Microcapsule wrapping solid sun-screening agent, preparation method and application thereof

A technology of microcapsules and sunscreen agents, which can be used in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., and can solve problems such as poor touch feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] Microcapsule preparation method of the present invention, comprises the following steps:

[0073] (a) dissolving the natural polymer in water or an aqueous solution to form a solution;

[0074] (b) dispersing the solid sunscreen in the solution obtained in step (a) to form an S / W dispersion, or heating and melting the solid sunscreen into a liquid, and dispersing it in the solution obtained in step (a) to form an O / W emulsion;

[0075] (c) dispersing the S / W dispersion liquid or O / W emulsion that step (b) obtains in the oily phase that contains lipophilic surfactant to form S / W / O emulsion or O / W / O emulsion;

[0076] (d) curing the S / W / O emulsion or O / W / O emulsion obtained in step (c) to obtain the microcapsules.

[0077] The natural polymer described in step (a), the solid sunscreen agent described in step (b) are as described above.

[0078] In step (a), the aqueous solution refers to the solution formed by acid and water, alkali and water, salt and water or polymer ...

Embodiment 1

[0099] Add 0.3 g of deacetylated chitosan (deacetylation degree 89%) to 20 g of 1 wt% acetic acid aqueous solution, stir at 200 RPM for 30 min to fully dissolve it for later use.

[0100] Add 5g of 2-(2'-hydroxyl-5'-methylphenyl)benzotriazole (UV360) and 0.017g of polyvinyl alcohol PVA (polymerization degree 1750) into the deacetylated chitosan solution for subsequent dissolution , and then stirred at room temperature and 1000 RPM for 10 min to obtain a S / W dispersion.

[0101] The mixed liquid 50g (Span80 accounts for 4wt% of olive oil weight) of olive oil and Span80 is standby as the oil phase containing lipophilic surfactant.

[0102] The above S / W dispersion was added to the olive oil oil phase containing the lipophilic surfactant Span80, and stirred at room temperature and 1000 RPM for 60 min to obtain the S / W / O emulsion. Then add dropwise 3.75×10 -3 g (the molar ratio of amino group to aldehyde group is 1:1) 1wt% glutaraldehyde aqueous solution, cross-linking reaction ...

Embodiment 2

[0105] Add 0.8 g of agar into 20 g of water, heat in an oil bath at 110° C. for 30 min to fully dissolve it, and then set aside at 95° C. for later use.

[0106] Mix 5g of organic ultraviolet absorber butylmethoxydibenzoylmethane (Parsol1789) and 0.3g Tween80 at 95°C, add to the above-mentioned dissolved agar solution, and then stir at 95°C and 1000RPM for 10min to obtain O / W lotion.

[0107] Preheat 50 g of the liquid paraffin and PO-500 mixed liquid (PO-500 accounts for 0.5 wt% of the liquid paraffin weight) to 95° C. as an oil phase containing lipophilic surfactant for later use.

[0108] The above O / W emulsion was added into the oil phase containing lipophilic surfactant, and stirred at 95° C. and 1000 RPM for 60 min to obtain an O / W / O emulsion.

[0109] The O / W / O emulsion was slowly stirred at 200RPM for 60min, cooled down to room temperature and solidified, and then filtered with suction and washed with distilled water.

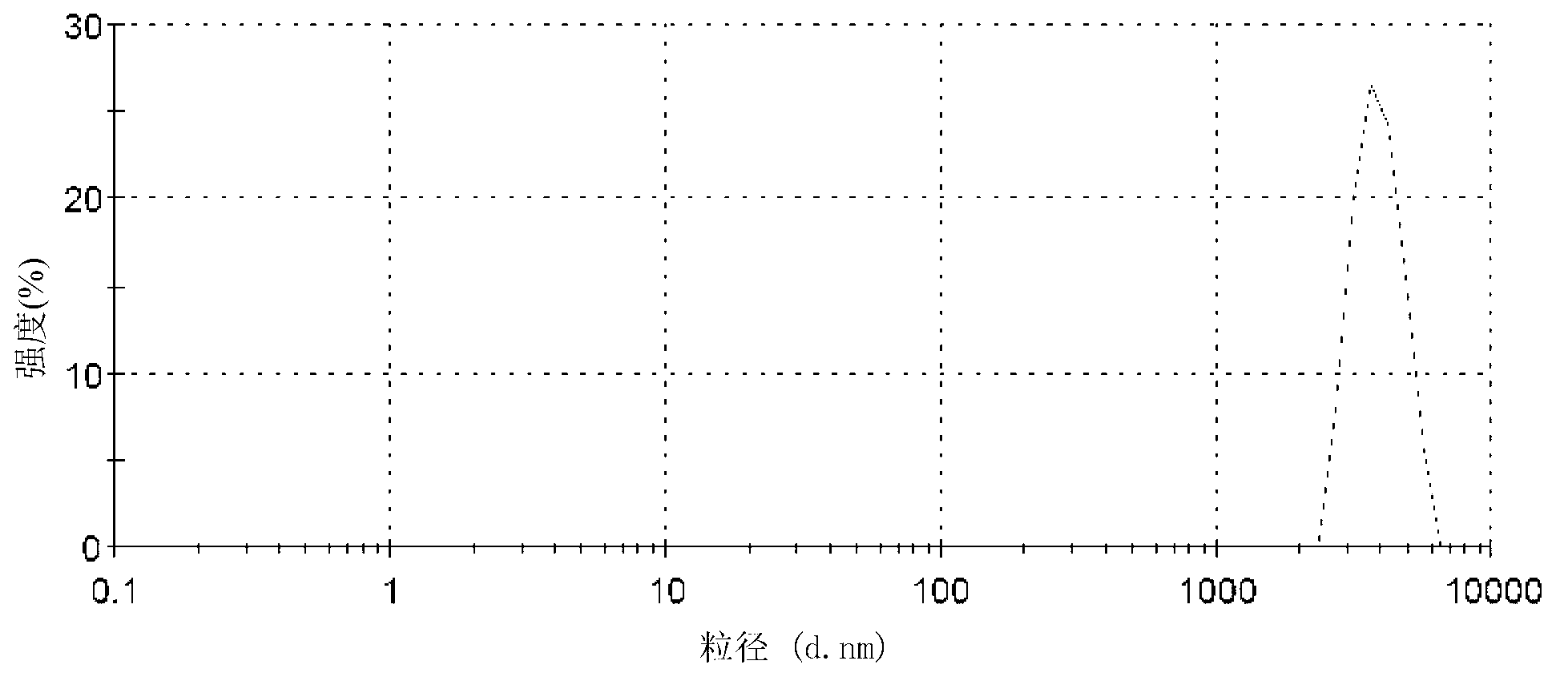

[0110] The photomicrograph of the prepared mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com