Method for improving luminescence intensity of room temperature phosphorescent material

A phosphorescent material and luminous intensity technology, applied in luminescent materials, chemical instruments and methods, organic chemistry, etc., can solve the problems of little room for luminous intensity improvement, difficult room temperature phosphorescence regulation, low luminous intensity, etc., and achieve good application prospects, High room temperature phosphorescence intensity and the effect of improving phosphorescence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a method for preparing a supramolecular room temperature phosphorescent material with high luminous intensity, comprising the following steps:

[0050] (1) heating the mixed solution of the organic solution of tetracarbonylphenyl metalloporphyrin (M-TCPP) and the aqueous solution of the cationic surfactant to 55°C-95°C, and keeping it warm for 1-10 minutes to obtain the first mixed solution;

[0051] Wherein, the chemical structural formula of M-TCPP is as follows:

[0052]

[0053] Wherein M is preferably one of Pd, Pt or Ir.

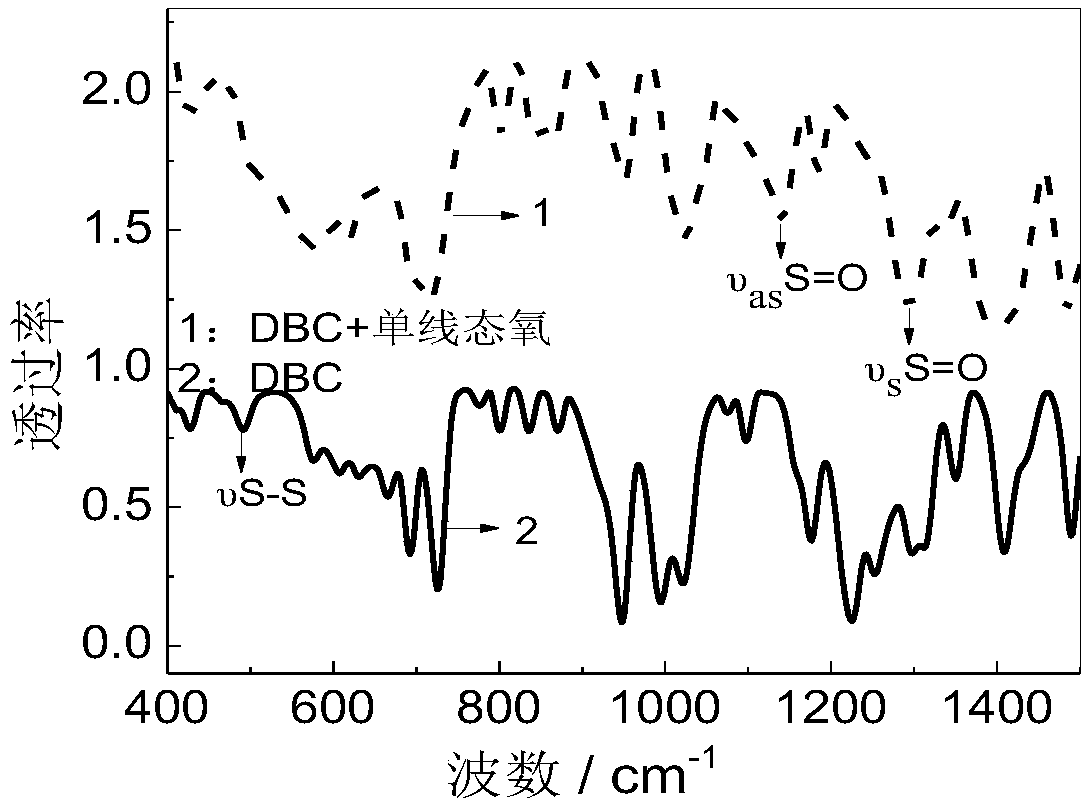

[0054] (2) Mix the first mixed solution with an organic solution of N,N'-dibenzoyl-L-cysteine (DBC) to obtain a second mixed solution, and cool the second mixed solution to At room temperature, a hybrid supramolecular material is obtained; wherein the concentration of tetracarbonylphenyl metalloporphyrin in the second mixed solution is 5×10 -7 ~5×10 -5 mol / L, the concentration of cationic surfactant is...

Embodiment 1

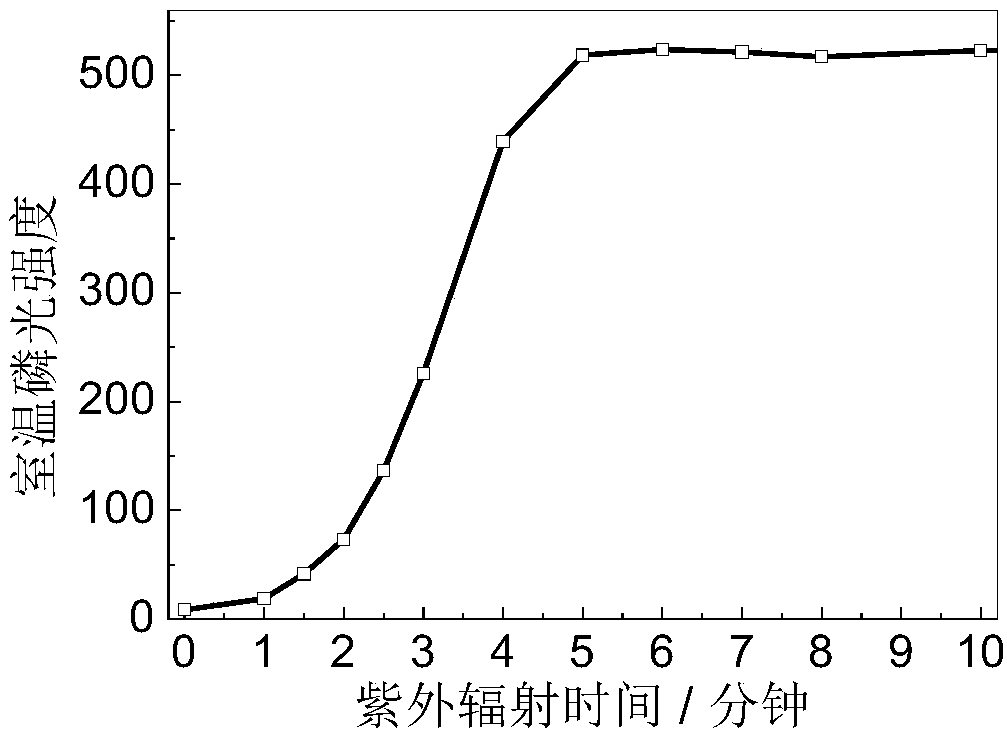

[0063] This example provides a supramolecular room-temperature phosphorescent material with high luminous intensity, and its preparation method is as follows: Take a clean test tube and add 50 μL of 1.0×10 -4 mol / L Pd-TCPP solution in DMSO, 800 μL distilled water, 100 μL 5.0×10 -3 mol / L cationic quaternary ammonium salt type gemini surfactant G 12-12-12 The aqueous solution was shaken on a circular shaker for 1 minute, heated in a water bath to 90 ° C, and kept for 1 minute, and 50 μL of 0.02 mol / LDBC DMSO solution was added, shaken on a circular shaker for 30 seconds, and then allowed to stand and cooled to room temperature to obtain complex The supramolecular room-temperature phosphorescent material with high luminous intensity of the present invention can be obtained after irradiating with an ultraviolet lamp for 5 minutes.

Embodiment 2

[0065] This example provides a supramolecular room-temperature phosphorescent material with high luminous intensity, and its preparation method is as follows: Take a clean test tube and add 50 μL of 1.0×10 -4 mol / LPt-TCPP solution in DMSO, 800 μL distilled water, 100 μL 5.0×10 -3 mol / L cationic quaternary ammonium salt type gemini surfactant G 12-12-12 Shake the aqueous solution on a circular shaker for 1 minute, heat the water bath to 90 ° C, keep warm for 1 minute, add 50 μ L of 0.02 mol / LDBC DMSO solution, shake it on a circular shaker for 30 seconds, and then let it stand and cool to room temperature to obtain the complex The supramolecular room-temperature phosphorescent material with high luminous intensity of the present invention can be obtained after irradiating with an ultraviolet lamp for 5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com