Ceramic material for photocuring 3D printing and ceramic member, and preparation methods thereof

A ceramic material, 3D printing technology, applied in the direction of additive processing, can solve the problems of poor stability, large deformation, time-consuming and labor-intensive processing, etc., and achieve the effect of ensuring printing requirements, high relative density, and high flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

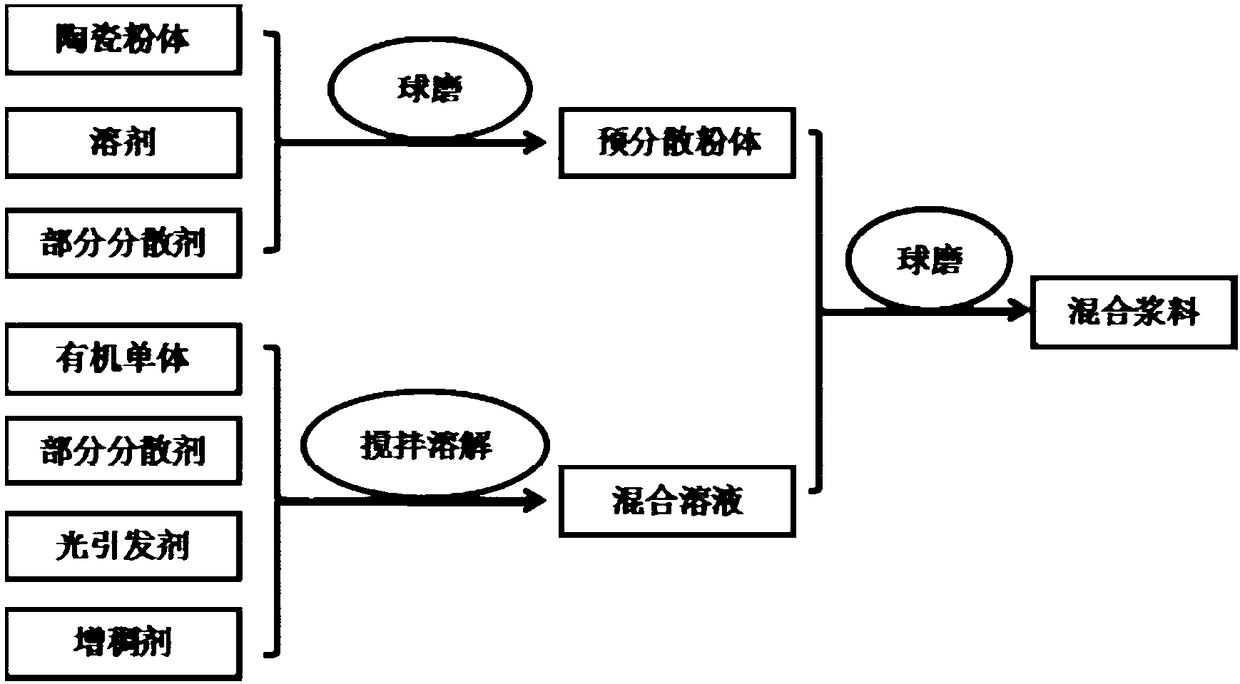

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in combination with specific embodiments and with reference to the accompanying drawings.

[0016] The concept of the present invention is: in the whole process flow of photo-curing 3D printing, the properties of materials used are very important, which determines the selection of printing process, parameter setting and the physical and chemical properties of the final ceramic parts. As far as the current situation is concerned, there are mainly two problems in the preparation of materials: first, the properties of the materials used must be uniform and stable. That is, while the ceramic powder is evenly distributed in the slurry, it must not settle and stratify for a long period of time. Second, the viscosity should be appropriate. Because the SLA printing process is used, the viscosity of the material has a great influence on the printing of the object. Therefore, the preparation process of materials is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com