Method for continuously adding catalyst for C5 petroleum resin production and special device

A technology of petroleum resin and catalyst, which is applied in the field of continuous addition of catalyst and special equipment for the production of C5 petroleum resin. It can solve the problems of difficult processing and use, small production scale of equipment, and deep resin color, so as to reduce product production cost and reduce equipment corrosion. , the effect of environmental protection work guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

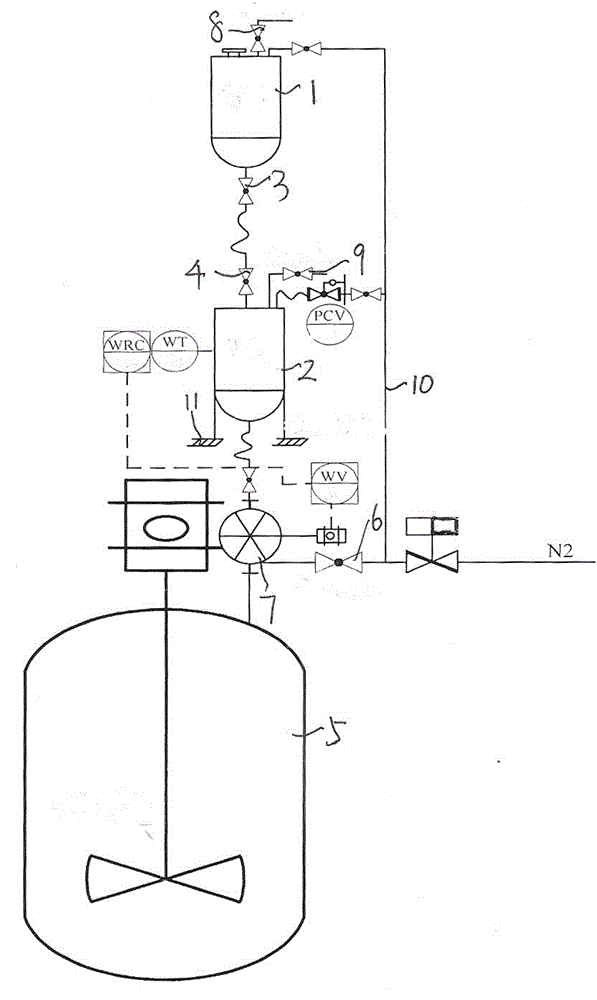

[0012] A special device for the catalyst continuous addition method produced by C5 petroleum resin, comprising a first tank 1, the first tank is connected to the second tank 2 through a pipeline, and a control valve is set on the pipeline between the first tank and the second tank 3, 4, the second tank is connected to the reactor 5 through a pipeline, and a rotary valve 7 controlled by a frequency conversion motor 6 is arranged on the pipeline between the second tank and the reactor, and the first tank and the second tank are respectively provided with a vent valve. The valves 8, 9, the first tank and the second tank are all connected to the nitrogen delivery pipeline 10, and the second tank is provided with an automatic weighing system 11.

[0013] A catalyst continuous adding method for C5 petroleum resin production, comprising the following steps: catalyst is added from a packaging barrel into a first tank, the first tank is connected with the second tank through a pipeline,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com