A thermal fly height control slider for hard drives

A technology for controlling sliders and drivers, which is applied to the hydrodynamic spacing of heads, the configuration/installation of recording heads, and the directions of support heads, etc. Write performance and storage capacity and other issues, to achieve the effect of easy manufacturing and installation, improve stability, and improve the efficiency of reading data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and example the structure of the thermal flying high control slider in the present invention is described in further detail.

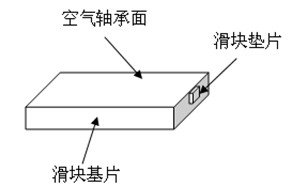

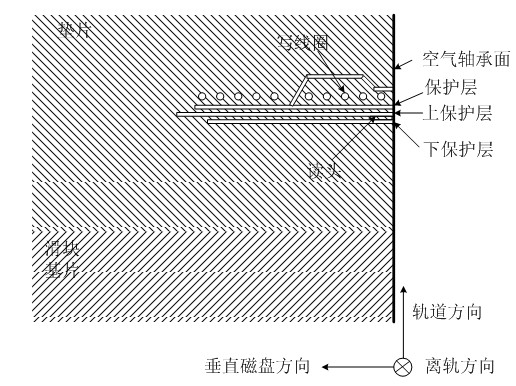

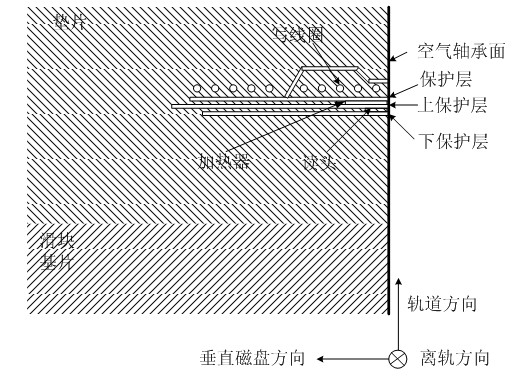

[0021] figure 1 is the overall structure diagram of the existing slider, figure 2 It is the local structure diagram of the existing slider without the micro-heater, image 3 It is a partial structural diagram of the thermal fly height control slider including the micro heater in the embodiment of the present invention. in, figure 1 The larger cube in the figure is the slider substrate, and its upper surface is the air bearing surface, while the smaller cube on the side is the slider spacer, and the magnetic head and heater are embedded inside the spacer. figure 2 Two separate protective layers sandwich the read head in the middle, and the write head is a helically wound coil. The ten small circles in the figure are the cross-sections of the helix. exist figure 2 Among them, the inward direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com