Patents

Literature

76results about How to "No oil spills" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

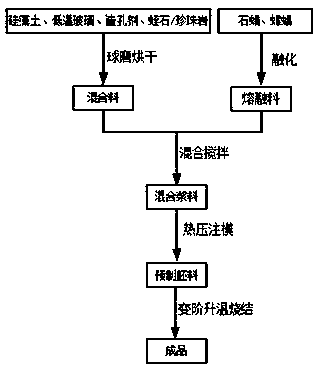

Porous ceramic atomizing core and preparation method thereof

ActiveCN110713379AGood dimensional stabilityFit tightlyTobaccoCeramicwareParaffin waxPorous ceramics

The invention discloses a porous ceramic atomizing core and a preparation method thereof. The porous ceramic atomization core is composed of a mixture and a molten material, wherein the mixture comprises: 40%-69% of diatomite, 20%-35% of low-temperature glass powder, 10%-20% of a pore-forming agent and 1%-2% of vermiculite and / or perlite; and the molten material comprises paraffin accounting for 40%-50% of the mass of the mixture and beewax accounting for 5%-10% of the mass of the mixture. The preparation method of the porous ceramic atomization core comprises the steps of material mixing, blank making and sintering. The porous ceramic atomization core material and the oil guide rod are integrally roasted and formed, so that the production efficiency is remarkably improved, the technological process is simple, the cost is low, the prepared porous ceramic atomization core is extremely high in size stability, the atomization core is tightly attached to the oil guide rod, and the oil leakage phenomenon cannot occur.

Owner:湖南福美来电子陶瓷有限公司

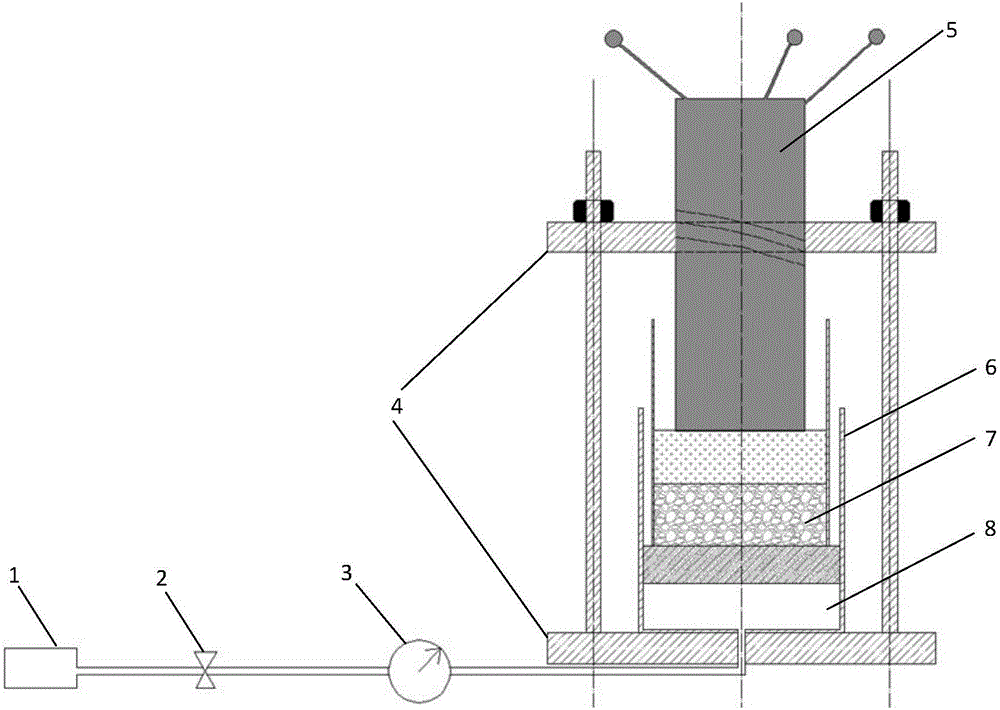

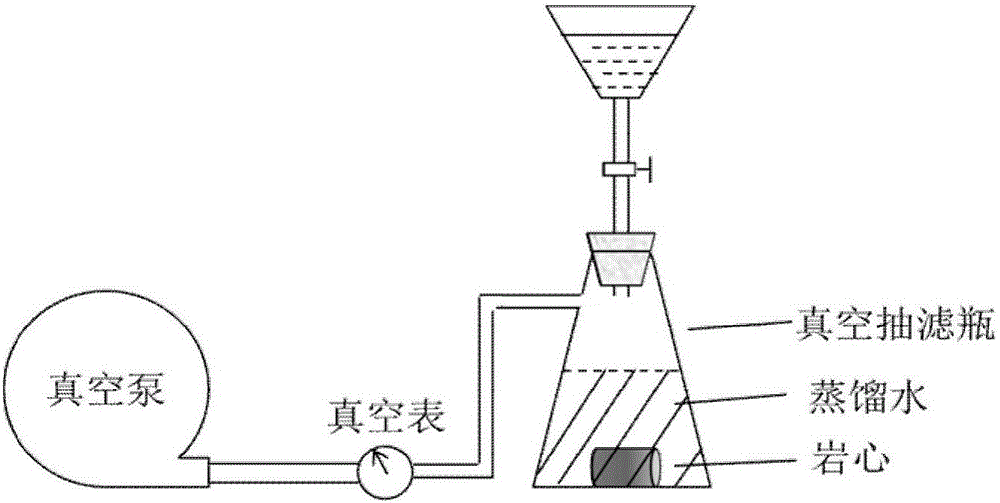

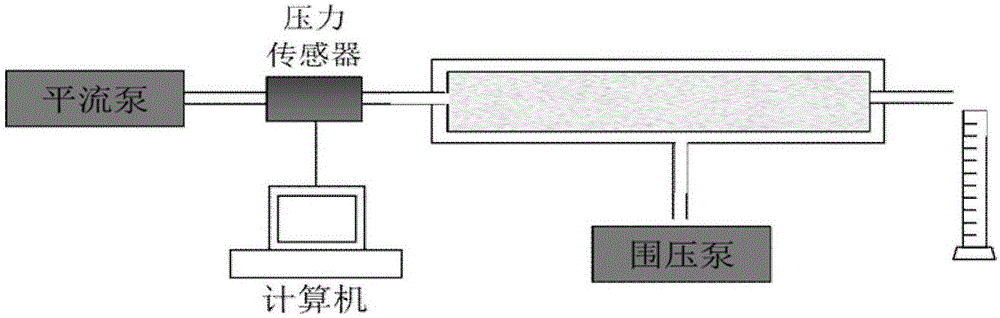

Semi-cemented artificial rock core model, and sand filling device and method thereof

ActiveCN106769751AAvoid squeezingAvoid dischargePreparing sample for investigationPermeability/surface area analysisRock coreOrganic glass

The invention relates to a semi-cemented artificial rock core model. The semi-cemented artificial rock core model is formed by a transparent organic glass tube, a quartz sand filling area at the middle portion, and sand grain cementing areas at two ends. A filling device of the semi-cemented artificial rock core model comprises a manual hydraulic pressure pump, a pressure release valve, a pressure meter, a fixed support, a solid threaded iron rod and a middle container with a stopper and an open end. The invention further provides a filling method of the semi-cemented artificial rock core model. The device and the method have the following advantages: 1, the making cost of the rock core is reduced, the technical threshold of making of the rock core is reduced, and the making efficiency of the rock core is improved; and 2, the aperture structure of the rock core is protected by the organic glass tube, so destroys of high confining pressure to the rock core and the change of the aperture structure are effectively avoided. The device has the advantages of simple structure, convenience in operation, high practicality and high simulation credibility, and the method is a novel rock core model making technology suitable for being promoted.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

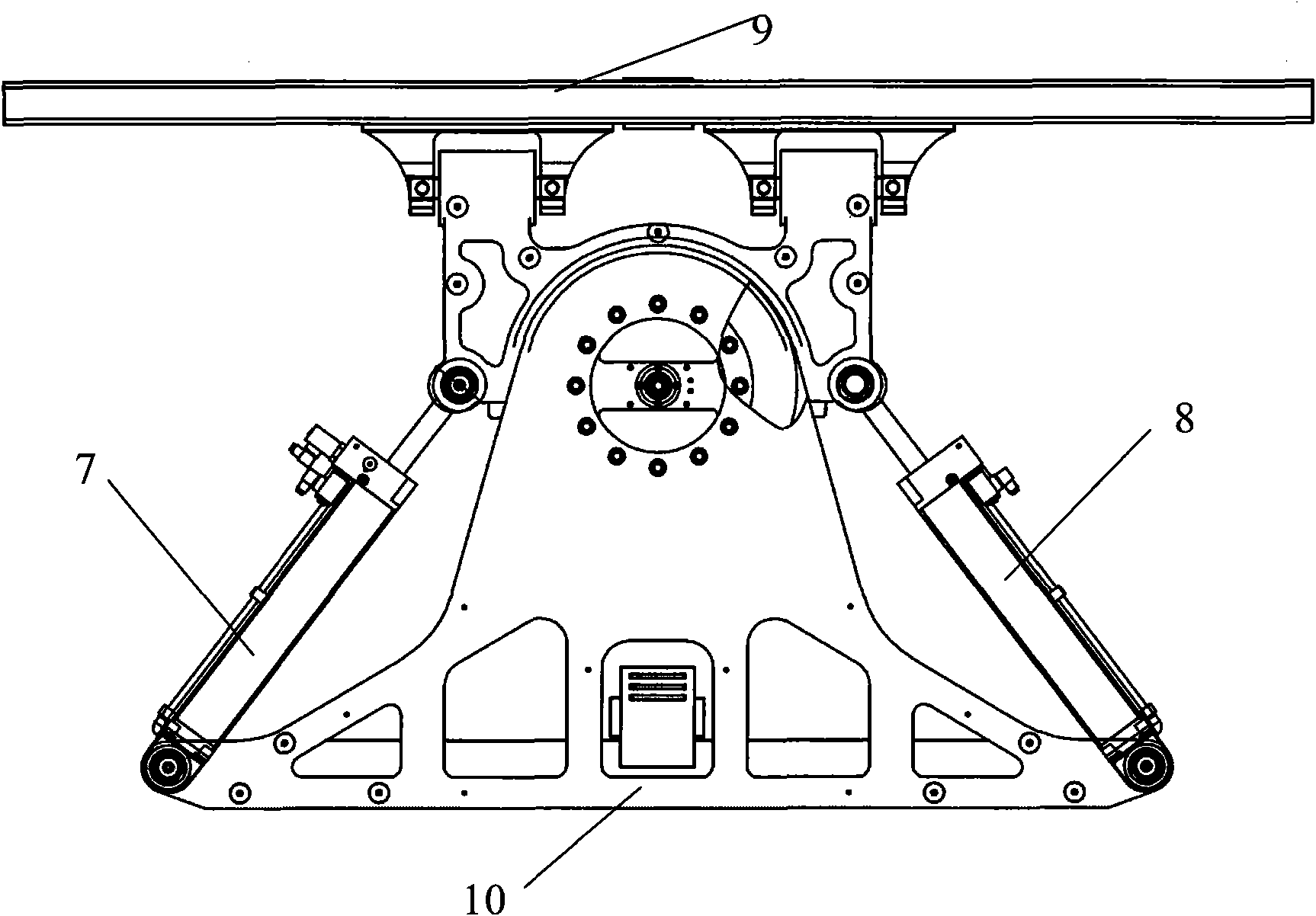

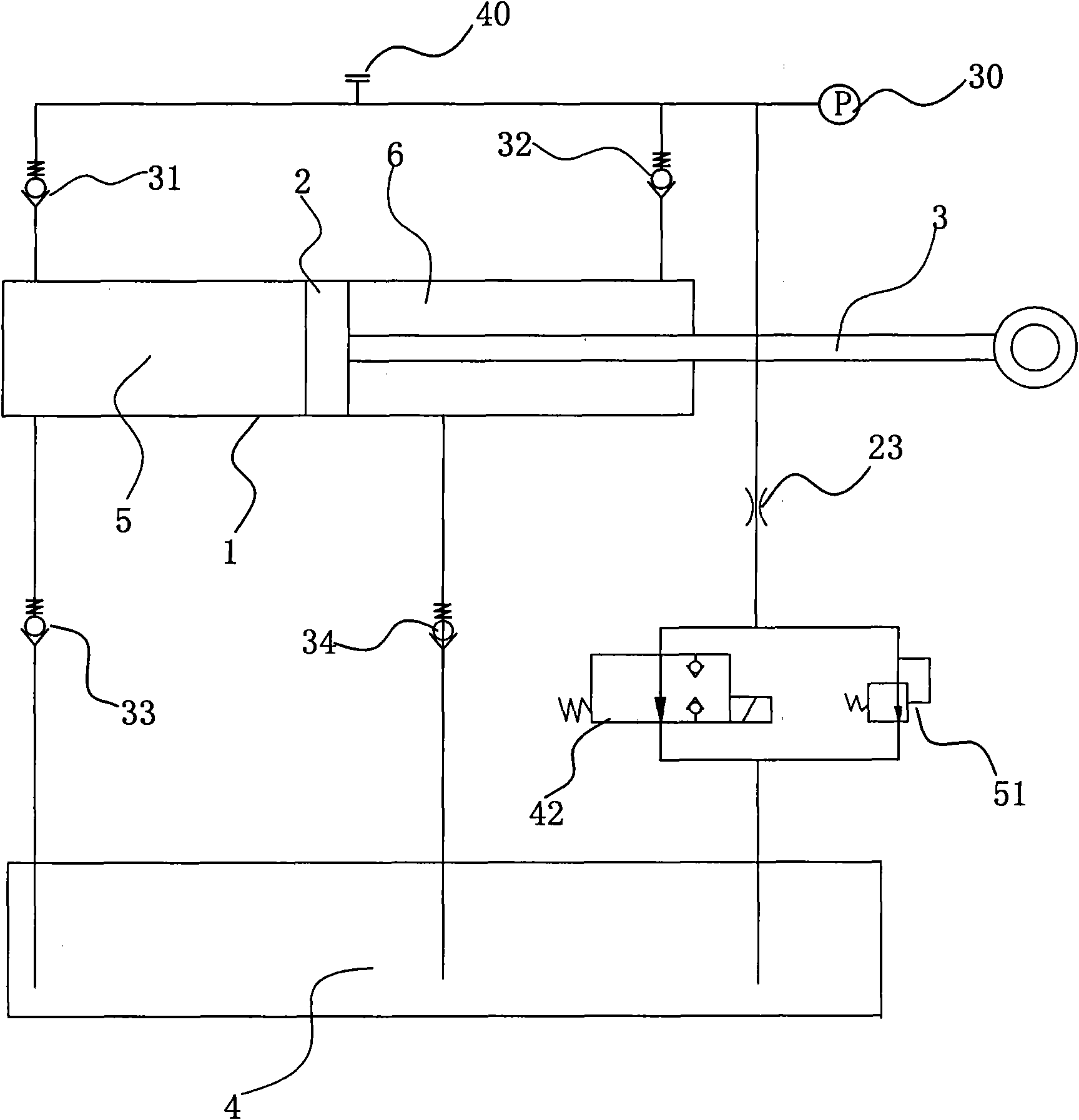

Hydraulic buffer system

ActiveCN102102728ASimple pressure controlLow failure rateSpringsLiquid based dampersFuel tankElectromagnetic valve

The invention relates to a hydraulic buffer system, which comprises a hydraulic cylinder, an oil storage tank, a first one-way valve, a second one-way valve, a third one-way valve, a forth one-way valve, a first hydraulic damper, a second hydraulic damper, a first electromagnetic valve and a second electromagnetic valve, wherein the hydraulic cylinder comprises a cylinder sleeve, a piston and a piston rod; the piston slides in the cylinder sleeve; and the hydraulic cylinder is divided into a buffer cavity and a locking cavity through the piston. The system has an ingenious design, a simple and compact structure, low production cost and a good buffering effect and is convenient to maintain when used on a vehicle; an oil discharge circuit is provided with a constant-value hydraulic damper, so that a resistance buffering effect which is proportional to the corner velocity of the vehicle is achieved; and the on-off of an oil circuit of the locking cavity is controlled through the electromagnetic valves, so that the vehicle has the functions of locking corner surpassing and recovering direct movement at the same time.

Owner:JOINTECH (SUZHOU) VEHICLE SYST CO LTD

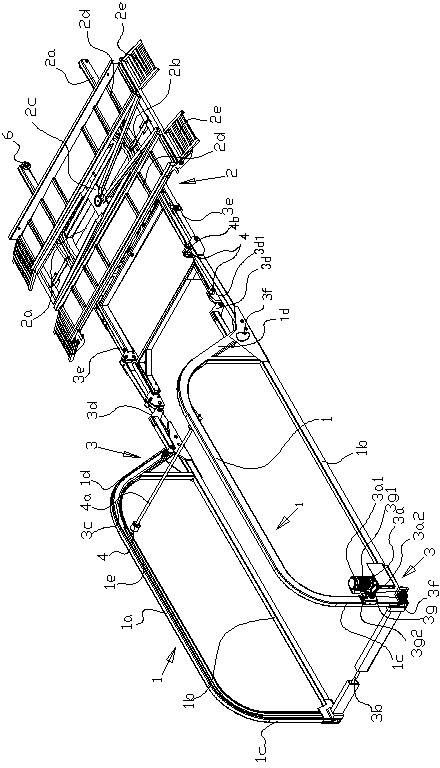

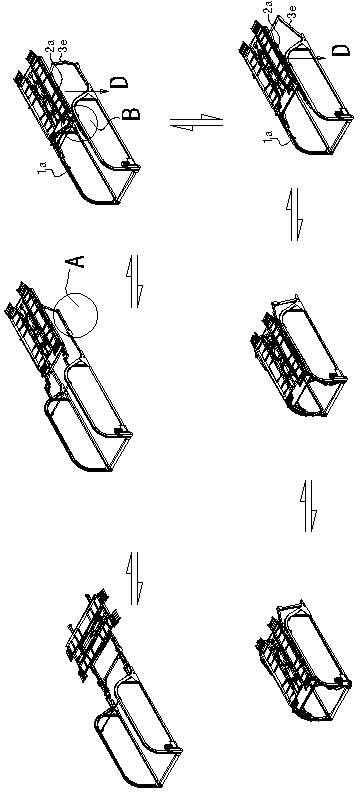

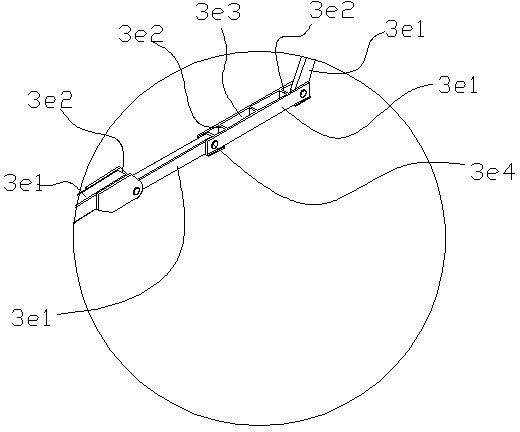

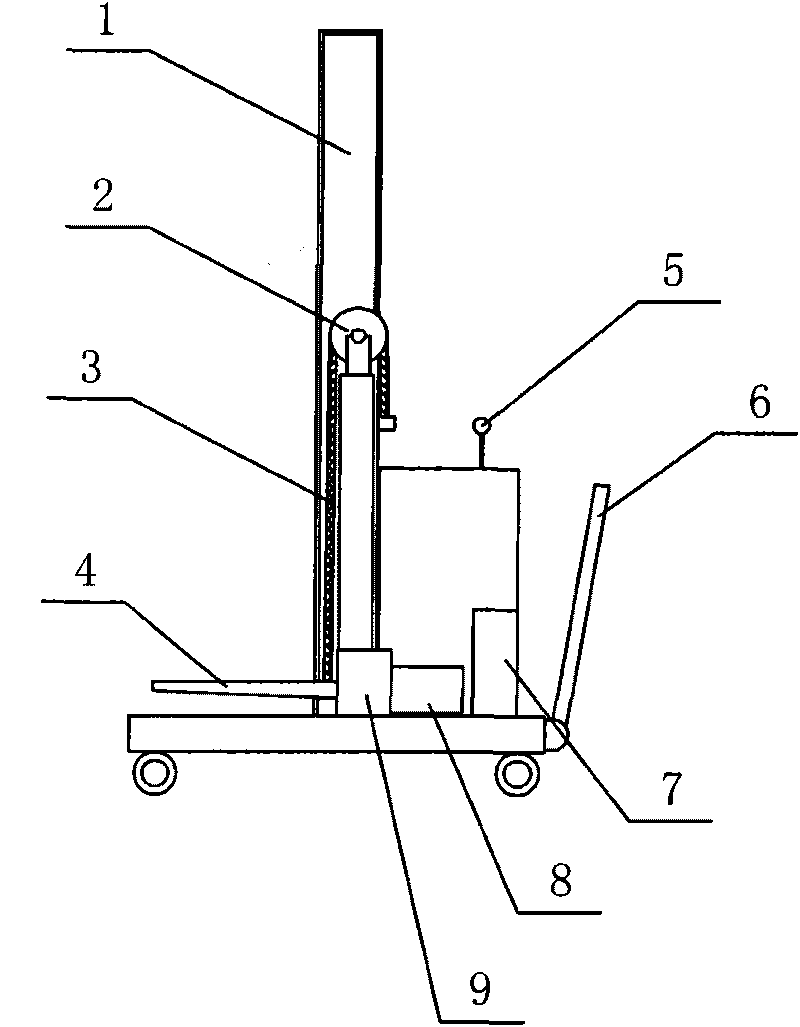

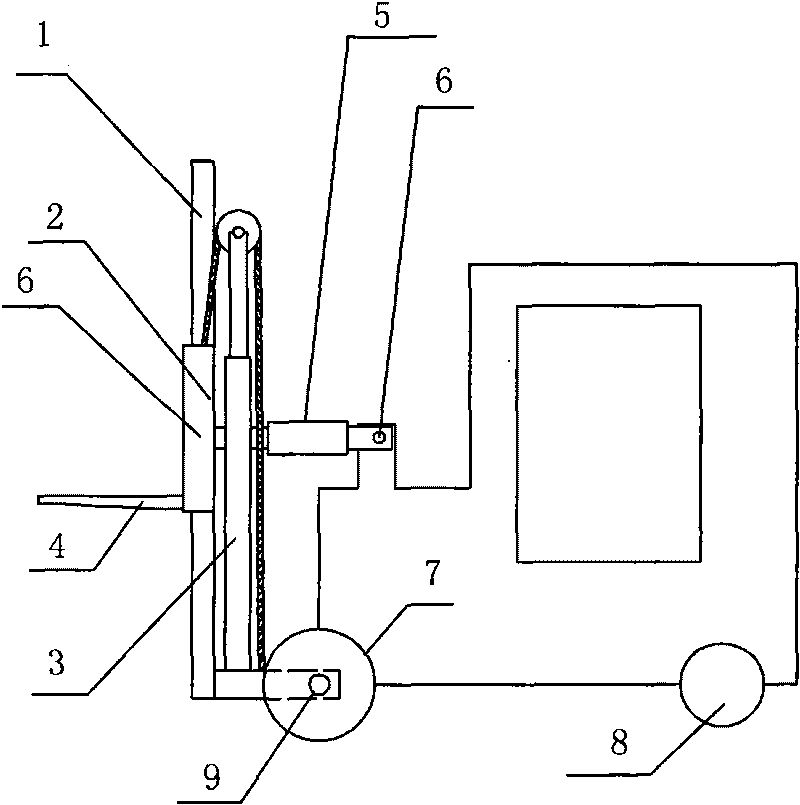

Pull type rotating double-layer parking device

ActiveCN102535905ASimple structureEasy to rotate and operateParkingsElectrical and Electronics engineeringPulley

A double-layer parking device is characterized by comprising a pair of parallelly arranged frames, a movement platform and a transmission mechanism. The movement platform comprises a seat, a platform rotatably arranged on the seat and a power device driving the platform to rotate. The pair of frames comprises an upper beam and a lower beam, a front vertical column and a rear vertical column, wherein the front vertical column and the rear vertical column are connected to two ends of both the upper beam and the lower beam. The section of the frames is in a horizontal C-shaped groove shape. The transmission mechanism comprises a power mechanism, a pair of synchronous belts driven by the power mechanism, a pair of pull rods and a pair of connecting rod mechanisms, wherein the pull rods are respectively driven by the pair of synchronous belts. A plurality of synchronous wheels are arranged on the lower beam arranged at the bottoms of the frames, the synchronous belts are arranged on the synchronous wheels, each connecting rod mechanism is two connecting rods, three connecting rods, four connecting rods or five connecting rods, one ends of the connecting rod mechanisms are hinged to the outer sides of the bottoms of the frames, and the other ends of the connecting rod mechanisms are hinged to the side portion of the seat. A limiting check block limiting connecting rods so as to enable the connecting rods to swing upwards for below 90 degrees from a horizontal state is arranged adjacent two connecting rods of the connecting rod mechanisms, and a pulley is arranged on the upper beam of the frames or at the position located below the seat opposite to the frames. Compared with the prior art, the double-layer parking device has the advantages of being simple in structure, being capable of meeting parking requirements of various fields, and enabling carport utilizing rate to reach 100%.

Owner:佛山市洋德自动化机械设备有限公司

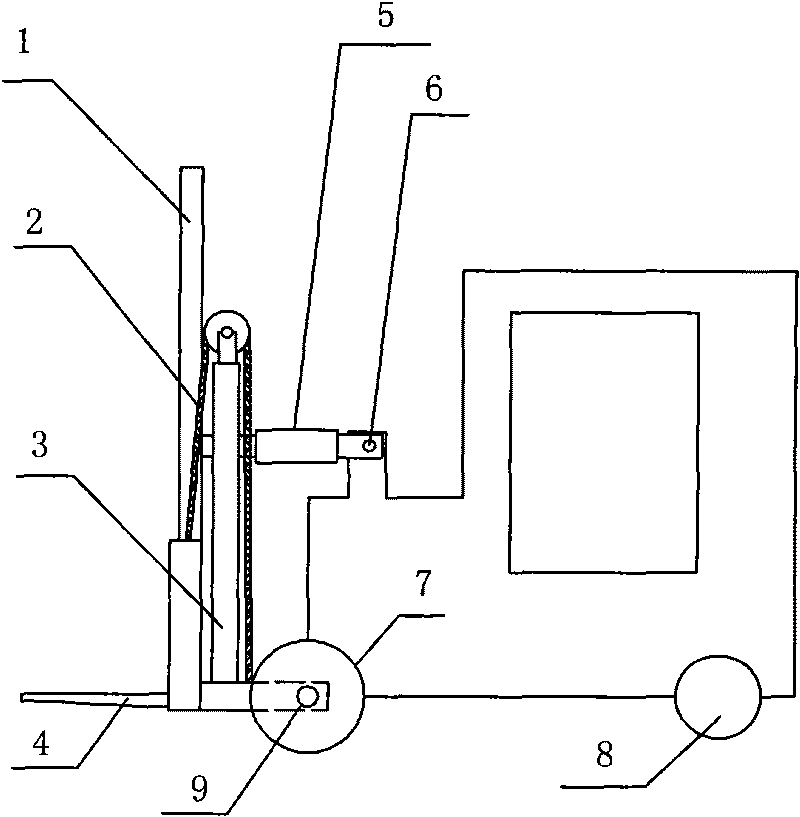

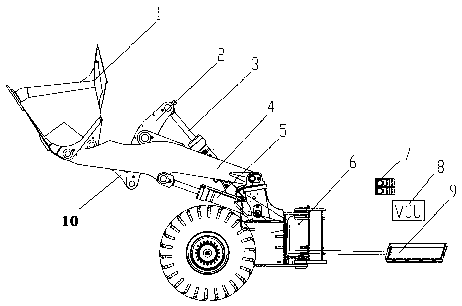

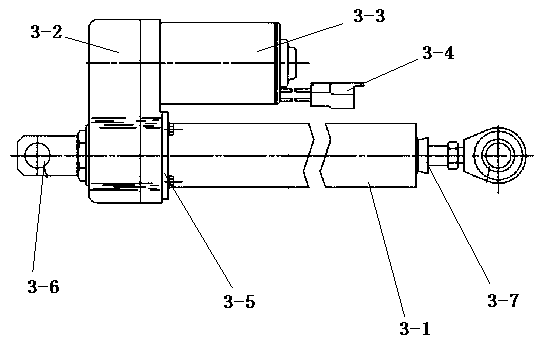

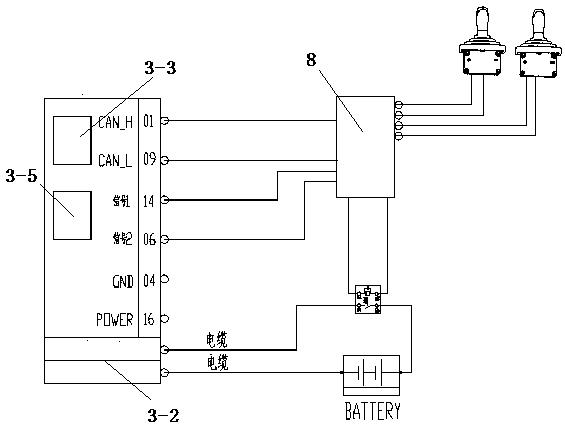

Electric control device of small-sized loader

InactiveCN103088855AImprove efficiencyDoes not consume energyMechanical machines/dredgersElectricityElectric control

The invention discloses an electric control device of a small-sized loader. The electric control device of the small-sized loader at least comprises a bucket, a loader body, an operating mechanism and a lifting mechanism of the small-sized loader, wherein the bucket is connected with the loader body through lifting arms, the lifting arms comprise a left arm, a middle arm and a right arm, and movable joints are arranged on the left arm, the middle arm and the right arm. The electric control device of the small-sized loader is characterized in that the left arm, the middle arm and the right arm are respectively connected with an electric cylinder telescopic arm, an electric cylinder is fixed with the loader body, and the electric cylinder is electrically connected with the operating mechanism. The electric control device of the small-sized loader solves the technical problems that an existing loader driving system is inconvenient to install, low in transmission efficiency, short in service life, large in running noise, and low in reliability.

Owner:QINGDAO LUDA PROJECT MACHINE MFR

Fork lifting device and electric fork truck

InactiveCN101717060AImprove efficiencyDoes not consume energyLifting devicesControl systemReduction drive

The invention relates to a fork lifting device and an electric fork truck. The fork lifting device comprises a drive motor and a motor control system, a speed reducer linked to the drive motor, an electric ball screw cylinder linked to the speed reducer, a drive sprocket and a drive chain. The electric fork truck comprises a truck body, a fork gate bracket, a control system, a vehicle-mounted storage battery and a fork lifting device. The fork lifting device and the electric fork truck have the advantages of high efficiency and long service life.

Owner:SHANXI GUOLI INFORMATION TECH

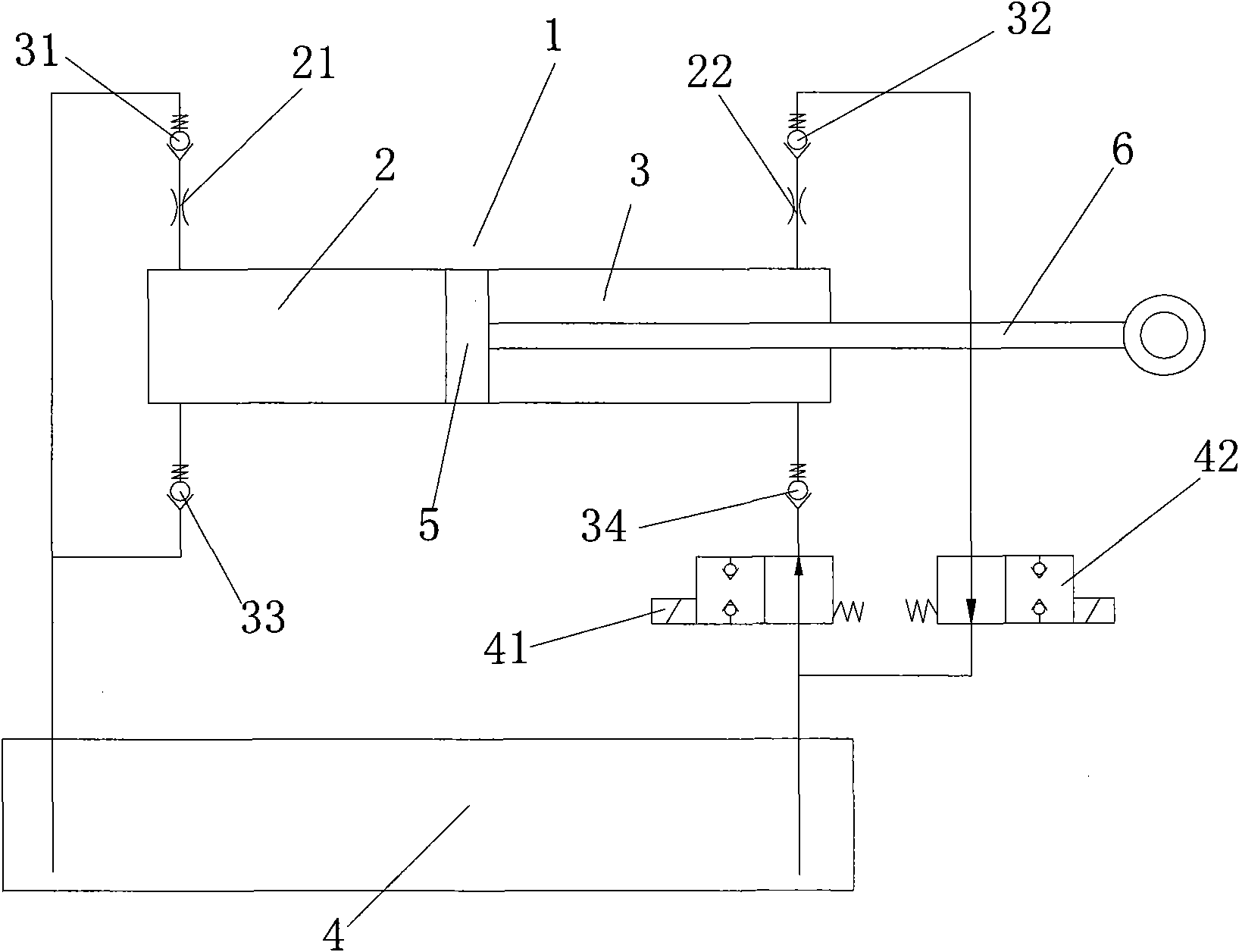

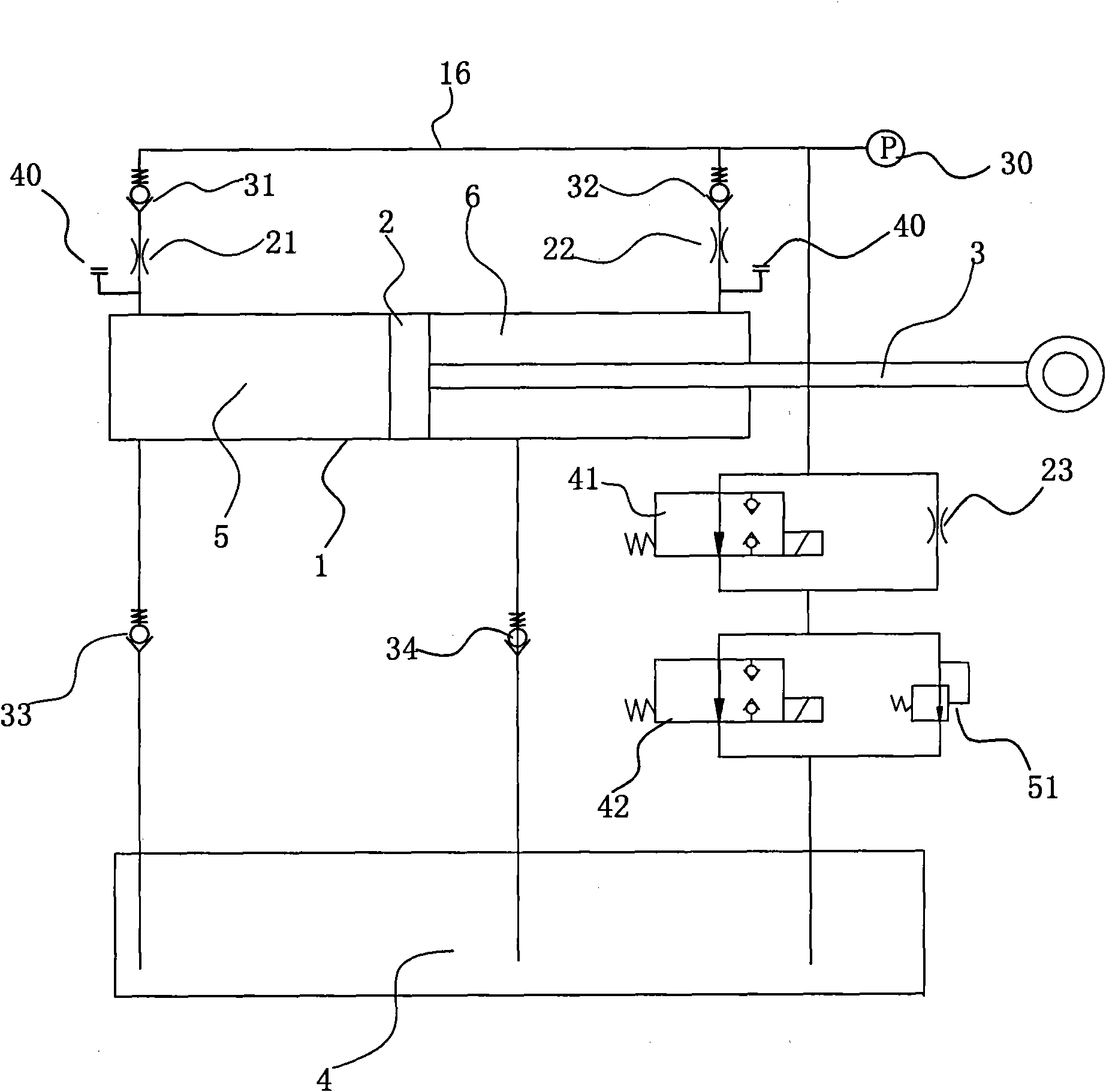

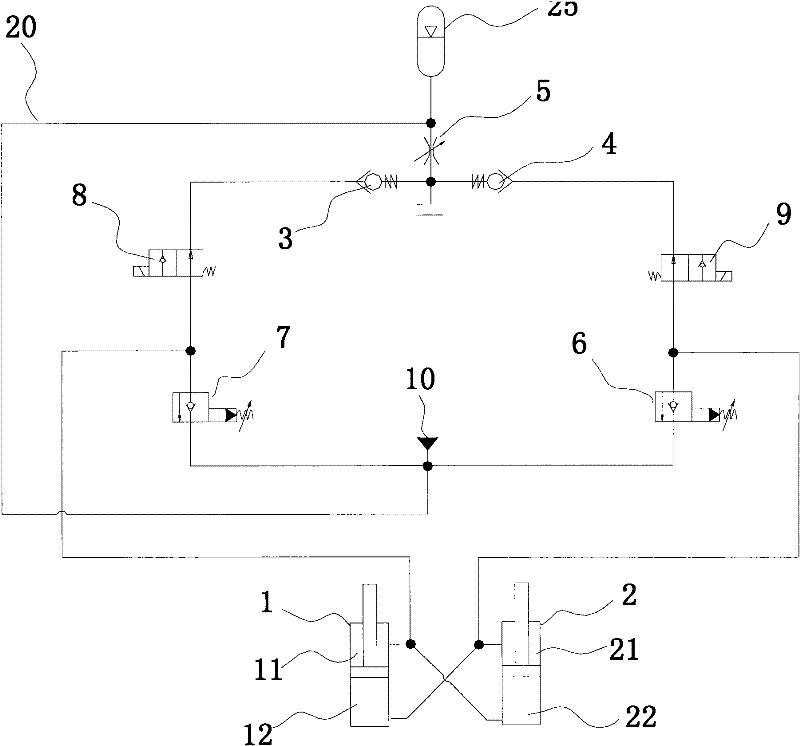

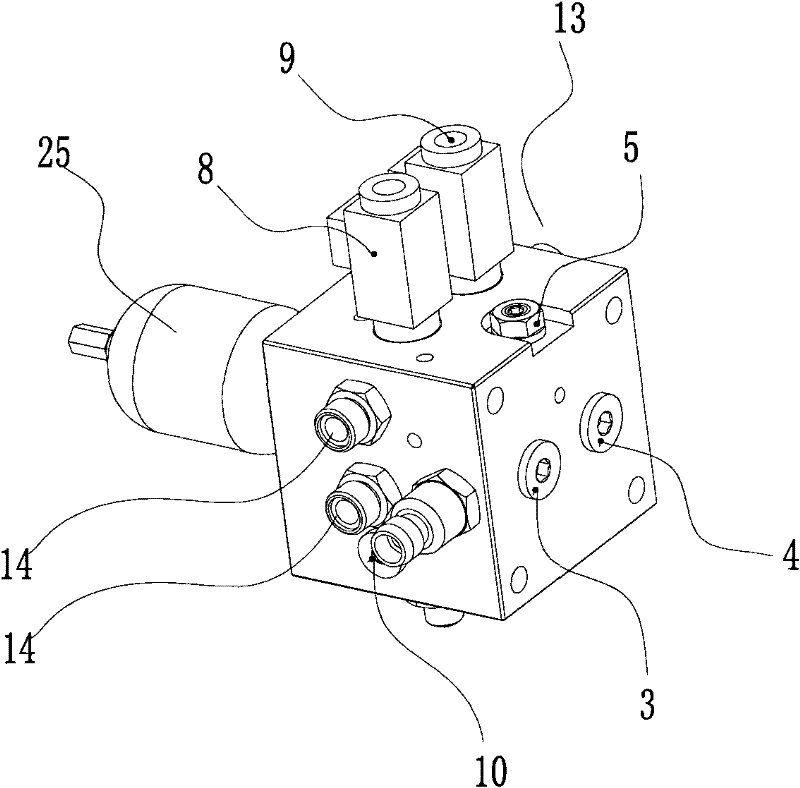

Pressurizing and locking hydraulic buffer system

ActiveCN102116332ASimple pressure controlNo oil spillsFluid-pressure actuatorsFailure rateHydraulic cylinder

The invention relates to a pressurizing and locking hydraulic buffer system, belonging to the field of hydraulic buffer. The system comprises a hydraulic cylinder and an oil storage tank, wherein the hydraulic cylinder comprises a cylinder sleeve, a piston and a piston rod; the hydraulic cylinder is divided into a first chamber and a second chamber by the piston; a first oil extraction oil line and a first oil absorption oil line are communicated by virtue of the first chamber and the oil storage tank; the pressurizing and locking hydraulic buffer system also comprises at least one overflow valve, at least one electromagnetic valve and at least one hydraulic damp; and the overflow valve and the electromagnetic valve are connected in parallel in the first oil extraction oil line and a second oil extraction oil line. The supercharging and locking hydraulic buffer system provided by the invention has the advantages of skillful design, simple and compact structure, low failure rate and good buffer effect; through setting the constant hydraulic damp, the resistance force buffer effect is achieved in proportion to the cornering speed of a vehicle; and as the overflow valve is arranged, the vehicle is enabled to be provided with the functions of super angle locking and safe protection.

Owner:JOINTECH (SUZHOU) VEHICLE SYST CO LTD

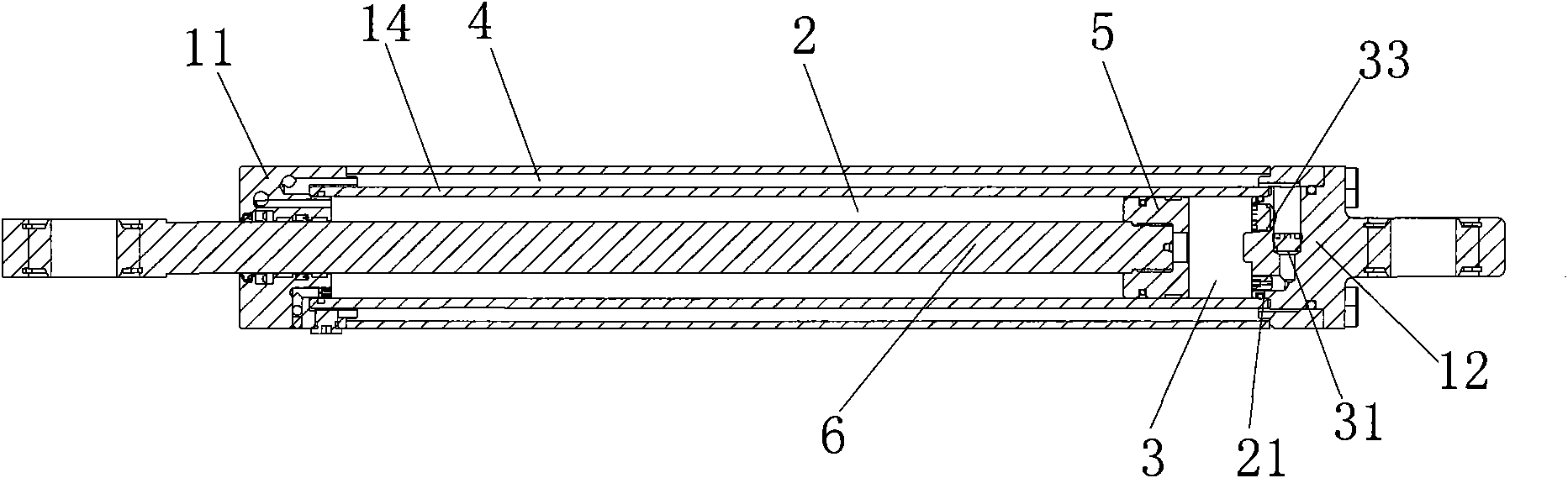

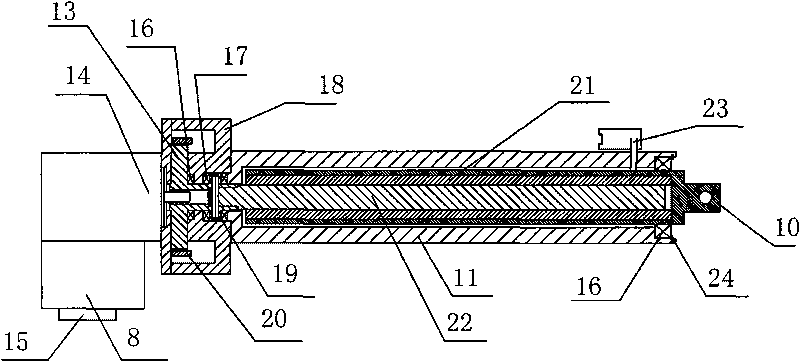

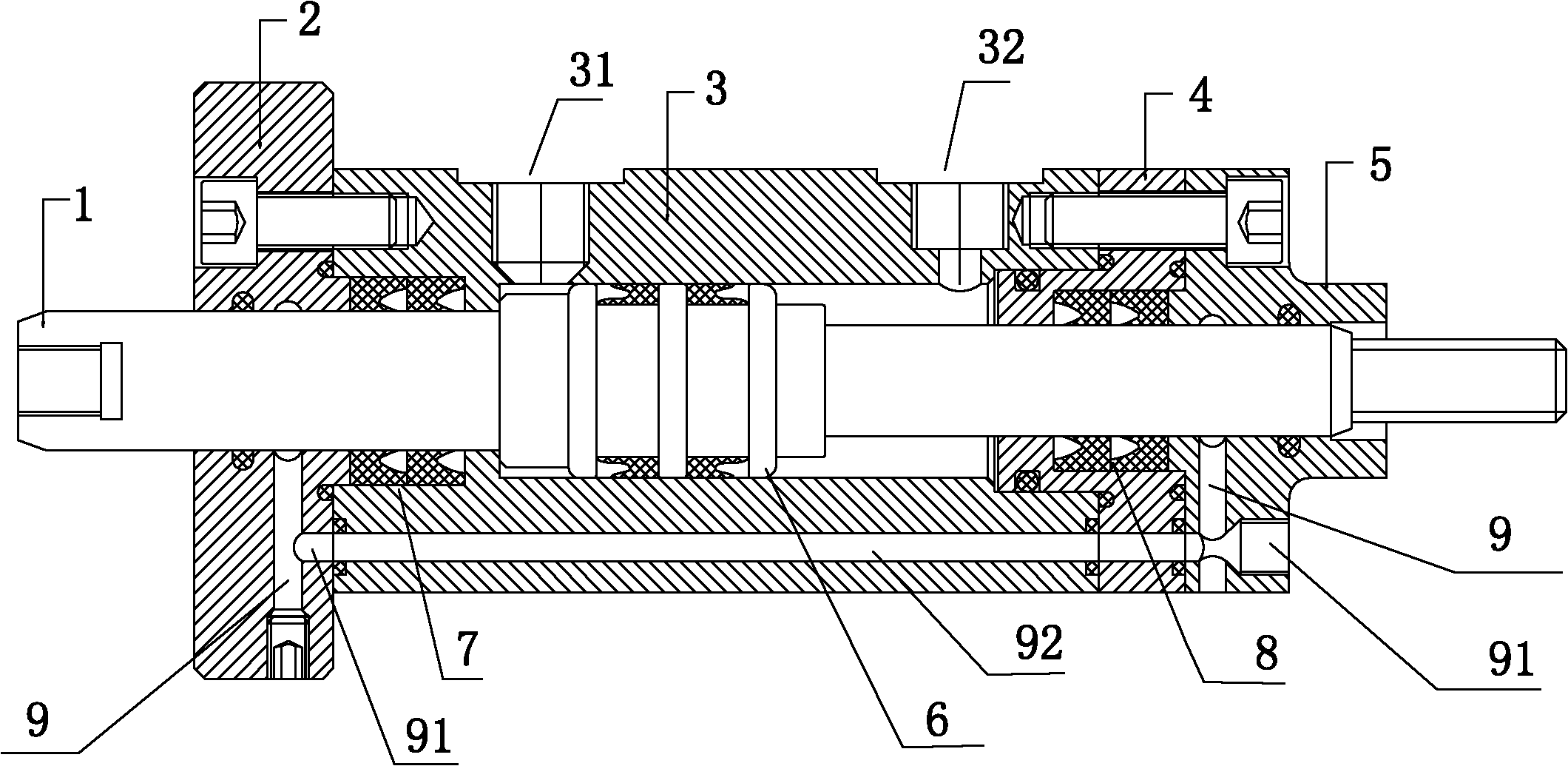

Oil cylinder

InactiveCN102108987AReduce wasteNo oil spillsFluid-pressure actuatorsFailure rateReciprocating motion

The invention discloses an oil cylinder, which includes a piston shaft, a front flange, a cylinder body, a locating sleeve, and a rear flange, wherein the front flange, the cylinder body, the locating sleeve, and the rear flange are sequentially arranged on the piston shaft in a penetrating way, and are matched and connected with each other; and a piston, which can perform reciprocating movement, is arranged in the cylinder body, and an oil inlet port and an oil outlet port are arranged on the cylinder body. By adopting the oil cylinder provided by the invention, a product and discharging oil are completely separated, the oil leakage cannot happen, the service life of the oil cylinder is prolonged, a series of problems caused by the oil leakage are solved, the finished product ratio is improved, the quality of the product is ensured, and the waste of material and the maintenance cost of the equipment are reduced; because an oil discharging channel is arranged, when a sealing part is under limiting wear, oil tightness of a shaft end can be guaranteed; the excess oil discharges from the oil discharging channel designed, so as to play a role of early warning; the oil cylinder has the advantages of simple structure, convenience in assembly, and firm combination among each component, and can ensure the machine to operate normally for a long term with small failure rate; and the oil cylinder has small and aesthetic appearance, and wide application range, and can replace the ordinary oil cylinder to use in various industries in the mechanical field.

Owner:SUZHOU DONON CARBON PRODS

Low-temperature oil-resisting nitrile rubber and preparation method and application thereof

The invention discloses low-temperature oil-resisting nitrile rubber and a preparation method application thereof, and belongs to the technical field of rubber sealing materials. The rubber is prepared from, by weight, 80-120 parts of siloxane modified butadiene-acrylonitrile rubber, 5-10 parts of zinc oxide, 0.5-1.5 parts of stearic acid, 1-3 parts of an anti-aging agent NAPM, 80-120 parts of composite reinforcing agent, 1-5 parts of composite sulfurizing agent, 1-3 parts of an accelerant and 20-40 parts of TP-90 B auxiliaries. The invention further provides the preparation method of the low-temperature oil-resisting nitrile rubber and application of the low-temperature oil-resisting nitrile rubber in an aviation sealing material. The low-temperature oil-resisting nitrile rubber has the excellent low temperature resistance and good oil resistance, has the good physical and mechanical properties and bonding strength, is applicable to the environment under the temperature of subzero 70 to 100 DEG C, achieves the purposes of onboard environment conditions and sealing non-leakage, ensures safety operation of airborne equipment, and meets the requirement for defense-related science and technology weaponry development.

Owner:青岛颐科密封材料有限公司

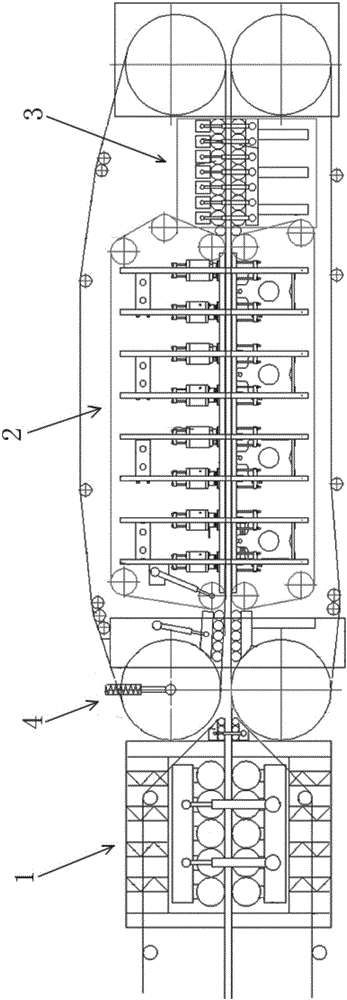

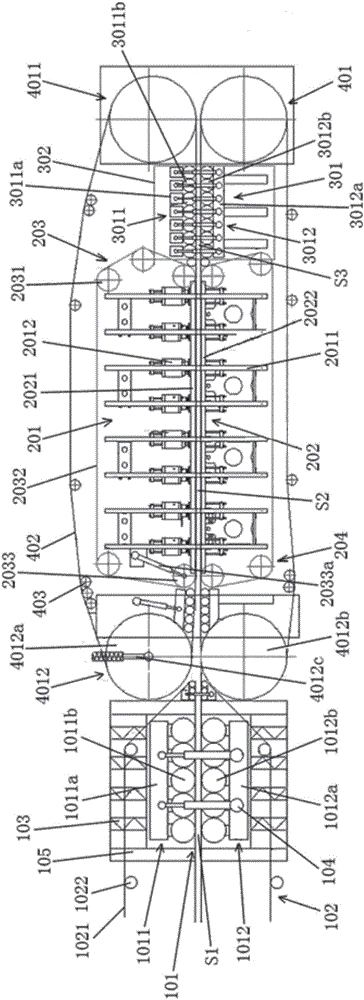

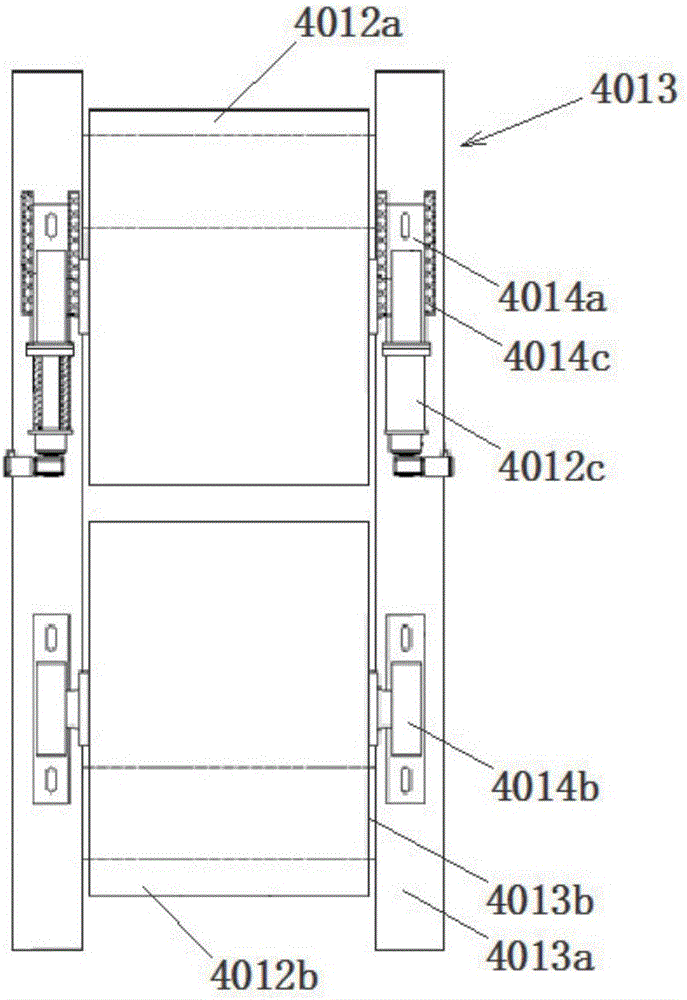

A continuous type press

PendingCN106607971ARealize continuous productionIncrease production capacityPlywood pressesVeneer pressesThermal isolationEngineering

The invention provides a continuous type press comprising a pre-heating and pressurizing unit, a heating and pressurizing unit, a cooling and pressurizing unit and a steel belt conveying unit used for connecting the heating and pressurizing unit and the cooling and pressurizing unit in series. The pre-heating and pressurizing unit comprises a first roller group mechanism used for providing pressure and a heating device used for providing non-contact heating, as well as a conveying device which is arranged between the first roller group mechanism, cooperates with the first roller group mechanism and is used for conveying mechanisms. The cooling and pressurizing unit comprises a second roller group mechanism used for providing pressure and a thermal isolation device used for maintaining the internal temperature of the cooling and pressurizing unit. The continuous type press has the advantages of low energy consumption, low cost, long service life, short production cycle, high plywood production efficiency and high forming quality.

Owner:CHINA FOMA GROUP

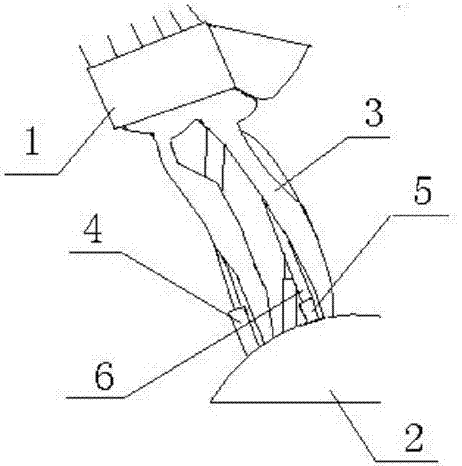

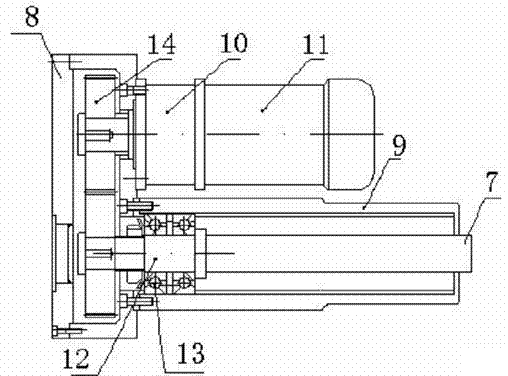

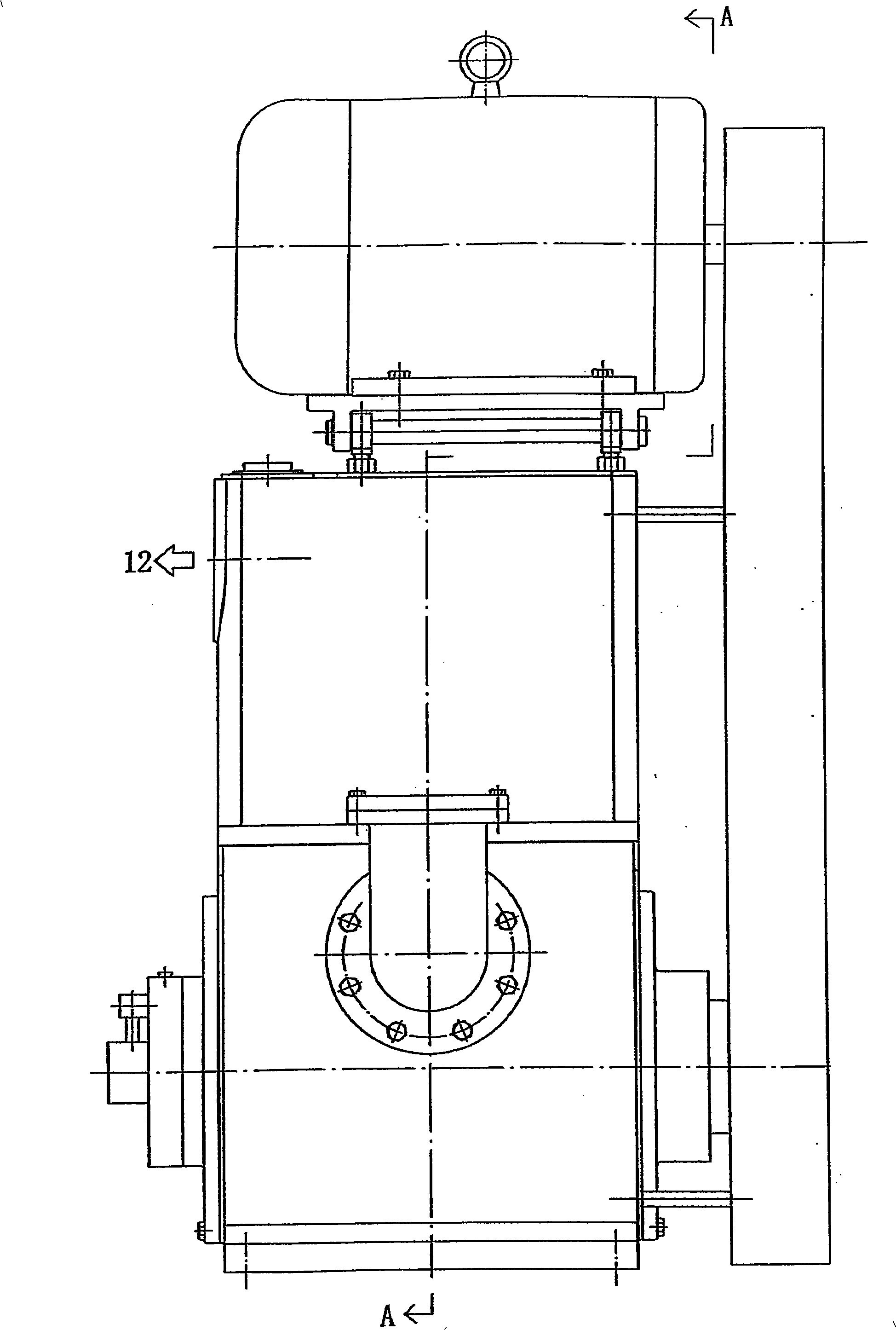

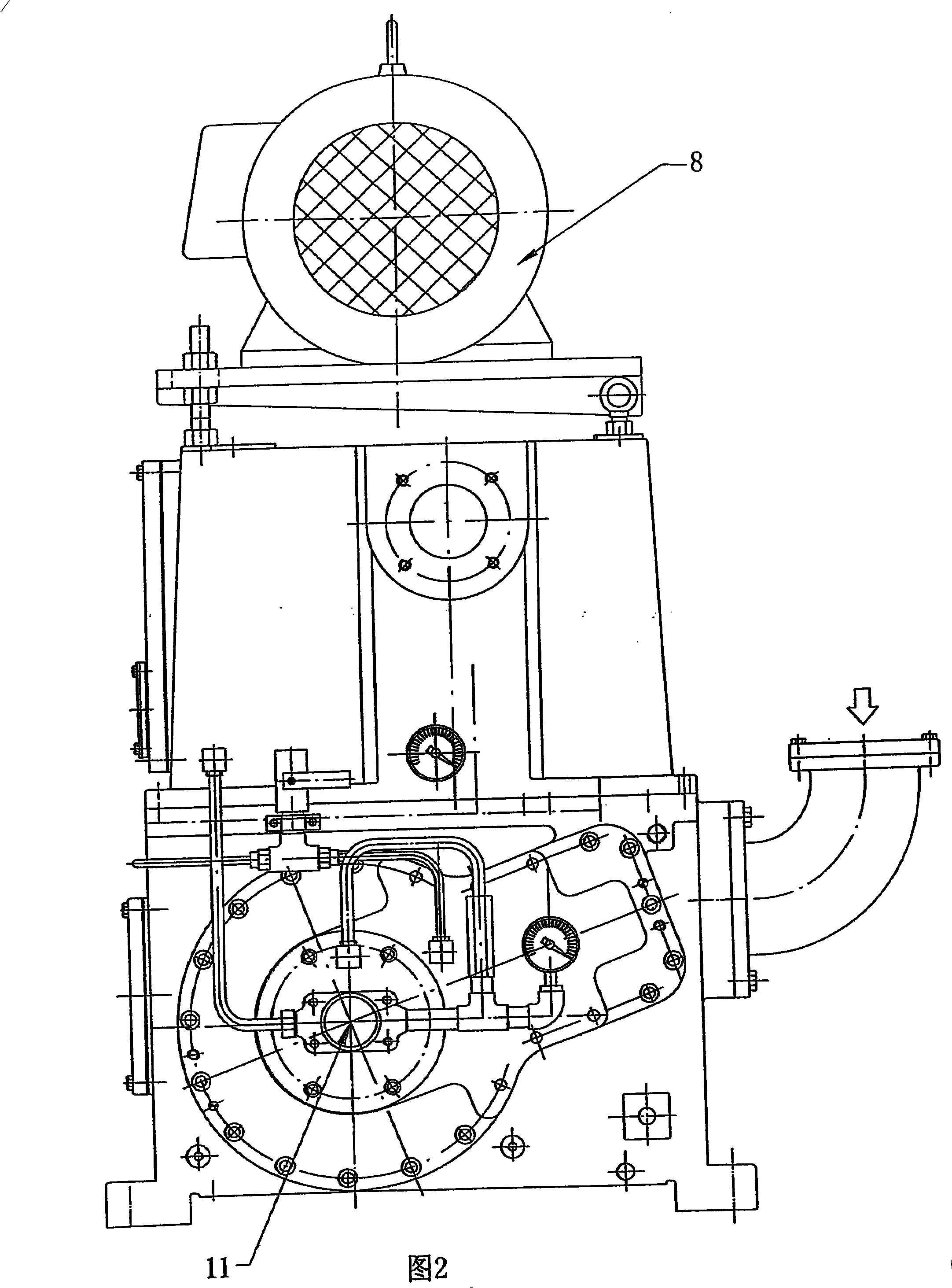

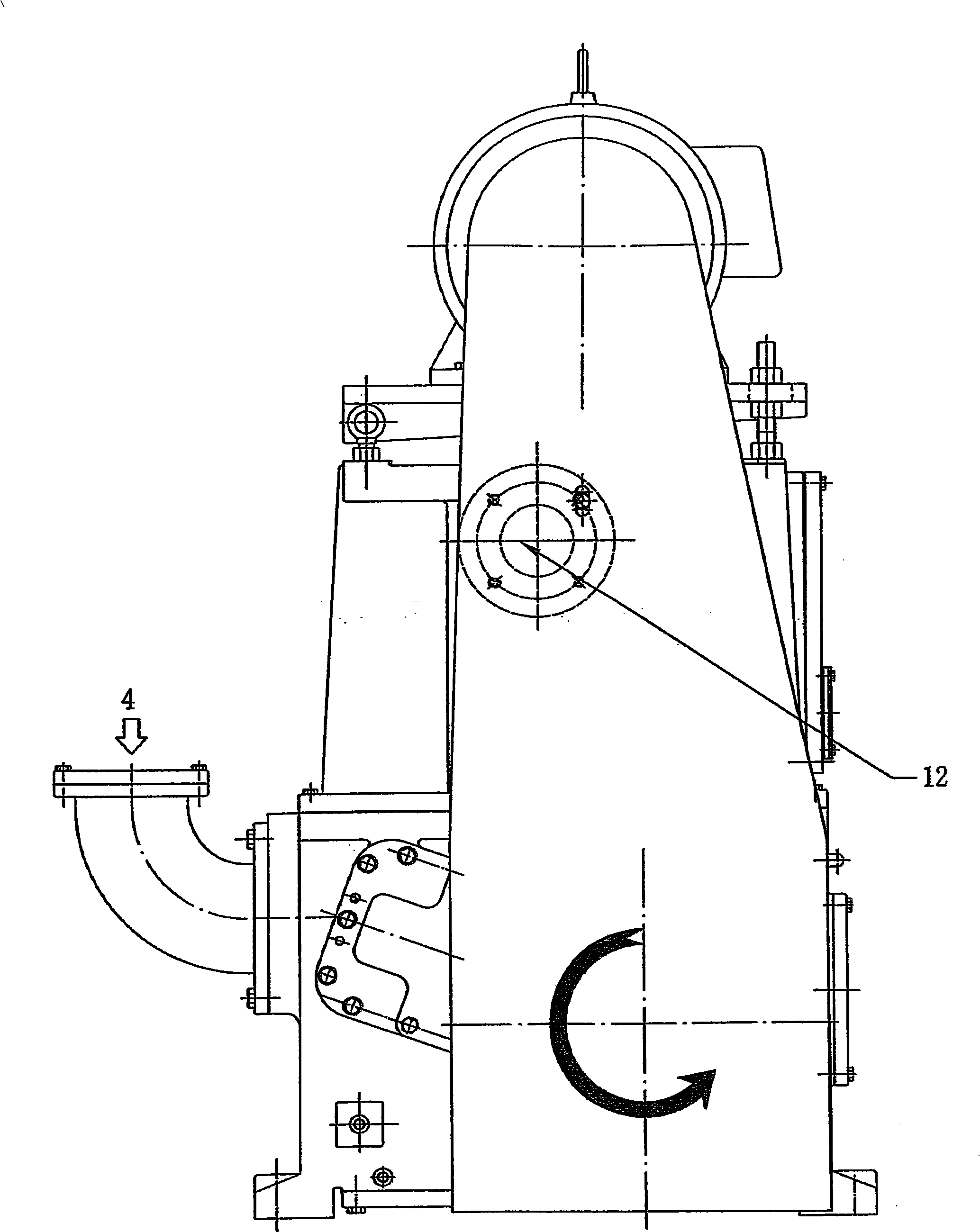

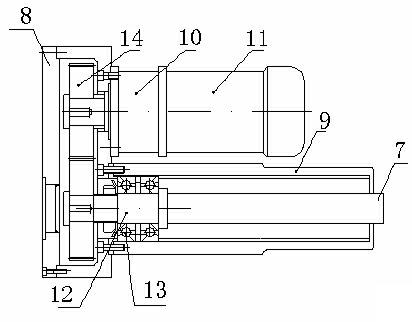

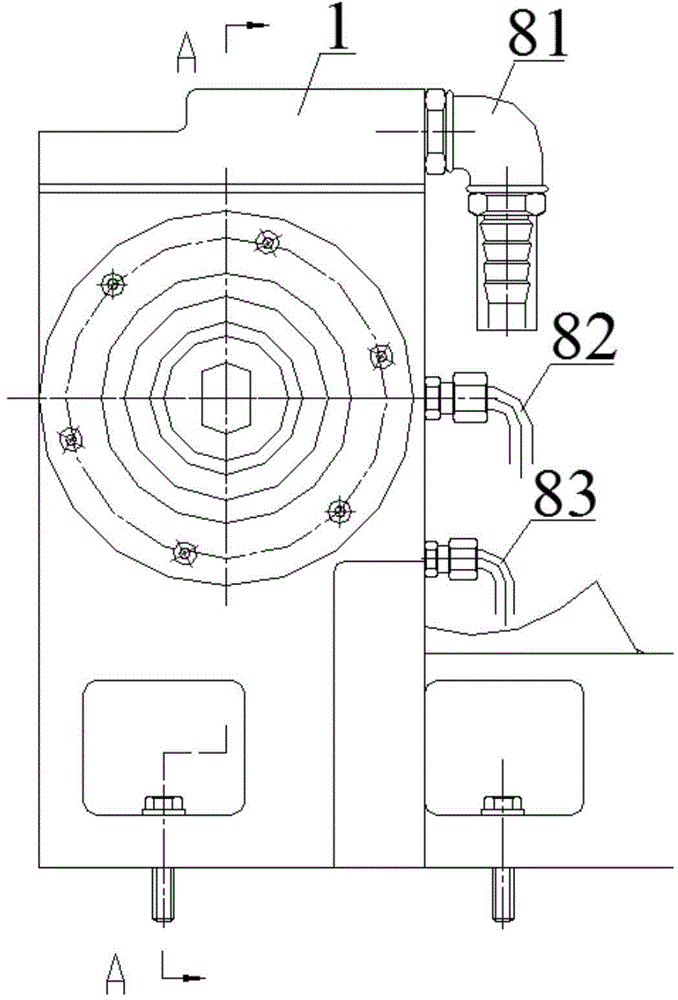

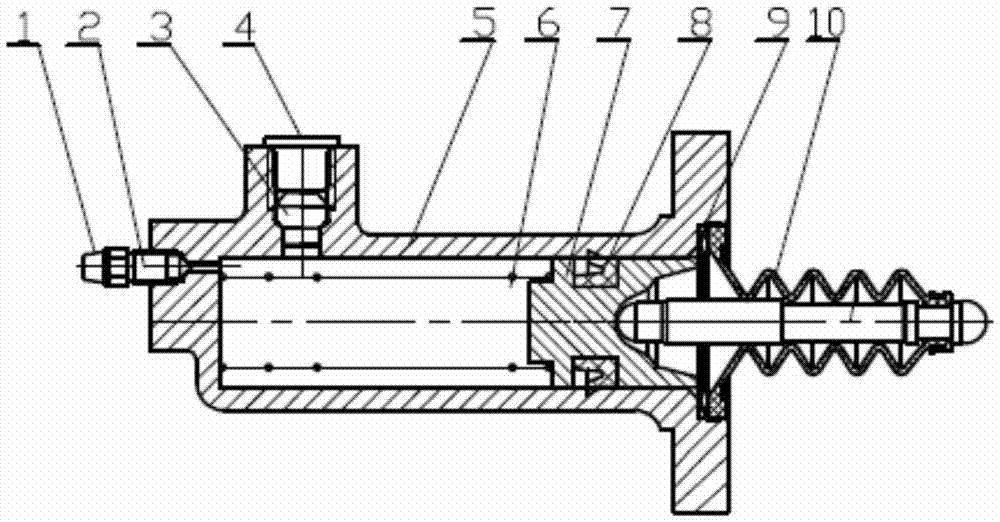

Novel non-leakage mechanical seal single-stage sliding valve vacuum pump

InactiveCN101354038AReduce coefficient of frictionExtended service lifeSealing arrangement for pumpsMachines/enginesSingle stageAlloy

The invention relates to a novel leak-free mechanically sealed single-stage slid valve vacuum pump, which is used for pumping the air etc., in a sealed container or a sealed system. The vacuum pump comprises a pump body (1); a cavity of the pump body is internally provided with a pump shaft (10); a shaft extending end lateral cover plate (1.7) is arranged on a shell wall of the pump body at the pump extending end of the pump shaft; the outer side of the shaft extending end lateral cover plate is fixedly provided with a mechanically sealed structure (14) which comprises an outer sealing receptacle (14.1), an inner sealing receptacle (14.2), a movable black lead sealing ring (14.9) and a static hard alloy sealing ring (14.8); the outer sealing receptacle (14.1) is fixedly arranged at the outer side of the shaft extending end lateral cover plate (1.7); the inner sealing receptacle (14.2), the movable black lead sealing ring (14.9) and the static hard alloy sealing ring (14.8) are closely sheathed on the shaft extending end of the pump shaft (10) in the outer sealing receptacle (14.1) from inside to outside in sequence; a plurality of springs (14.3) are evenly distributed in the circumferential direction of the inner sealing receptacle; the springs are arranged between a step surface of an inner hole of the inner sealing receptacle and the movable black lead sealing ring. The vacuum pump of the invention has simple sealing structure, good reliability, long service life and no oil leakage and air leakage happening.

Owner:JIANGYIN TIANTIAN VACUUM EQUIP

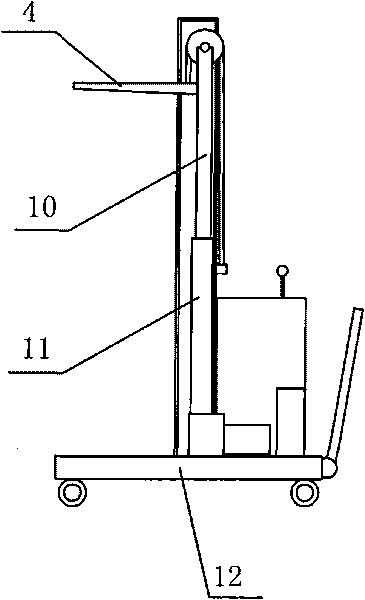

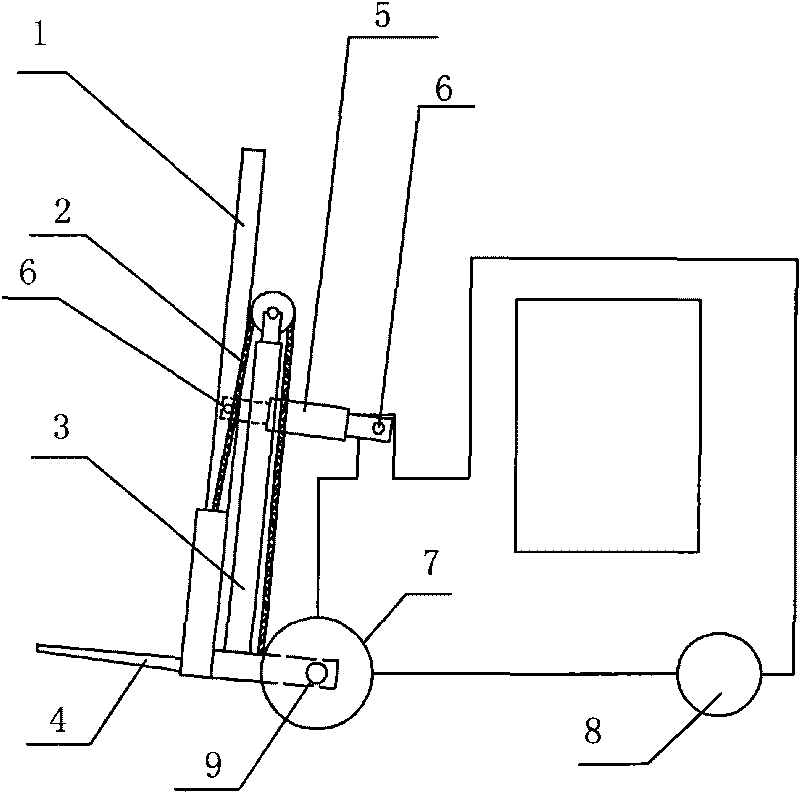

High-efficiency energy-saving forklift hoisting mechanism

ActiveCN101955140AImprove efficiencyDoes not consume energyLifting devicesHydraulic cylinderHeadframe

The invention relates to a battery forklift, in particular to a high-efficiency energy-saving forklift hoisting mechanism. The mechanism at least comprises a forklift body, a fork frame connected at the front end of the forklift body, forks and a guide frame, wherein the fork frame and the guide frame are in sliding connection through a guide groove; two horizontal forks on the left and right are in sliding connection with the fork frame through fork rods; the upper end of the guide frame is connected to the upper end of the forklift body through a left front boom drive cylinder and a right front boom drive cylinder, and the lower end of the guide frame is fixed on the chassis of the fork body; and the fork frame slides and moves up and down in the guide groove along the guide frame under the driving of a transmission belt / chain. The forklift hoisting mechanism is characterized in that: the lower end of a transverse lift rod is vertically fixedly connected with pull rods of electric cylinders; and the electric cylinders are fixed bilaterally symmetrically to the center of the guide frame. The forklift hoisting mechanism adopts an electric ball screw to replace a fork drive cylinder, a rotating cylinder of the booms, a steering cylinder, a fork transverse moving cylinder and other hydraulic cylinders of the battery forklift.

Owner:SHANXI GUOLI INFORMATION TECH

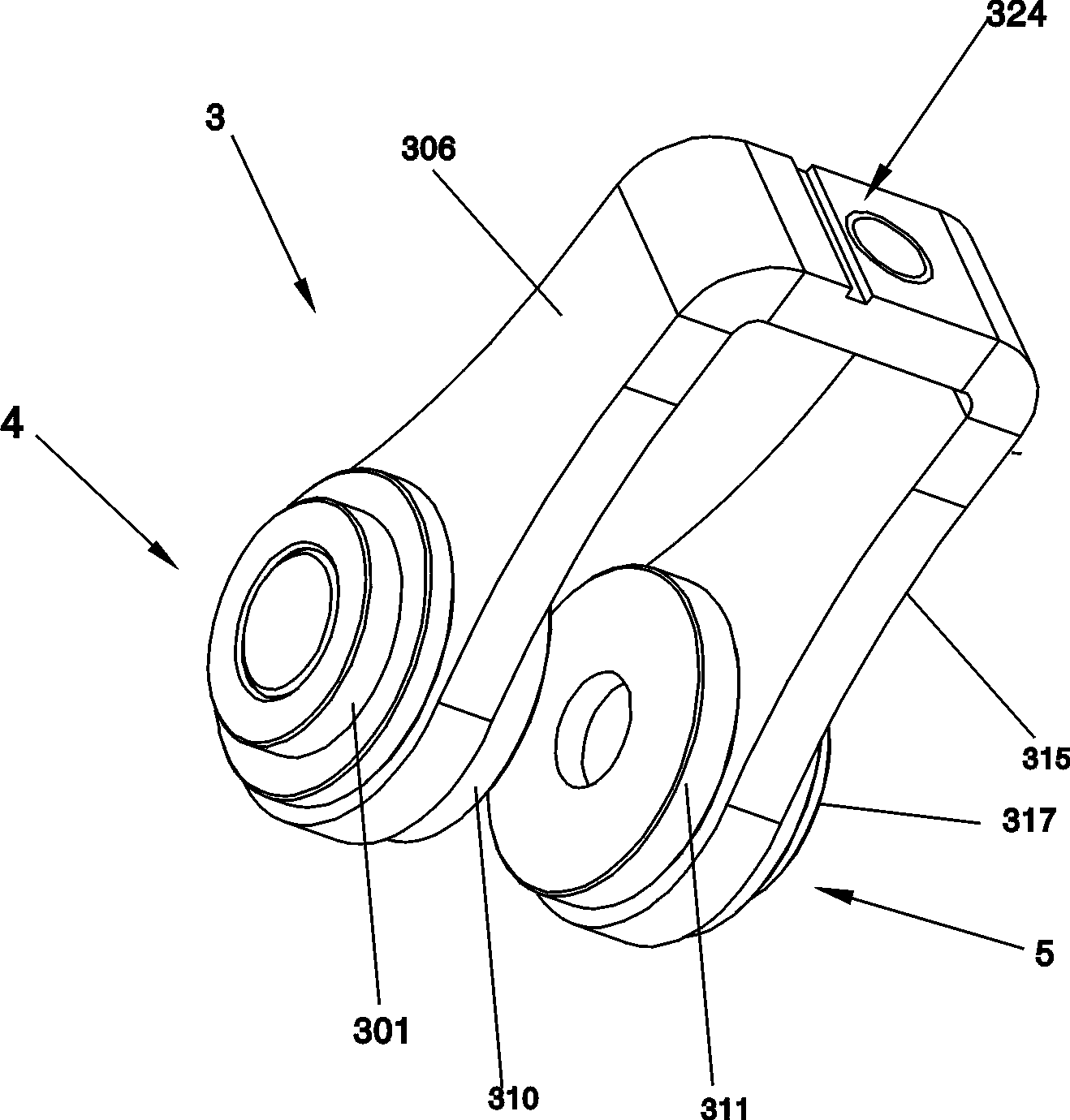

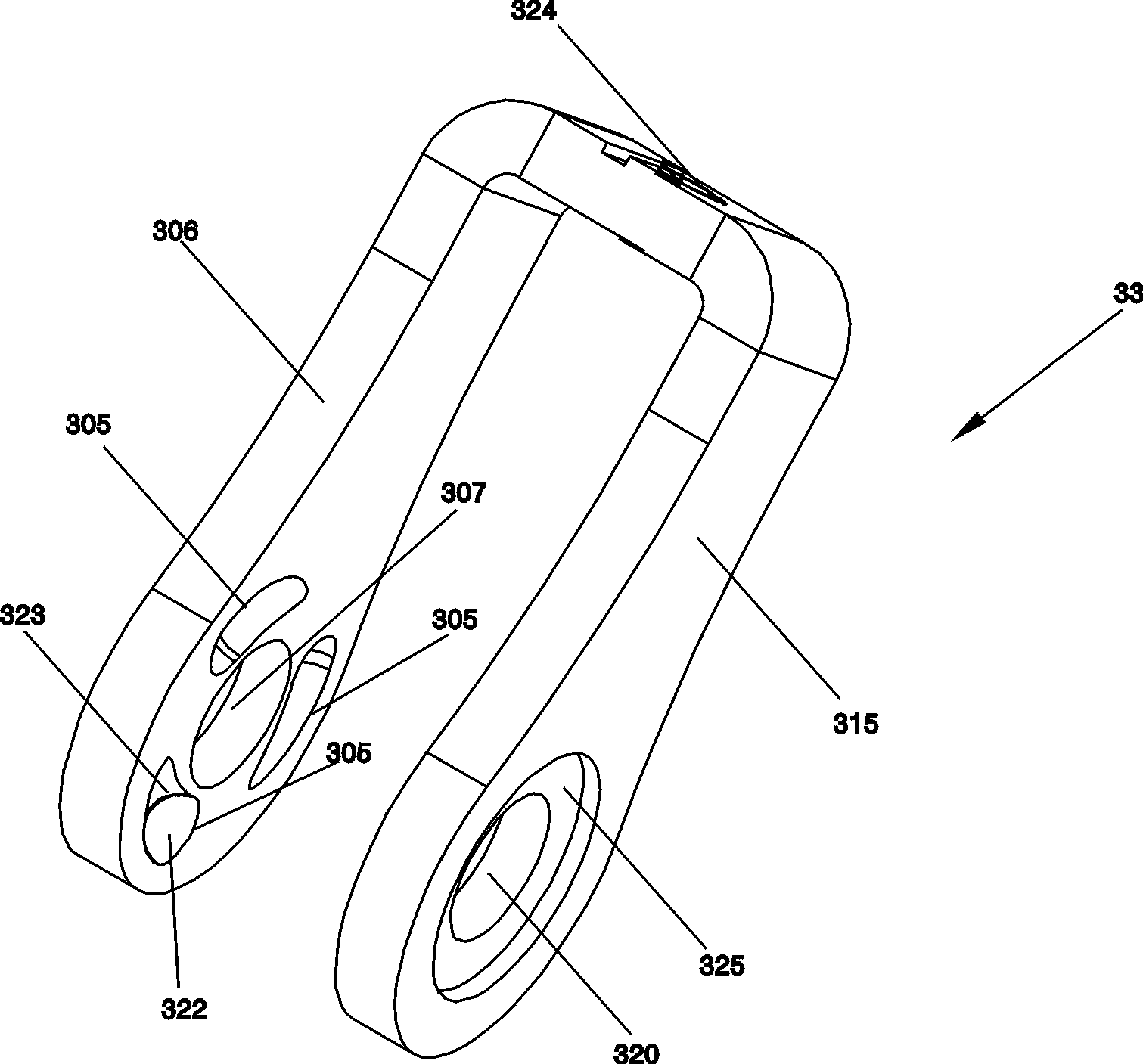

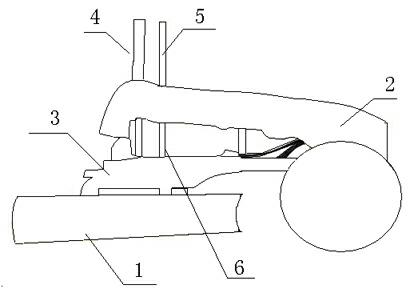

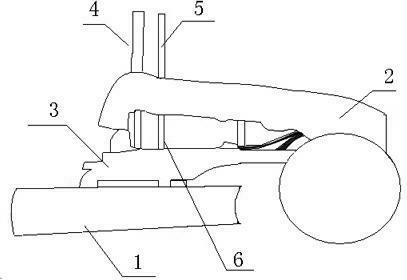

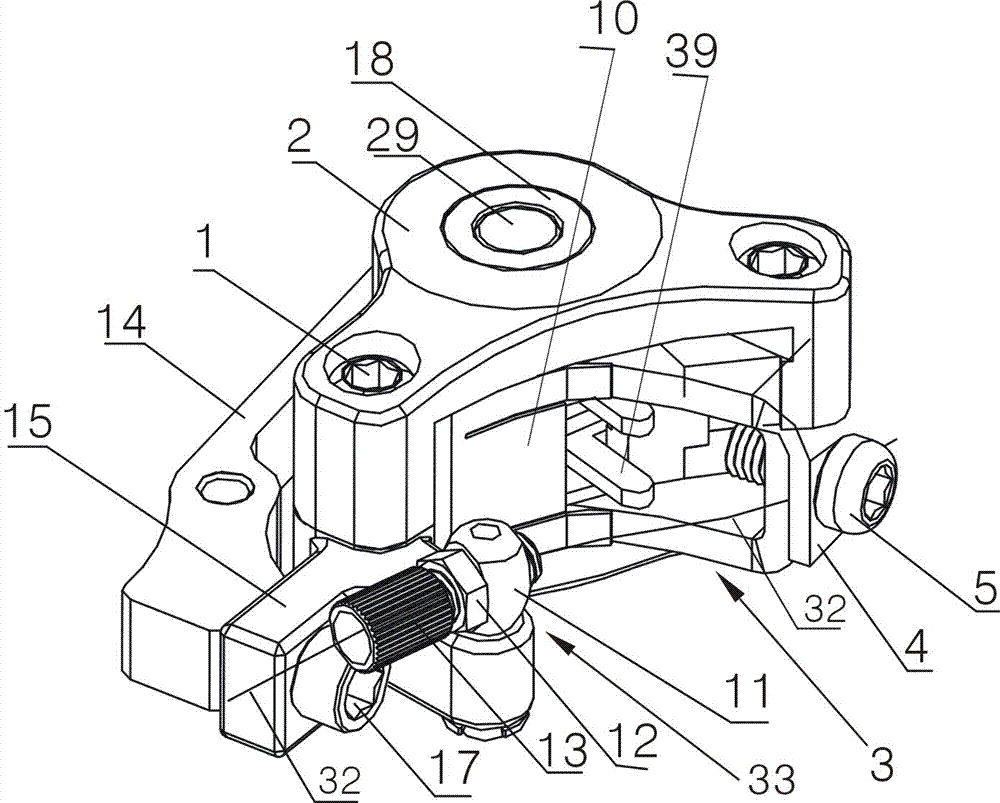

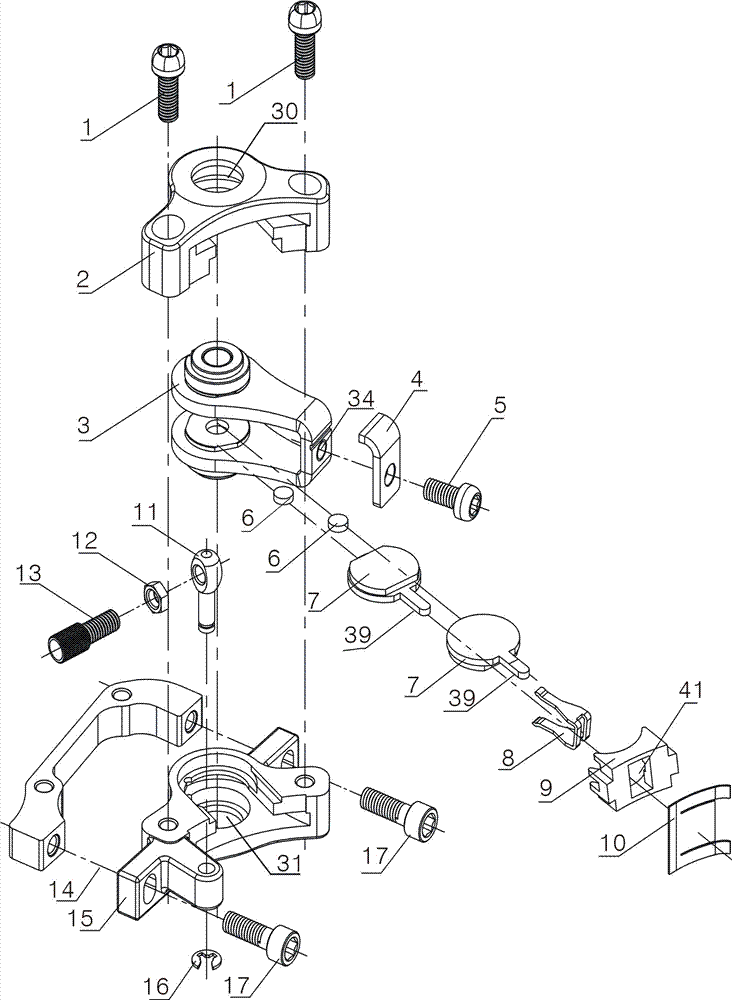

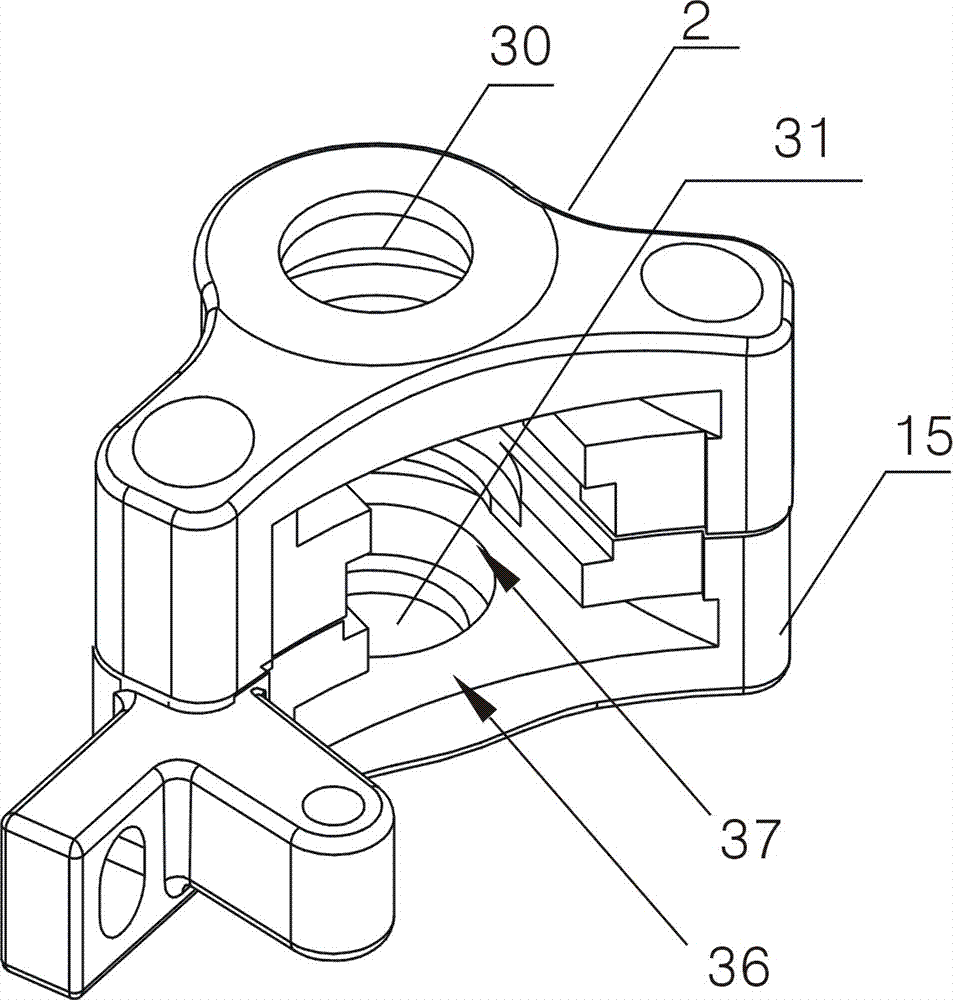

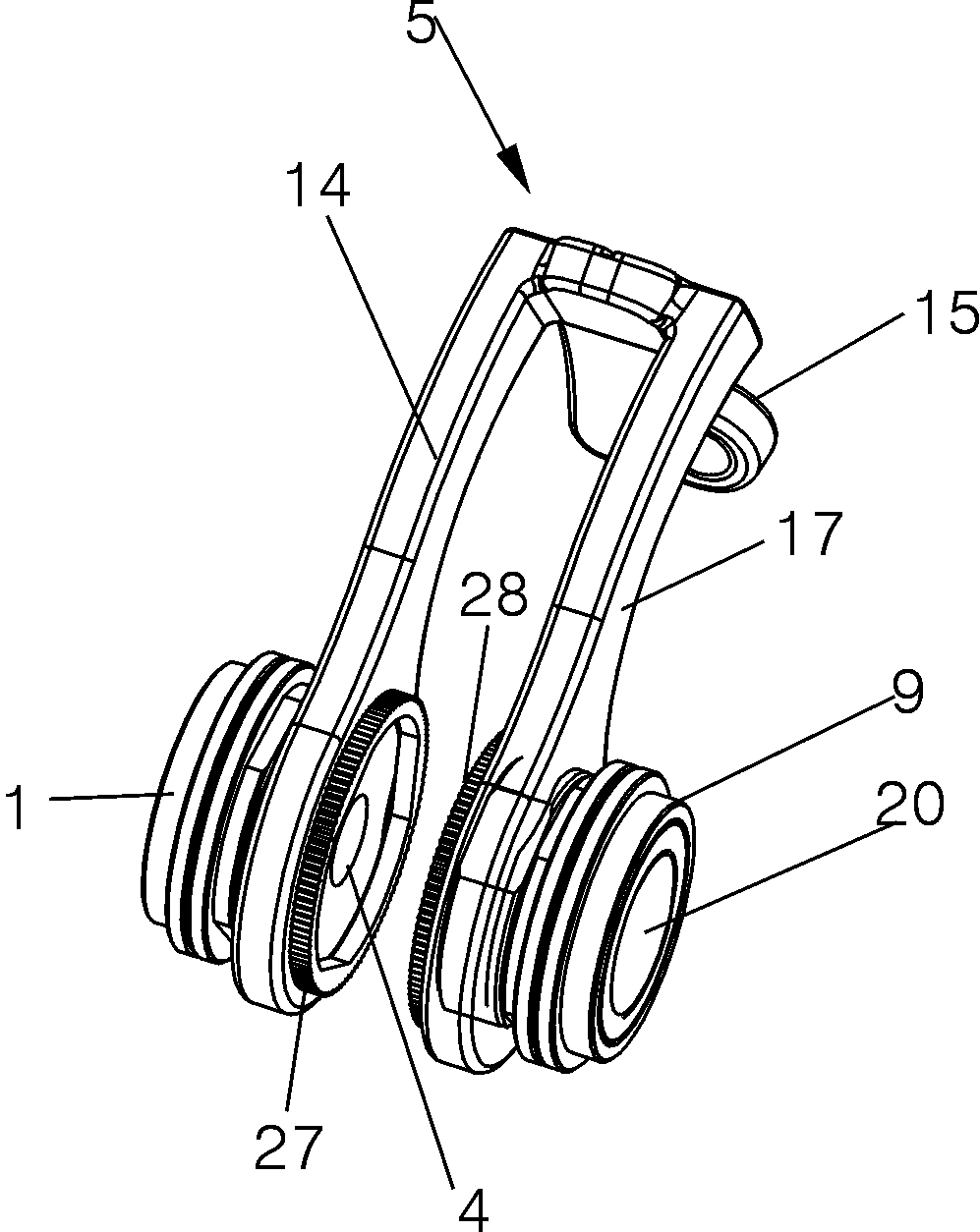

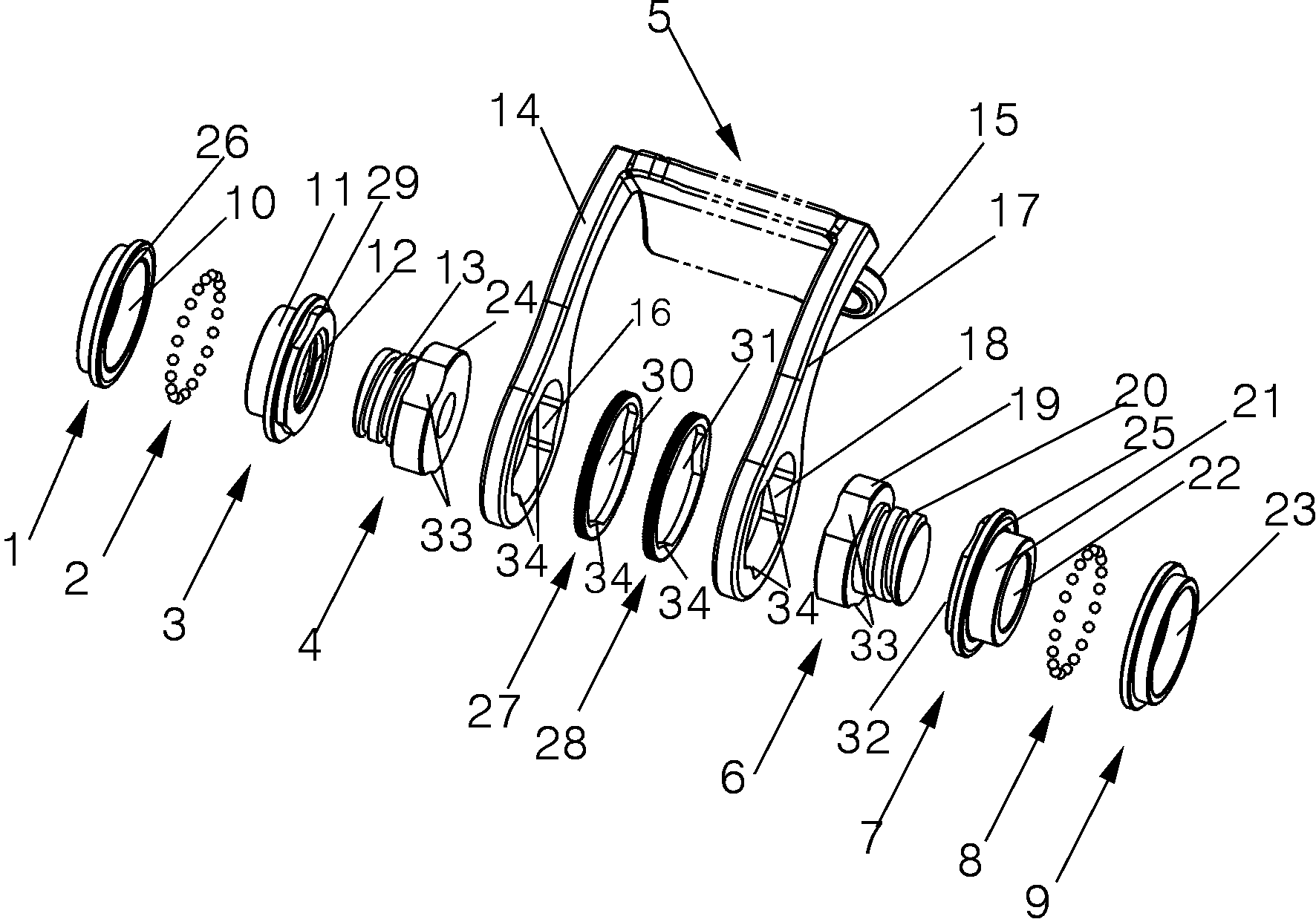

Brake device used for mechanical disc brake of bicycle

The invention relates to a brake device used for a mechanical disc brake of a bicycle. The brake device comprises a double-shaft connecting rod, wherein a brake cable connecting part is arranged at the upper part of the double-shaft connecting rod; a first shaft arm and a second shaft arm both in same structure are connected to the two sides of the brake cable connecting part respectively; a first shaft arm hole and a second shaft arm hole are formed in the lower ends of the first shaft arm and the second shaft arm respectively; a first brake component and a second brake component in the same structure are mounted in the first shaft arm hole and the second shaft arm hole respectively. The brake device is mounted in the mechanical disc brake and can realize bilateral braking, a disc plate is enabled to be not deformed easily, a brake pad is abraded hardly, and a good braking effect is achieved. A bilateral braking effect with an oil pressure is achieved, and an oil leakage phenomenon is avoided. The cost is low, and the structure is simple and practical.

Owner:邳州绍鼎电子科技有限公司

Brake device for mechanical disc brake of bicycle

The invention relates to a brake device for a mechanical disc brake of a bicycle. The brake device comprises a double-shaft connecting rod, a first brake component and a second brake component, a brake cable connecting portion is arranged at the upper end of the double-shaft connecting rod, two sides of the brake cable connecting portion are connected with a first shaft arm and a second shaft arm respectively, a first shaft arm hole and a second shaft arm hole are formed in the lower ends of the first shaft arm and the second shaft arm respectively, and the first brake component and the second brake component are arranged in the first shaft arm hole and the second shaft arm hole respectively. The brake device is mounted in the mechanical disc brake, can realize bilateral brake, is fine in braking effect, low in cost and simple and practical in structure and has hydraulic bilateral brake effects, a disc does not easily deform, a brake pad is not easily abraded, labor is saved, and oil leakage is avoided.

Owner:谢绍利

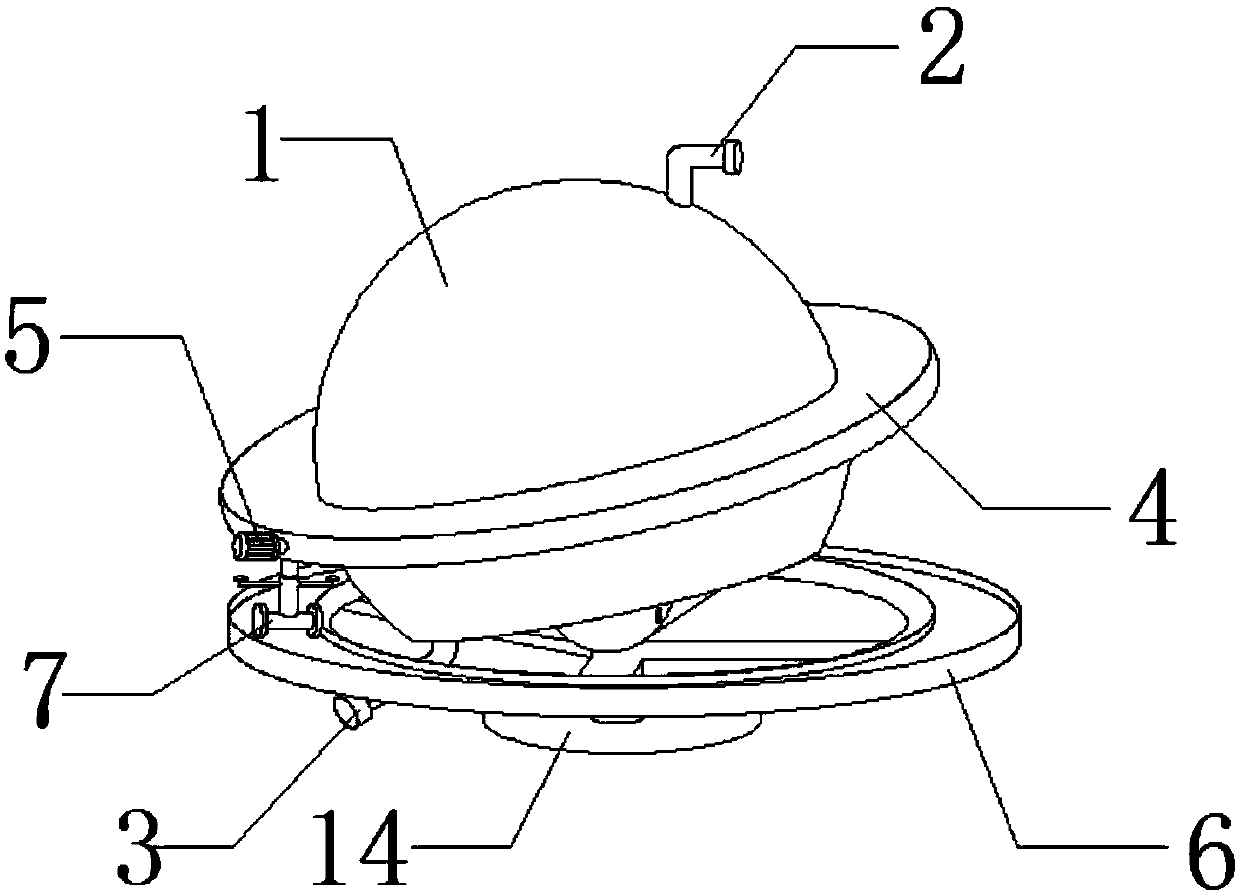

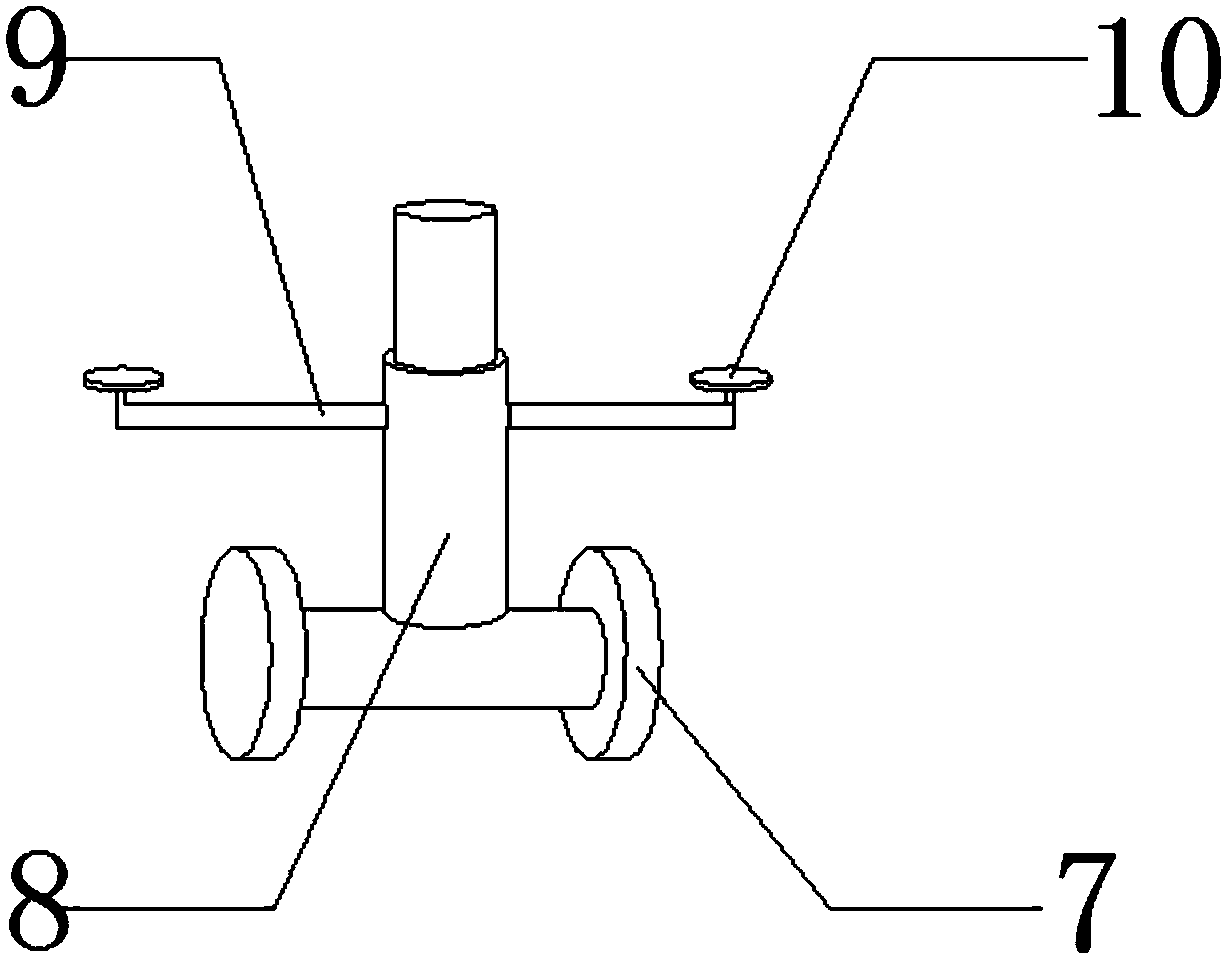

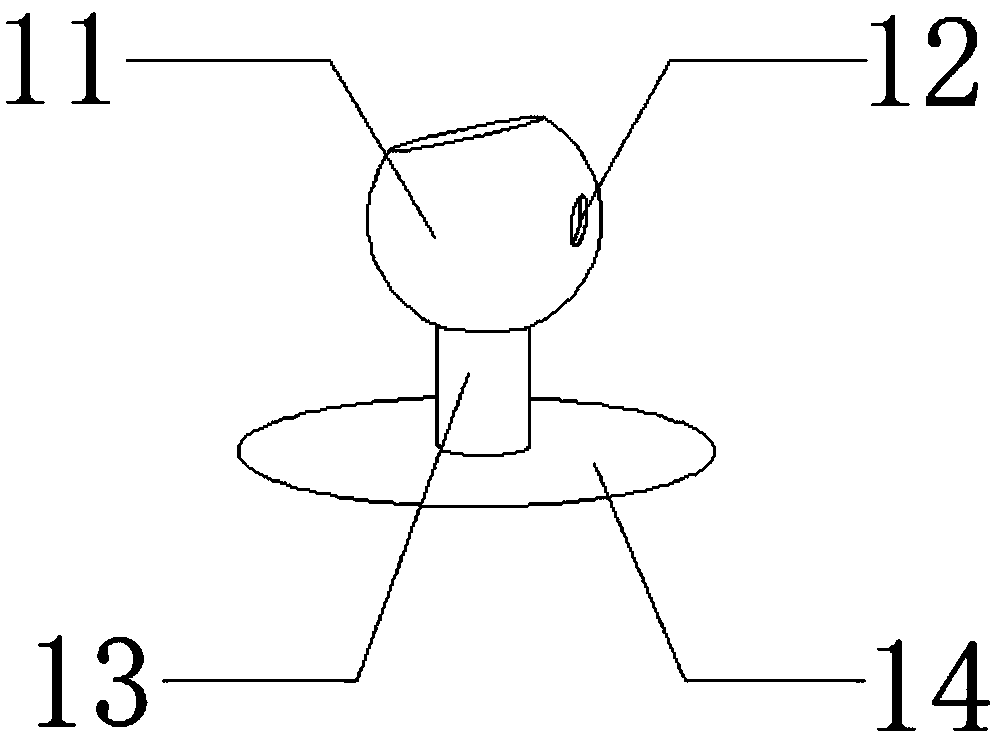

Storing device for petroleum refining

InactiveCN108045721APrevent precipitationIncrease production costShaking/oscillating/vibrating mixersHollow article cleaningAsphaltene precipitationPetroleum

The invention discloses a storing device for petroleum refining. The storing device comprises an oil storing barrel, an oil inlet, an oil outlet, a fixing ring, a motor, a track, rolling wheels, a rotating rod, a transverse rod, a turning wheel, a connecting ball, a water through opening, a supporting rod, a base and a spraying head. The storing device has the beneficial effects that the fixing ring is welded to the outer wall of the oil storing barrel, the oil storing barrel is supported through the supporting rod, the track is mounted on the outer wall of the supporting rod, the fixing ringis connected with the track through the rotating rod provided with the rolling wheels, and a motor controls the rolling wheels to rotate; during motor starting, the rolling wheels circle the track, and the oil storing barrel is driven to slowly wobble, so that the situation that internal asphaltene is precipitated when being subjected to still standing for a certain time after petroleum is collected out, and the production cost of petroleum refining is improved are prevented; besides, the whole oil storing barrel is of an integral spherical structure, a spliced mounting mode is avoided, and oil leakage is avoided after the petroleum enters; and the storing device has the characteristics of reducing the refining cost and being convenient to clean.

Owner:佛山市万良商贸有限公司

Full electric forklift

InactiveCN101734577AImprove efficiencyDoes not consume energyLifting devicesEngineeringEnergy conversion efficiency

The invention relates to a full electric forklift, comprising a vehicle-mounted storage battery, a forklift drive device, a front upper arm rotating device, a forklift traverse drive device and a steering gear. The invention solves the technical problems of inconvenient installation, low transmission efficiency, low service life, high operation noise and low reliability of the existing battery forklift due to the adoption of a hydraulic drive system. The full electric forklift of the invention has the advantages of high conversion efficiency, long service life, no pollution to environment and low manufacture cost and the like.

Owner:SHANXI GUOLI INFORMATION TECH

Constant pressure damping control and buffering system

ActiveCN102444687ANo stuckNo electrical system failureSpringsShock absorbersHydraulic cylinderTurn angle

The invention relates to a constant pressure damping control and buffering system, which belongs to the technical field of hydraulic buffering, and includes a first hydraulic cylinder and a second hydraulic cylinder, as well as a first one-way valve, a second one-way valve, a first one-way overflow valve, a second one-way overflow valve and a pressure regulating valve, wherein a second hydraulic cylinder rodless cavity, a first hydraulic cylinder rod chamber, a first one-way valve, the pressure regulating valve, the first one-way overflow valve, a second hydraulic cylinder rod chamber and a first hydraulic cylinder rodless cavity are sequentially connected in series to form a first oil circuit; and the first hydraulic cylinder rodless cavity, the second hydraulic cylinder rod chamber, the second one-way valve, the pressure regulating valve, the second one-way overflow valve, the first hydraulic cylinder rod chamber and the second hydraulic cylinder rodless cavity are sequentially connected in series through a pipeline to form a second oil circuit. The constant pressure damping control and buffering system has unique design, low manufacturing cost, convenience for maintenance, excellent buffering effect, and the functions of locking and safety protection in case that the turning angle of vehicle is too big.

Owner:JOINTECH (SUZHOU) VEHICLE SYST CO LTD

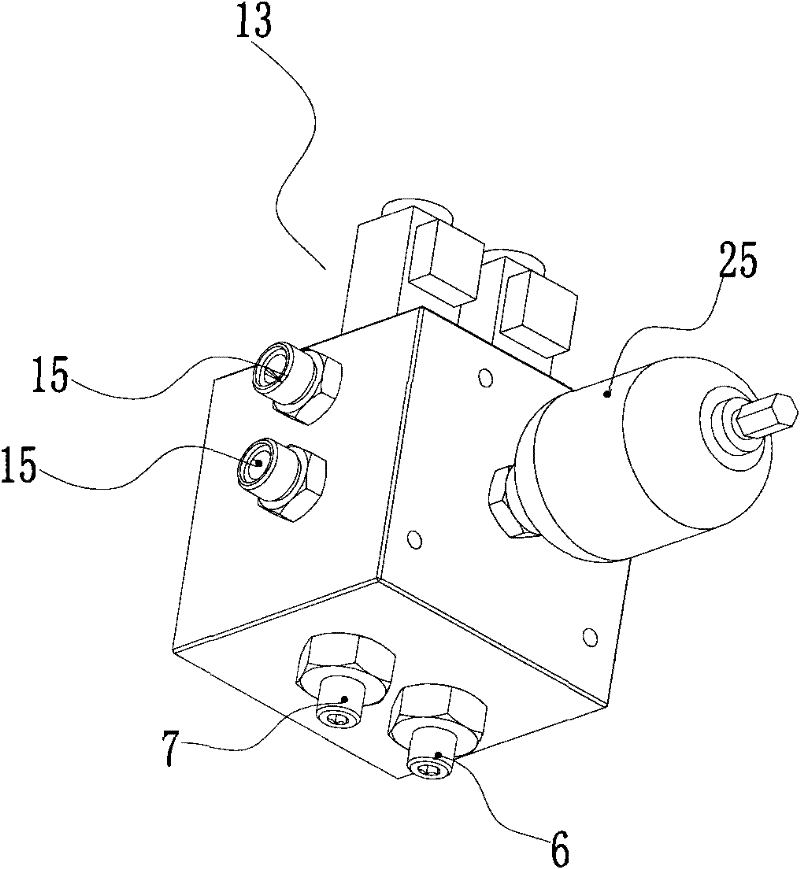

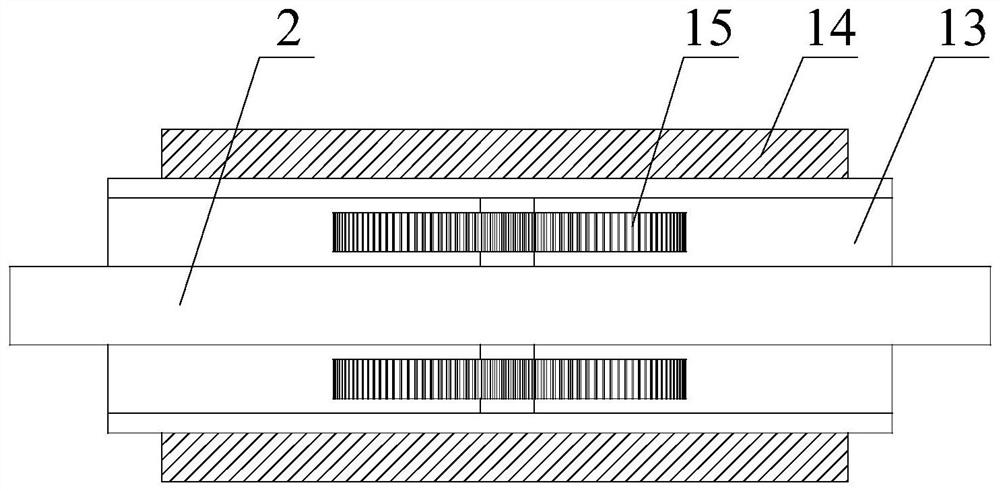

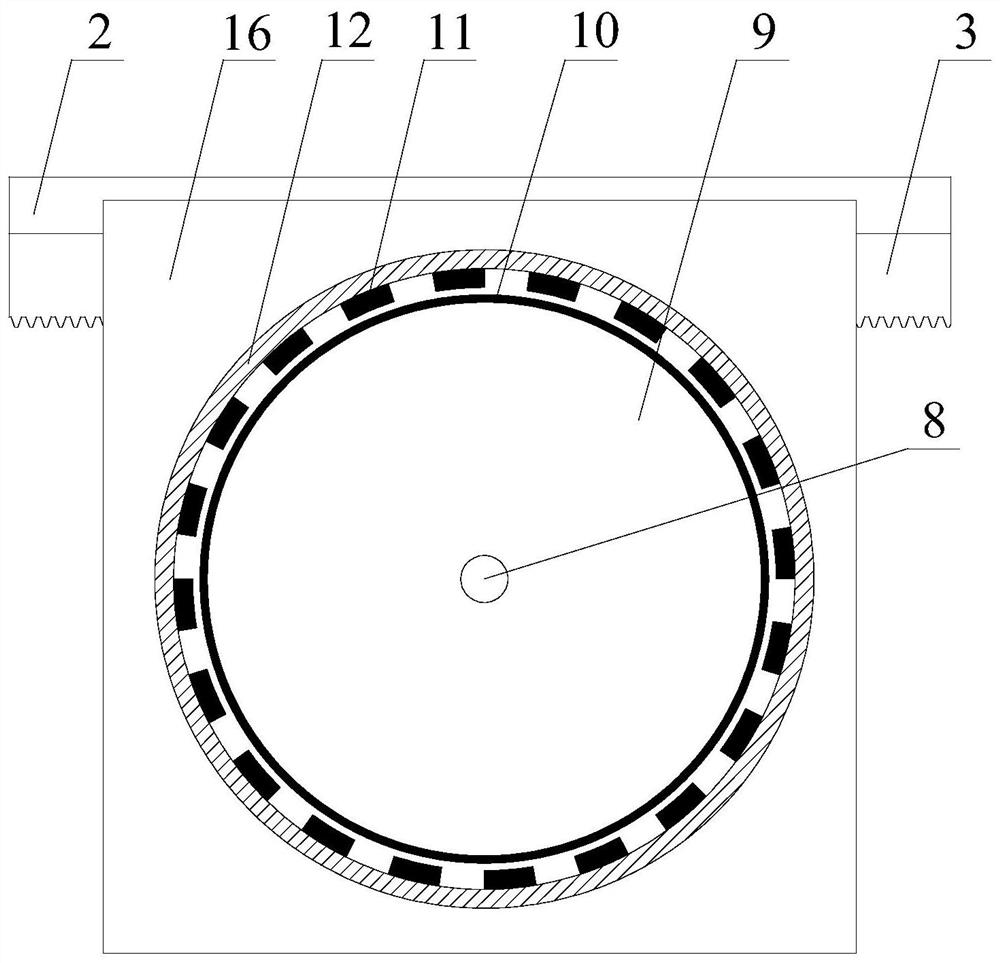

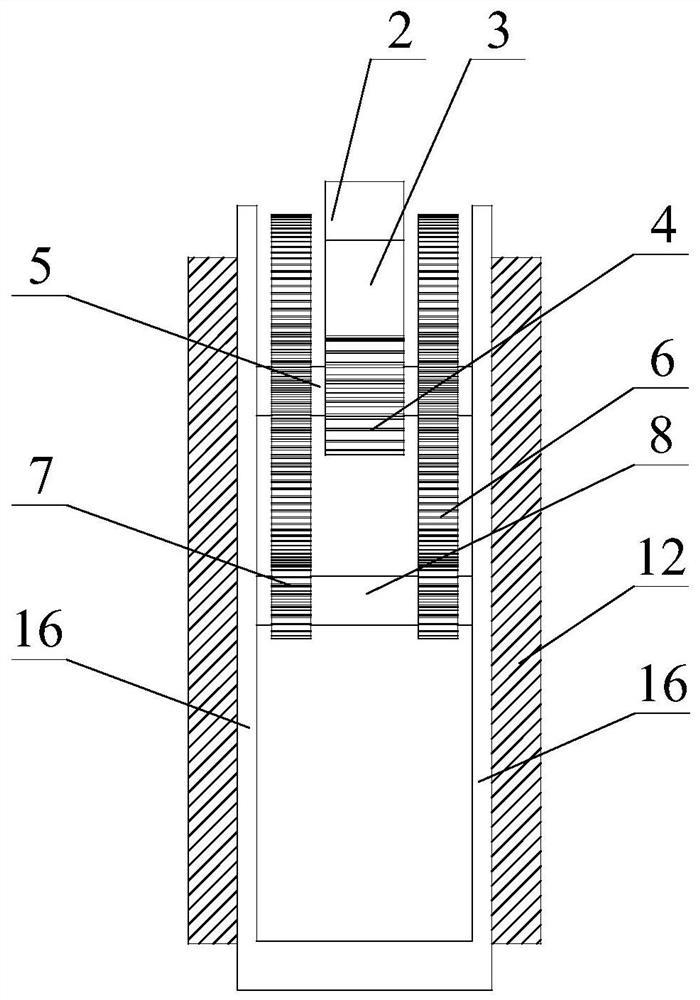

Eddy-current damping wall and building

PendingCN111827514ANo oil spillsLow maintenanceWallsProtective buildings/sheltersElectrical conductorDrive shaft

The invention relates to the field of buildings, in particular to an eddy-current damping wall and a building. The eddy-current damping wall comprise a first transmission shaft, at least one eddy current assembly and a transmission mechanism. The eddy current assembly comprises conductor plate back iron rotationally connected with the first transmission shaft, the outer side of the conductor plateback iron is sleeved with a conductor plate and permanent magnet back iron in sequence, at least two permanent magnets are arranged on the inner wall of the permanent magnet back iron, and the at least two permanent magnets are arranged in the circumferential direction of the permanent magnet back iron at intervals. The transmission mechanism is in driving connection with the first transmission shaft, and is used for converting linear motion into rotation of the first transmission shaft. According to the eddy-current damping wall, the eddy current assembly and the transmission mechanism are adopted as a main structure, an oil leakage phenomenon rarely happens or is avoided, the later maintenance charge is low, and the durability is good; and the eddy-current damping wall only generates damping, and therefore the eddy-current damping wall can also be suitable for the situation that the structural rigidity cannot be improved.

Owner:HUNAN UNIV

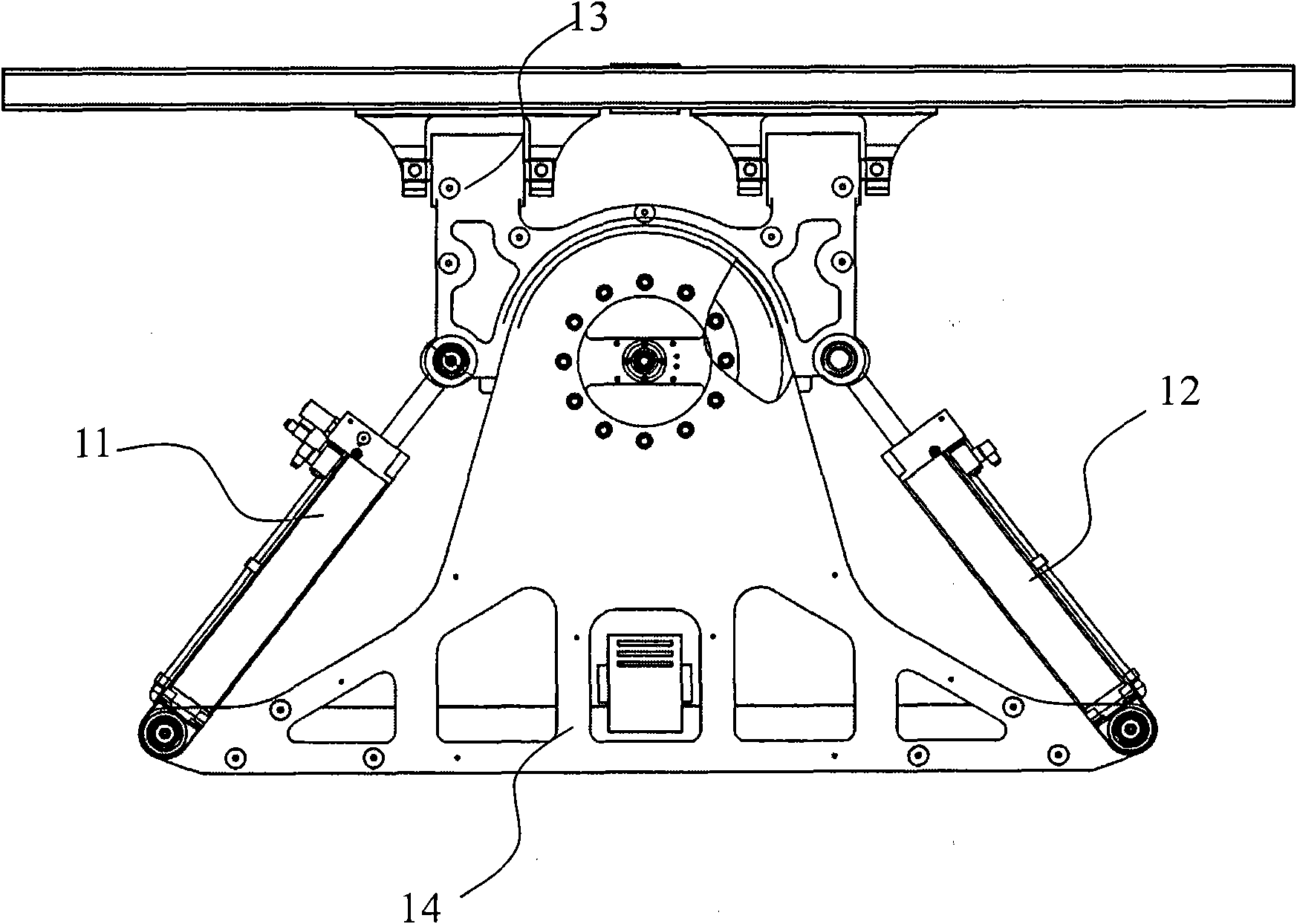

Electrically controlled manipulation method of grader

ActiveCN102561429AImprove efficiencyDoes not consume energyMechanical machines/dredgersElectrical connectionEngineering

The invention relates to a loader, in particular to an electrically controlled manipulation method of a grader, which at least comprises a flat bucket, a grader body, an operating mechanism and a lifting mechanism of the loader, wherein the flat bucket is connected with the grader body through a ground arm; the ground arm comprises a left arm and a right arm; and the left arm and the right arm are provided with movable joints. The method is characterized in that the left arm and the right arm are respectively connected with a telescopic arm of an electric cylinder, the electric cylinders are fixed at the grader body and are electrically connected with the operating mechanism, the operating mechanism controls the electric cylinders of the left arm and the right arm, and a push rod of a telescopic electric cylinder drives the flat bucket to lift up and down and turn over. The invention provides an electrically controlled manipulation method of the grader, so as to solve the technical problems of inconvenient installation, low transmission efficiency, a short service life, large running noises and low reliability of the existing loader driving system.

Owner:SHANXI GUOLI INFORMATION TECH

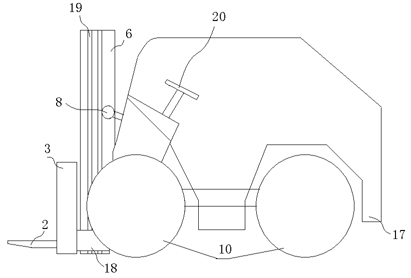

Loader working system based on servo electric cylinders

PendingCN109457743AImprove efficiencyDoes not consume energyMechanical machines/dredgersElectric controlControl theory

The invention discloses a loader working system based on servo electric cylinders, and belongs to the technical field of shovel-transport engineering machinery vehicles. The movable arm servo electriccylinders are hinged between the middles of movable arms and a loader body. A bucket is hinged to the other ends of a pair of movable arms, and a rocker is hinged to the middle of the bucket. A rocker pull rod is hinged to the other end of the rocker, the middle of the rocker pull rod is hinged to the pair of movable arms, and the bucket servo electric cylinder is hinged between the other end ofthe rocker pull rod and the loader body. A battery pack for supplying power to the bucket servo electric cylinder and the movable arm servo electric cylinders is mounted on the loader body. Drive andcontrol of the servo electric cylinders are achieved by an electronic control handle through CAN bus signal transmission, the system is high in efficiency, and no energy is consumed when the system isnot lifted. The servo electric cylinders have the beneficial effects that the working stroke and the working speed are precise and controllable, high reliability is achieved, no oil leakage is generated, and the system is convenient to mount. The problems that in the original technology, the noise is high, multiple leakage points exist, the transmission efficiency is low, and the maintenance costis high are avoided.

Owner:XCMG CONSTR MACHINERY

Bicycle double-brake mechanical disc-braking device

The invention discloses a bicycle double-brake mechanical disc-braking device which comprises an upper cover and a lower cover. A power double-axis rotor set is arranged in an inner cavity between the upper cover and the lower cover, and comprises a double-axis connection rod, a first stator, a first rotor, a second stator, a second rotor and roll balls. Brake pads are fixed on the inner surface of the first rotor and the inner surface of the second rotor respectively. By means of the bicycle double-brake mechanical disc-braking device, a disc can not easily deform, the brake pads can not be easily abraded, the braking effect is good, the bilateral braking effect of oil pressure is achieved, and the phenomenon of oil leakage can not occur. The bicycle double-brake mechanical disc-braking device is low in cost, simple in structure, and practical.

Owner:黄国政

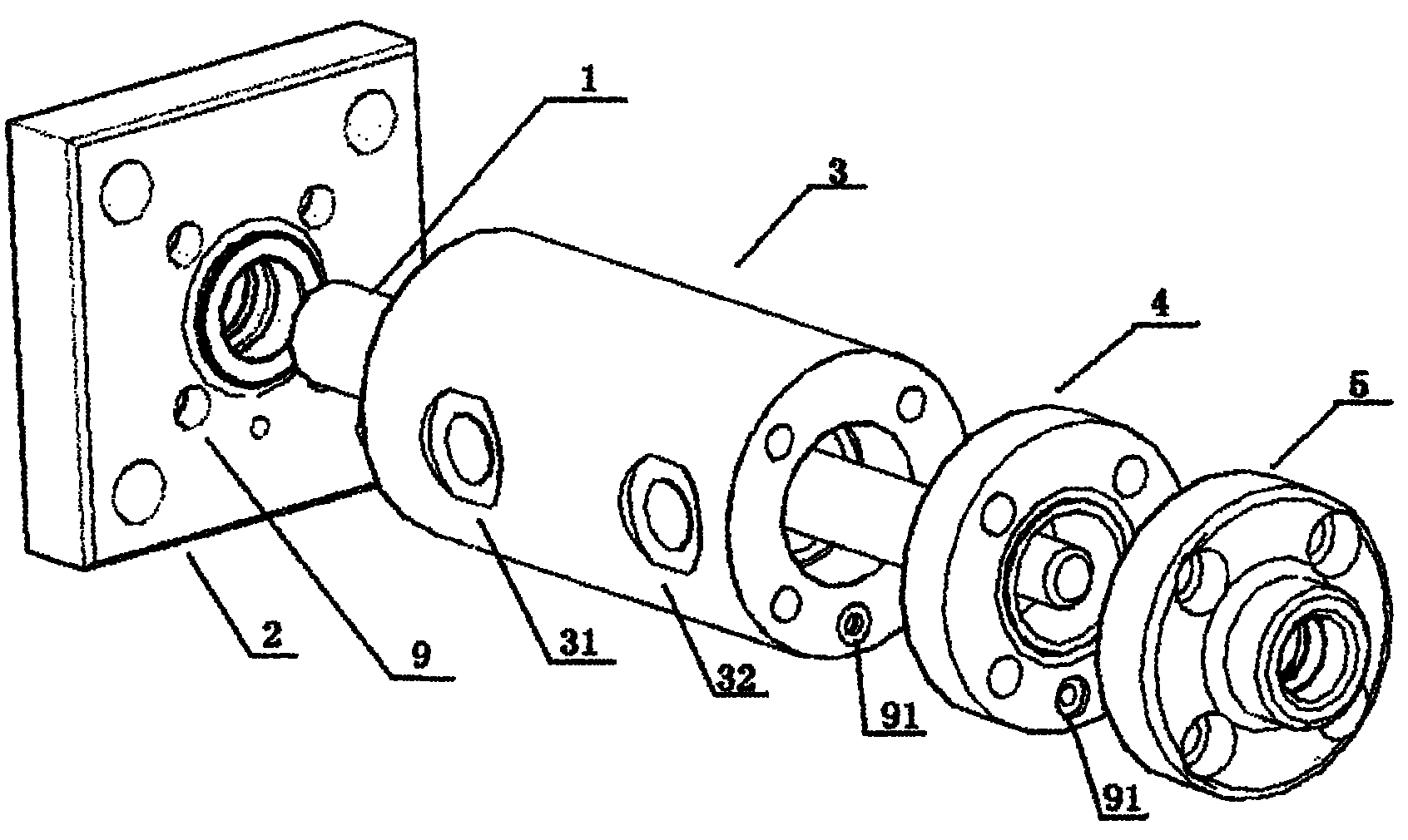

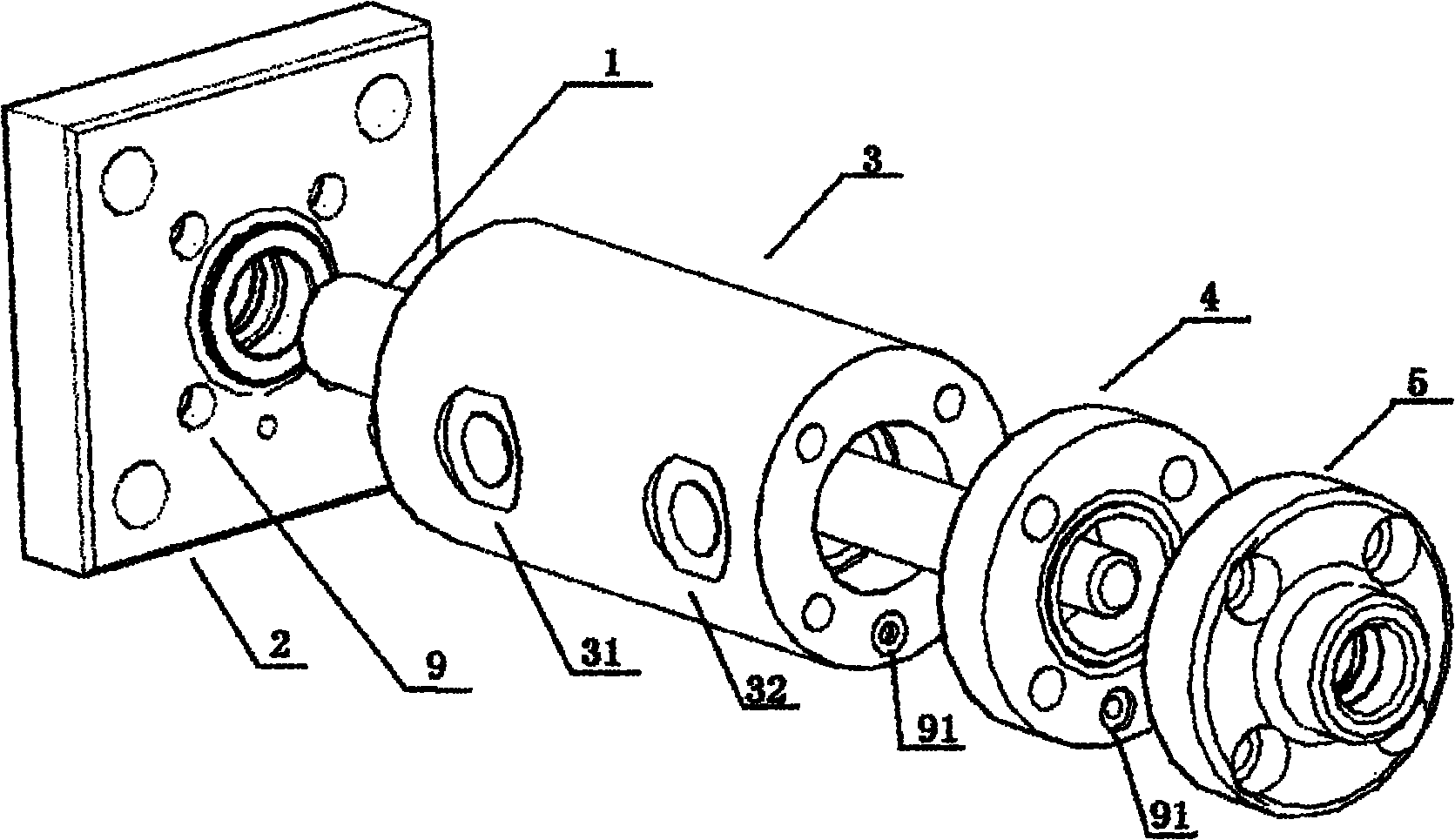

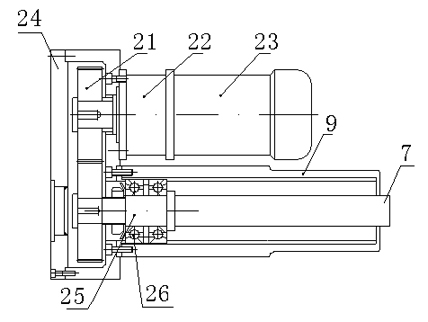

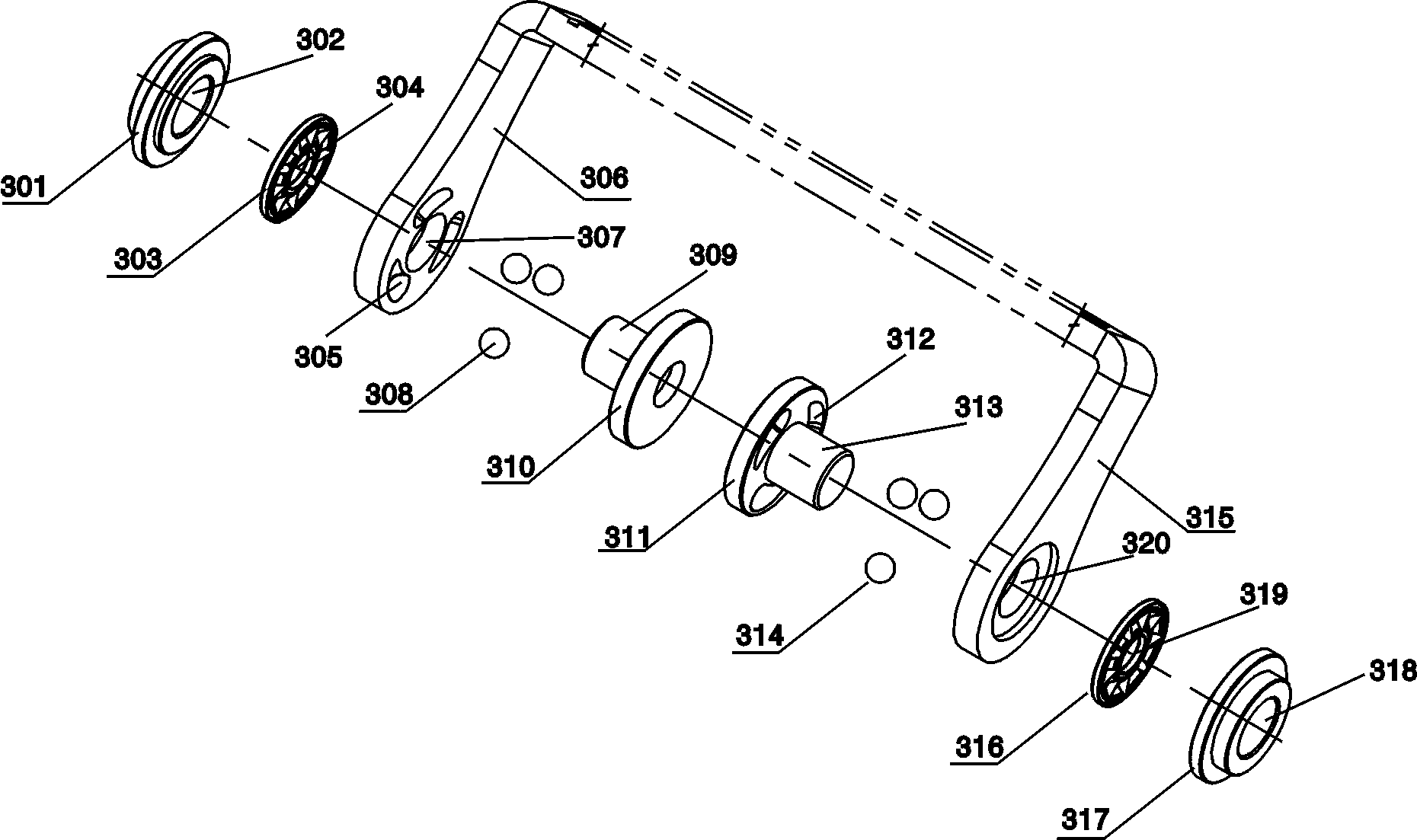

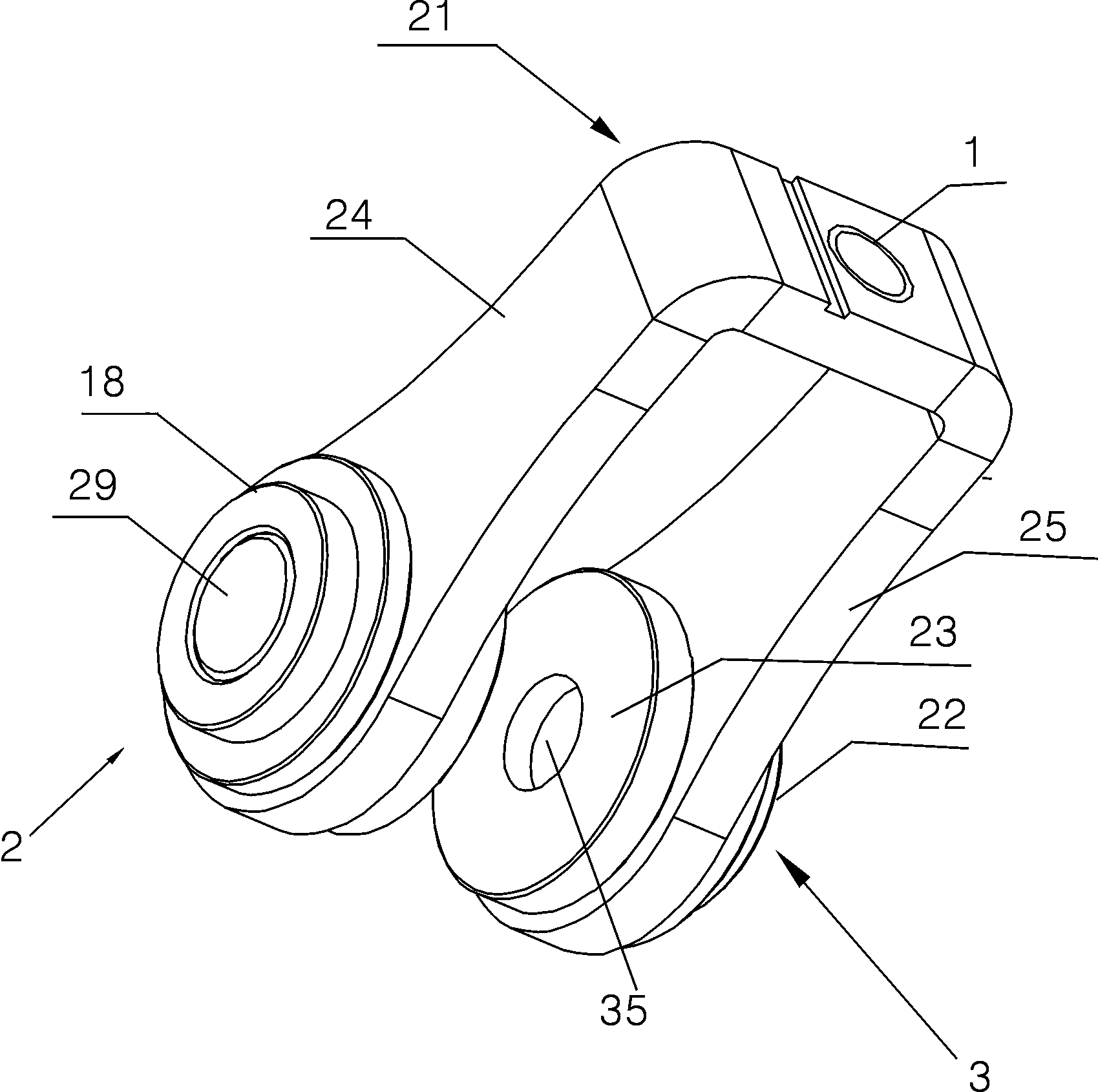

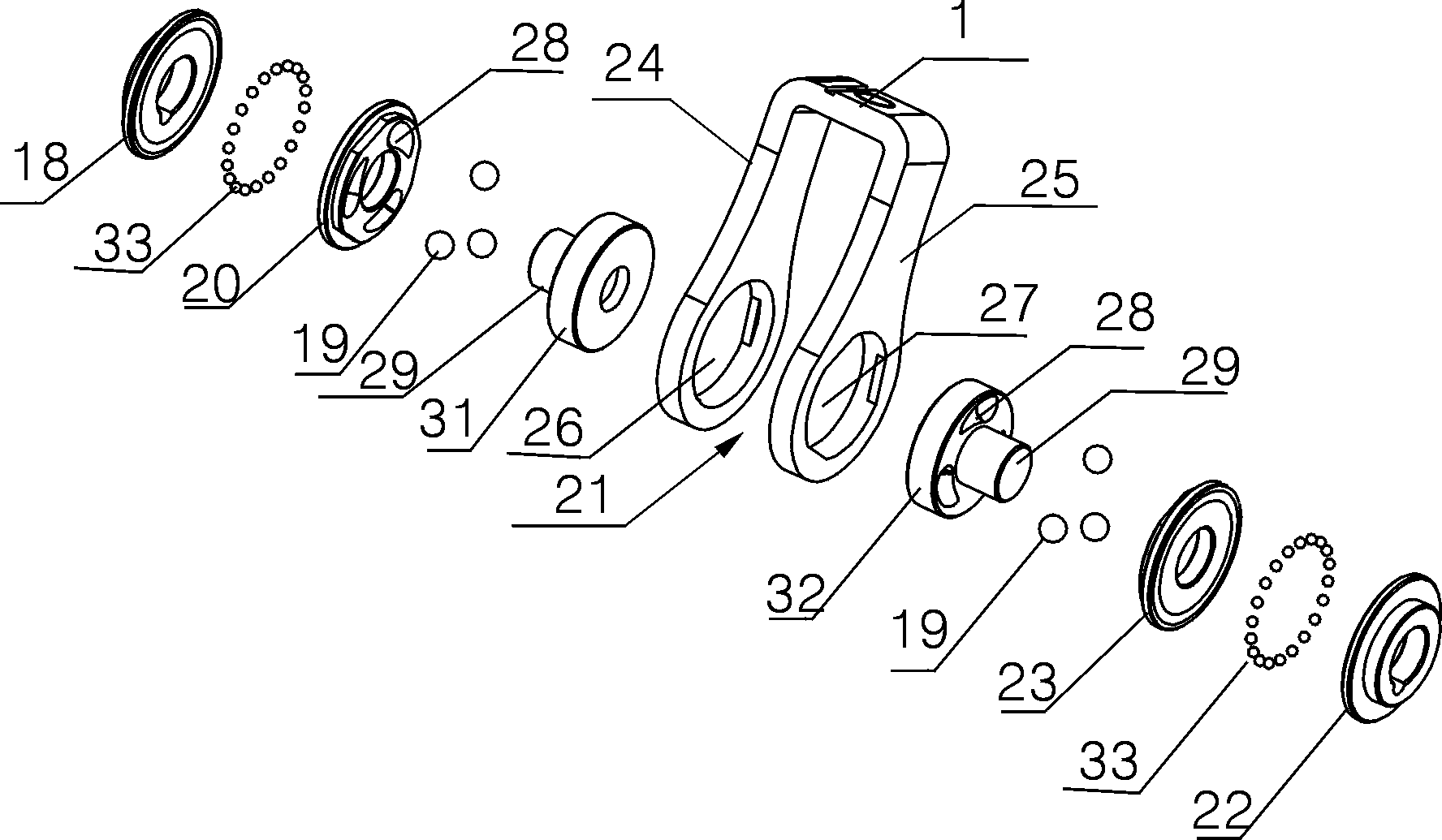

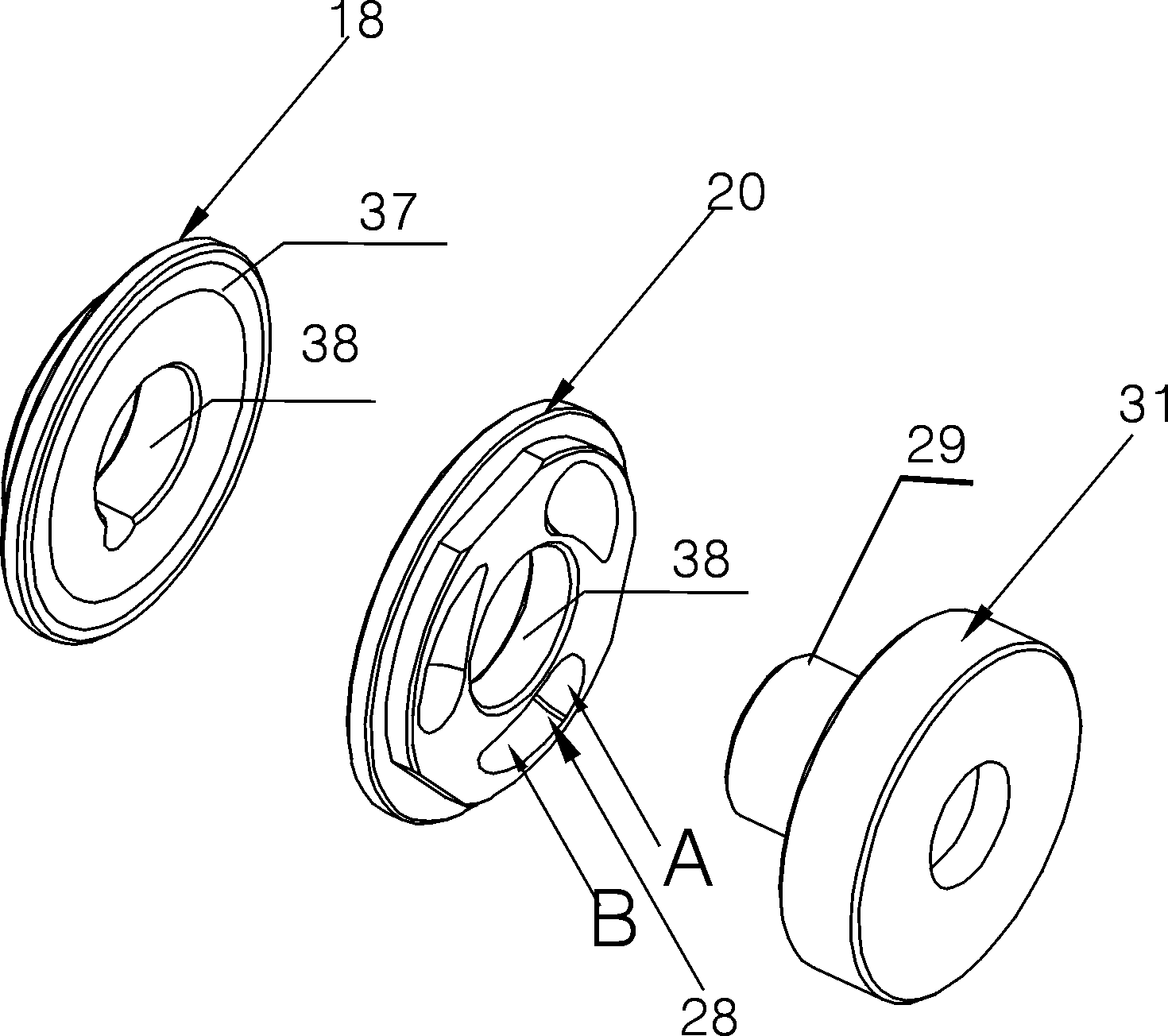

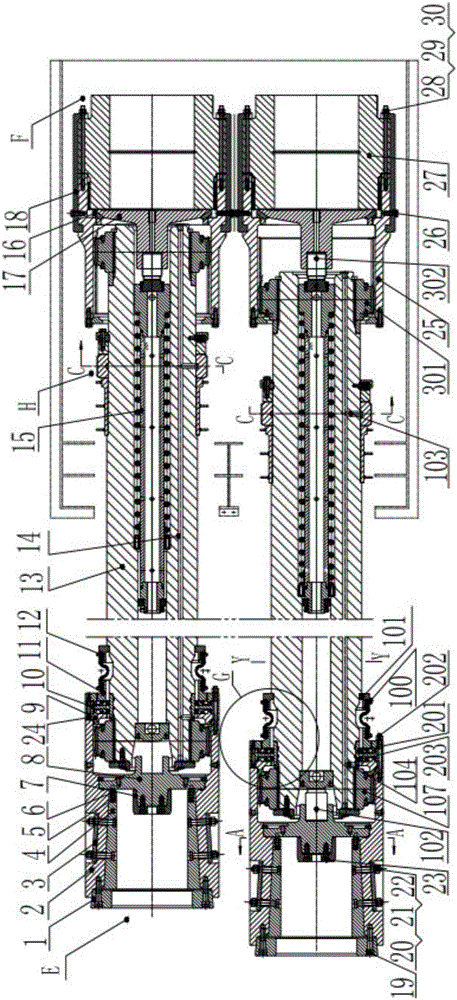

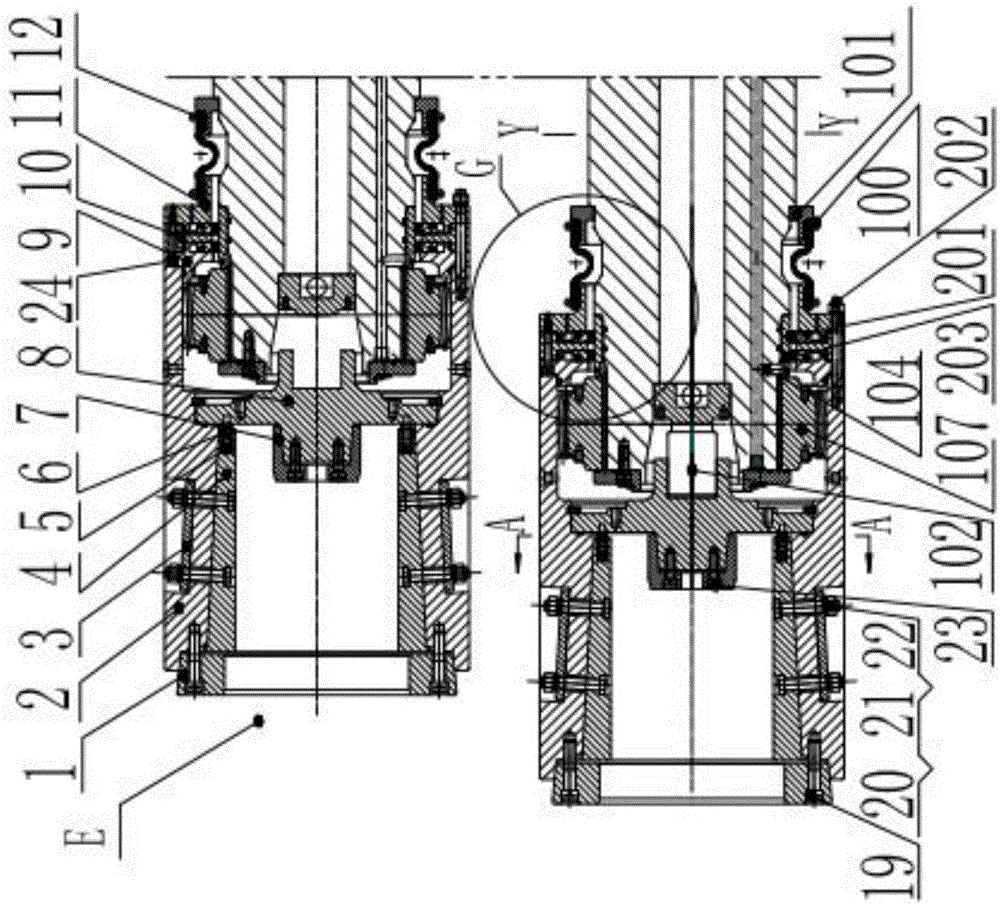

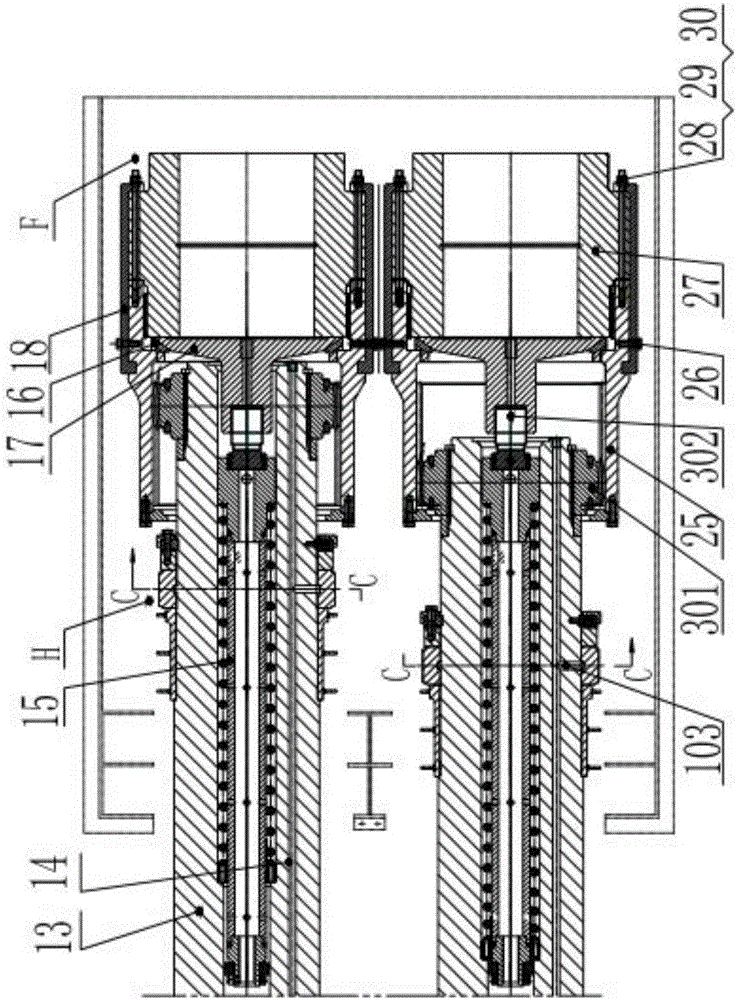

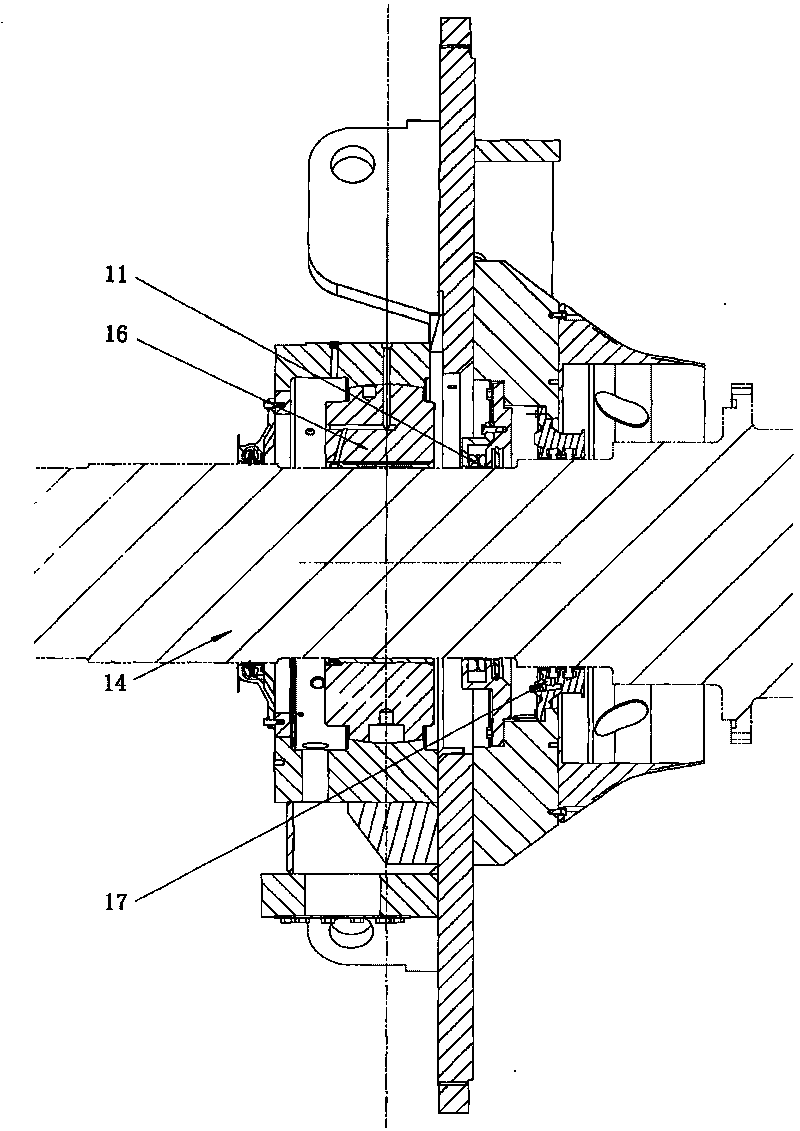

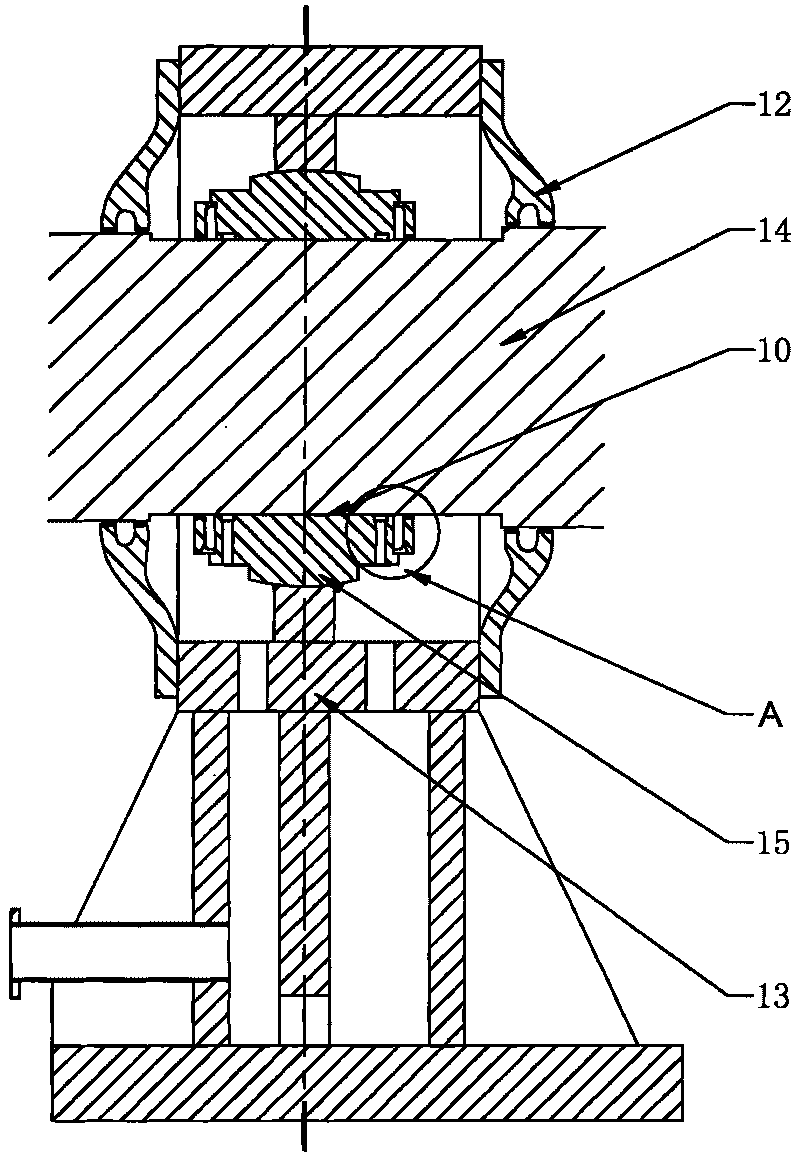

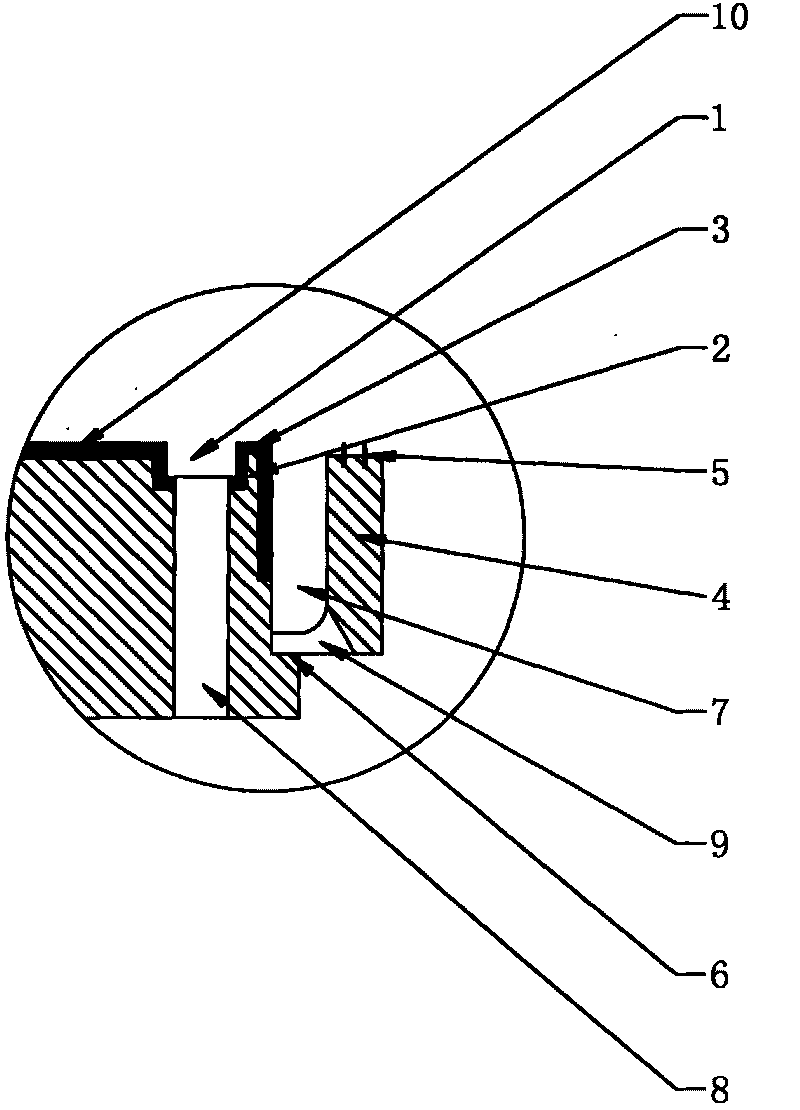

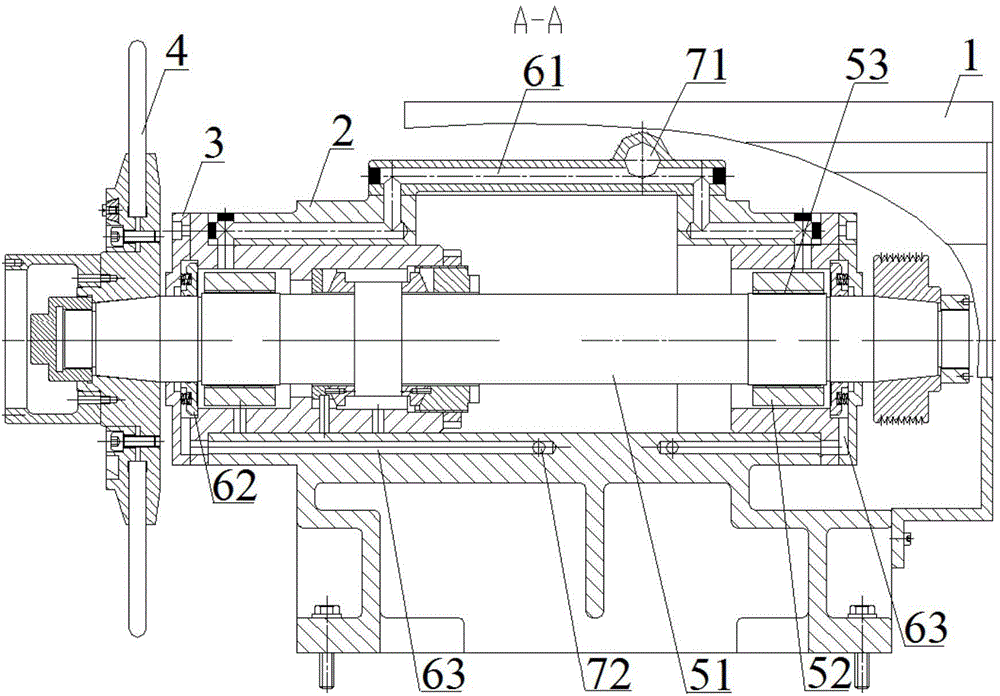

Modified thin oil lubrication drum-shaped tooth type coupling

ActiveCN106424153AOptimized structural formExtended service lifeRolling mill drivesMetal rolling arrangementsCouplingLubrication

The invention discloses a thin oil lubrication drum-shaped tooth type coupling which comprises a spindle, a roller end assembly E, a tooth end assembly F, an oil inlet ring assembly H and a spring assembly. The roller end assembly E, the tooth end assembly F and the oil inlet ring assembly H are arranged on the spindle. The spring assembly is arranged in the spindle. The roller end assembly E is an adjustable roller end assembly and comprises a roller end shaft sleeve, a roller end connecting disc, an outer centering, an inner centering, a roller end top block and a roller end outer tooth ring. The roller end connecting disc and the outer centering are connected with the roller end shaft sleeve. The inner centering and the roller end top block are connected with the roller end connecting disc. The roller end shaft sleeve is engaged with the roller end outer tooth ring through inner teeth. The roller end outer tooth ring is matched with the spindle. By adoption of the thin oil lubrication drum-shaped tooth type coupling, the defects of existing thin oil lubrication drum-shaped tooth type couplings are overcome, the overall service life of the thin oil lubrication drum-shaped tooth type coupling is prolonged, and the requirements of continuous rolling mill characteristics are met; and meanwhile, the production cost of a hot continuous rolling factory is also lowered, and benefits are created.

Owner:TAIER HEAVY IND

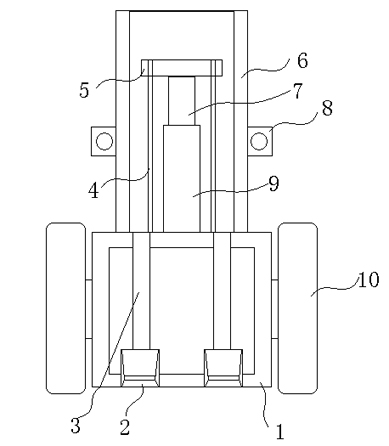

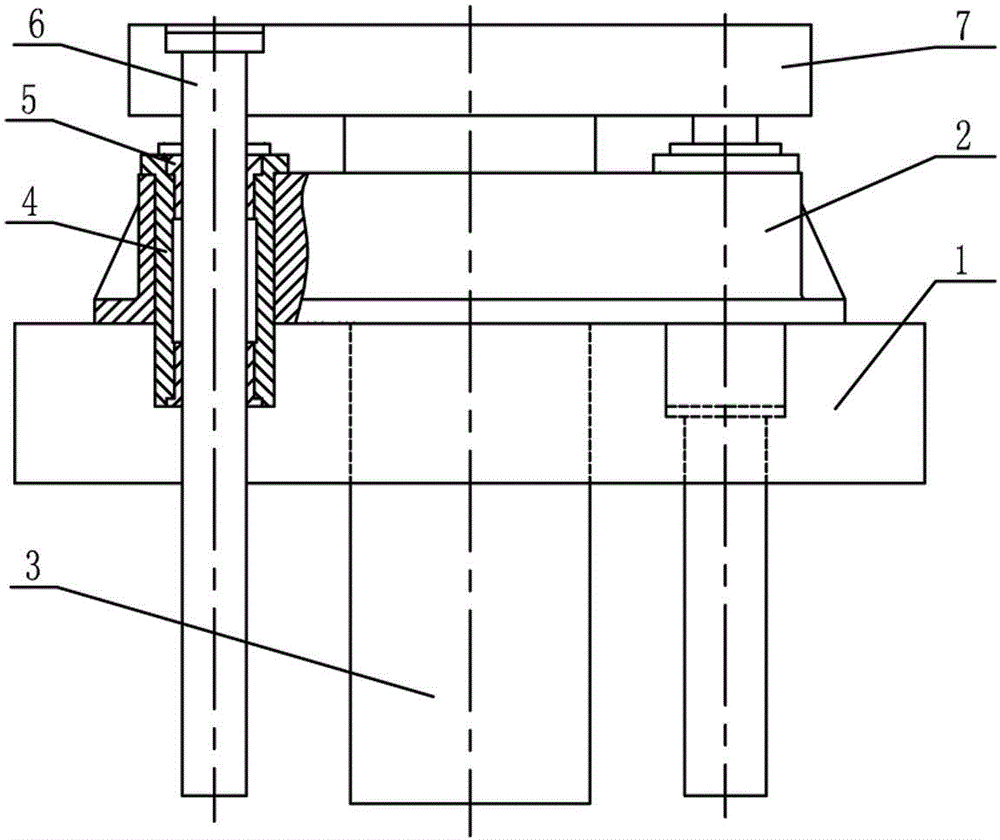

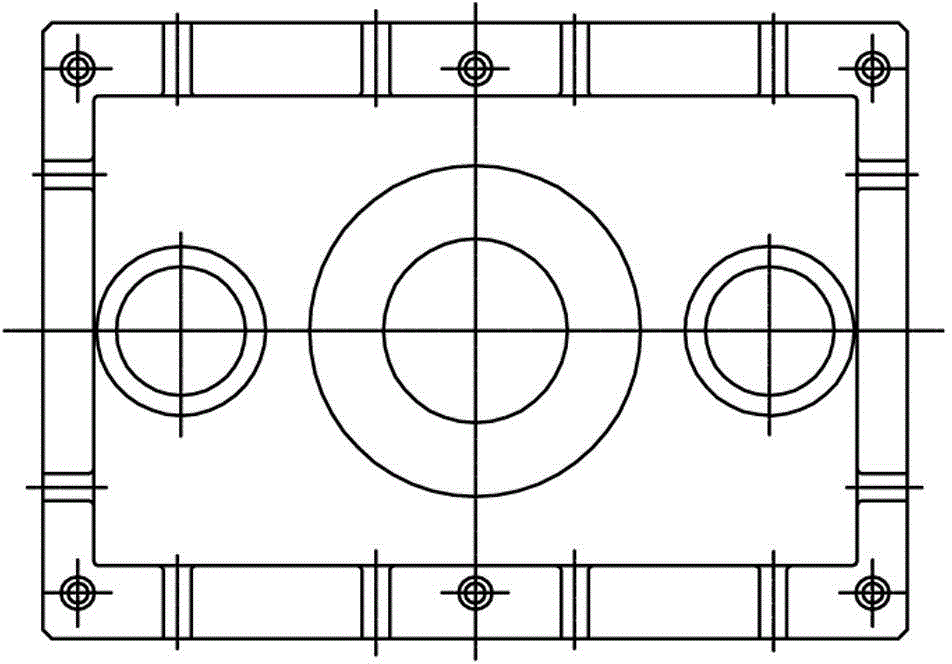

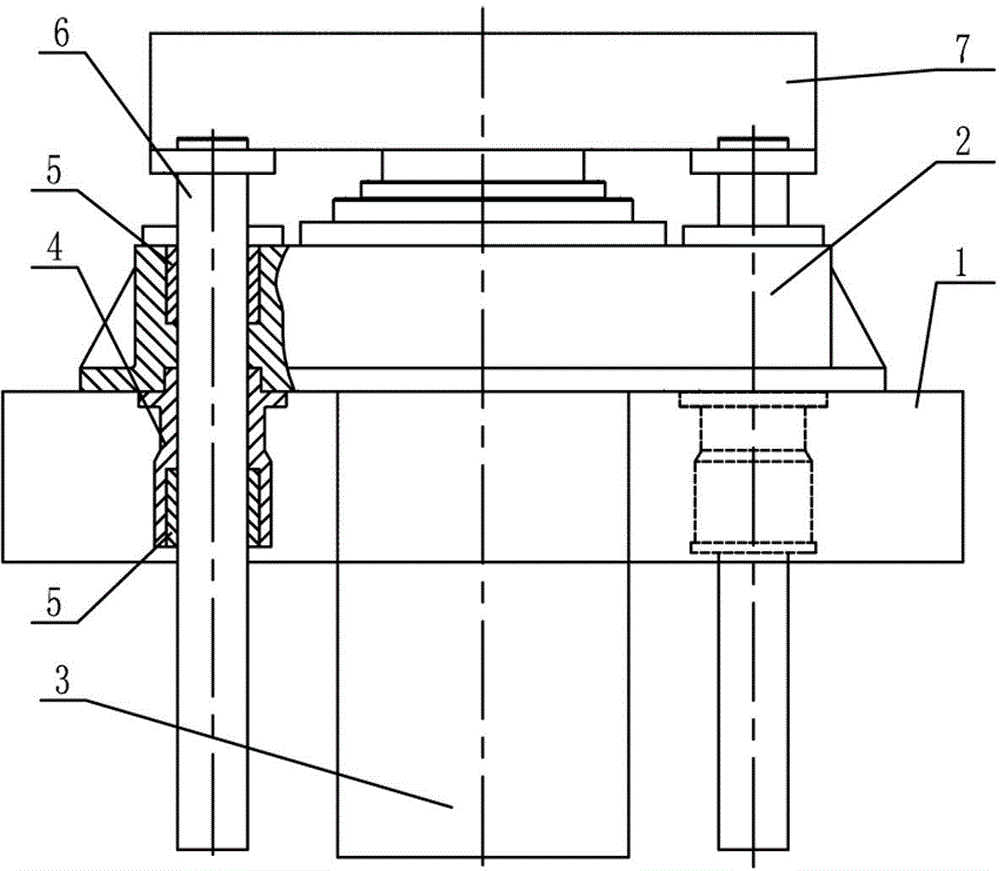

Lifting and compacting mechanism of horizontal parting slip flask shoot-squeeze molding machine

The invention discloses a lifting and compacting mechanism of a horizontal parting slip flask shoot-squeeze molding machine. The lifting and compacting mechanism comprises a bottom girder, a master cylinder, a master cylinder base, a flask lifting piston cover and four lifting guide bars. The master cylinder base is fixedly arranged on the bottom girder, the master cylinder is mounted on the master cylinder base, the flask lifting piston cover is fixedly arranged on the end face of a master cylinder piston rod, a guiding sleeve and two copper sleeves are arranged corresponding to each lifting guide bars, the four guiding sleeves are correspondingly distributed at four vertex angles of the master cylinder base, the four lifting guide bars are respectively mounted in corresponding guiding sleeves, and the top ends of the lifting guide bars are inserted to the lower end of the flask lifting piston cover and are fixed with the lower end face of the flask lifting piston cover. According to the lifting and compacting mechanism of the horizontal parting slip flask shoot-squeeze molding machine, the rigidity and strength of the whole mechanism are greatly enhanced, so that a movement process for the whole mechanism is smoother, and the possibility of tilting and deforming is reduced; and the lifting and compacting mechanism is easy to manufacture and fabricate.

Owner:WUXI HUAPEI MACHINERY MFG

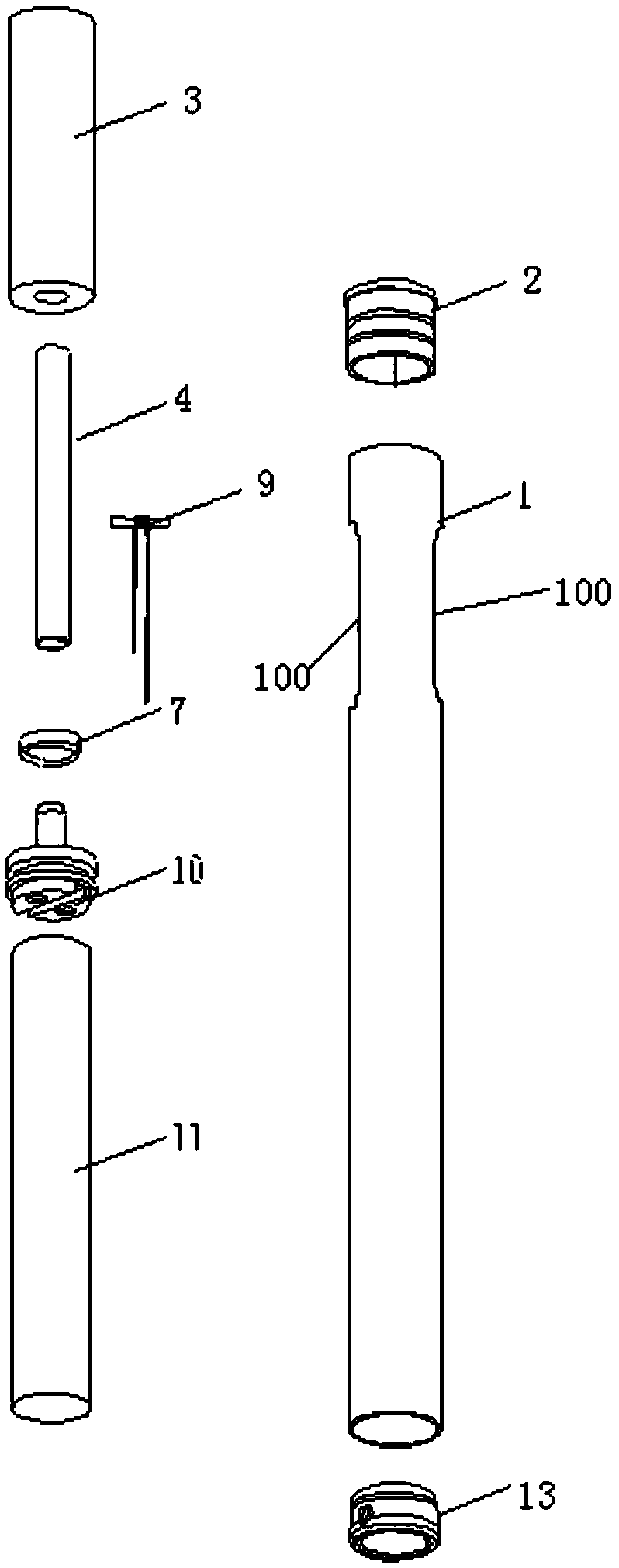

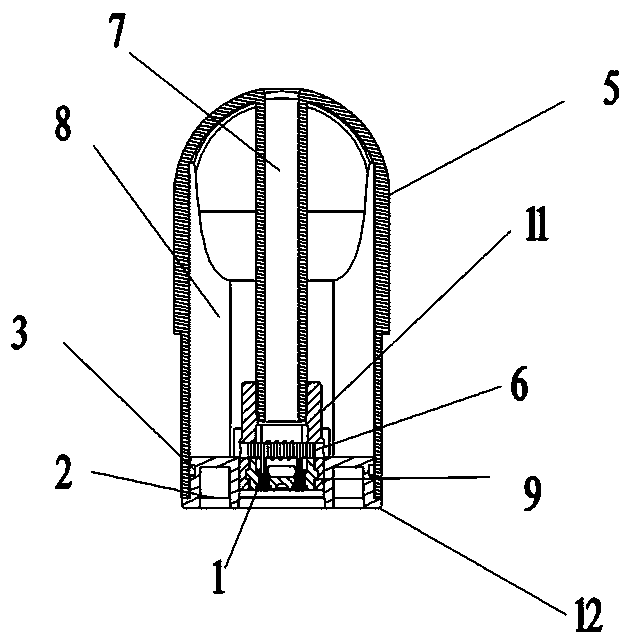

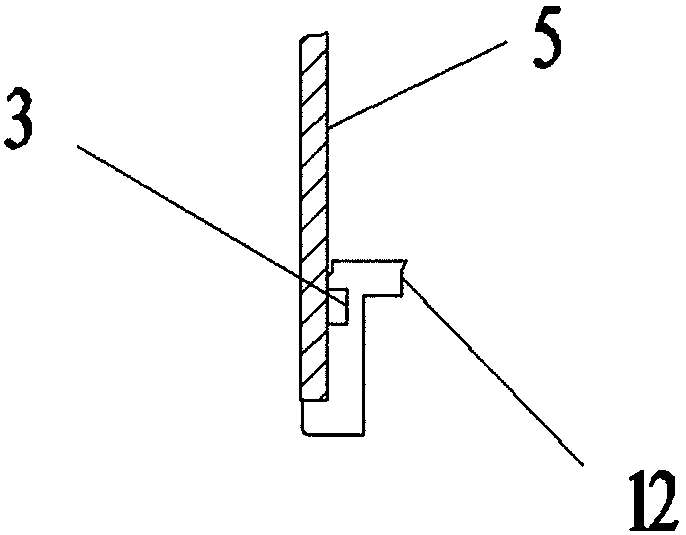

Capsule type e-liquid storage e-cigarette

The invention discloses a capsule type e-liquid storage e-cigarette, which is characterized in that the e-cigarette comprises the following parts: a shell body (1); a cigarette holder cover (2); a capsule storage body (3), wherein a plurality of e-liquid capsules (5) are stored; a vaporization assembly (6); a battery assembly (11); a center control assembly (12); a flue gas pipe (4), wherein the capsule storage body (3), the vaporization assembly (6), the battery assembly (11) and the center control assembly (12) are arranged in the shell body (1); two shell openings (100) are formed in two radially opposite sides of a shell (1) wall outside the capsule case (3); the flue gas pipe (4) is sheathed in the capsule storage body (3); and the e-liquid capsules (5) are stored between the outer wall of the flue gas pipe (4) and the inner wall of the capsule storage body (3). The capsule type e-liquid storage e-cigarette solves the problems of great contamination probability of e-liquid, leakage of the e-cigarette liquid and underutilization of the e-liquid, and thus a smoker can have better smoking experience.

Owner:SHENZHEN HUAYU TECH DEV CO LTD

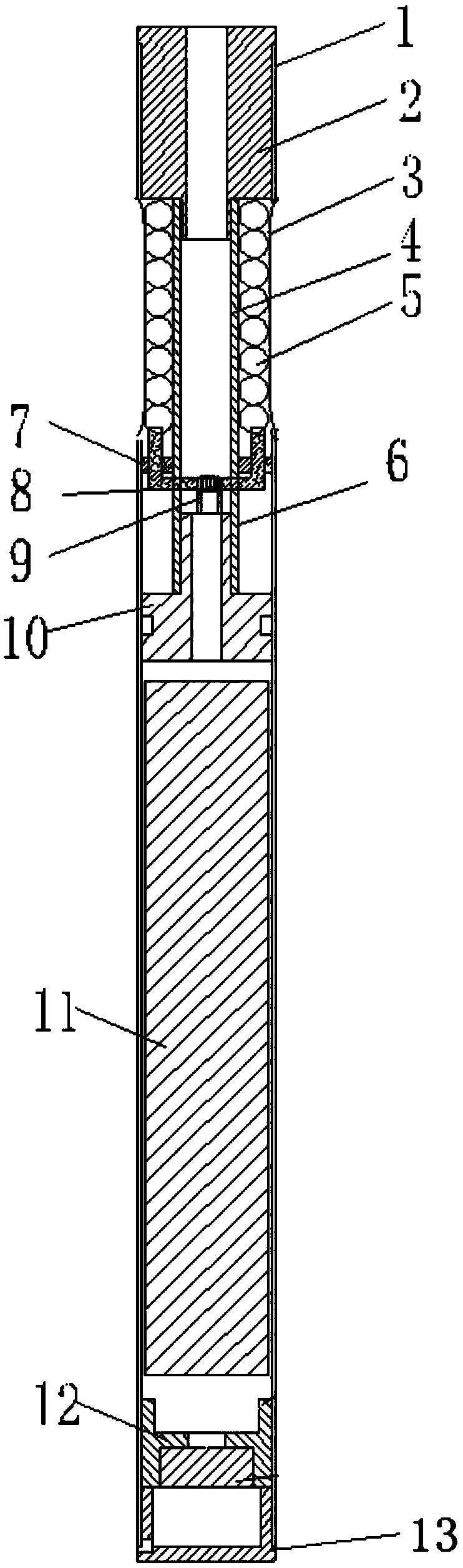

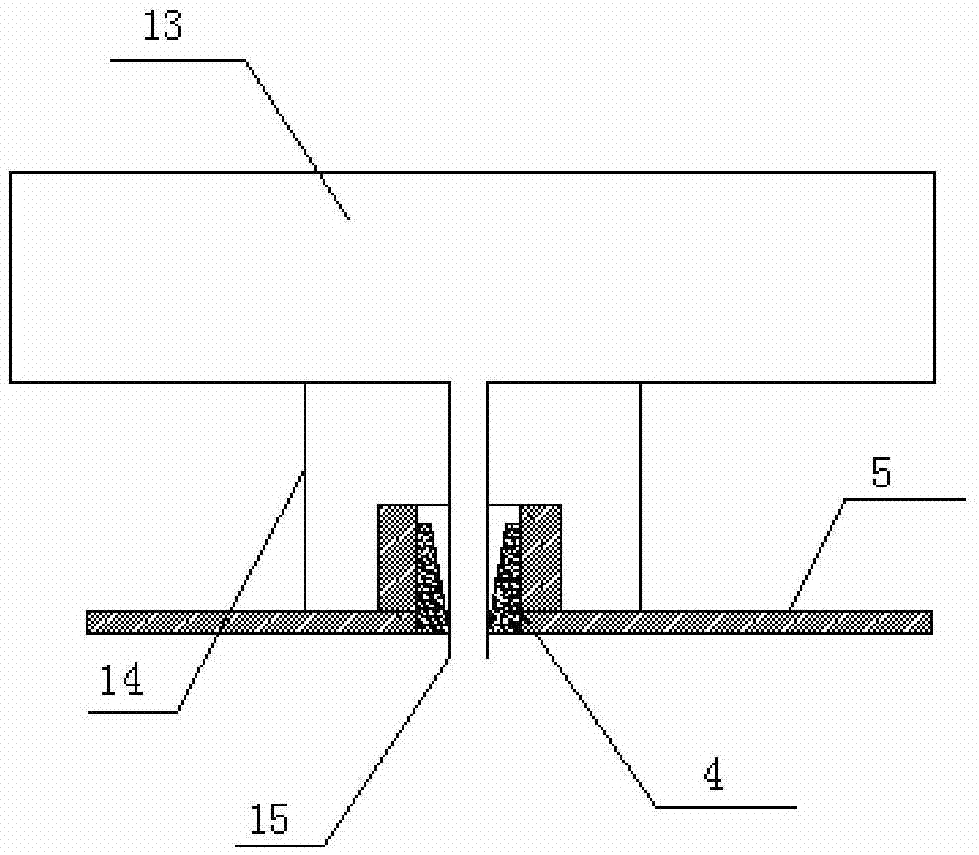

Inside oil baffle structure of bearing bush machine for dynamic balance test of rotor of large turbo-type generator

ActiveCN101762359AImprove dynamic balance and block oilNo oil spillsEngine testingStatic/dynamic balance measurementDynamic balanceEngineering

The invention relates to an inside oil baffle structure of a bearing bush machine for the dynamic balance test of a rotor of a large turbo-type generator, which comprises a drain pan and an oil baffle table at the inner side of the bearing bush machine, a tungsten structure on the surfaces of the drain pan and the oil baffle table, a small oil baffle cover assembled at the inner side of the bearing bush machine for test, a copper comb embedded into the small oil baffle cover and a structure of spigot positioned between the small oil baffle cover and the bearing bush for test. In the invention, the application of the oil baffle structure of the bearing bush for test reduces the installation requirement of the bearing for test than before, and the effect of oil baffling is enhanced obviously than before without oil leakage not for a moment.

Owner:HARBIN ELECTRIC MASCH CO LTD

Cylindrical grinder easy to assemble and maintain

ActiveCN104690613AHigh precisionHigh surface finishGrinding machine componentsRevolution surface grinding machinesCeramic coatingThermal expansion

The invention discloses a cylindrical grinder easy to assemble and maintain and belongs to the technical field of machine tools. The cylindrical grinder comprises a sleeve, a shell, a cover plate, a grinding wheel and a sliding bearing, the shell is arranged inside the sleeve, two ends of the shell are sealed through the cover plate, the sliding bearing transversely penetrates the shell, and one end of the sliding bearing is connected with the grinding wheel; a ceramic coating is arranged on the sliding bearing and at the contact position of a spindle and a bearing bush, a return oil pipeline is arranged inside the shell and is communicated with a lubricating oil tank on the outer portion of the sleeve, and lubricating oil is circulated in the return oil pipeline in zero-pressure circulation. The ceramic coating is sprayed at the friction position of the spindle and the bearing bush, so that problems about thermal expansion deformation and abrasion of the metal spindle are solved by the aid of outstanding performance of ceramic; meanwhile, according to self structural features of the cylindrical grinder, a brand new oil leakage prevention pipeline is designed for the cylindrical grinder, zero-pressure circulation lubrication of the lubricating oil in an oil cavity is realized, long-term operation is achieved without disassembling the grinder for maintenance, and maintenance cost is greatly lowered.

Owner:MAANSHAN HENGLIDA MACHINE BLADE +1

Tar-core separated jacking structure

The invention discloses a tar-core separated jacking structure. The structure comprises an electronic cigarette, and further comprises an electrode, a magnet, a sealing ring, a tobacco tar bin and a heating wire which are arranged on the electronic cigarette; an atomizing chamber and a tar storage chamber are arranged in the tobacco tar bin, the atomizing chamber is located at thecenter positionofthe tobacco tar bin, and the heating wire is arranged at the bottom of the atomizing chamber; the tobacco tar bin and the atomizing chamber are through by means of a tar dripping hole, the tar dripping hole is in a closed state, and a battery is arranged just below the tar dripping hole; a tobacco tar bin bottom cover is arranged at the bottom of the tobacco tar bin, and the tobacco tar bin bottom cover seals the tar storage chamber; an air inlet hole is arranged at the bottom of the tobacco tar bin, and a bulge part is arranged at the side face of the air inlet hole; and tar absorbent cottonis covered on the surface of the heating wire and is horizontally arranged. An atomizing core is hard to be flooded; a user is not proneto suckingthe tobacco tar, the tar leakage is avoided before use, the liquid is prevented from entering the internal space at which the tar-core separated jacking structure control element is located, thereby preventing a controller from losing efficiency.

Owner:SHENZHEN AIFURUISI TECH CO LTD

Oil leakage preventing clutch slave cylinder

The invention discloses an oil leakage preventing clutch slave cylinder. The oil leakage preventing clutch slave cylinder comprises a cylinder body and a piston arranged in the cylinder body in a slidable manner, wherein a bulge structure is arranged on the outer surface of the cylinder body, an oil hole communicated with a closed space is formed in the bulge structure, and a cut-through round through hole is formed in an elastic oil plug. The clutch slave cylinder further comprises an oil tank, an oil guiding pipe is arranged on the oil tank, one end of the oil guiding pipe communicates with the oil tank, the other end of the oil guiding pipe penetrates through the elastic oil plug and extends into the closed space, a retaining nut is arranged on the oil guiding pipe in a sleeving manner, one end of the retaining nut is fixed to the oil tank, and the other end of the retaining nut is arranged on the bulge structure in a screwing manner. The problem of the existing clutch slave cylinder that because an oil outlet nozzle of the hydraulic oil tank is directly arranged on an oil inlet nozzle on the clutch slave cylinder in a screwing manner and the connecting part between the hydraulic oil tank and the clutch slave cylinder easily loosens, oil leaks from the connecting part is solved.

Owner:WUHU HENGKUN AUTO PARTS

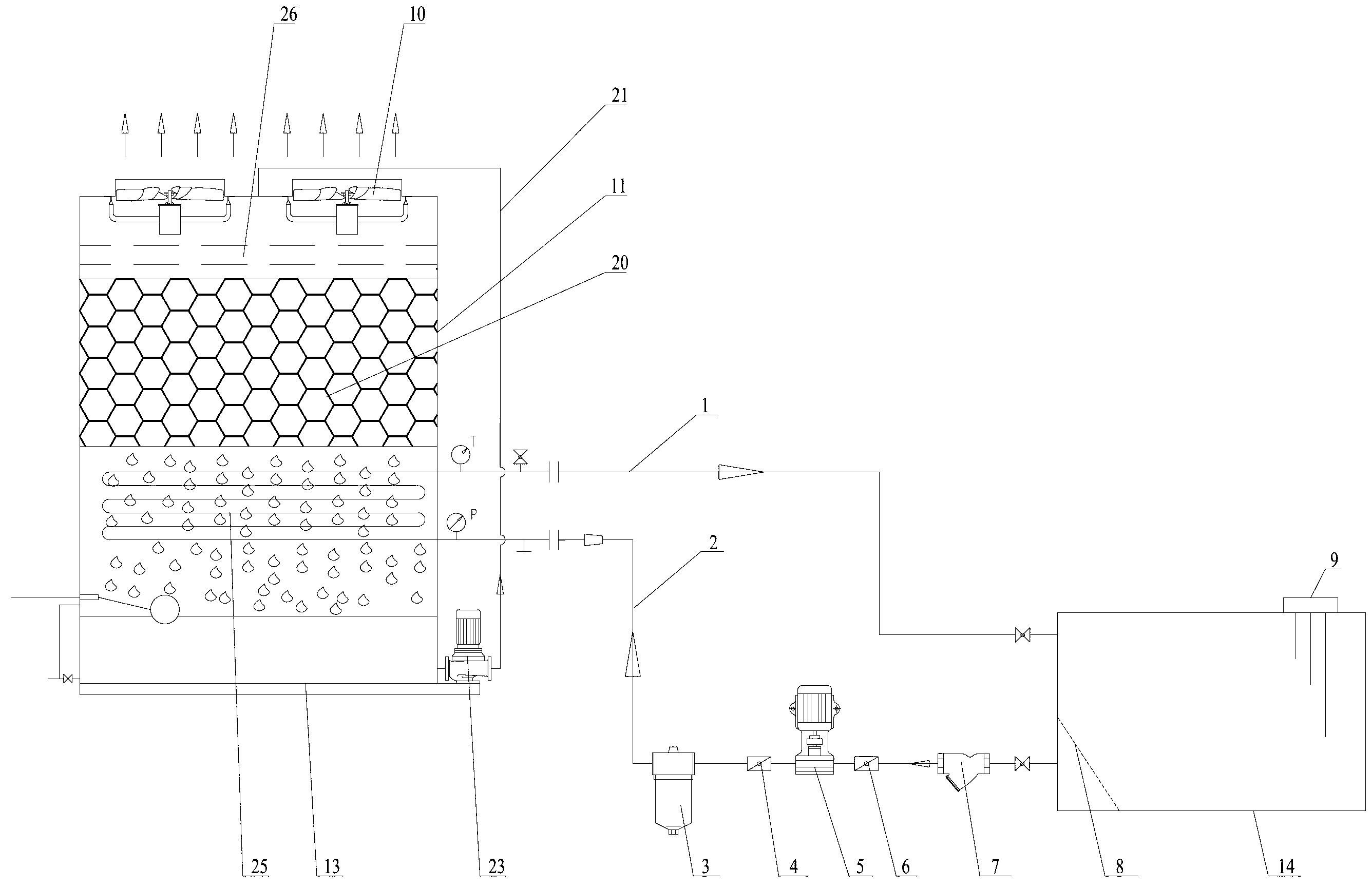

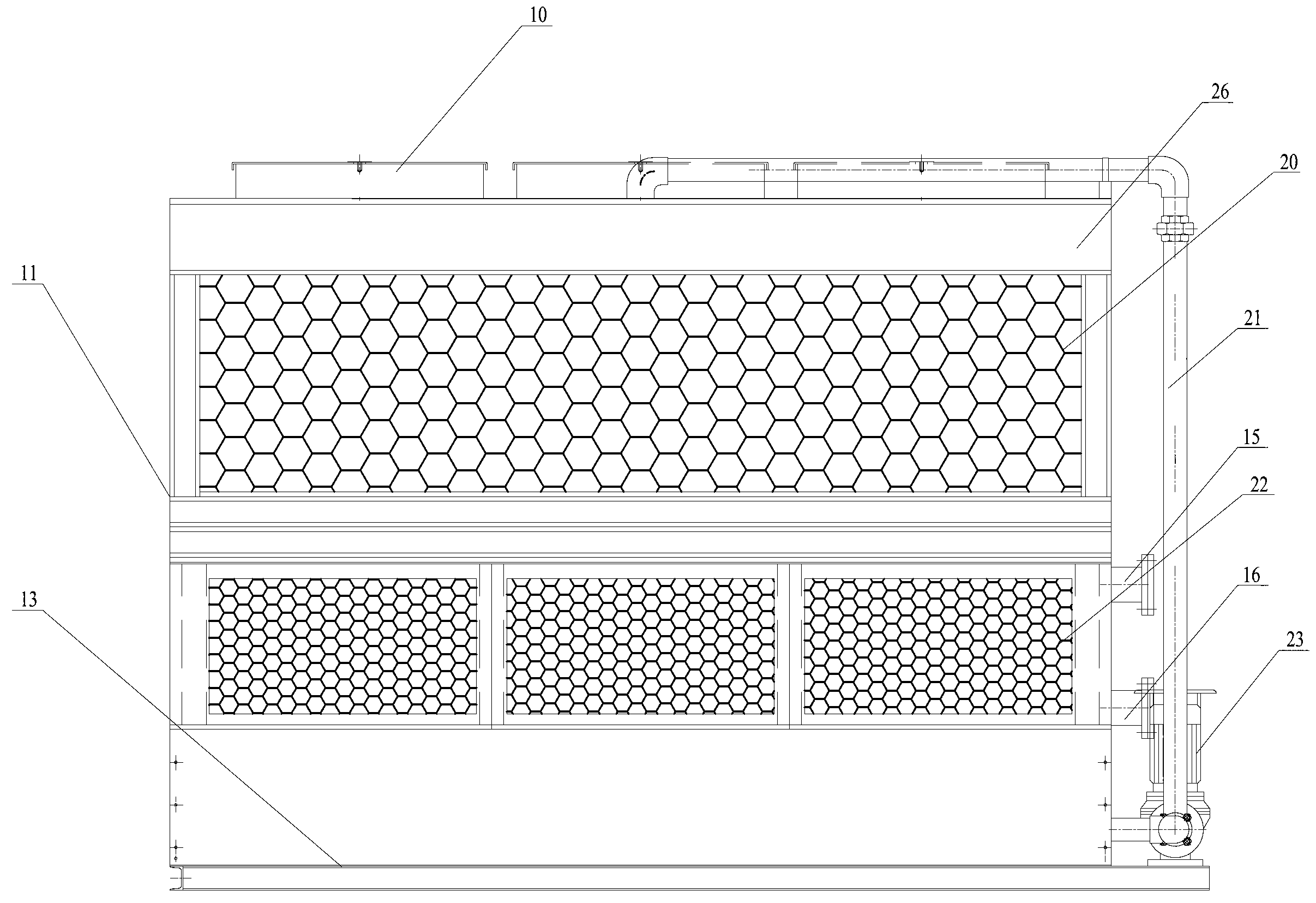

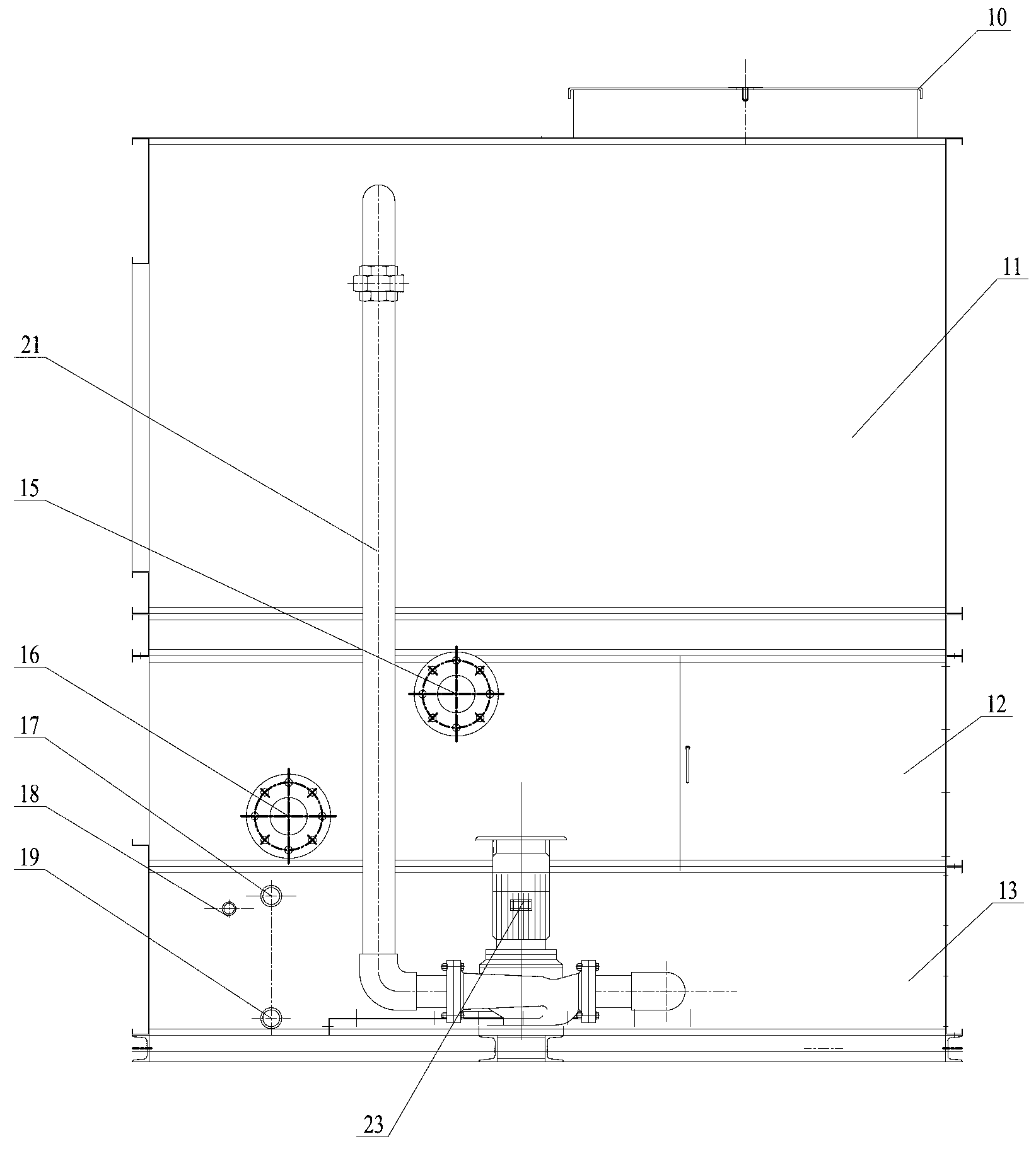

Closed cooling tower cooling device for forging and stamping industries

The invention relates to a closed cooling tower cooling device for forging and stamping industries. A coil is fixed on a support, an air inlet grill is arranged on a closed cooling tower, a cold oil outlet is formed in one end of the coil, a hot oil inlet is formed in the other end of the coil, a cold oil pipe is connected between the cold oil outlet and the inlet end of an oil tank, a hot oil pipe is connected between the outlet end of the oil tank and the hot oil inlet, a water collection tank is fixed in the closed cooling tower, a sewage drainage valve is arranged at the bottom of the water collection tank, an overflow valve and a water replenishing valve are arranged on the water collection tank, spraying fillers are arranged in the closed cooling tower, a bulk water disk is arranged in the closed cooling tower, the inlet end of the bulk water disk is connected with a spraying pipe, a spraying pump is arranged on the spraying pipe, and a fan is positioned at the top end of the closed cooling tower. Work oil of the closed cooling tower cooling device is cooled in a closed cycle mode, oil and water are separated, and oil leakage and oil-water streaming are avoided. The closed cooling tower cooling device improves production efficiency, saves water and reduces power consumption.

Owner:WUXI KEJU MACHINERY MFG

Thread type braking device used for mechanical disk brake of bicycle

The invention relates to a thread type braking device used for a mechanical disk brake of a bicycle. The thread type braking device comprises a double-shaft connecting rod, a brake cable connecting part is arranged at the upper end of the double-shaft connecting rod, and a first shaft arm and a second shaft arm which are of the same structure are connected to the two sides of the brake cable connecting part respectively. A first shaft arm hole and a second shaft arm hole are formed in the lower end of the first shaft arm and the lower end of the second shaft arm respectively. A first braking assembly and a second braking assembly which are of the same structure are installed in the first shaft arm hole and the second shaft arm hole respectively. Double-side braking can be achieved when the thread-type braking device is installed in the mechanical disk brake, a disk is not prone to deformation, and a brake pad is not prone to abrasion. The thread type braking device is good in braking effect, low in cost and simple and practical in structure and has the oil pressure double-side braking effect and the labor saving effect, and meanwhile oil leakage will not occur.

Owner:于洋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com