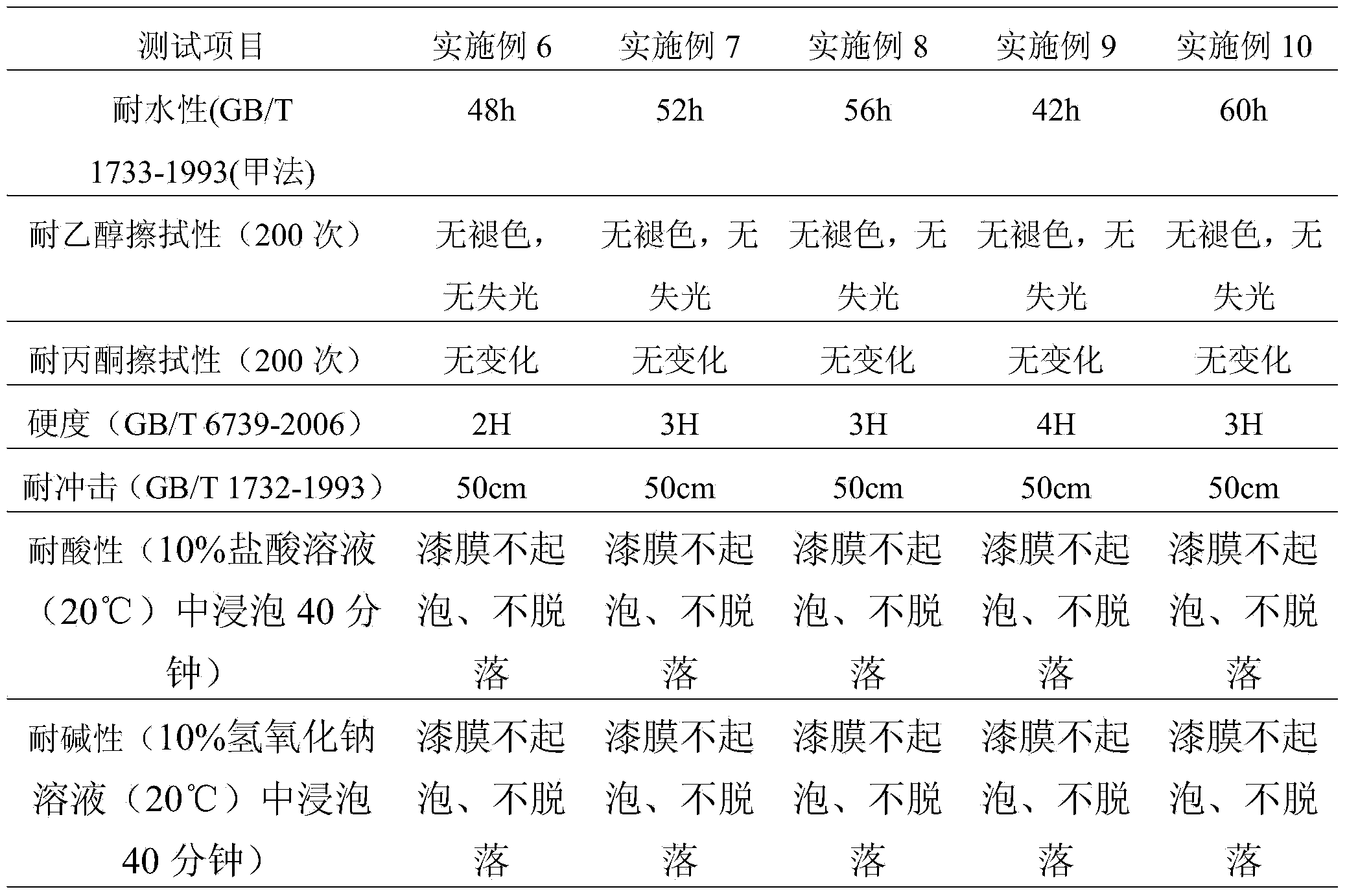

The invention provides a hyperbranched water-based polyurethane coating and a preparation method thereof, belongs to the field of water-based coating, and is used for solving the problem that the existing hyperbranched water-based polyurethane is poor in waterproofness, solvent resistance and weather fastness. The coating comprises 35-68 parts of hyperbranched water-based polyurethane, 0.3-0.9 part of water-based wetting agent, 0.2-0.7 part of water-based flatting agent, 0.5-1.1 parts of water-based deformaer, 8-12 parts of water-based cosolvent and 2.5-4.3 parts of curing agent. The hyperbranched water-based polyurethane is prepared with hyperbranched polyester BoltornTMH40 as a soft segment and diaminosulfonate as a hydrophilic chain extender. A film formed by the cured hyperbranched water-based polyurethane coating provided by the invention has no phenomena of blushing, bubbling and falling even after being soaked in normal-temperature water for 60 hours, and also has no phenomena of blushing, facing and dulling even after being wiped 200 times by using ethanol and acetone.

Owner:CHANGCHUN SANHUA IND

High-strength electric-control solid propellant

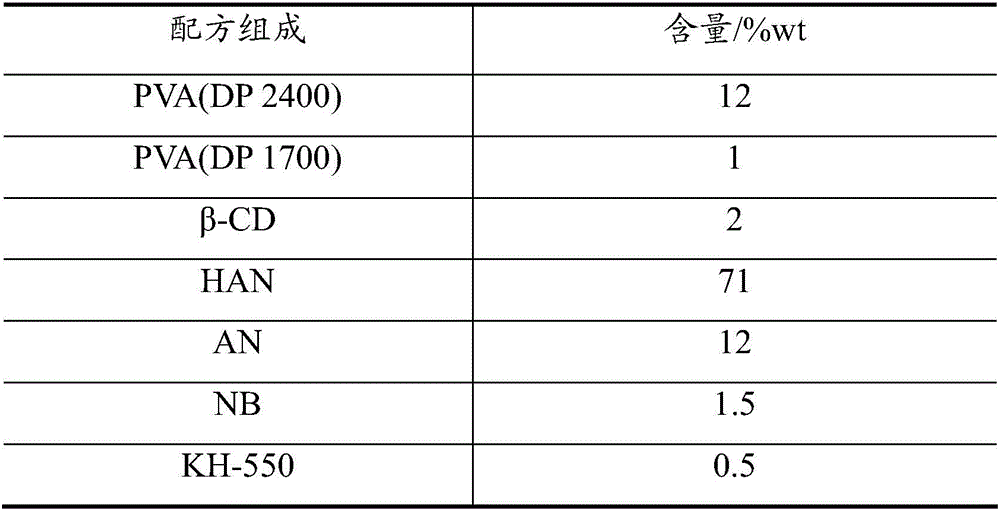

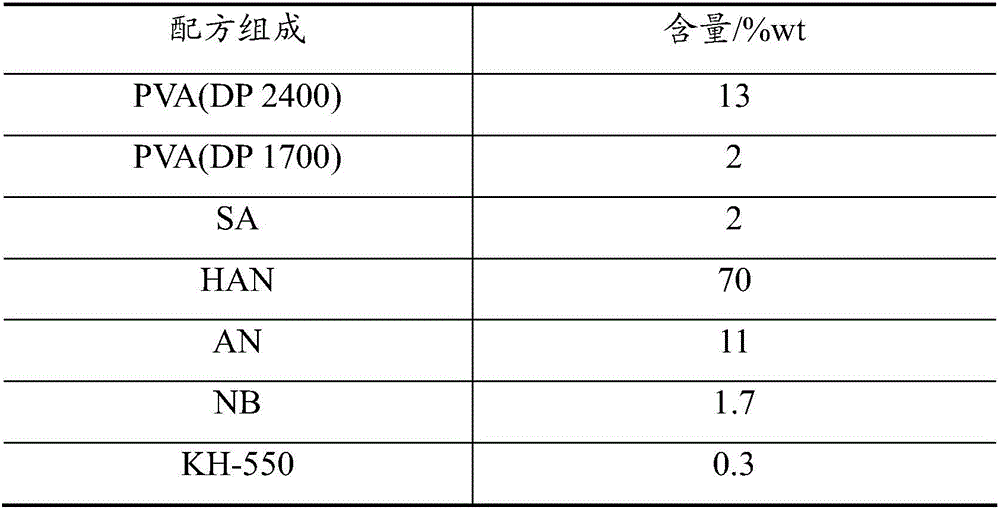

InactiveCN106365935AImproved viscosity and degree of crystallizationConducive to process performance and mechanical propertiesPressure gas generationChemistryWater soluble

The invention relates to a high-strength electric-control solid propellant which comprises the following components in percentage by mass: 10-20% of adhesive, 60-80% of main oxidizer, 5-20% of auxiliary oxidizer, 1-2% of crosslinking agent, 0.1-0.5% of coupling agent and 1-5% of fuel additive. The adhesive is water-soluble polyvinyl alcohol (PVA); the main oxidizer is hydroxylammonium nitrate (HAN); the auxiliary oxidizer is one or combination of ammonium nitrate (AN) and ammonium perchlorate (AP); the crosslinking agent is one or combination of boric acid and borax; the coupling agent is a silane coupling agent; and the fuel additive is one or combination of cyclodextrin, sodium alginate, polyvinylpyrrolidone (PVP) and gelatin. The normal-temperature tensile strength of the electric-control solid propellant can be obviously enhanced, and the maximum normal-temperature strength can reach 8 MPa or above. The electric-control solid propellant is suitable to be used as an attitude control or orbit control propellant with higher requirements for normal-temperature strength.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

Defatted cheese and preparation method thereof

InactiveCN101167499ADense tissue structureGood glossCheese manufactureFood preparationFat substituteSucrose

The invention relates to a fermentation dairy product in food field, which is a lean cheese and process for preparation. Crystalline cellulose is utilized as fat substitute and sucrose fatty acid ester is utilized as fat imitation to produce novel low-caloric lean cheese with rich nutrition. During producing, the crystalline cellulose and the sucrose fatty acid ester is pro rata mixed and swelled with part butter milk as premix compound. After high speed shearing type stirring, the crystalline cellulose forms a micro-mesh shape cellulose dispersion with high viscosity, and the stereo meshed structure is filled with fat imitation sucrose fatty acid ester for improving physical arrangement of products. Then the above premix compound is charged to the rest butter milk or low-caloric butter milk powder reconstructed milk to evenly stir, to high pressure homogeneously treat, and to be charged with leaven and other addition agents, such as perfume compounds, condiment, coloring matter and the like, thereby producing the lean cheese product of the invention after fermenting, with missible oil shape appearance and taste similar to that of whole cheese.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

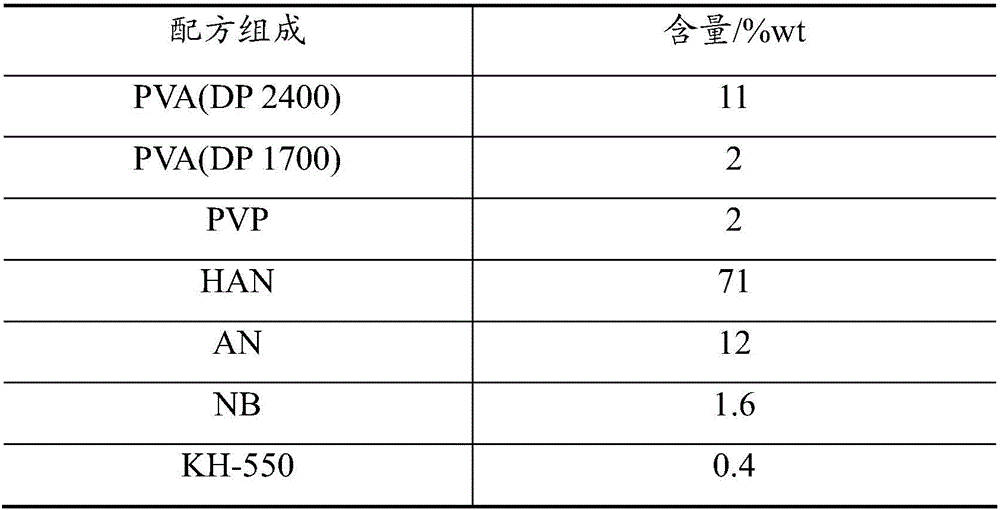

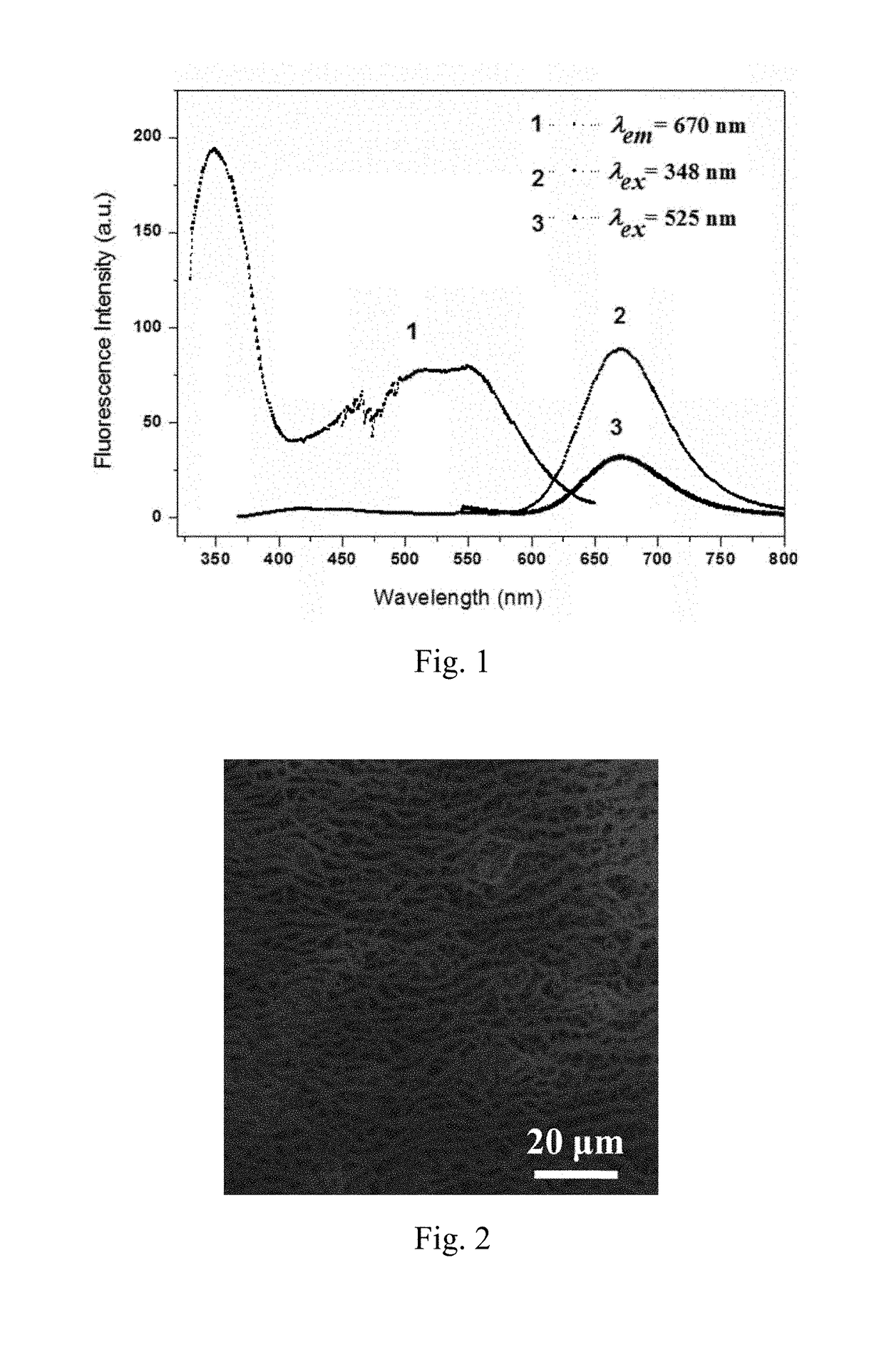

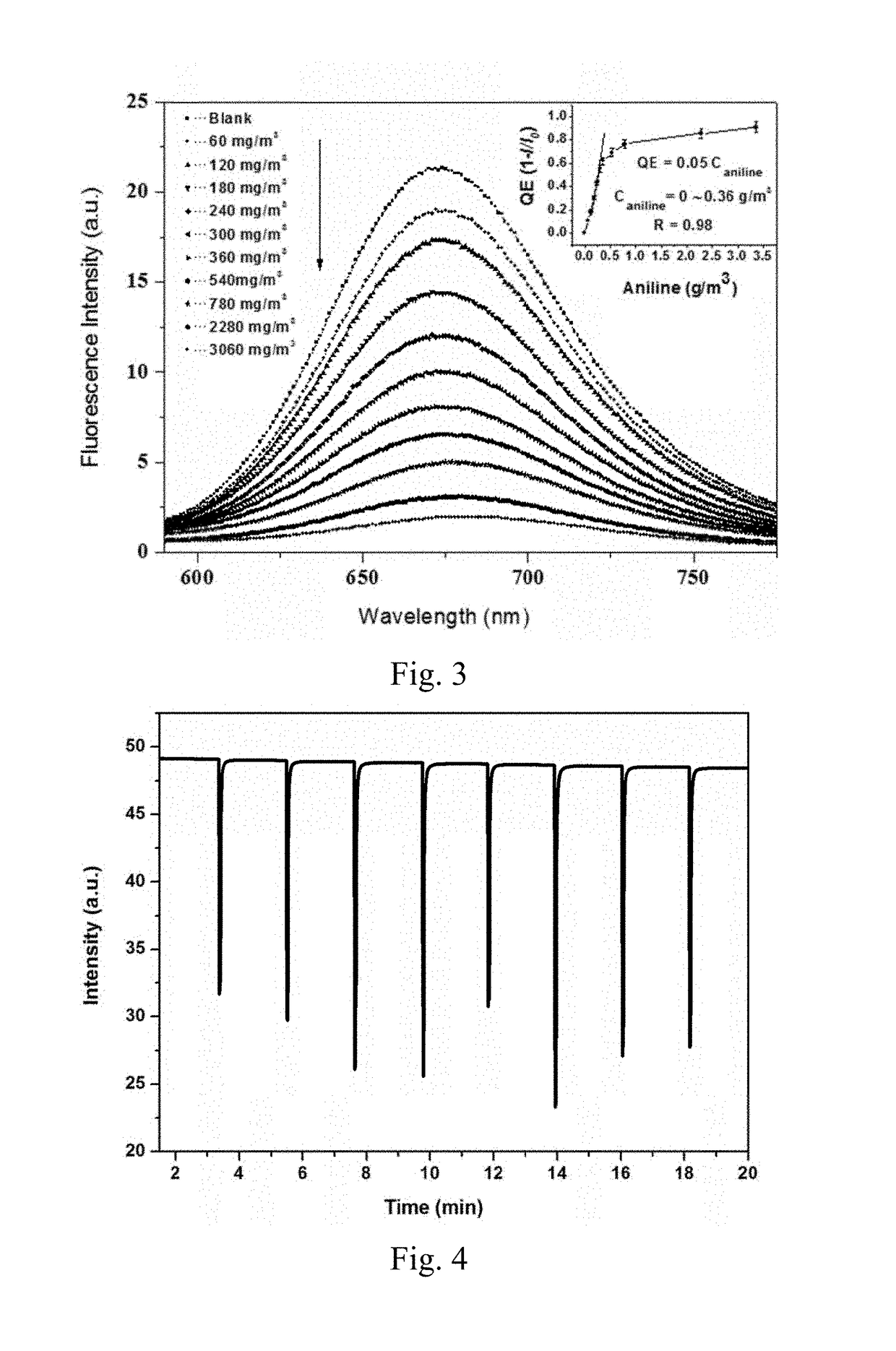

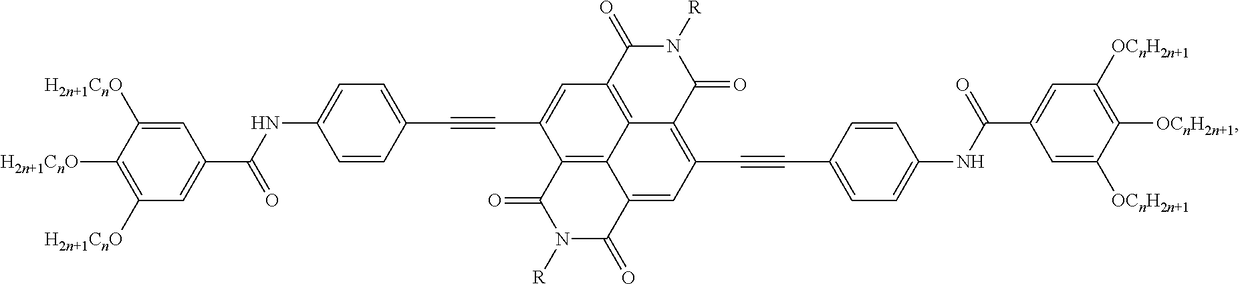

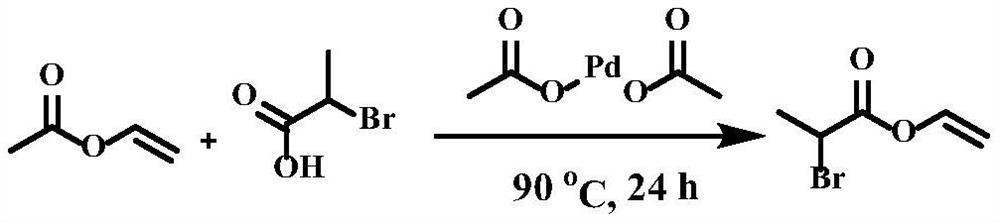

Preparation method and application of fluorescent compound having sensing ability to aniline and o-toluidine gas, and fluorescent film with the same

ActiveUS20190062629A1Easy to operateImprove stabilityOrganic chemistryFluorescence/phosphorescenceSolubilityTerra firma

The present invention discloses a fluorescent compound having a sensing ability to aniline and o-toluidine, a preparation method thereof, a preparation method and application of a fluorescent sensing film. The compound contains a naphthalenediimide (NDI) unit, two alkynyl aniline conjugate fragments and two long alkyl chain fragments; compared with perylene anhydride (PDI), naphthalenediimide (NDI) has better solubility, rich photophysical property, good photochemical stability and strong π-π stacking effect; these building units make the prepared fluorescent compound have supramolecular characteristics and more abundant gelling behavior and assembly behavior. Therefore, the sensing film prepared with the fluorescent compound is controllable in the microstructure, good in stability, high in sensitivity, long in service life and able to be repeatedly used. The present invention achieves the sensitive detection of aniline, and more importantly, the detection is completely reversible, so as to lay the solid foundation for the realization of aniline fluorescence sensor.

Owner:SHAANXI NORMAL UNIV

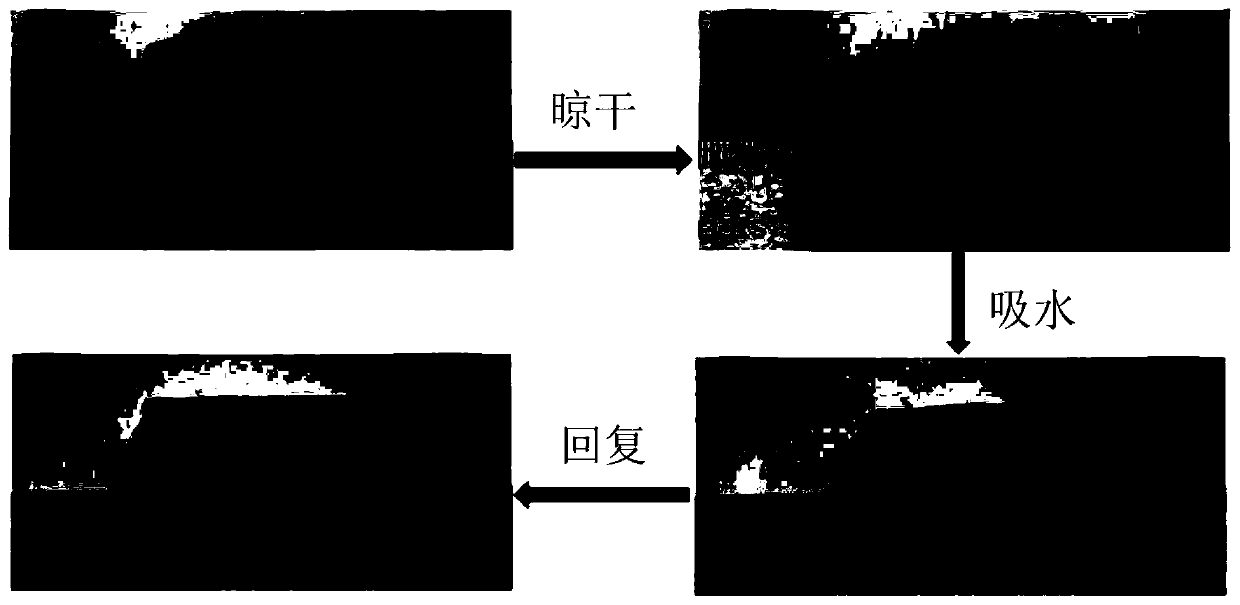

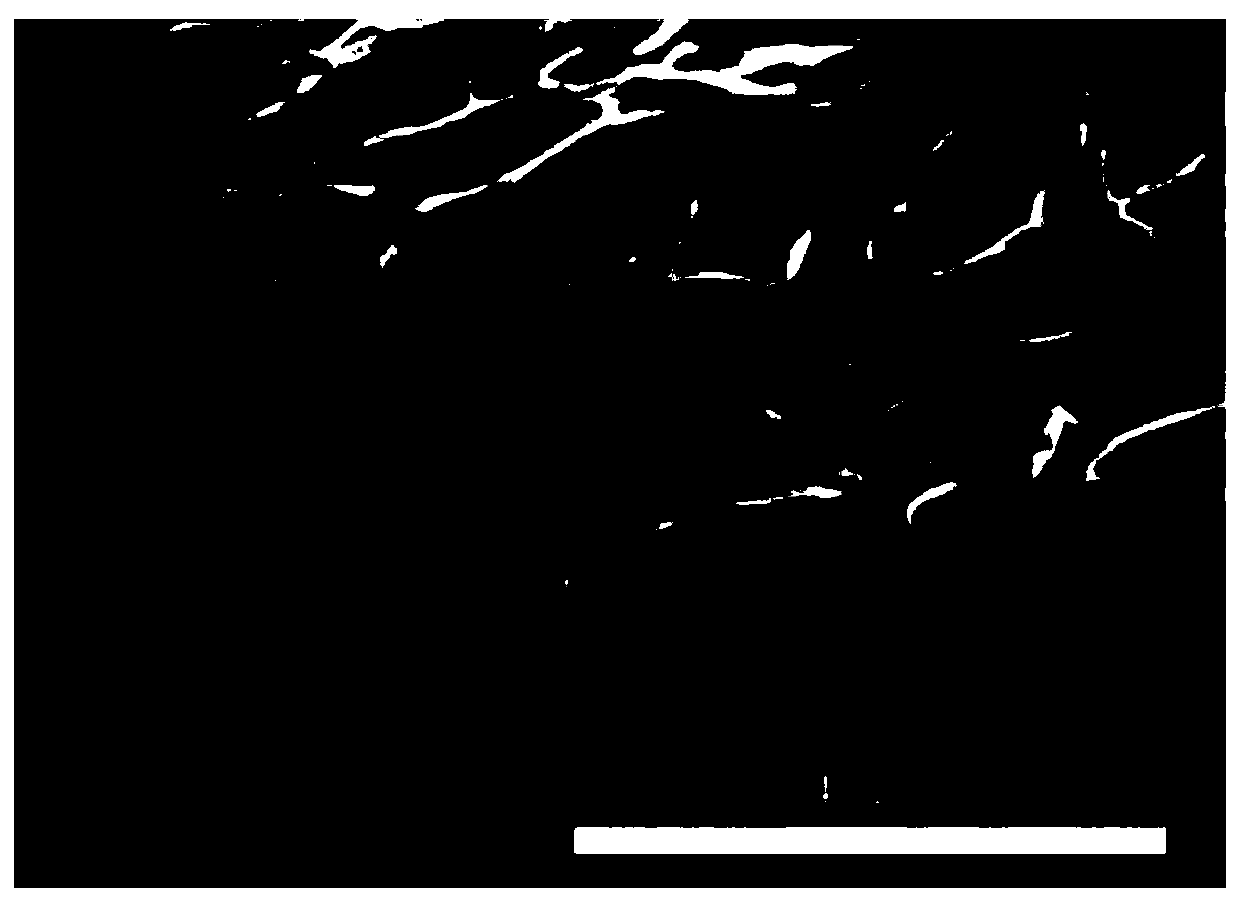

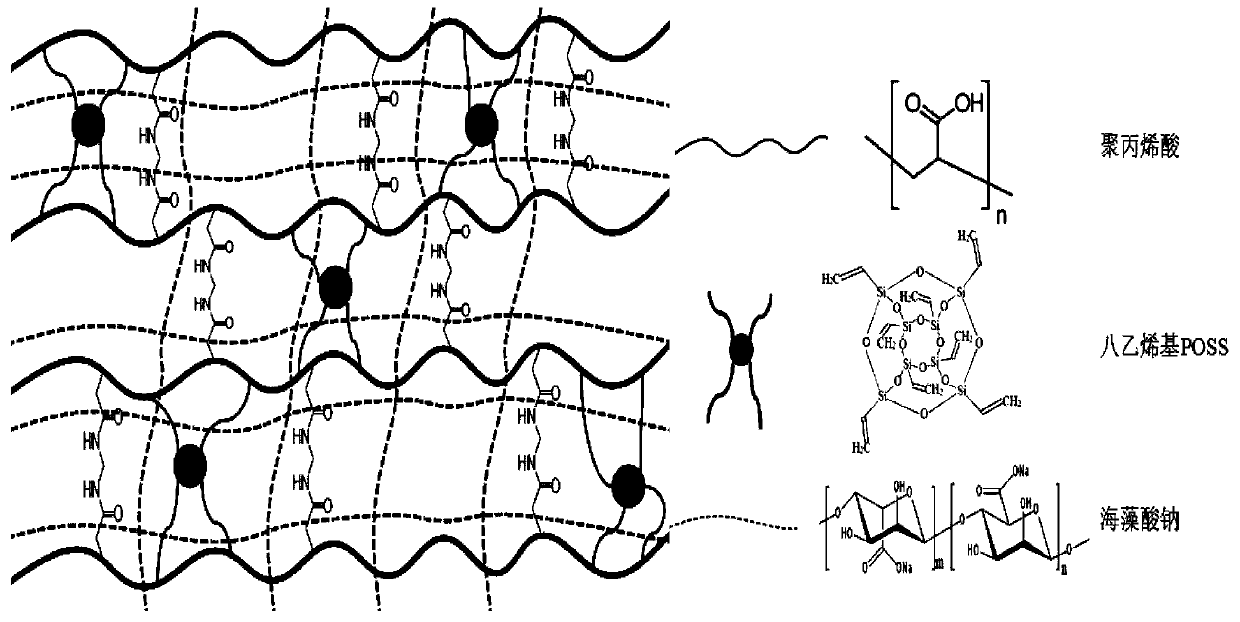

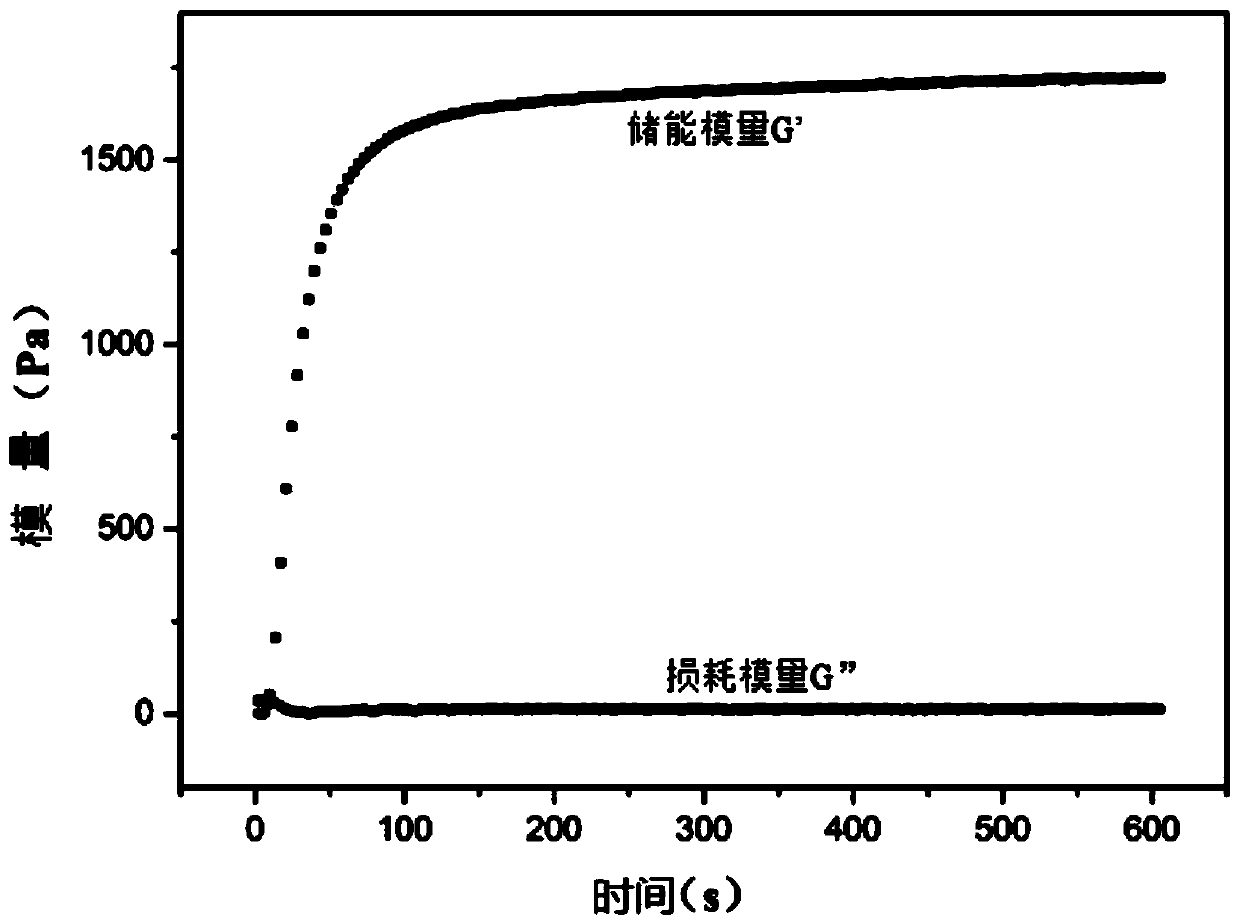

Preparation method of polyacrylic acid flexible composite hydrogel electrolyte

ActiveCN110690062AImprove mechanical propertiesDense network structureHybrid capacitor electrolytesHybrid/EDL manufactureMeth-Polymer chemistry

The invention discloses a preparation method of a polyacrylic acid flexible composite hydrogel electrolyte. The preparation method comprises the following steps of: (1) dissolving sodium alginate in distilled water, performing stirring, and carrying out ultrasonic dispersion to form a solution for later use; (2) adding acrylic acid, N-N'-methylene bisacrylamide, octavinyl polyhedral oligomeric silsesquioxane and an emulsifier into the solution obtained in the step (1), performing stirring, and carrying out ultrasonic dispersion to form a reaction system; (3) adding an initiator into the reaction system obtained in the step (2), and performing stirring and dissolving; (4) putting the product obtained in the step (3) into an oven at a temperature of 60 DEG C, performing standing and reactingfor 5 hours to obtain hydrogel; (5) naturally airing the hydrogel obtained in the step (4) for 36-54 hours; and (6) soaking the hydrogel obtained in the step (5) in a redox active substance solutionfor 18-48 hours to obtain the polyacrylic acid flexible composite hydrogel electrolyte.

Owner:SHANDONG UNIV OF SCI & TECH

Production method for fish oil microcapsule product with ultrafine edible fungus powder as main wall material

ActiveCN103340398ASuppress fishy smellFragrant smellFood shapingFood preparationBiotechnologyTremella

The invention provides a production method for a fish oil microcapsule product with ultrafine edible fungus powder as a main wall material. Main materials for microcapsule encapsulation are ultrafine mushroom and tremella powder and perilla oil used as a deodorization substance for fish oil. The production method comprises the following steps: preparation of the ultrafine mushroom and tremella powder; preparation of composite fish oil; and preparation of a fish oil microcapsule. The prepared fish oil microcapsule product has a pure white color and good appearance and can effectively encapsulate a core material. The product has strong antibacterial activity, effectively inhibits fishy smell of the fish oil, supplements and reinforces the function of unsaturated fatty acid of the fish oil and has the excellent characteristics of water solubility, thickening performance, gelatinization, film formation, etc. The wall material of the fish oil microcapsule becomes a nutrition component for the product and enriches nutritional functions of the fish oil product.

Owner:浙江天顺控股集团有限公司

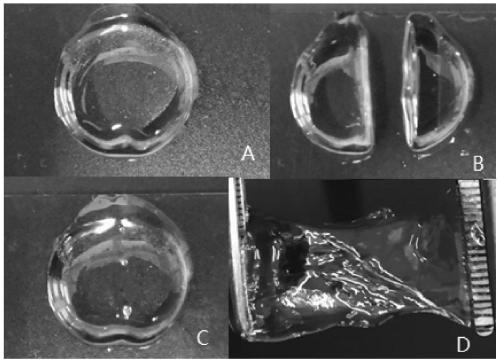

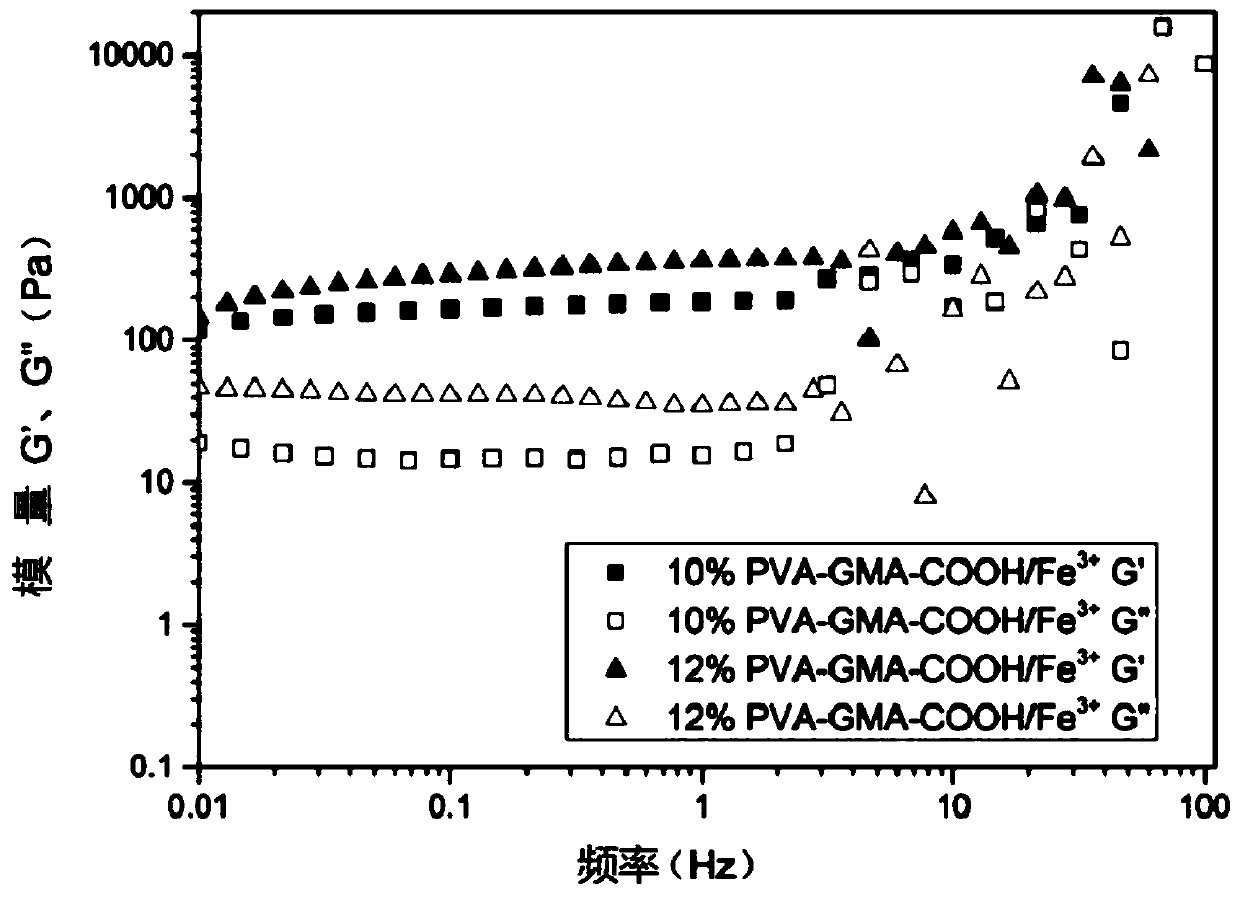

Quick-molding self-healing hydrogel and preparation method thereof

ActiveCN111393675AAvoid time-consuming forming processAvoid the disadvantages of many stepsPolymer scienceGlycidyl methacrylate

The invention provides a quick-molding self-healing hydrogel and a preparation method thereof. The preparation method comprises the following steps: by taking polyvinyl alcohol as a raw material, firstly, reacting the polyvinyl alcohol with glycidyl methacrylate to synthesize methacrylated polyvinyl alcohol, and then, carrying out esterification reaction on carboxyl on succinic anhydride and hydroxyl on the methacrylated polyvinyl alcohol to prepare carboxylated methacrylated polyvinyl alcohol; preparing a precursor mixed solution, mixing the precursor mixed solution with an iron tartrate solution containing ferric ions, and carrying out ultraviolet polymerization molding to prepare the quick-molding self-healing hydrogel with a physicochemical double-crosslinked single-network structure.The hydrogel has the advantages of being high in forming speed and excellent in self-healing performance, and has excellent mechanical properties.

Owner:北京昊坤康源医疗科学技术发展有限责任公司

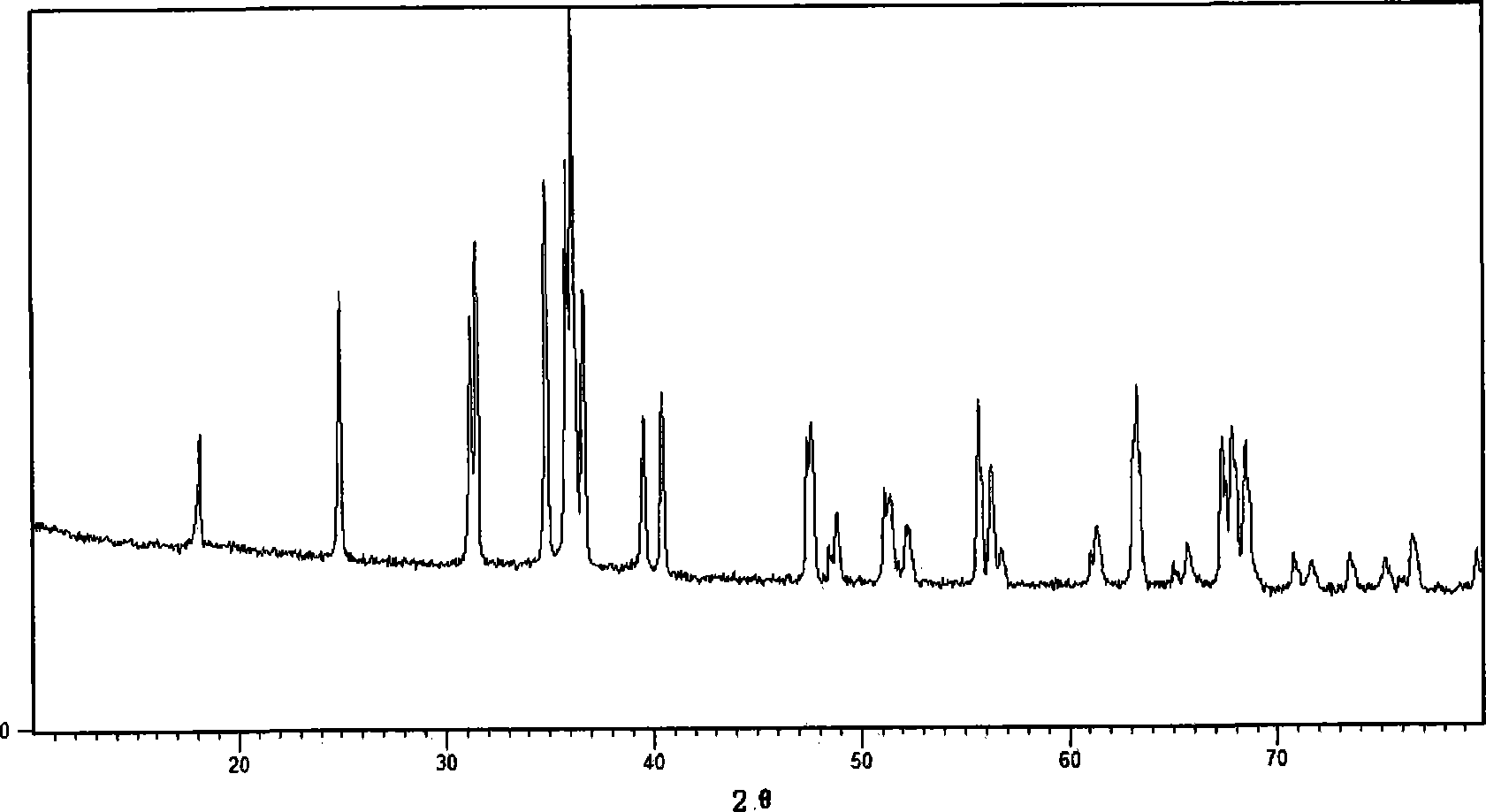

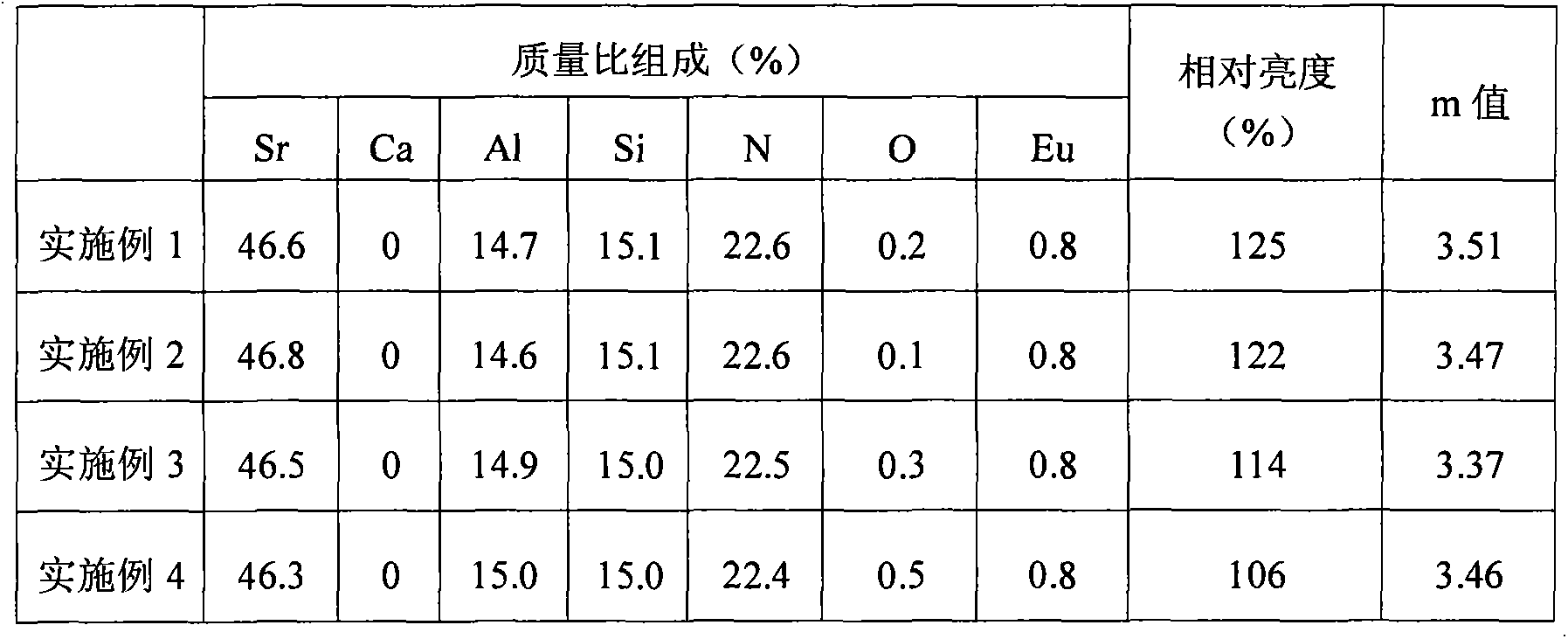

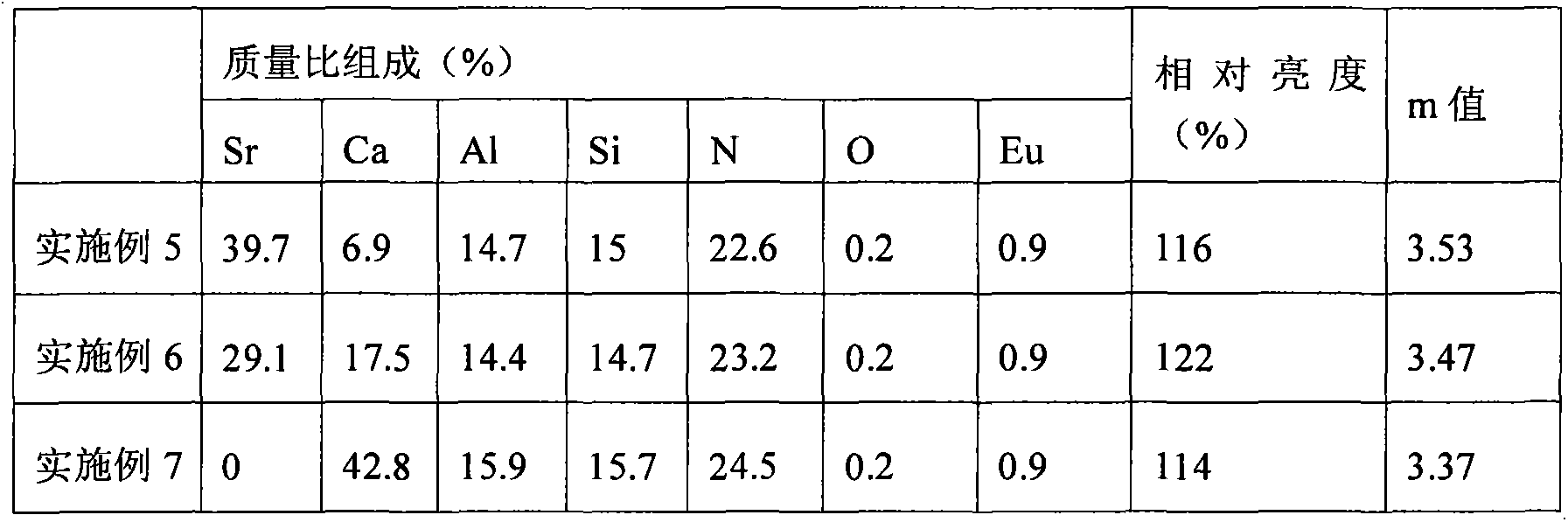

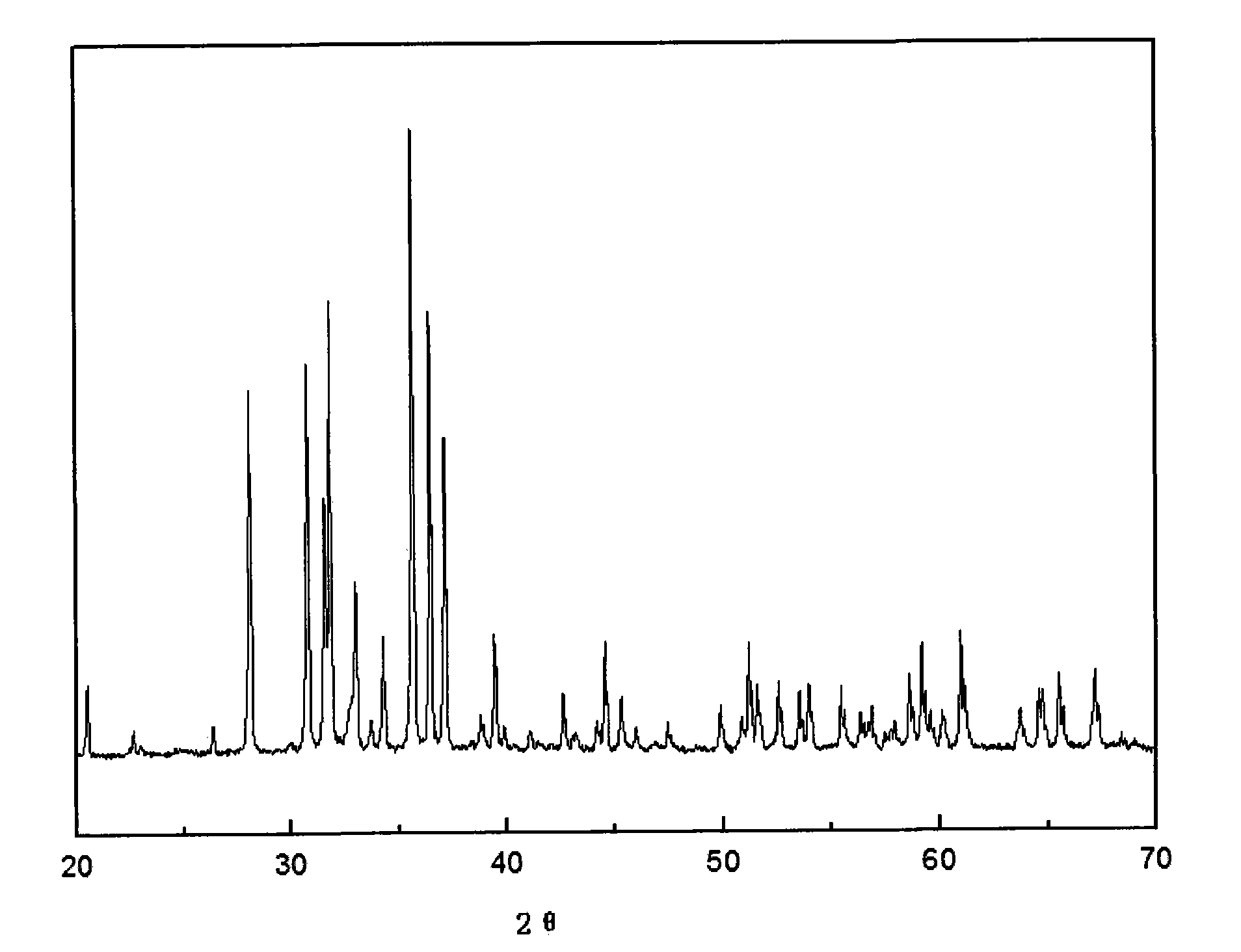

Nitride fluorescent powder and preparation method thereof, light-emitting device comprising nitride fluorescent powder

ActiveCN103320130ACompact structureDense network structureLuminescent compositionsSemiconductor devicesNitrideLight emitting device

The invention discloses a nitride fluorescent powder and a preparation method thereof, a light-emitting device comprising the nitride fluorescent powder. The nitride fluorescent powder is a CaAlSiN3 structure, and comprises the following components in percentage by weight: 32-48% of alkali earth metal, 9-34% of Si, 10-25% of N, 0.1-0.8% of O, 13-26% of Al and 0.2-8% of Eu. The ratio of the sum of weight percents of Al and Si in any unit volume within the 0-50nm range from particle surface to the particle center to the weight percent of Si in any unit volume beyond the range is m, and 1.5<=m<=5. The nitride fluorescent powder disclosed by the invention has higher light-emitting efficiency.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

Water retention and slow release fertilizer coated with cow hair keratin and preparation method of water retention and slow release fertilizer

InactiveCN106007926AHigh strengthReduce solubilityBio-organic fraction processingAnimal corpse fertilisersPolyvinyl alcoholRed mud

The invention discloses water retention and slow release fertilizer coated with cow hair keratin. The water retention and slow release fertilizer is prepared from raw materials in parts by weight as follows: 20-21 parts of cow hair, 80-85 parts of sorghum stalks, 65-70 parts of bagasse, 30-35 parts of fish scales, 22-24 parts of bovine bones, 20-22 parts of fish meal, 40-42 parts of red mud, 1-1.2 parts of zinc humate, 1-1.2 parts of sodium alginate, 1-1.2 parts of super absorbent resin powder, 20-22 parts of attapulgite clay, 0.2-0.3 parts of fatty acid methyl ester ethoxylate, 0.2-0.3 parts of sodium carbonate, 20-21 parts of mercaptoethanol, 18-19 parts of urea, 3-4 parts of sodium dodecyl sulfate, 0.2-0.3 parts of transglutaminase, 3-4 parts of starch, 18-20 parts of a 10% polyvinyl alcohol solution, 7-8 parts of a 5% carboxymethylcellulose solution, 4-5 parts of formaldehyde, 5-6 parts of glycerin, 0.2-0.3 parts of borax and 2-2.5 parts of microbial powder. The water retention and slow release fertilizer can improve the water retention of soil.

Owner:ANHUI YONGGUAN AGRI TECH CO LTD

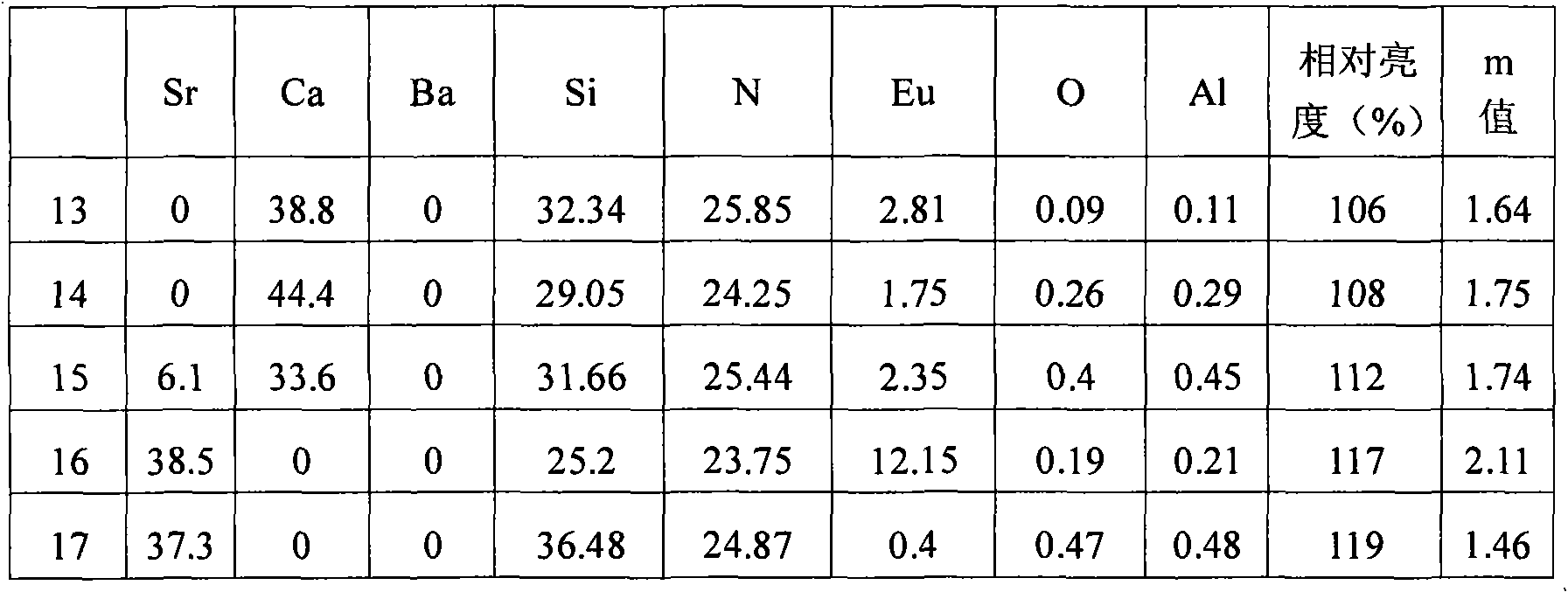

Fluorescent powder, preparation method thereof and light-emitting device comprising same

ActiveCN103275705ADense network structureStable physical and chemical propertiesLuminescent compositionsSemiconductor devicesLight emitting deviceMaterials science

The invention discloses fluorescent powder, a preparation method thereof and a light-emitting device comprising same. The fluorescent powder has an Sr2Si5N8 structure and comprises 32-45% of alkaline earth, 25-38% of Si, 22-27% of N, 0.05-0.5% of O, 0-0.5% of Al and 0.2-13% of Eu by weight percentage, the ratio of the total weight percentage of Al and Si in any unit volume within the range of 0-50 nm extending to the particle center from the particle surface in fluorescent powder particles to the weight percentage of Si in any unit volume outside the range is m, and the value range of m is not less than 1.2 and not more than 2.5. The fluorescent powder provided by the invention is higher in light-emitting efficiency.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

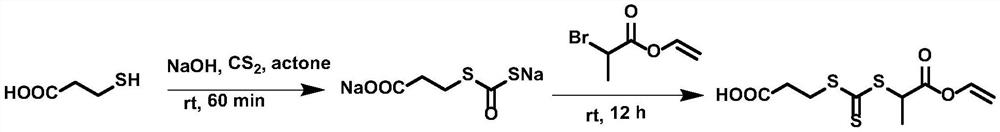

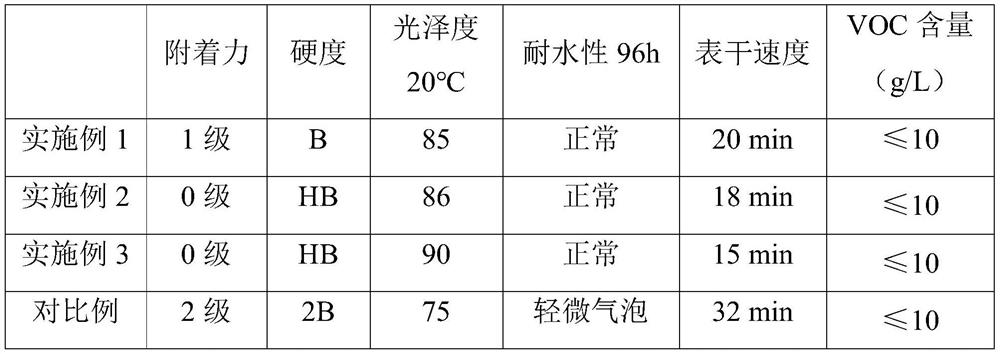

Ultraviolet-cured acrylic resin water-based coating material and preparation method thereof

The invention relates to an ultraviolet-cured acrylic resin water-based coating material, which is prepared from the following components in parts by weight: 50-60 parts of acrylic resin prepolymer, 1-3 parts of defoaming agent, 1-3 parts of emulsifier, 20-30 parts of filler, 2-4 parts of dispersing agent and 100 parts of water. According to the invention, an ultraviolet curing agent is directly grafted into a hyperbranched polymer structure, so that cross-linking and curing can be performed in molecules to form a three-dimensional network structure so as to achieve high curing efficiency; a curing reaction only starts cross-linking curing under ultraviolet irradiation, so that the performance of a finally cured film is easy to control, and the construction difficulty of the coating material is remarkably reduced; water is used for replacing an organic solvent, so that the method has the obvious advantages of environmental protection, no toxicity, high efficiency and cost reduction, and has remarkable economic and social benefits; and the water-based coating material prepared by the invention has the advantages of extremely strong adhesive force, high surface drying speed and highpaint film glossiness, and can be widely applied to coating of wood product surfaces.

Owner:HUARONG COUNTY HENGXING BUILDING MATERIALS CO LTD

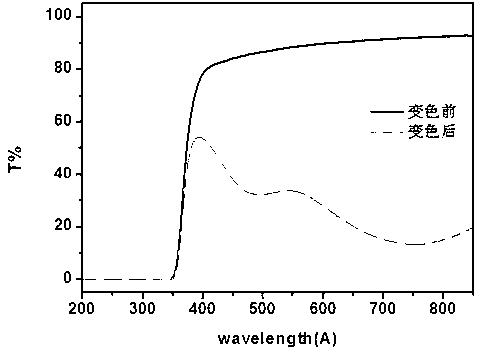

Carboxymethyl cellulose based reversible photochromic hydrogel and its preparation method

ActiveCN103224631AReduce usageGood biocompatibilityTenebresent compositionsCarboxymethyl celluloseAqueous solution

The invention relates to a preparation method of a carboxymethyl cellulose based reversible photochromic hydrogel. The preparation method comprises the following steps: dissolving carboxymethyl cellulose of different substitution degrees into water to prepare a carboxymethyl cellulose aqueous solution, preparing a phospho-tungstic acid aqueous solution, mixing the phospho-tungstic acid solution and the carboxymethyl cellulose aqueous solution under the condition of continuous stirring, controlling addition manner and dosage of phospho-tungstic acid, and finally stopping stirring and standing for 2h so as to obtain the carboxymethyl cellulose based hydrogel.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +2

Lycopene micro-capsule powder and preparation method thereof

PendingUS20200297655A1Increase appetiteLow production costHydrocarbon active ingredientsAntinoxious agentsEmulsionDisaccharide

The present invention discloses a method for preparing a lycopene micro-capsule powder, wherein lycopene is fully mixed with an aqueous phase to obtain a lycopene emulsion, and the emulsion is then ground to a particle size less than 1 μm, and spray dried. The aqueous phase comprises: a gelatin enzymatic hydrolysate with a molecular weight of 5,000-10,000 Da, disaccharide, polysaccharide, and an antioxidant. The disaccharide is one or more of sucrose, maltose and lactose; and the polysaccharide is one or more of pullulan and chitosan.

Owner:CHENGUANG BIOTECH GRP CO LTD

High-toughness high-conductivity carbon paper material for proton exchange membrane battery

InactiveCN111129555ASimple structureGive full play to electrochemical performanceCell electrodesFuel cellsHydrofluoric acidThin film electrode

The invention relates to a high-toughness high-conductivity carbon paper material for a proton exchange membrane battery, and belongs to the technical field of carbon paper materials. By utilizing a constant-temperature liquid-phase oxidation-reduction reaction between potassium permanganate and concentrated sulfuric acid, a nano manganese dioxide material is effectively loaded on the surface of the carbon paper material; meanwhile, polydimethylsiloxane is effectively coated on the surface of the polydimethylsiloxane, and the cross-linked polydimethylsiloxane is etched through hydrofluoric acid; the polydimethylsiloxane material is effectively etched, and holes are formed in the polydimethylsiloxane material, so that the conduction of the current material is ensured; meanwhile, the material structure is effectively coated and improved by the technical scheme; and a layer of ultrathin nano MnO<2> nano film is prepared on a carbon paper substrate by a chemical oxidation-reduction method,in this way, the specific surface area of the MnO<2> film electrode can be greatly increased, the capacity of double electric layers is increased, the electrochemical performance and power performance of the MnO<2> material are brought into full play, the utilization rate of the MnO<2> material is increased, meanwhile, the toughness and strength of the material are effectively modified through the coated and modified polydimethylsiloxane, and the mechanical property of the material is improved.

Owner:梁十根

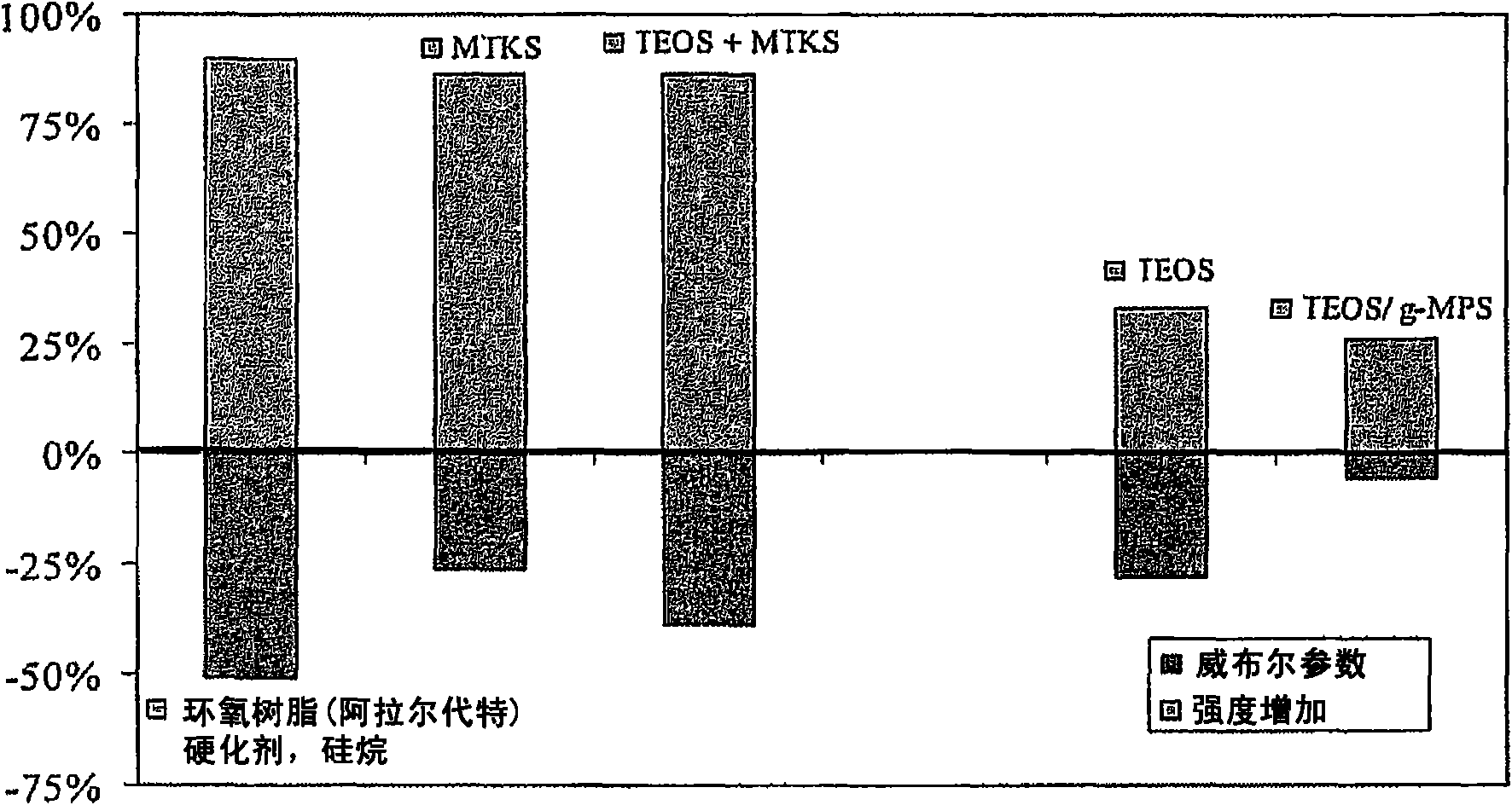

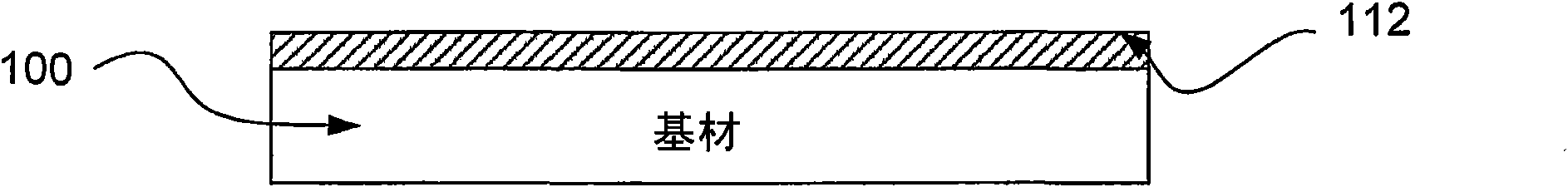

Strengthening glass using coatings

InactiveCN101641302AEasy to understandAvoid spreadingGlass shaping apparatusCoatingsAlkoxy groupChemical measurement

Compositions and methods of creating and applying coatings for strengthening glass substrates are made from precursors and additives that use an under-stoichiometric amount of water, for example, wherein a ratio of water in said additive to said precursor is equal or less than about 0.5 moles of water per mole alkoxy group in the precursor.

Owner:CORNING INC

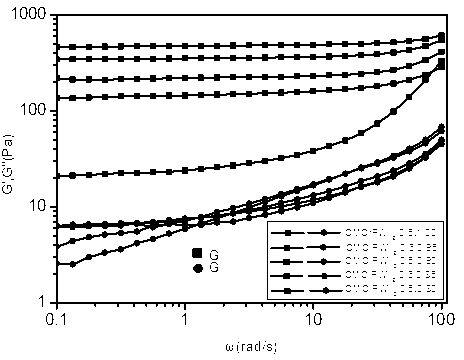

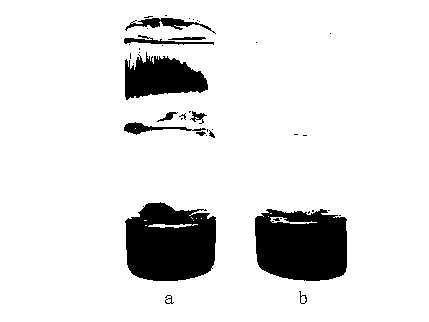

Baking type waterborne acrylic intermediate coating composition with anti-sagging characteristics and a preparation method thereof

ActiveCN109554048APrevent saggingGood anti-sag performanceAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinPolyurea

The invention relates to the technical field of coating, in particular to a baking type waterborne acrylic intermediate coating composition with anti-sagging characteristics and a preparation method thereof. The composition is mainly prepared from, by mass, 25-40% of hydroxyl functionalized waterborne acrylic resin, 2.2-3.1% of waterborne amino resin, 1.5-5.5% of a cosolvent A, 0.2-0.9% of a dispersant, 0.1-0.35% of a leveling agent, 0.05-0.2% of a defoamer, 0.02-0.1% of a pH regulator, 6-29% of pigment, 20-40% of a filler, 3.5-15% of a waterborne anti-sagging polymer containing a polyurea group and 5.83-10.45% of deionized water. The composition has excellent sagging resistance, adhesive force, waterproofness and resistance to stone crash.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Medium trace element containing cowhair keratin coated slow-released fertilizer and preparation method thereof

InactiveCN106007921AHigh strengthReduce solubilityCalcareous fertilisersBio-organic fraction processingCalcium bicarbonateBran

The invention discloses a medium trace element containing cowhair keratin coated slow-released fertilizer. The medium trace element containing cowhair keratin coated slow-released fertilizer is prepared from, by weight, 20-21 parts of cowhair, 40-45 parts of peanut bran, 50-52 parts of sugar residues, 35-37 parts of corn residues, 45-50 parts of peel, 18-19 parts of spirulina powder, 20-22 parts of kieselguhr, 20-22 parts of clay, 1-1.2 parts of itaconic acid, 1.5-2 parts of calcium bicarbonate, 1.2-1.3 parts of magnesium sulfate, 1-1.1 parts of manganese sulfate, 0.8-0.9 part of ammonium molybdate, 0.2-0.3 part of fatty acid methyl ester ethoxylate, 0.2-0.3 part of sodium carbonate, 20-21 parts of mercaptoethanol, 18-19 parts of urea, 3-4 parts of lauryl sodium sulfate, 0.2-0.3 part of transglutaminase, 3-4 parts of starch, 18-20 parts of 10% polyvinyl alcohol solution, 7-8 parts of 5% carboxymethylcellulose solution, 4-5 parts of formaldehyde, 5-6 parts of glycerin, 0.2-0.3 part of boron and 2-2.5 parts of microorganism bacterial powder. The medium trace element containing cowhair keratin coated slow-released fertilizer contains rich medium trace elements and is high in fertilizer efficiency, the fertilize absorption level of crops can be improved, the yield can be increased, and the quality can be improved.

Owner:ANHUI YONGGUAN AGRI TECH CO LTD

Organic-inorganic hybrid material, gas barrier film and method for producing the same

InactiveUS20090163670A1Contributing to adhesivenessContributing to durabilityCoatingsSurface layerHybrid material

The invention provides an organic-inorganic hybrid material including: a support, and a graft polymer layer containing a graft polymer chain directly bonding to a surface of the support or a surface layer provided on the support, the graft polymer layer containing an inorganic component including a crosslinked structure formed through hydrolysis and polycondensation of an alkoxide of an element selected from Si, Ti, Zr and Al. The organic-inorganic hybrid material is useful as a gas barrier film.

Owner:FUJIFILM CORP

Bactericidal ox hair keratin-coated slow-release fertilizer and preparation method thereof

InactiveCN105924297AHigh strengthReduce solubilityBioloigcal waste fertilisersNitrogenous fertilisersFertilizerChemistry

The invention discloses a bactericidal ox hair keratin-coated slow-release fertilizer. The bactericidal ox hair keratin-coated slow-release fertilizer is prepared from, by weight, 20-21 parts of ox hair, 80-83 parts of sugarcane peel, 80-85 parts of fallen leaves, 55-60 parts of soybean meal, 7-8 parts of malt sugar, 35-40 parts of bentonite, 20-22 parts of turfy soil, 10-11 parts of calcium powder, 24-25 parts of mineral powder, 1-1.2 parts of tea polyphenol, 30-32 parts of mosquito-repellent incense ash, 0.2-0.3 part of fatty acid methyl ester ethoxylate, 0.2-0.3 part of sodium carbonate, 20-21 parts of mercaptoethanol, 18-19 parts of urea, 3-4 parts of lauryl sodium sulfate, 0.2-0.3 part of glutamine transaminase, 3-4 parts of starch, 18-20 parts of a 10% polyvinyl alcohol solution, 7-8 parts of a 5% carboxymethylcellulose solution, 4-5 parts of formaldehyde, 5-6 parts of glycerin, 0.2-0.3 part of borax and 2-2.5 parts of microbial powder. The fertilizer achieves the bactericidal effect by adding tea polyphenol and the mosquito-repellent incense ash.

Owner:ANHUI YONGGUAN AGRI TECH CO LTD

Method for processing longsnout catfish tailing protein sausage

The invention discloses a method for processing a longsnout catfish tailing protein sausage. The method comprises the following steps that the tailings obtained by slicing longsnout catfishes are subjected to bone removal, rinsing and filtration to remove fish skin and broken bones so as to obtain minced fish meat, the fish proteins of the minced fish meat are recovered by an isoelectric retrogradation recombinant technology, and the recovered fish proteins are processed into the fish protein sausage by a gel color and tissue improving technology. The recovered fish protein has high content of gel protein, low fat content, high ash content, high nutritive value, high breaking strength of gel, indentation and strength of gel and perfect processing property; and moreover, the method is positively meaningful for promoting the application research on the isoelectric retrogradation recombinant technology of protein, realizing the diversified application of tailings of iced fish products, improving the quality of fish protein gel products and guiding processers and exporters of iced longsnout catfish fillets to walk on a road of sound development.

Owner:JIANGSU FOOD SCI COLLEGE

Preparation method of gelatin filled silk protein gelatin gel fiber membrane

InactiveCN108560244AImprove thermal stabilityImprove gel performancePhysical treatmentPotassium persulfateFiber

The invention provides a preparation method of a gelatin filled silk protein gelatin gel fiber membrane. The preparation method comprises the following steps: under a nitrogen gas environment, takingacrylamide as a monomer and water as a solvent, and taking potassium persulfate and sodium sulfite as an oxidization reduction initiator; dividing the oxidization reduction initiator into three equalparts; adding the first part of the initiator into a water solution of the acrylamide; firstly, carrying out low-temperature polymerization reaction; adding the second part of the initiator and continually reacting; adding rabbit skin gelatin particle sponge and the third part of the initiator; reacting again; dropwise adding hydroquinone to obtain a polyacrylamide modified gelatin solution; dissolving a silk protein nano-fiber membrane into a formic acid solution; adding the rabbit skin gelatin particle sponge and uniformly mixing to obtain a spinning solution; carrying out electrostatic spinning to obtain the silk protein gelatin gel nanofiber membrane; immersing the silk protein gelatin gel nanofiber membrane into the polyacrylamide modified gelatin solution; dropwise adding glutaraldehyde and carrying out microwave oscillation treatment; taking out the fiber membrane and drying to obtain the gelatin filled silk protein gelatin gel fiber membrane.

Owner:武汉智达纺织科技有限公司

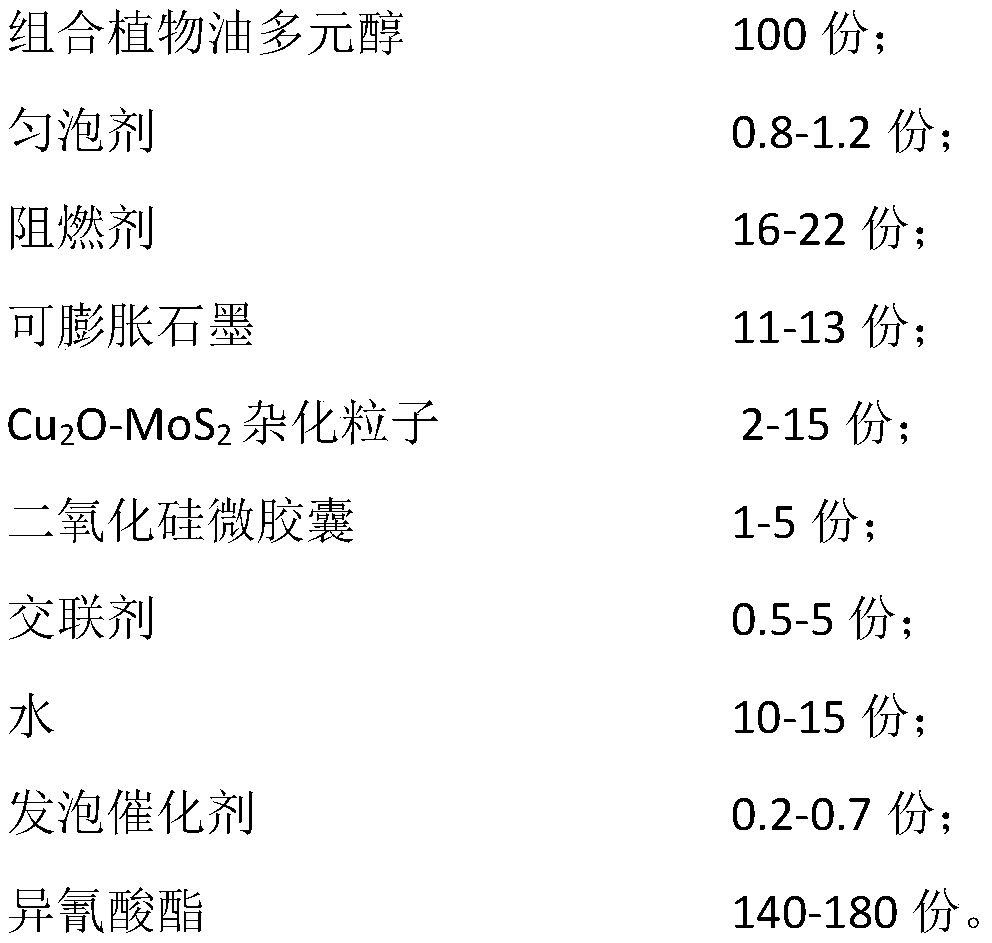

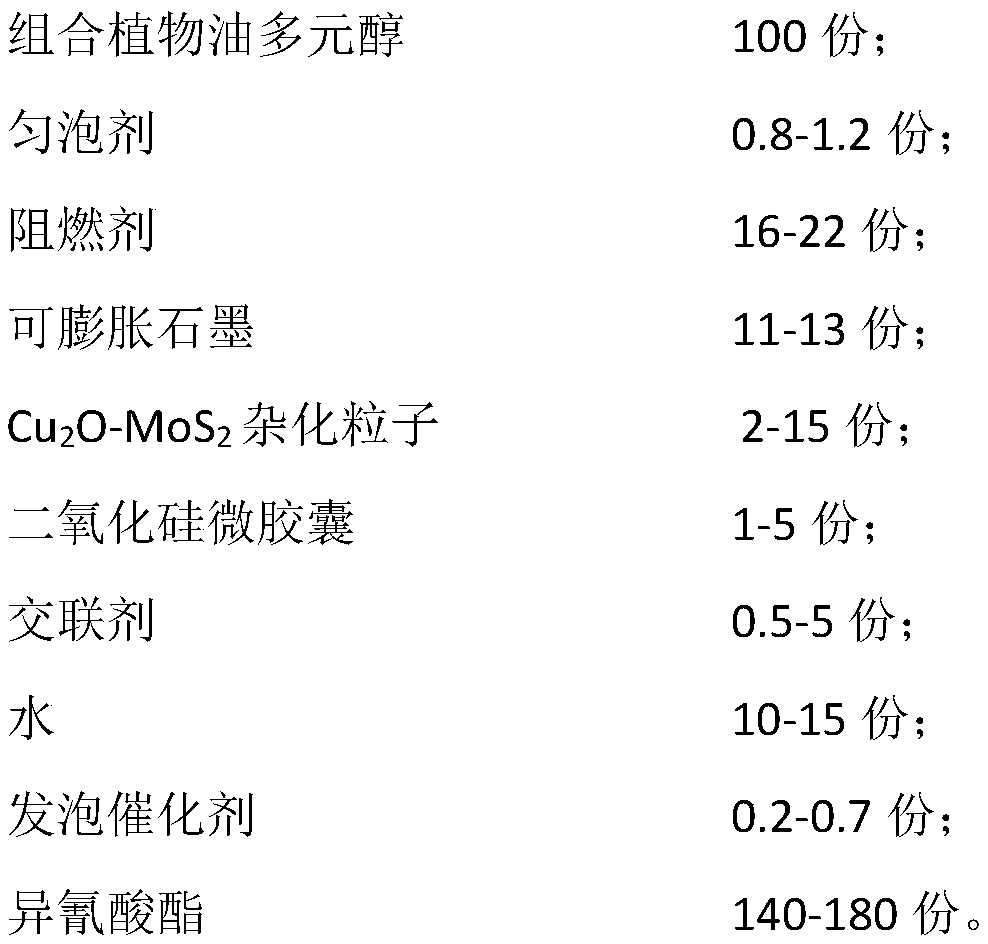

Sound-absorbing flame-retardant vegetable oil-based polyurethane foam material and preparation method thereof

ActiveCN111040104AImprove smoke and poison suppression propertiesGood sound-absorbing and flame-retardant propertiesPolymer scienceVegetable oil

The invention discloses a sound-absorbing and flame-retardant vegetable oil-based polyurethane foaming material and a preparation method thereof, wherein the foaming material is prepared from the following raw materials in parts by weight: combined vegetable oil polyol, a foam stabilizer, a flame retardant, expandable graphite, Cu2O-MoS2 hybrid particles, silicon dioxide microcapsules, a cross-linking agent, water, a foaming catalyst, isocyanate and the like. The sound-absorbing and flame-retardant vegetable oil-based polyurethane foaming material disclosed by the invention has good sound-absorbing and flame-retardant properties; due to the addition of Cu2O-MoS2 hybrid particles, the smoke inhibition and toxicity inhibition characteristics of the flame-retardant material are effectively improved; the silicon dioxide microcapsules are added, and the foam bare board is preheated, so that the appearance of a formed part is smooth and flawless; and after the foam bare board is preheated, the foam aperture ratio is increased, and the sound absorption performance of foam is improved.

Owner:浙江华江科技股份有限公司

Root-strengthening cattle hair keratin coated controlled-release fertilizer and preparation method thereof

InactiveCN106007924AHigh strengthReduce solubilitySuperphosphatesAnimal corpse fertilisersPolyvinyl alcoholSodium sulfate

The invention discloses a root-strengthening cattle hair keratin coated controlled-release fertilizer. The fertilizer is prepared from, by weight, 20-21 parts of cattle hair, 50-55 parts of cottonseed hulls, 40-45 parts of sugarcane leaves, 45-46 parts of pomace, 30-32 parts of shrimp shells, 30-32 parts of weathered coal, 25-30 parts of hawthorn seeds, 1-1.1 parts of paclobutrazol, 1-1.2 parts of calcium superphosphate, 1-1.2 parts of ammonium sulfate, 1.2-1.5 parts of polyacrylamide, 0.9-1 part of diethyl aminoethyl hexanoate, 40-45 parts of bentonite, 0.2-0.3 part of fatty acid methyl ester ethoxylate, 0.2-0.3 part of sodium carbonate, 20-21 parts of mercaptoethanol, 18-19 parts of urea, 3-4 parts of lauryl sodium sulfate, 0.2-0.3 part of transglutaminase, 3-4 parts of starch, 18-20 parts of a 10% polyvinyl alcohol solution, 7-8 parts of a 5% carboxymethylcellulose solution, 4-5 parts of formaldehyde, 5-6 parts of glycerine, 0.2-0.3 part of borax and 2-2.5 parts of microbial bacterium powder. The fertilizer can effectively improve the granular structure of soil, promote the growth of crop roots and strengthen the roots.

Owner:ANHUI YONGGUAN AGRI TECH CO LTD

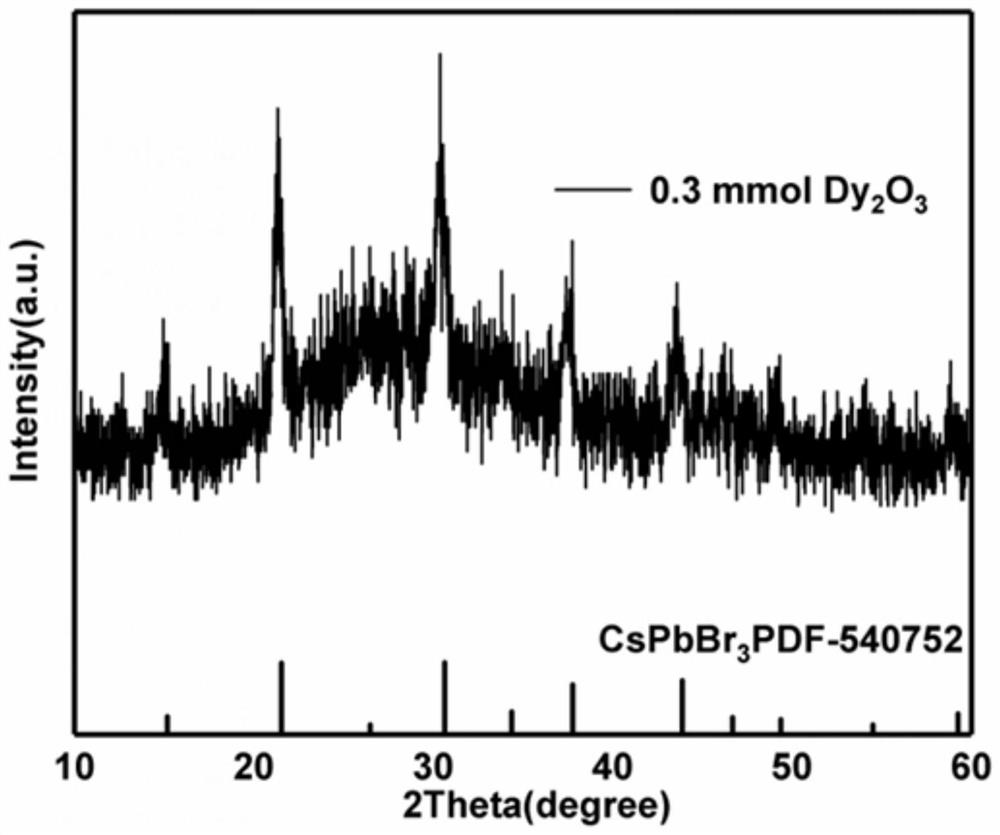

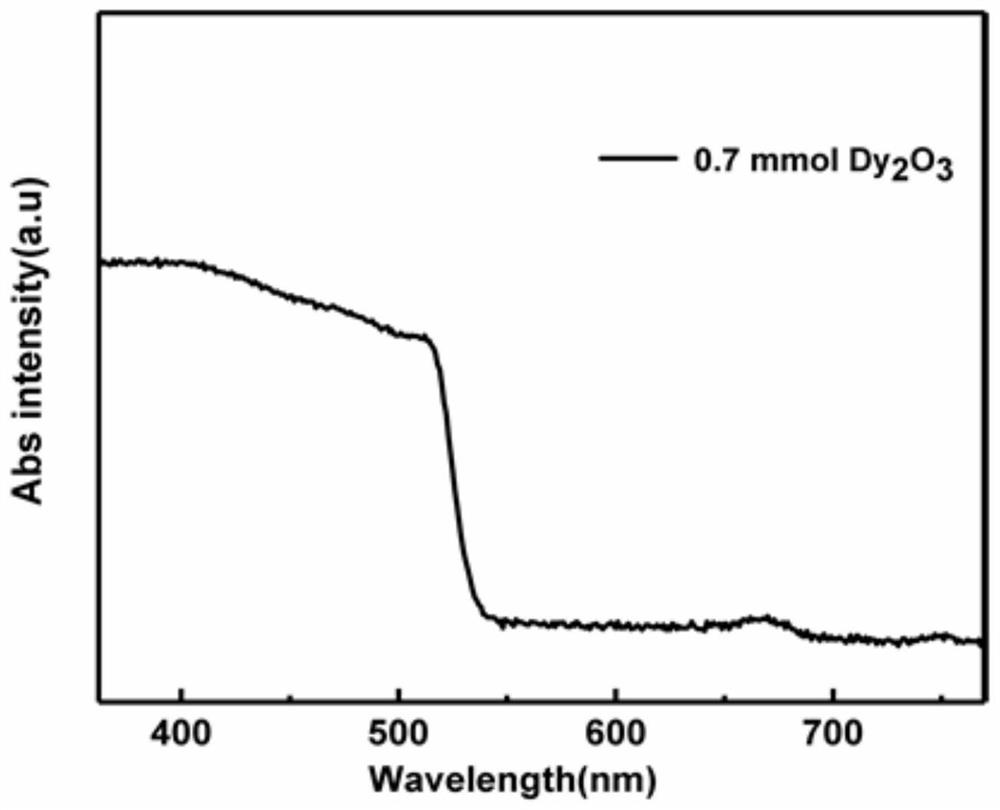

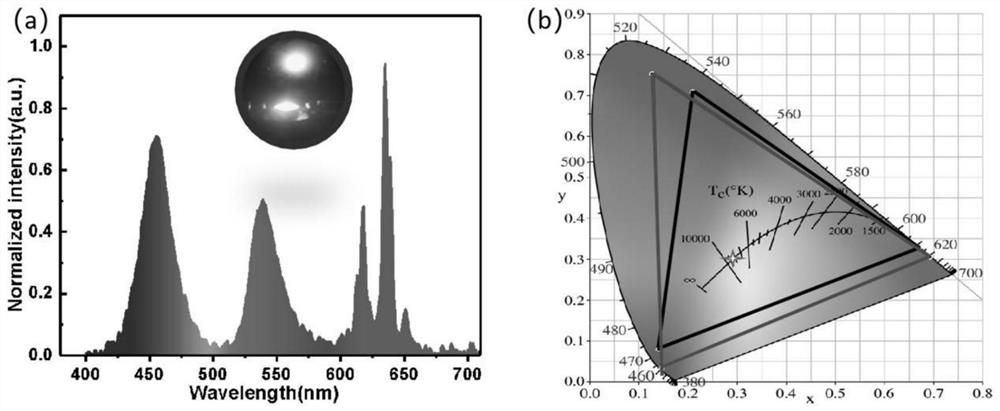

Formula, preparation method and application of CsPbBr3: xDy < 3 + > quantum dot glass

ActiveCN113831022AImprove luminous efficiencyHigh crystallinityGlass shaping apparatusEnergy efficient lightingPhysical chemistryQuantum dot

The invention discloses a formula, a preparation method and application of CsPbBr3: xDy < 3 + > quantum dot glass. A glass matrix and a doping material are matched according to the molar mass of 5-10 mol% of Na2CO3, 20-30 mol% of ZnO, 80-100 mol% of H3BO3, 15-30 mol% of SiO2, 10-30 mol% of BaCO3 and x Dy2O3 (x=0 mol%, 0.1 mol%, 0.3 mol%, 0.5 mol%, 0.7 mol% and 0.9 mol%); the preparation method comprises the following steps: proportioning quantum dot raw materials according to the molar mass of 1.5-3% of Cs2CO3, 3-6% of PbO, 9-18% of NaBr (mol%), fully grinding the weighed raw materials, drying the ground raw materials, carrying out high-temperature sintering to obtain precursor glass, and carrying out internal stress elimination and heat treatment on the precursor glass to finally obtain the CsPbBr3: xDy < 3 + > quantum dot glass, and using the CsPbBr3: xDy < 3 + > quantum dot glass for preparing a white light LED device. Dy2O3 is used for doping for the first time, the CsPbBr3: xDy < 3 + > quantum dot glass is prepared, the white light LED device is prepared, the luminous efficiency of the CsPbBr3: xDy < 3 + > quantum dot glass can be effectively improved, use of a lead source is reduced, and the CsPbBr3: xDy < 3 + > quantum dot glass is a luminescent material which is high in stability, high in crystallinity and environmentally friendly.

Owner:SHANGHAI INST OF TECH

Preparation method of soybean protein based wood adhesive

InactiveCN108048004AHigh bonding strengthHigh strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveMoisture resistance

The invention discloses a preparation method of a soybean protein based wood adhesive. The method includes: firstly adding sodium periodate, sodium bisulfite oxidation-sulfonation modified microcrystalline cellulose into a soybean protein-polyvinyl alcohol solution for grafting modification to obtain a sulfonated microcrystalline cellulose-soybean protein-polyvinyl alcohol compound solution, thenadding styrene and carrying out solution polymerization reaction to obtain an adhesive stock solution, and subjecting the adhesive stock solution and borax to mixing and crosslinking to obtain a soybean protein based wood adhesive. The wood adhesive prepared by the method provided by the invention has a dense network structure, high bonding strength, good moisture resistance and waterproofness, and stable performance, also in low in cost, green and environment-friendly, and has good environmental and economic benefits.

Owner:ANHUI BEIMA TECH CO LTD

Ox hair keratin coated slow-release fertilizer capable of improving saline and alkaline land and preparation method of slow-release fertilizer

InactiveCN105948998AHigh strengthImprove solubilityCalcareous fertilisersBio-organic fraction processingPolyvinyl alcoholPhosphogypsum

The invention discloses ox hair keratin coated slow-release fertilizer capable of improving saline and alkaline land. The ox hair keratin coated slow-release fertilizer is prepared from raw materials in parts by weight as follows: 20-21 parts of ox hair, 20-22 parts of Chinese honeylocust fruits, 75-80 parts of reed, 30-34 parts of potatoes, 40-42 parts of waste paper, 50-55 parts of tea seed meal, 15-17 parts of wheat middling, 30-35 parts of bentonite, 1-1.5 parts of ammonium nitrate, 2-3 parts of ardealite, 1-1.5 parts of sodium acid pyrophosphate, 0.2-0.3 parts of fatty acid methyl ester ethoxylate, 0.2-0.3 parts of sodium carbonate, 20-21 parts of mercaptoethanol, 18-19 parts of urea, 3-4 parts of lauryl sodium sulfate, 0.2-0.3 parts of transglutaminase, 3-4 parts of starch, 18-20 parts of a 10% polyvinyl alcohol solution, 7-8 parts of a 5% carboxymethylcellulose solution, 4-5 parts of formaldehyde, 5-6 parts of glycerin, 0.2-0.3 parts of borax and 2-2.5 parts of microbial powder. The slow-release fertilizer can improve the soil, and added phosphogypsum can improve the saline and alkaline land.

Owner:ANHUI YONGGUAN AGRI TECH CO LTD

Soilless spray-seeding substrate for mine greening and preparation method of soilless spray-seeding substrate

ActiveCN114467680AImprove adhesionImprove water absorptionGrowth substratesCulture mediaBiologySeaweed food

The invention discloses a soilless spray seeding substrate for mine greening and a preparation method thereof, and belongs to the technical field of plant cultivation. The soilless spray-seeding substrate for mine greening comprises a spray-seeding base material, an adhesive solution and a water-retaining agent solution. The spray-seeding basic material is prepared from 40 to 120 parts of vermiculite powder, 60 to 160 parts of perlite, 100 to 200 parts of northeast black charcoal soil and 600 to 1000 parts of plant fibers; the adhesive solution is prepared from 5 to 50 parts of urea, 1000 to 10000 parts of water, 100 to 400 parts of cottonseed meal and 5 to 50 parts of citric acid; the water-retaining agent solution is prepared from 30 to 200 parts of sodium alginate, 1500 to 10000 parts of water and 10 to 50 parts of multivalent metal ions. The plant culture medium disclosed by the invention has the advantages of good adhesive force, rain wash resistance, good water retention capacity and transpiration resistance, soft base material, difficulty in hardening and good air permeability.

Owner:湖南纳森生态建设有限公司

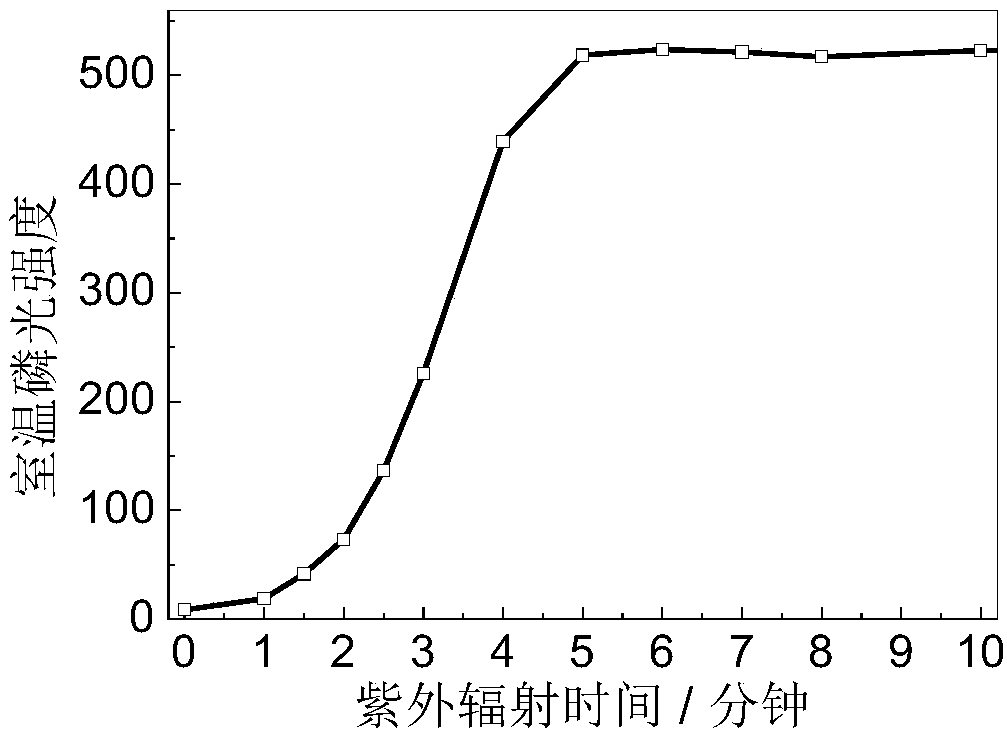

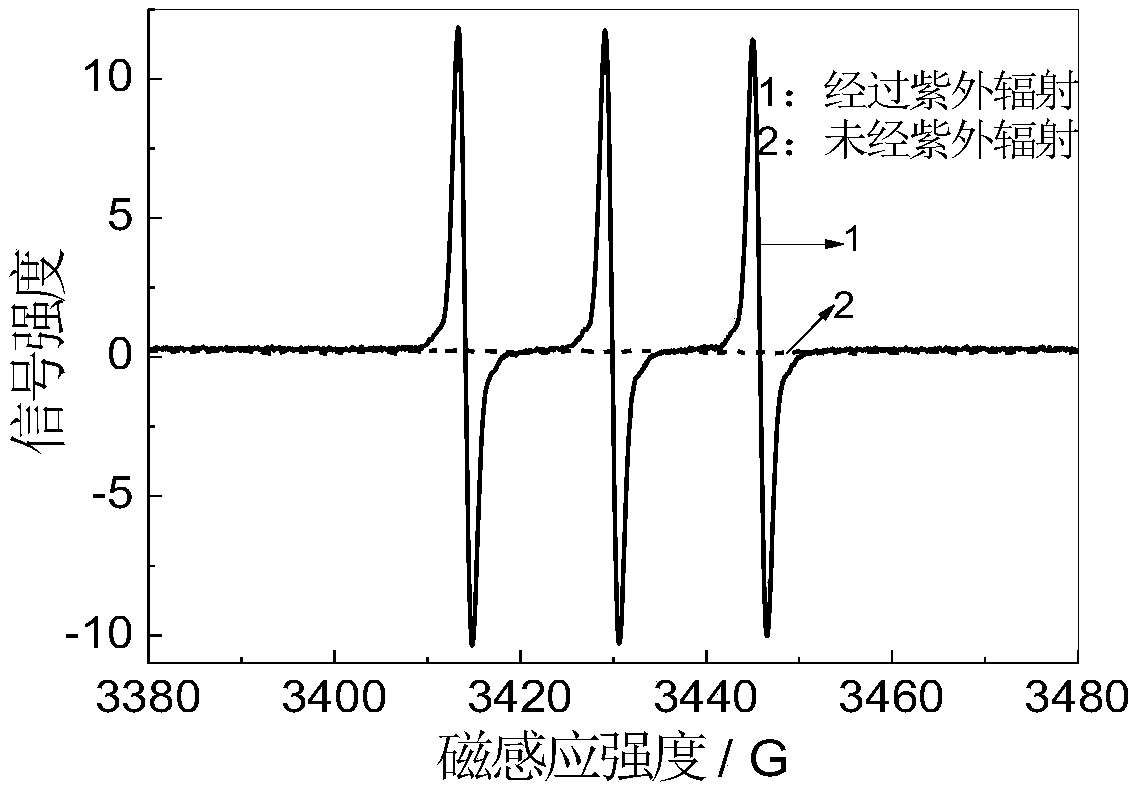

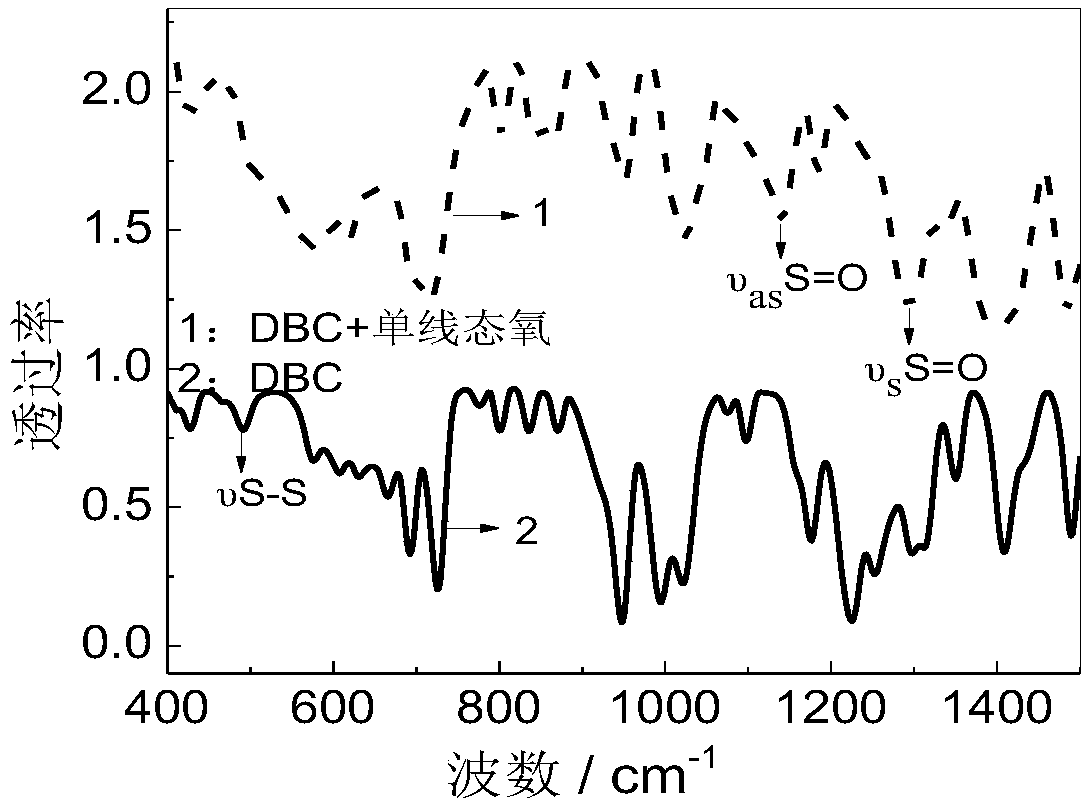

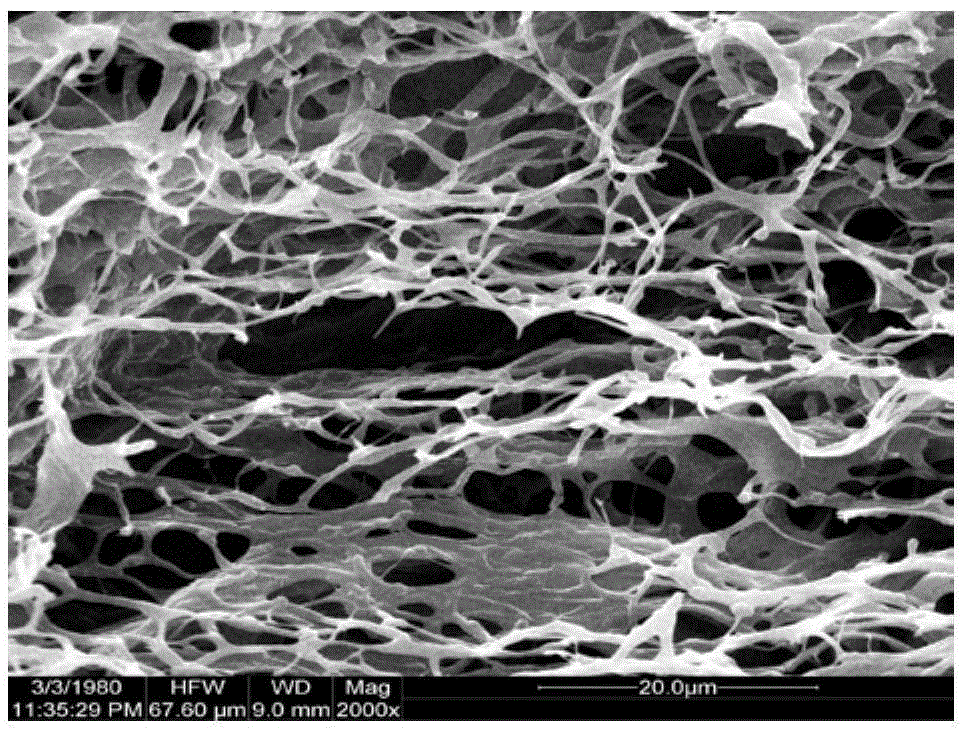

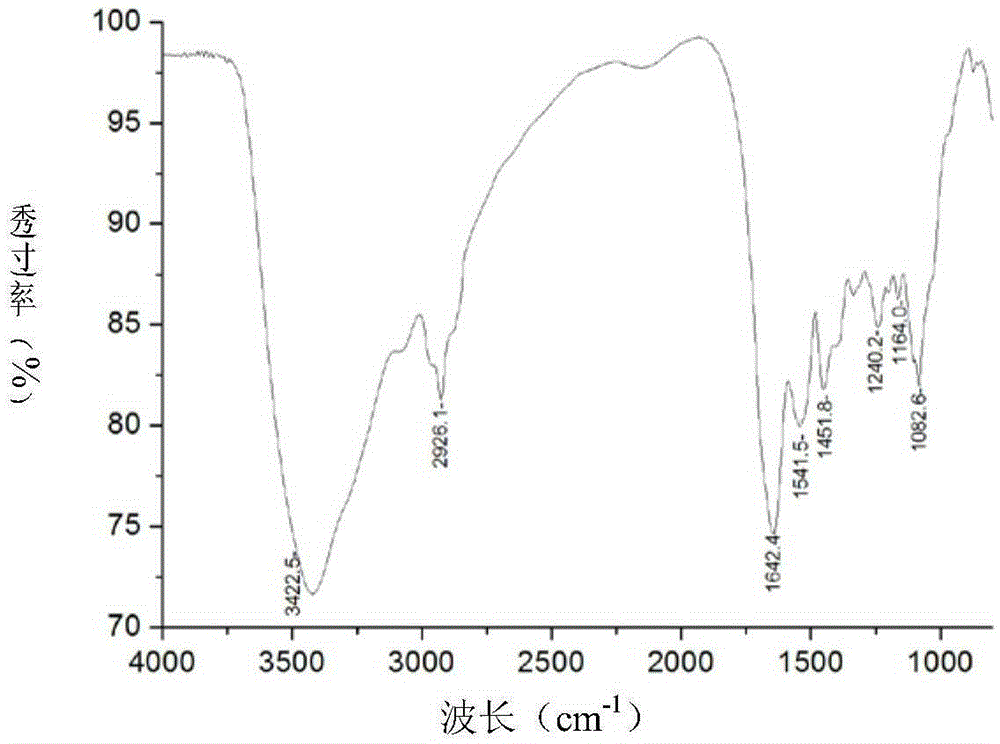

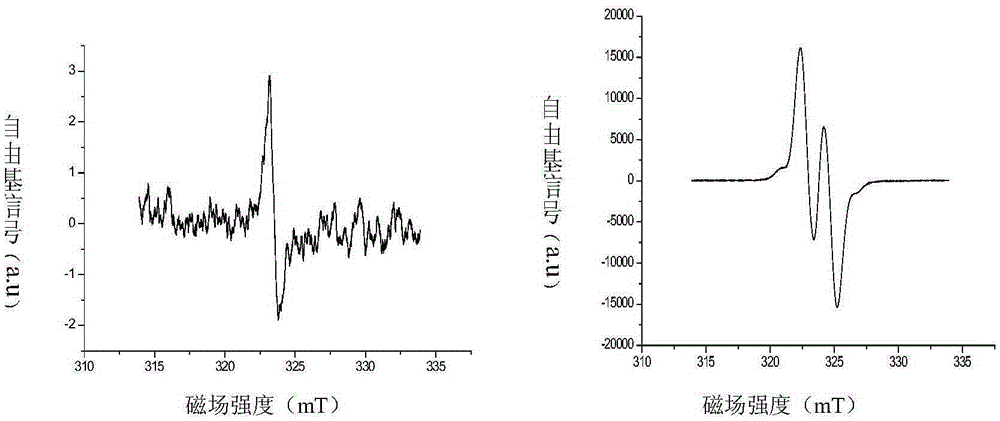

Method for improving luminescence intensity of room temperature phosphorescent material

ActiveCN108912128AHigh luminous intensityDense network structureOrganic chemistryGel preparationDBcCysteine thiolate

The invention belongs to the field of luminescent materials, particularly relates to a method for improving the luminescence intensity of a room temperature phosphorescent material and provides a highluminescence intensity supramolecular room temperature phosphorescent material and a preparation method thereof. Through direct or indirect oxidation treatment on a hybrid supramolecular gel phosphorescent material formed from tetracarbonyl phenyl metal porphyrin (M-TCPP), a cationic surfactant and N, N'-dibenzoyl-L-cysteine (DBC) so that the disulfide bond of the gel factor in the phosphorescentmaterial is oxidized into a sulfonic acid group and the room temperature phosphorescent material with high luminescence intensity is obtained. Compared with the material without direct or indirect oxidation, the room temperature phosphorescent material improves luminescence intensity by close to 100 times and keeps the stability of the luminescence intensity at pH of 2-12.

Owner:HUAZHONG UNIV OF SCI & TECH

A kind of preparation method of radiation crosslinking modified gelatin film

The invention belongs to the technical field of foods and medicines and provides a preparation method of an irradiation-crosslinked modified gelatin film. The preparation method is characterized by comprising the following steps: (1) selecting raw materials according to the condition that a mass ratio of gelatin to water to glycerol is 1:8:(0.2-1); (2) mixing to obtain a gelatin-glycerol water solution; (3) selecting the raw materials according to the condition that a mass ratio of sodium stearate to water is 1:9, and mixing to obtain a transparent pasty material; (4) uniformly coating the transparent pasty material obtained in the step (3) on the bottom inside a plastic tray, and air-drying to obtain an anti-adhesion layer for later use; (5) pouring the gelatin-glycerol water solution prepared in the step (2) into the tray coated with the anti-adhesion layer; (6) drying to obtain a solidified gelatin film; (7) irradiating the gelatin film solidified in the step (6) at room temperature by an irradiation source at an irradiation dose of 4-8 kGy; (8) drying the gelatin film irradiated in the step (7) and uncovering the film to obtain the irradiation-crosslinked modified gelatin film. The gelatin film prepared by the method has good mechanical properties and can be used as a film material for foods and medicines.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI

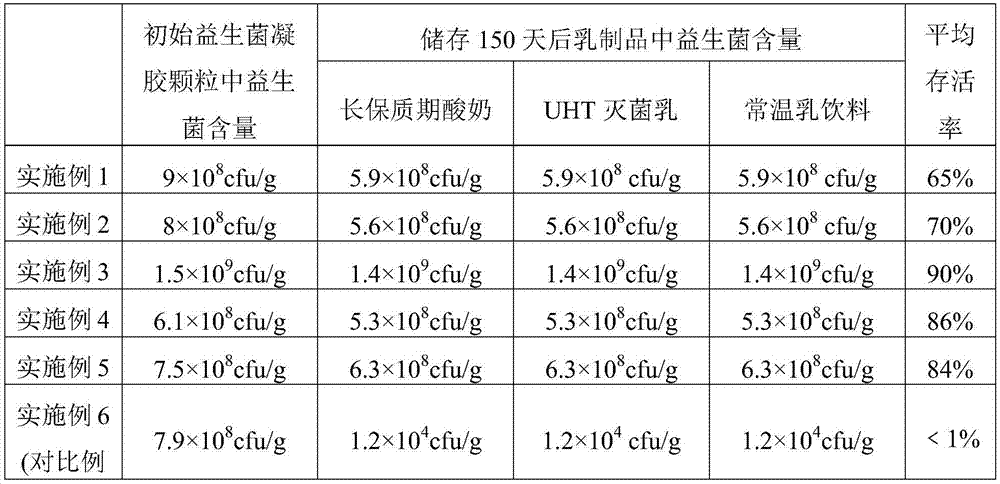

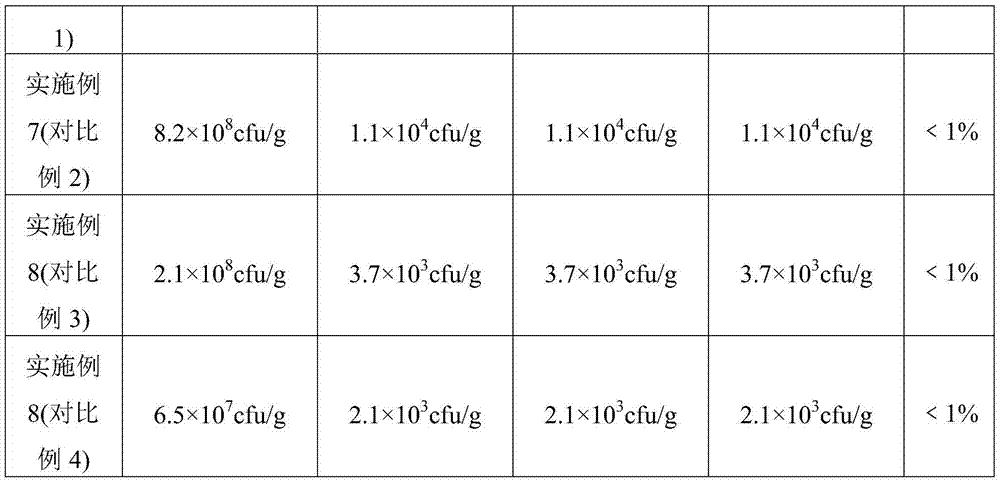

Probiotic gel particles and preparation method thereof

InactiveCN106900848AGood embedding effectDense network structureMilk preparationCarrageenanEdible oil

The invention discloses probiotic gel particles and a preparation method thereof. The probiotic gel particles are prepared from the raw materials: 0.5 to 2.5 wt% of Carrageenan, 0.1 to 2 wt% of amorphophallus konjac, 2.1 to 7 wt% of edible oil and fat, 0.5-5 wt% of liquid strain culture medium, and 0.2 to 0.8 wt% of probiotic. The viable bacteria of the probiotic is high in survival rate, and the mouth feel of the probiotic gel particles provided by the invention is more smooth and clean.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com