Surface coating type reinforced concrete corrosion inhibitor and preparation method thereof

A technology of reinforced concrete and rust inhibitor, which is applied in the field of reinforced concrete rust inhibitor and surface-coated reinforced concrete rust inhibitor, can solve problems such as application difficulties, achieve simple preparation process, prevent and inhibit steel corrosion, and inhibit corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

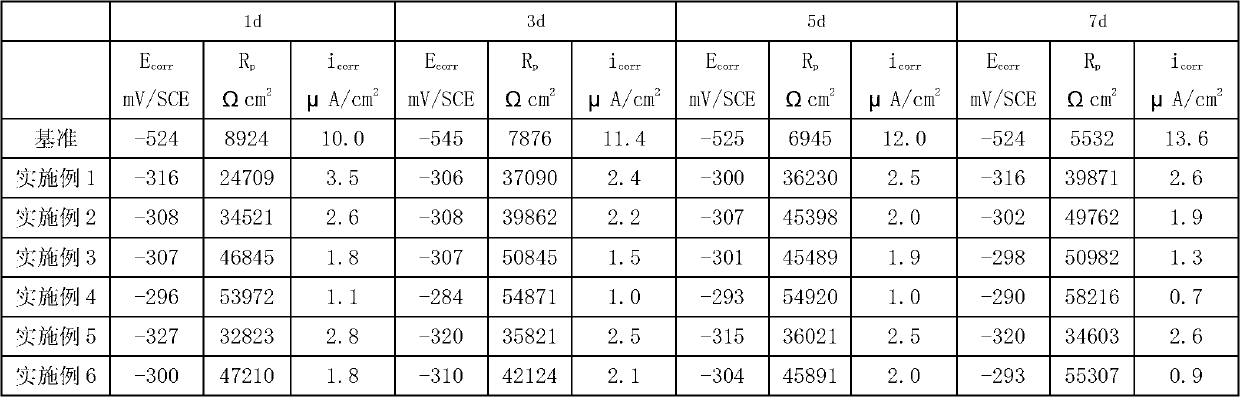

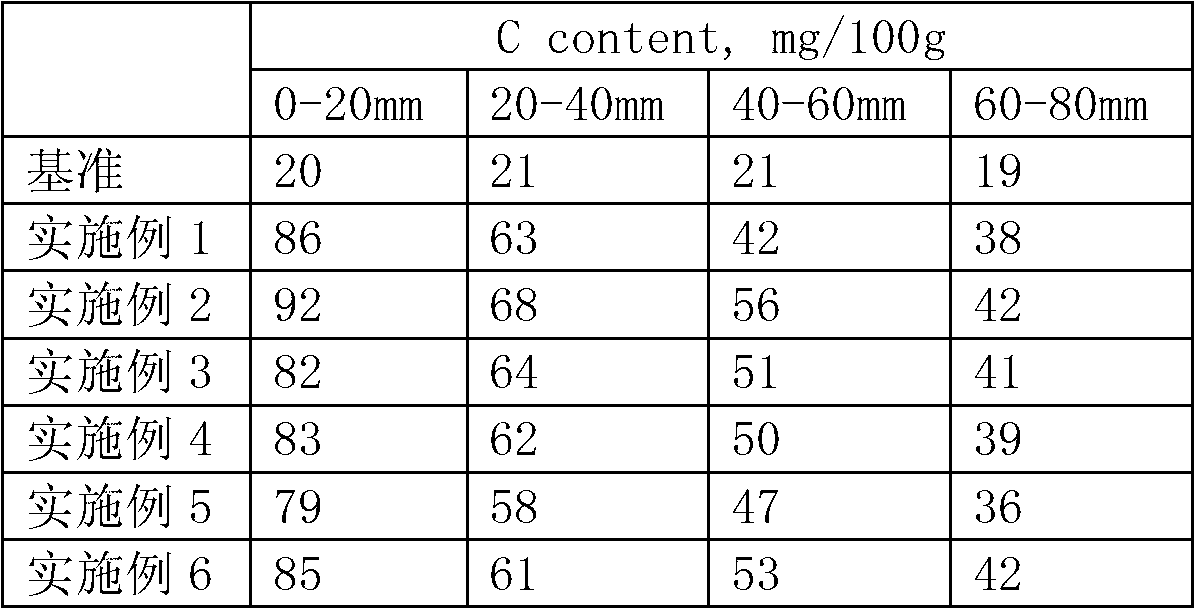

Examples

Embodiment 1

[0019] Weigh by weight: 15g polyoxyethylene (15) sorbitan monolaurate, 15g polyoxyethylene (30) sorbitan monooleate, 7g 1,3-bis-di-n-butylamino-2- Propanol, 16g n-pentanol, 12g n-dodecyl alcohol and 35g water, first mix polyoxyethylene (15) sorbitan monolaurate, polyoxyethylene (30) sorbitan monooleate, 1,3- Stir and mix di-n-butylamino-2-propanol, n-pentanol and n-dodecyl alcohol at a temperature of 45°C. After the mixture is completely melted, slowly add water dropwise and stir while adding until the mixed liquid changes from turbid to until clear.

Embodiment 2

[0021]Take by weight: 38g polyoxyethylene (20) sorbitan monostearate, 10g dodecylamine, 5g benzotriazole, 5g1-aminobenzotriazole and 42g water, first polyoxyethylene (20 ) sorbitan stearate, polyoxyethylene sorbitan monooleate, laurylamine, benzotriazole and 1-amino-benzotriazole were stirred and mixed at a temperature of 85°C, and the mixture was completely melted Finally, slowly add water dropwise, stirring while adding, until the mixed liquid changes from cloudy to clear.

Embodiment 3

[0023] Weigh by weight: 30g polyoxyethylene (30) sorbitan monooleate, 20g cinnamic acid, 16g dimethylethanolamine, 5g sodium sebacate and 29g water, first mix polyoxyethylene (30) sorbitan Stir and mix monooleate, cinnamic acid, dimethylethanolamine and sodium sebacate at 60°C. After the mixture is completely melted, slowly add water dropwise and stir while adding until the mixed liquid changes from turbid to until clear.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com