Production technology for HDPE hot-galvanizing-zinc-aluminum-alloy pre-stress steel strand

A technology of prestressed steel strand and production process, applied in hot dip plating process, metal material coating process, coating and other directions, can solve problems such as cable breakage, a lot of manpower, economic loss, etc. The effect of large area and high linear density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

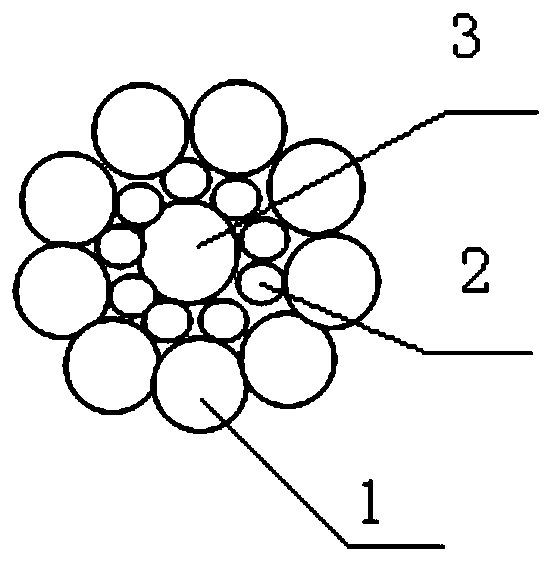

[0032] The HDPE hot-dip galvanized aluminum alloy prestressed steel strand production process includes the following processes:

[0033] Wire rod preparation inspection - including nine inner wire rods, nine outer wire rods and one center wire rod;

[0034] Pickling and phosphating treatment process—use degreasing furnace degreasing plus multiple sets of electrolytic alkaline cleaning and pickling combined technology for pre-plating treatment;

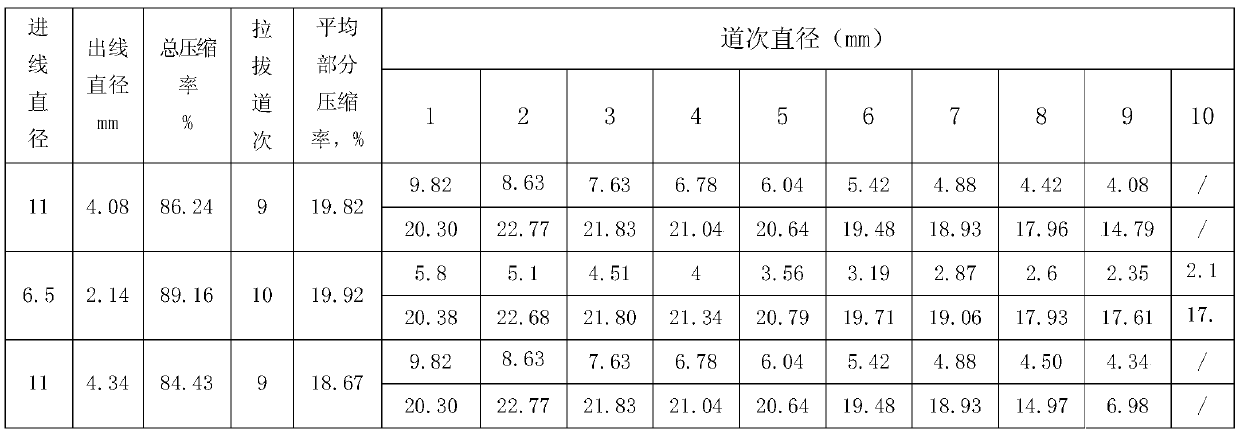

[0035] Wire drawing process - using multi-pass, small compression ratio, stirring lubrication and rotating cooling mold combination technology;

[0036] Specifically, taking the diameter of the inner layer wire rod as φ6.5, the diameter of the outer layer wire rod as φ11, and the diameter of the center wire rod as φ11 as an example, the specific diameter of the wire drawing matching die is shown in Table 1:

[0037] Table I

[0038]

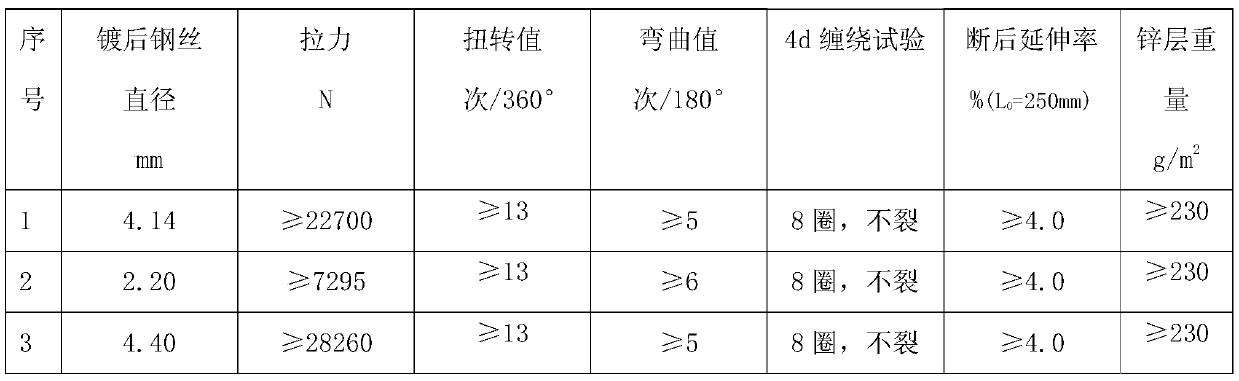

[0039] Hot-dip galvanizing process—hot-dip galvanizing-5% aluminum-mixed rare earth alloy coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com