High-strength mattress material and preparation method thereof

A high-strength, mattress technology, applied in the field of mattress materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of described high-strength mattress material, comprises the following steps:

[0033] S1: Stir and mix polyolefin, carbon fiber, chain extender, foaming agent, foam stabilizer and catalyst according to the weight ratio, the stirring rate is 500-600r / min, and the time is 30-60min;

[0034] S2: Add toluene diisocyanate to the mixed solution obtained in step S1, stir and mix, leave to react and foam, and form polyurethane foam;

[0035] S3: Mix the grafted polyether, triethylenediamine and surfactant at high speed, the stirring speed is 800-1000r / min, the time is 20-30min, then add polyurethane foam and mix evenly to obtain a polyurethane mixture;

[0036] S4: Graphene is placed in deionized water and ultrasonically dispersed to obtain a uniformly dispersed graphene aqueous solution. Pour the silica airgel into the graphene aqueous solution, stir mechanically at 80-100°C until it becomes a slurry, and spray dry the graphite Graphene is dispersed in ...

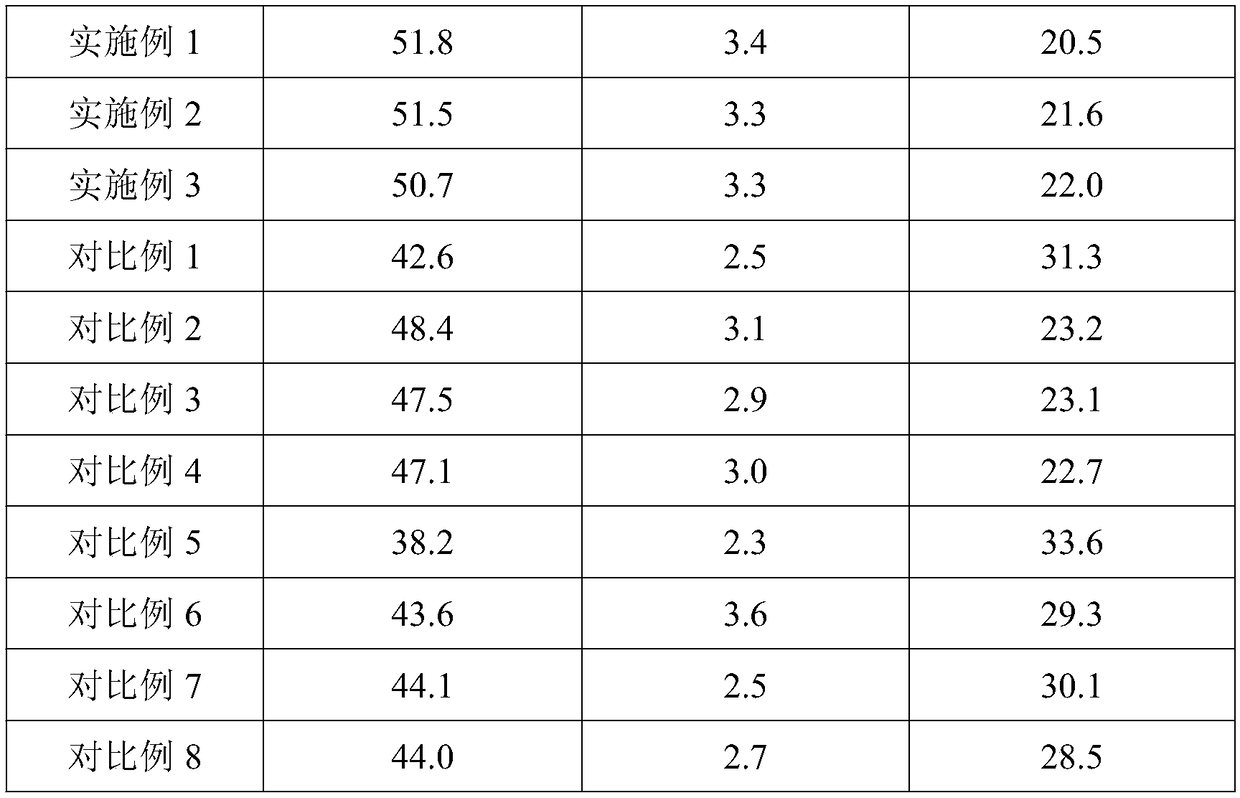

Embodiment 1

[0039] The high-strength mattress material includes the following raw materials in parts by weight: 20 parts of toluene diisocyanate, 70 parts of polyolefin, 3 parts of glycerin, 3 parts of trimethylolpropane, 18 parts of carbon fiber, 2 parts of water, polyolefin 2.4 parts of methyl siloxane, 0.2 parts of N,N-dimethylcyclohexylamine, 1.2 parts of silicone oil, 1.6 parts of triethylenediamine, 5 parts of grafted polyether, 6 parts of silica airgel, graphene 2 parts, 0.5 parts of sodium bicarbonate.

[0040] The preparation method of described high-strength mattress material, comprises the following steps:

[0041] S1: Stir and mix polyolefin, carbon fiber, chain extender, foaming agent, foam stabilizer, and catalyst according to the weight ratio, the stirring rate is 500r / min, and the time is 60min;

[0042] S2: Add toluene diisocyanate to the mixed solution obtained in step S1, stir and mix, leave to react and foam, and form polyurethane foam;

[0043] S3: Mix the graft pol...

Embodiment 2

[0047] The high-strength mattress material includes the following raw materials in parts by weight: 30 parts of toluene diisocyanate, 60 parts of polyolefin, 9 parts of sorbitol, 15 parts of carbon fiber, 1.5 parts of water, and 2.2 parts of polydimethylsiloxane , 0.6 parts of tetramethylalkylene diamine, 0.8 parts of silicone oil, 1.4 parts of triethylenediamine, 4 parts of grafted polyether, 2 parts of silica airgel, 1 part of graphene, and 1.5 parts of sodium bicarbonate.

[0048] The preparation method of described high-strength mattress material, comprises the following steps:

[0049] S1: Stir and mix polyolefin, carbon fiber, chain extender, foaming agent, foam stabilizer, and catalyst according to the weight ratio, the stirring rate is 600r / min, and the time is 40min;

[0050] S2: Add toluene diisocyanate to the mixed solution obtained in step S1, stir and mix, leave to react and foam, and form polyurethane foam;

[0051] S3: Mix the grafted polyether, triethylenediam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com