Textile printing and dyeing wastewater decolorizing flocculant and preparation method thereof

A decolorizing flocculant, textile printing and dyeing technology, applied in textile industry wastewater treatment, chemical instruments and methods, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as difficulty in meeting environmental protection requirements, high monomer toxicity, and poor stability. To achieve the effect of strong adaptability of raw water, large molecular weight and fast sedimentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of textile printing and dyeing wastewater decolorization flocculant, specifically as follows:

[0031] Add ferrous sulfate, potassium aluminum sulfate, magnesium sulfate, and calcium chloride to deionized water in turn, and stir to form a homogeneous solution. The molar mass ratio of ferrous sulfate, potassium aluminum sulfate, magnesium sulfate, and calcium chloride is 5:2: 1:1, use citric acid to adjust the pH of the system to 4-5, then add the above organic components, grafted modified chitosan, modified zeolite powder, polyacrylamide, stir at 700r / min for 1.5h, drop Hydrogen peroxide, so that the generated Fe 3+ with the remaining Fe 2+ The molar mass ratio is 1:1, and it can be sealed and cooked for 24 hours.

[0032] The organic components were prepared as follows:

[0033] Mix dicyandiamine, 25% formaldehyde aqueous solution and ammonium chloride in an ice bath under nitrogen protection. The molar mass ratio of dicyandiamine to melamine is...

Embodiment 2

[0039] A preparation method of textile printing and dyeing wastewater decolorization flocculant, specifically as follows:

[0040] Add ferrous sulfate, aluminum potassium sulfate, magnesium sulfate, and calcium chloride to deionized water in turn, and stir to form a homogeneous solution. The molar mass ratio of ferrous sulfate, aluminum potassium sulfate, magnesium sulfate, and calcium chloride is 6:1: 1:1, use citric acid to adjust the pH of the system to 4-5, then add the above organic components, grafted modified chitosan, modified zeolite powder, polyacrylamide, stir at 600r / min for 2h, drop over Oxidation of hydrogen, resulting in Fe 3+ with the remaining Fe 2+ The molar mass ratio is 1:1, and it can be sealed and cooked for 20 hours.

[0041] The organic components were prepared as follows:

[0042] Mix dicyandiamine, 20% formaldehyde aqueous solution and ammonium chloride in an ice bath under nitrogen protection. The molar mass ratio of dicyandiamine to melamine is 6...

Embodiment 3

[0048] A preparation method of textile printing and dyeing wastewater decolorization flocculant, specifically as follows:

[0049] Add ferrous sulfate, aluminum potassium sulfate, magnesium sulfate, and calcium chloride to deionized water in turn, and stir to form a homogeneous solution. The molar mass ratio of ferrous sulfate, aluminum potassium sulfate, magnesium sulfate, and calcium chloride is 4:3: 1:1, use citric acid to adjust the pH of the system to 4-5, then add the above organic components, grafted modified chitosan, modified zeolite powder, polyacrylamide, stir at 800r / min for 1h, drop over Oxidation of hydrogen, resulting in Fe 3+ with the remaining Fe 2+ The molar mass ratio is 1:1, and it can be sealed and cooked for 25 hours.

[0050] The organic components were prepared as follows:

[0051] Mix dicyandiamine, 25% formaldehyde aqueous solution and ammonium chloride in an ice bath under nitrogen protection. The molar mass ratio of dicyandiamine to melamine is 6...

PUM

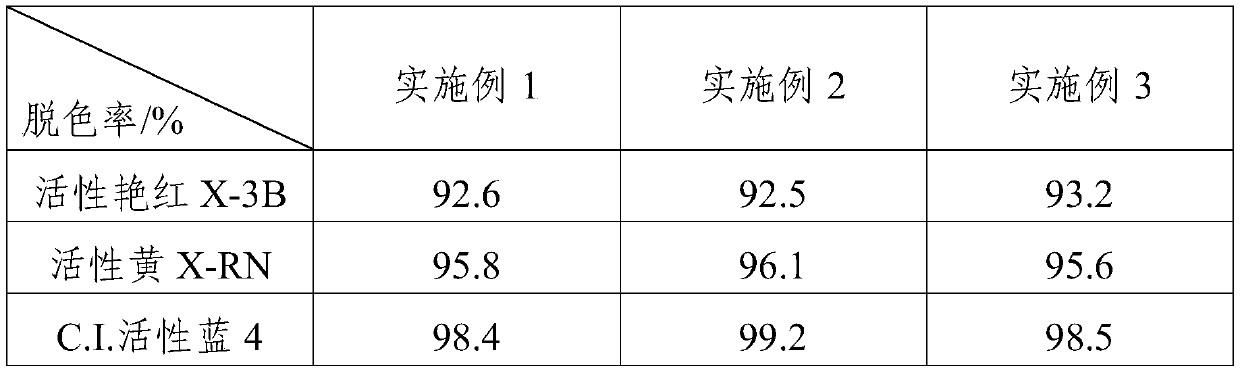

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com