Single yarn, manufacturing method of single yarn, single yarn products and manufacturing method of single yarn product

A single yarn and product technology, applied in the field of polymer materials, can solve the problems of complex process, easy fiber breakage, twisting, entanglement, and easy burrs on the fiber surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 3

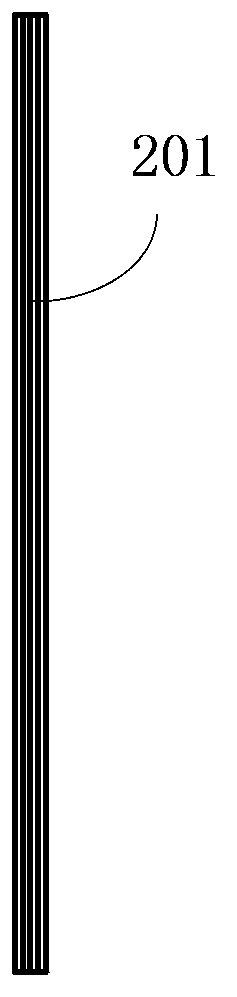

[0069] Example 3: A plurality of single yarns can be arranged and connected in one direction to form a single yarn product with a single layer structure.

[0070] For example: a plurality of single yarns can be arranged in parallel along the length direction of the single yarns, and connected as a whole by non-interweaving methods such as binding connection, adhesive bonding or hot pressing connection, to prepare unidirectional fabric 801 (such as Figure 8 ). The unidirectional fabric prepared by this scheme can be used but not limited to the preparation of products such as reinforced structural parts, high-strength bags, bulletproof panels, impact-resistant panels, bulletproof helmets, bulletproof and riot-proof bags, etc., which can better meet the requirements of these products on fabric strength, weight, bulletproof, etc. and other special requirements for performance.

example 4

[0071] Example 4: A plurality of single-layer structures obtained by unidirectional arrangement and connection of multiple single yarns can be cross-laminated at a certain angle to obtain a single-yarn product with a multi-layer structure.

[0072] Among them: the intersection angle of any adjacent two single-layer structures can be the same, and the intersection angle can be any angle from 0 to 90 degrees, such as: the intersection angle is 45 degrees; or the intersection angle is 90 degrees, such as multi-layer The unidirectional fabric 801 is laminated sequentially at 0 / 90 degrees crosswise, and each layer of unidirectional fabric is glued or connected by heat and pressure, thus making a weft-free fabric 901 (such as Figure 9 ) and other single yarn products with multi-layer structure. The single-yarn product produced by this solution has high strength, and when subjected to strong external impact such as bullet injection, the force-bearing point can be diffused into a for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com