Epoxy chain extender and preparation method thereof

A technology of epoxy chain extender and organic solvent, which is applied in the field of epoxy chain extender and its preparation, can solve the problem of affecting the promotion and application of recycled biodegradable polymer materials, and is not suitable for the environment-friendly characteristics of biodegradable polymer materials. , the thermal stability and poor mechanical properties of biodegradable materials, etc., to achieve the effect of wide source of raw materials and reagents, improved performance and large molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

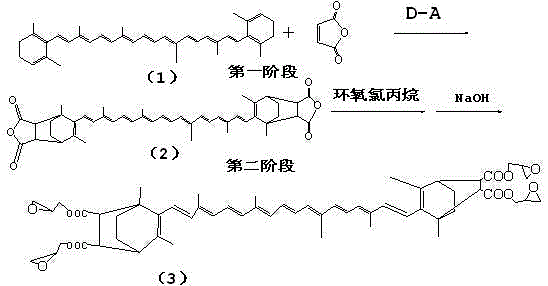

[0011] Embodiment 1 of the present invention: the preparation of epoxy chain extender, in the 200ml there-necked bottle with magnetic stirrer, add the benzene of 60ml, 25gγ-carotene and 9.8g maleic anhydride, heat to 140 ℃, in D-A reaction occurred under the protection of nitrogen for 4 hours; add 93g epichlorohydrin and 0.7g ammonium bromide to the mixture, heat and reflux for 6 hours; after cooling to 73°C, add excess sodium hydroxide; filter, wash repeatedly with distilled water, pump Filter to obtain 36.75 g of light yellow multi-epoxide functional group chain extender.

Embodiment 2

[0012] Embodiment 2 of the present invention: preparation of epoxy chain extender, add 60ml of toluene, 22g gamma-carotene and 9g maleic anhydride to a 200ml there-necked flask with a magnetic stirrer, heat to 170°C, D-A reaction occurred under protection for 3 hours; add 90g epichlorohydrin and 0.6g ammonium bromide to the mixture, heat and reflux for 5 hours; after cooling to 75°C, add excess sodium hydroxide; filter, wash repeatedly with distilled water, and suction filter 29.82 g of a white polyepoxide functional chain extender was obtained.

Embodiment 3

[0013] Embodiment 3 of the present invention: preparation of epoxy chain extender, add 60ml of acetonitrile, 27g γ-carotene and 11g maleic anhydride to a 200ml there-necked flask with a magnetic stirrer, heat to 130°C, D-A reaction occurred under protection for 5 hours; add 90g epichlorohydrin and 0.6g ammonium bromide to the mixture, heat and reflux for 4 hours; after cooling to 75°C, add excess sodium hydroxide; filter, wash repeatedly with distilled water, and suction filter 33.92 g of a white polyepoxide-functional chain extender were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com