Method for preparing synergistic sunscreen micron capsule by virtue of composite condensation

A complex coagulation and encapsulation technology, applied in the field of preparation of synergistic sunscreen microcapsules, can solve the problems of sunscreen damage, large amount of sunscreen, limited sunscreen effect of sunscreen, etc., and achieves low price, high sunscreen effect and good biological phase. capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

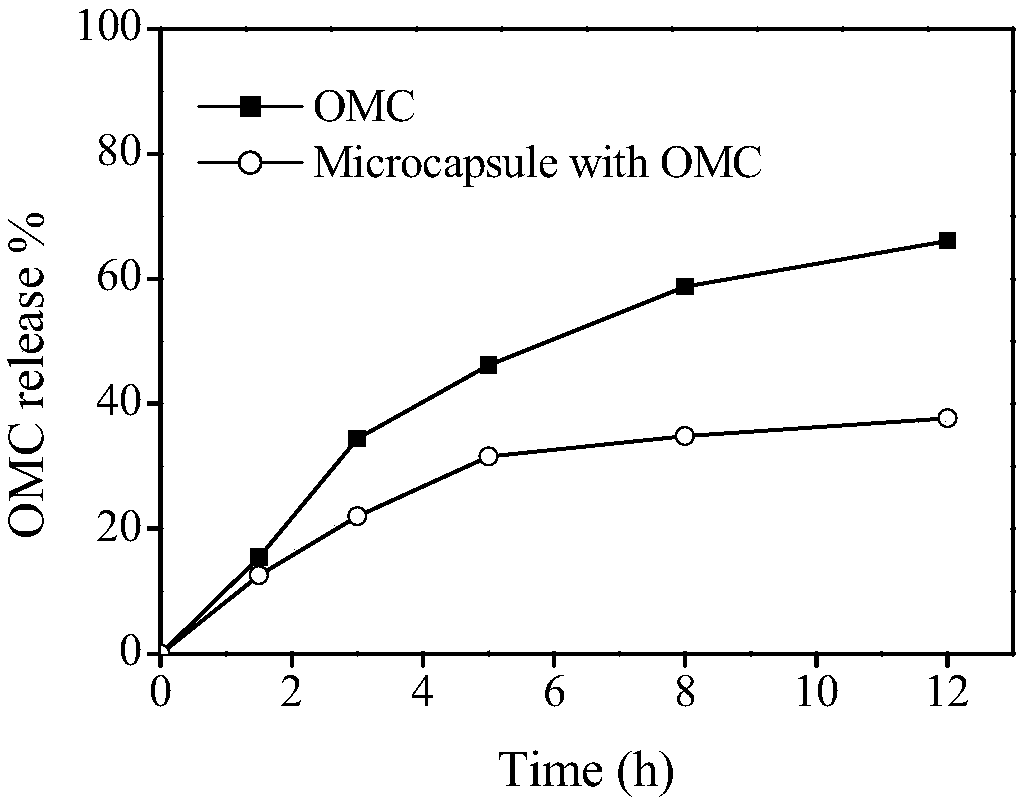

Embodiment 1

[0026] Weigh Arabic gum to prepare 1% gum Arabic solution, take 15 mL of gum Arabic solution in a beaker, put it in a water bath at 50 °C and add it. Weigh the sodium caseinate solution to prepare 1% sodium caseinate solution. Weigh octyl methoxycinnamate so that the ratio of wall material to core material is 1:1, add 15 mL of sodium caseinate solution, homogenize for 5 min, and rotate at 10,000 rpm. Add the homogenized emulsion into the gum arabic solution, control the stirring speed to 500 rpm, quickly add glacial acetic acid to adjust the pH to 2.5, and react for 10 minutes. The solution was taken out, stirred and cooled to room temperature, then 1% glutaraldehyde was added, and reacted for 30 minutes. The reacted solution is left to stand, separated into layers, and the supernatant is precipitated, and the precipitate is freeze-dried to obtain synergistic sunscreen microcapsules.

Embodiment 2

[0028] Weigh arabic gum to prepare 0.5% gum arabic solution, take 15 mL gum arabic solution in a beaker, put it in a water bath at 50 °C and add it. Weigh the sodium caseinate solution to prepare 0.5% sodium caseinate solution. Weigh octyl methoxycinnamate so that the ratio of wall material to core material is 1:2, add 15 mL sodium caseinate solution, homogenize for 5 min, and rotate at 10000 rpm. Add the homogenized emulsion into the gum arabic solution, control the stirring speed to 500 rpm, quickly add glacial acetic acid to adjust the pH to 2.5, and react for 10 minutes. The solution was taken out, stirred and cooled to room temperature, then 1% glutaraldehyde was added, and reacted for 30 minutes. The reacted solution is left to stand, separated into layers, and the supernatant is precipitated, and the precipitate is freeze-dried to obtain synergistic sunscreen microcapsules.

Embodiment 3

[0030] Weigh Arabic gum to prepare 1.5% gum Arabic solution, take 15 mL of gum Arabic solution in a beaker, put it in a water bath at 50 °C and add it. Weigh the sodium caseinate solution to prepare a 1.5% sodium caseinate solution. Weigh octyl methoxycinnamate so that the ratio of wall material to core material is 2:1, add 15 mL of sodium caseinate solution, homogenize for 5 min, and rotate at 10,000 rpm. Add the homogenized emulsion into the gum arabic solution, control the stirring speed at 500 rpm, quickly add glacial acetic acid to adjust the pH to 2.8, and react for 10 minutes. The solution was taken out, stirred and cooled to room temperature, then 1% glutaraldehyde was added, and reacted for 30 minutes. The reacted solution is left to stand, separated into layers, and the supernatant is precipitated, and the precipitate is freeze-dried to obtain synergistic sunscreen microcapsules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com