Apparatus for producing multi pulse by Dammann grating pair

A Daman grating and multi-pulse technology is applied in the field of devices that generate multi-pulse, can solve problems such as low cost, and achieve the effect of low cost and easy fabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

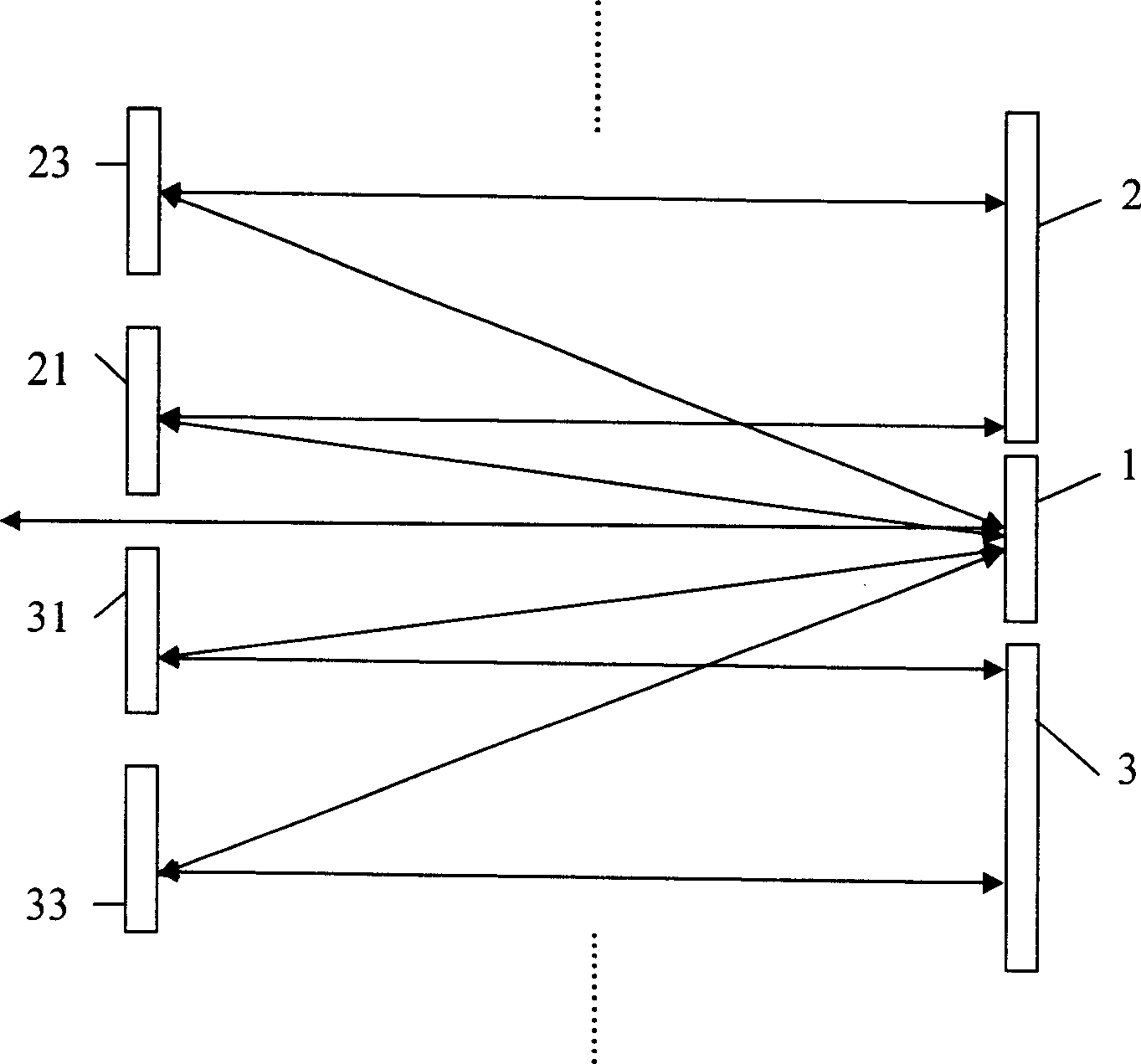

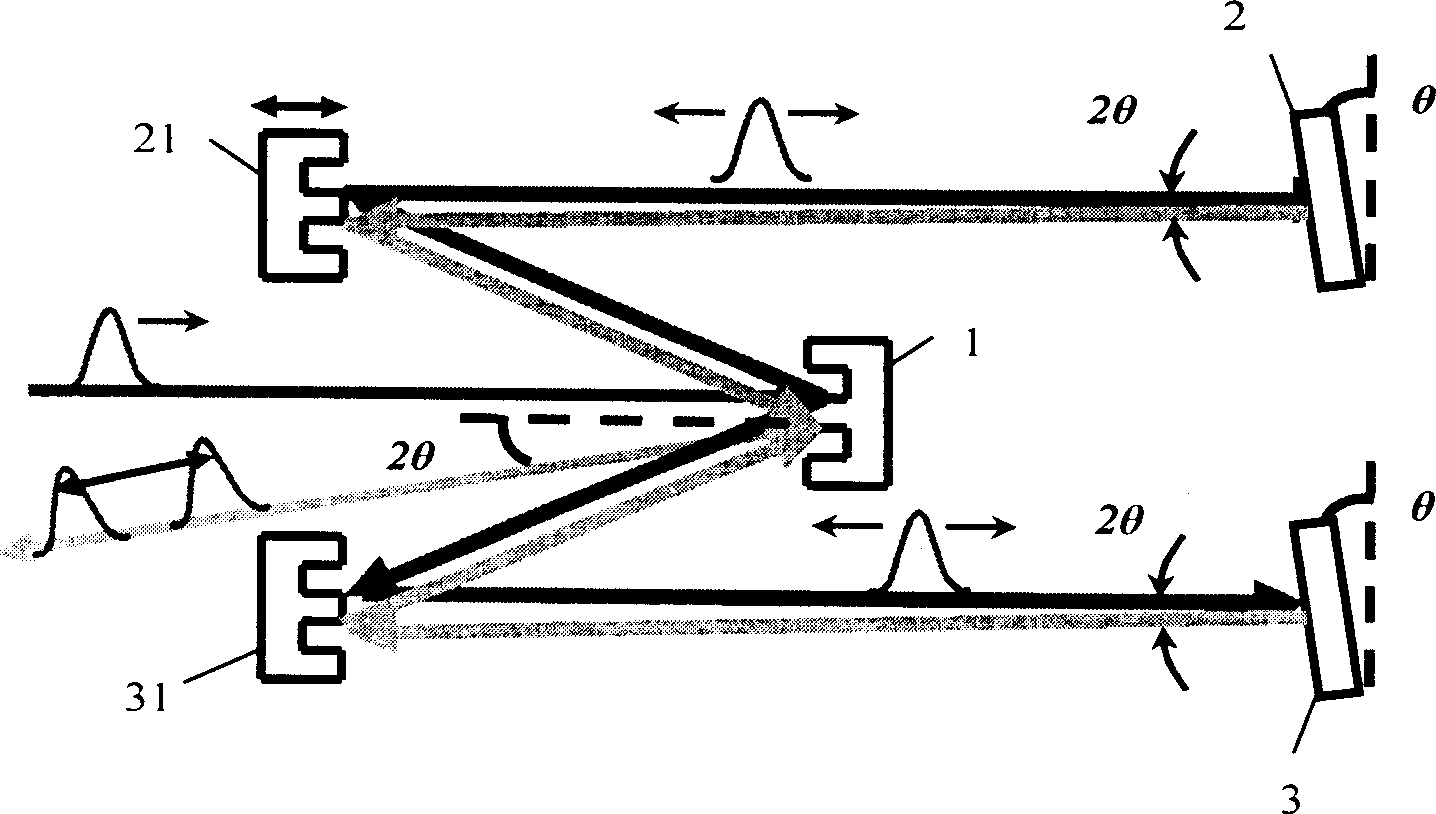

[0049] Such as figure 2 As shown, the main grating 1 is a 1×2 reflective Damman grating with a period of 25 μm, and two completely identical 1×2 reflective first-stage Damman gratings 21 and 31 are placed at a distance of 30 cm as compensation gratings; The symmetry axes of the primary Damman gratings 21, 31 are on the normal line of the main grating 1, and the normal directions of the main grating 1 and the primary Damman gratings 21, 31 are parallel. The horizontal distance between the two centers is 2cm. Place the first total reflection mirror 2 and the second total reflection mirror 3 apart from the first-order Damman grating 21,31-35cm;

[0050] The laser pulse with positive chirp is incident on the main grating 1, and its positive and negative first-order diffracted lights are respectively incident on the first-order Damman grating 21, 31; the reflected light is reflected by the first total reflection mirror 2 and the second total reflection mirror 3 , the surface of ...

Embodiment 2

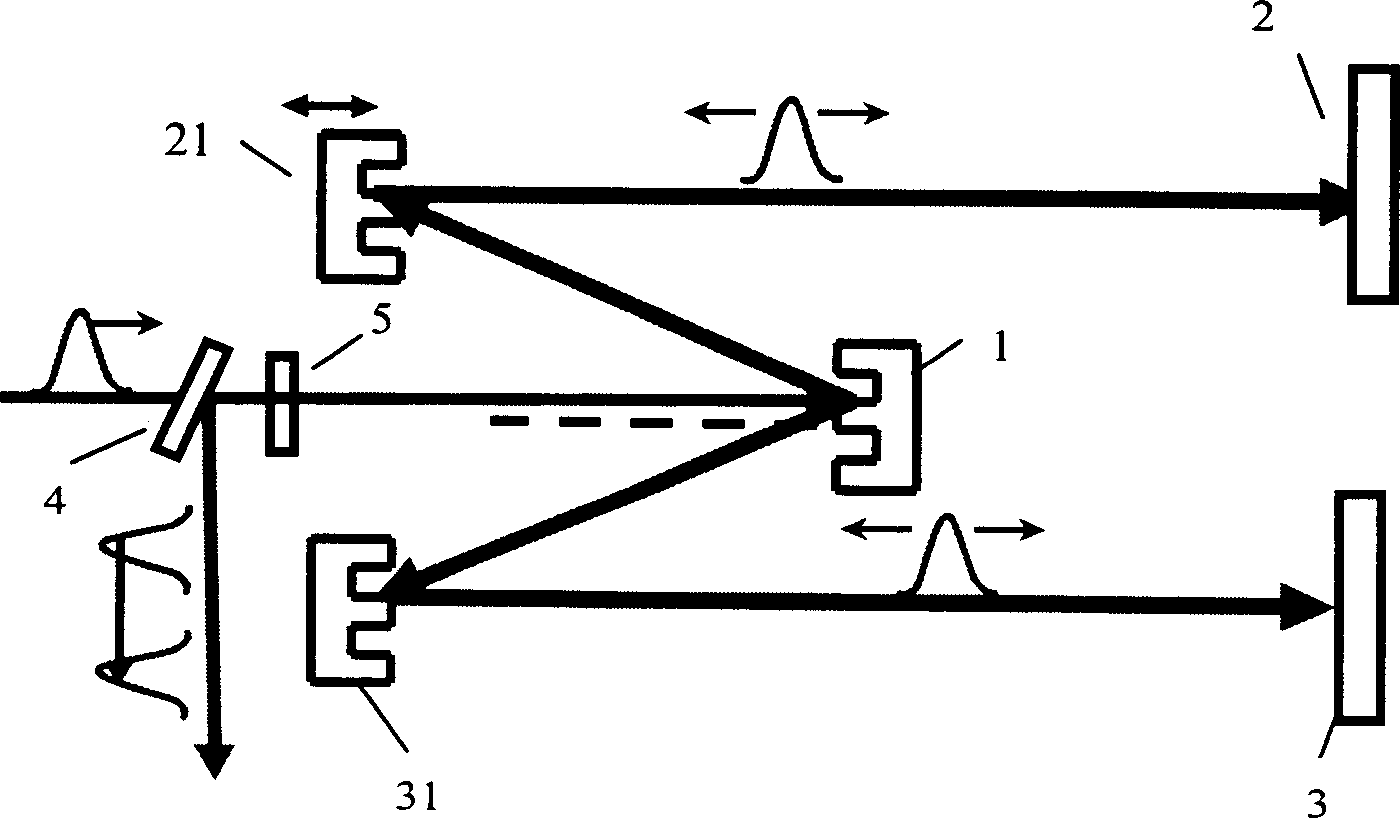

[0052] We can separate the input and output light in another way. Such as image 3 As shown, on the normal line of the main grating 1, that is, along the direction of the incident light, a polarizing dielectric template 4 and a 1 / 4 wave plate 5 that are 45° to the optical path are arranged in sequence, and the polarizing dielectric template 4 is opposite to the 45° incident light P-polarized light is completely transparent, while S-polarized light is completely reflected. If the incident light is p-polarized, the output light will become s-polarized due to passing through the 1 / 4 wave plate 5 twice. The p-polarized light is transmitted, and the s-polarized light is totally reflected at 45°, so that the output light and the input light are separated.

Embodiment 3

[0054] The structures of this embodiment and embodiment 2 are basically the same, as Figure 4As shown, when the diameter Φ of the first total reflection mirror 2 and the second total reflection mirror 3 is constant, the distance s between them and the primary Damman grating 21, 31 is not arbitrary, and if s is too small, it will hinder the main grating 1 diffracted light, so there is a minimum s min =Φctgα; α is the diffraction angle of the positive and negative order of the Damman grating used.

[0055] In the experiment, the input pulse measured by the standard second harmonic frequency resolution optical switch device is a double pulse with a chirp of 0.00031 rad / fs, an input pulse of 88.5 fs, and an output pulse of 46.2 fs, which has obvious pulse compression. By adjusting the first-stage Damman gratings 21, 31, a series of double pulses with different pulse intervals can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com