Production method of polyester polyol

A technology of polyester polyol and production method, which is applied in the field of polyester polyol production, can solve problems such as lack of long-term stability of polyether polyol, and achieve the effects of low cost, improved functionality, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

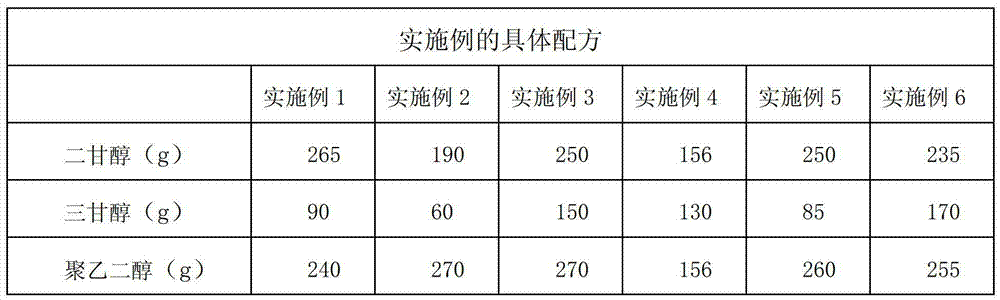

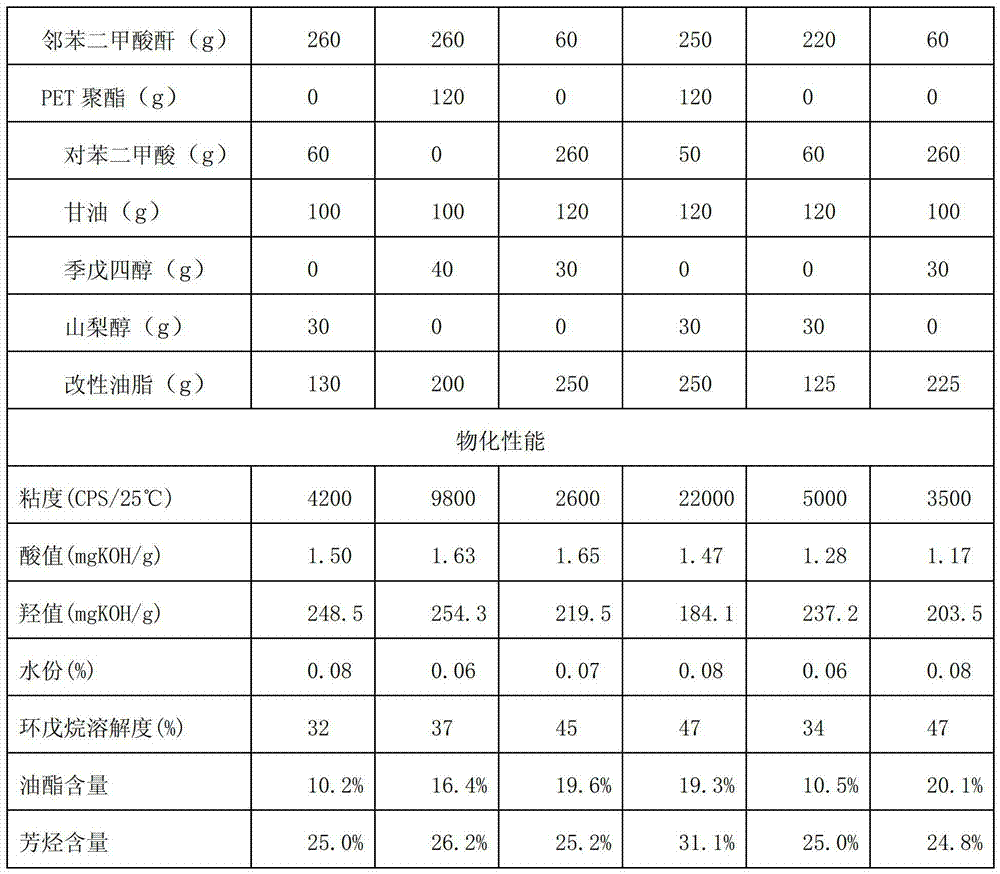

Examples

Embodiment 7

[0034]Embodiment 7: basically the same as Example 1, the difference is: the natural oil is coconut oil, cottonseed oil, linseed oil, olive oil, palm oil, palm kernel oil, peanut oil, sunflower oil, through leaching and purifying Any of the natural oils.

Embodiment 8

[0035] Example 8: It is basically the same as Example 1, except that the esterification catalyst includes any of isopropyl titanate, butyl titanate, monobutyltin oxide (MBTO), calcium oxide, and zinc oxide. A sort of.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com