Pressurizing and locking hydraulic buffer system

A technology of hydraulic buffering and locking, applied in the direction of fluid pressure actuating device, etc., can solve the problems of oil leakage, large space occupation and high cost, and achieve the effects of reducing manufacturing cost, simple pressure control and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

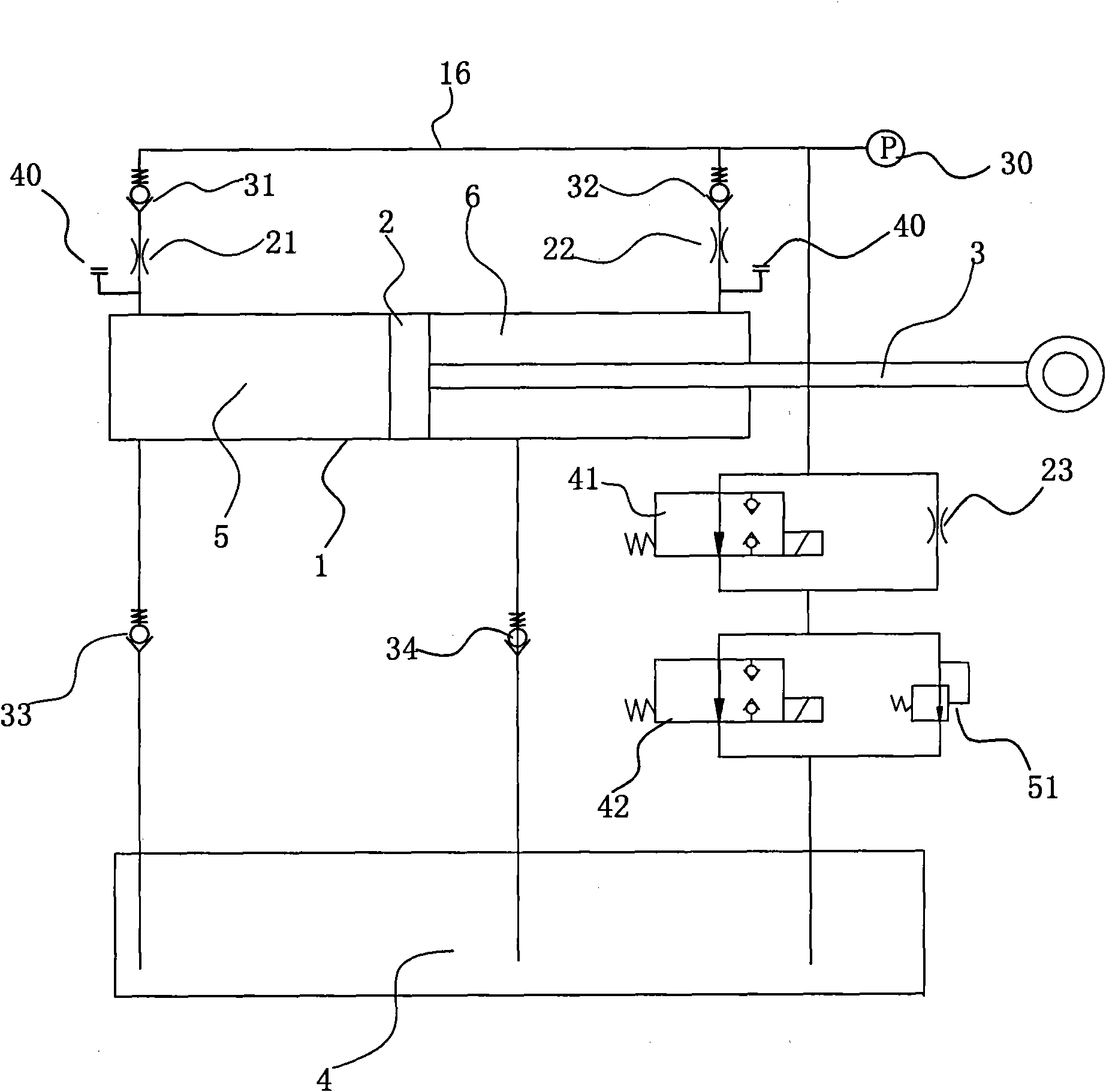

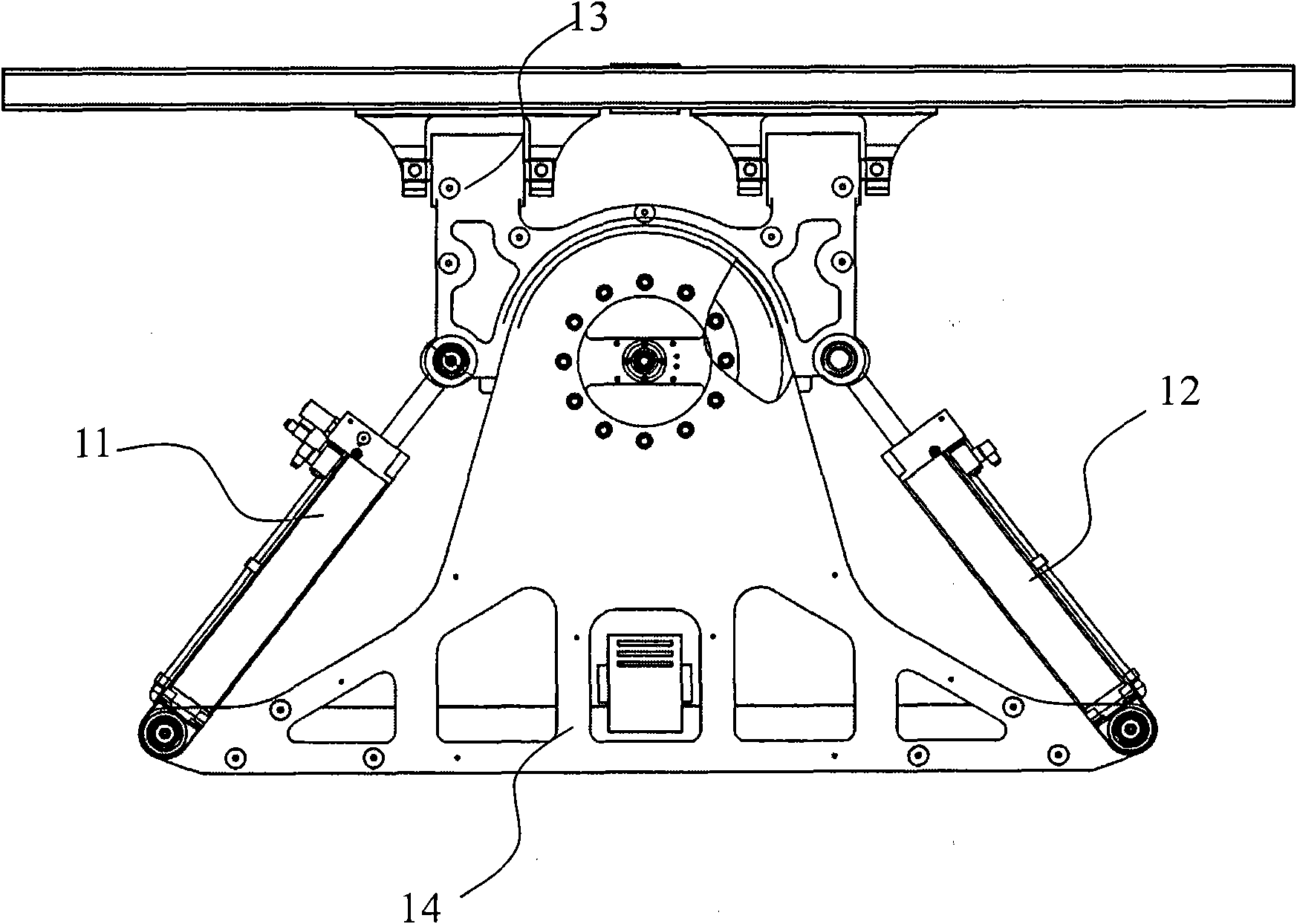

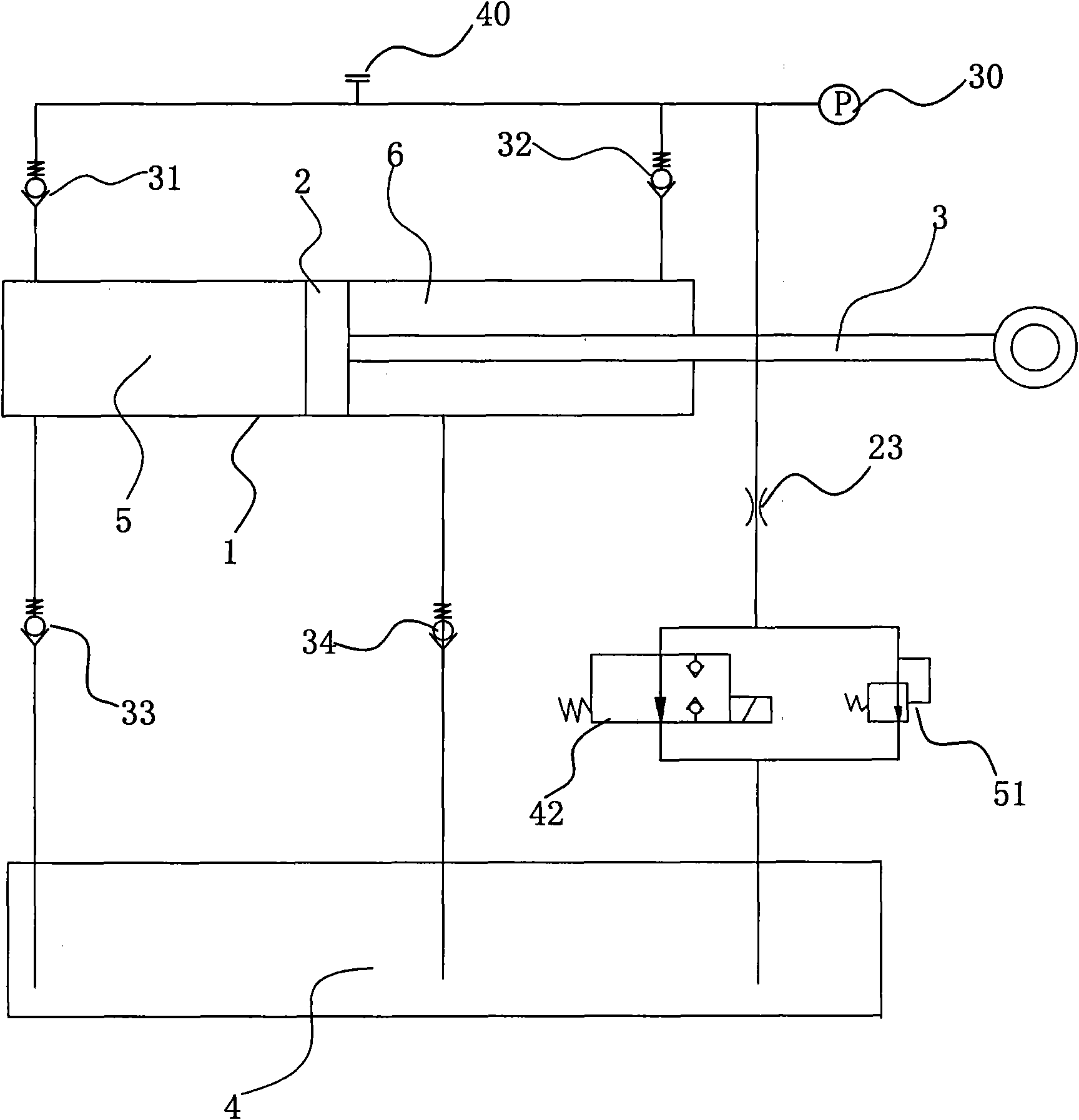

[0030] Such as Figure 1-Figure 10 As shown, the present invention relates to a pressurized locking hydraulic buffer system, including a hydraulic cylinder 1 and an oil storage tank 4, the hydraulic cylinder 1 includes a piston 2, a piston rod 3 and a cylinder liner 7, and the piston 2 is slidably arranged on The hydraulic cylinder 1 is divided into a first cavity 5 and a second cavity 6, the piston 2 and the piston rod 3 are fixedly connected, and the pressurized hydraulic buffer system also includes at least one overflow valve (51, 52 ), at least one solenoid valve (41, 42), at least one hydraulic damper (23, 21, 22) and four check valves (31, 32, 33, 34);

[0031] The first chamber 5, the third one-way valve 33 and the oil storage tank 4 form the first oil suction circuit, and the second chamber 6, the fourth one-way valve 34 and the oil storage tank 4 form the second oil suction circuit. Road; the first chamber 5, the first one-way valve 31 and the oil storage tank 4 pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com