Recycling method of waste HIPS

A waste and chain extender technology, applied in recycling technology, plastic recycling, etc., can solve problems such as inappropriate promotion, coking phenomenon, lack of macro performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

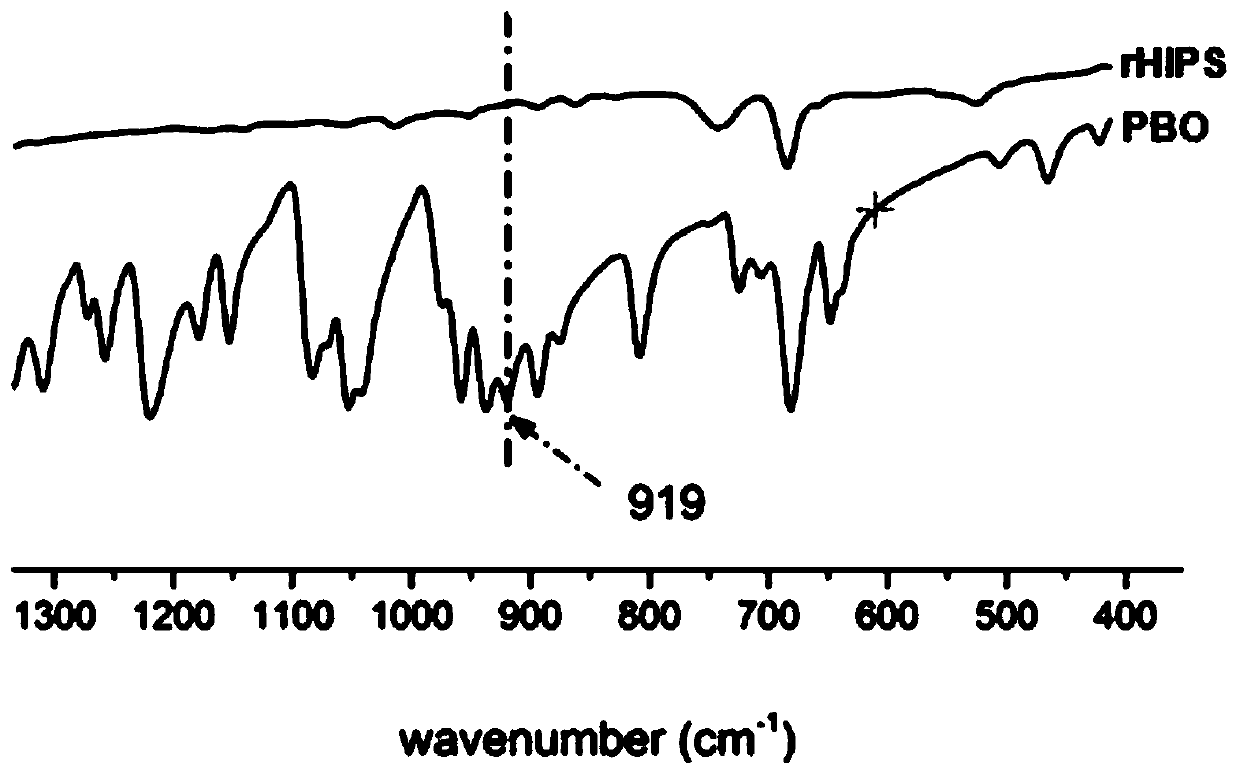

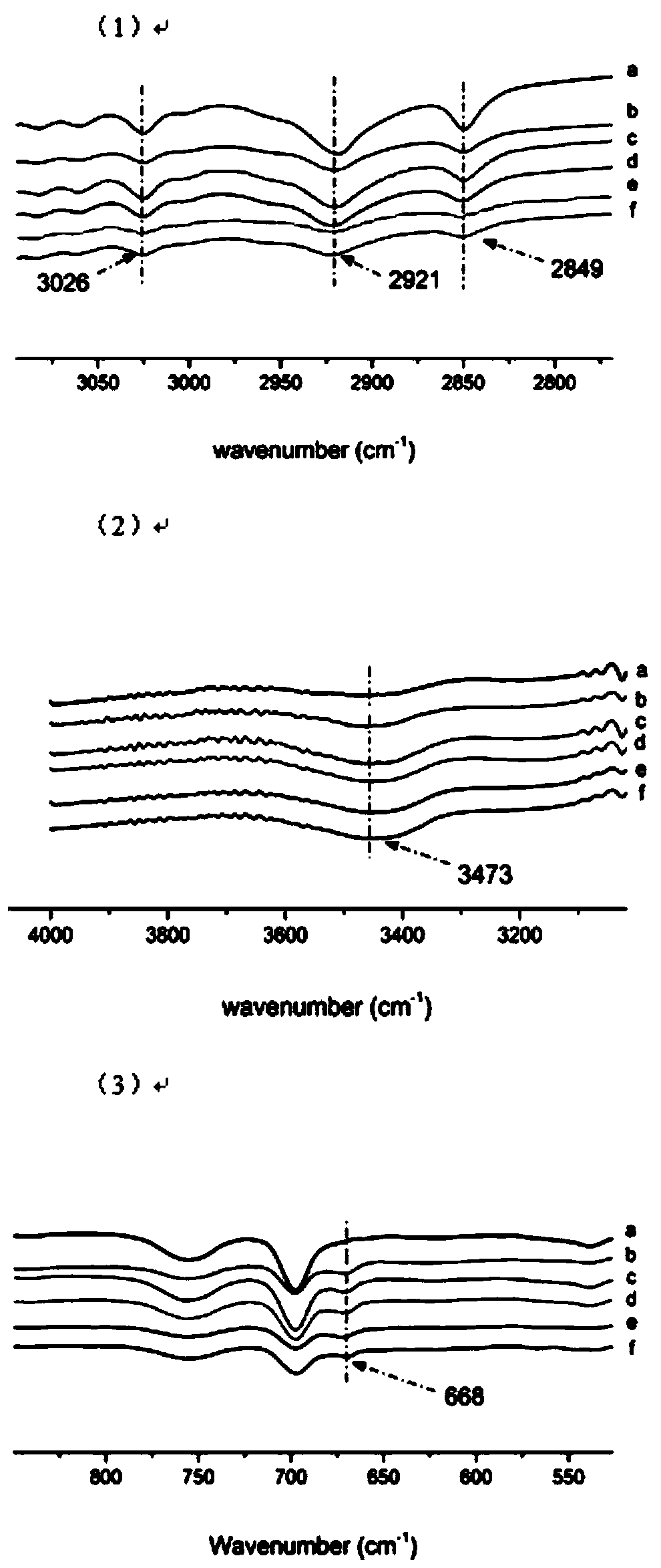

[0024] The chain extender 2,2'-(1,3-phenylene)-bisoxazoline (PBO) and waste HIPS are added to the twin-screw extruder for blending according to the mass ratio of 1.3:100, and the twin-screw extruder The length-to-diameter ratio of the screw is 40, and the screw is referred to as 450r / min. In the process of melt extrusion, the chain extender reacts with the carboxyl functional group on the molecular chain of the waste HIPS in situ. The temperature control is as follows: T1=180°C, T2=200°C, T3=215°C, T4=230°C, T5=250°C, the speed of the twin-screw extruder is 300r / min, and the residence time in the twin-screw extruder 3-5 minutes, the extruded material is cooled and formed in cold water at 5-30°C, so as to realize the regeneration of waste HIPS.

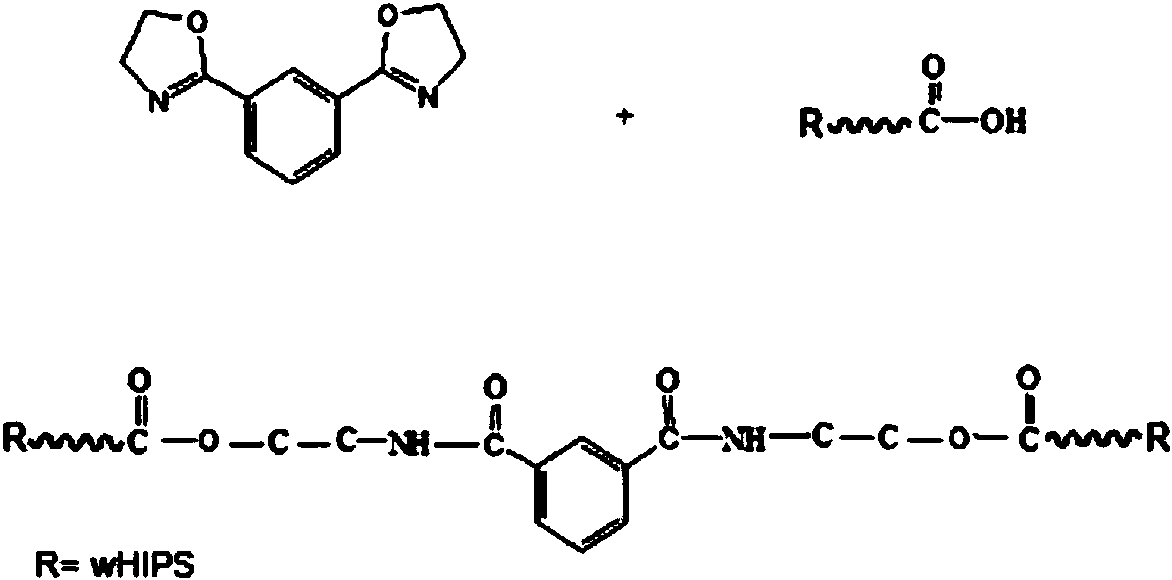

[0025] The chain extension reaction of PBO and wHIPS is shown in the following formula chain extension one and chain extension two. During the reaction, the oxazoline in the 2,2'-(1,3-phenylene)-bisoxazoline (PBO) structure The ring i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact performance | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Financial index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com