Multicolor Air Jet Loom

An air-jet loom, loom technology, applied in looms, textiles, textiles and papermaking, etc., can solve problems such as inconsistent pressure loss, and achieve the effects of reducing inconsistency, easy pressure control, and reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described below based on the drawings.

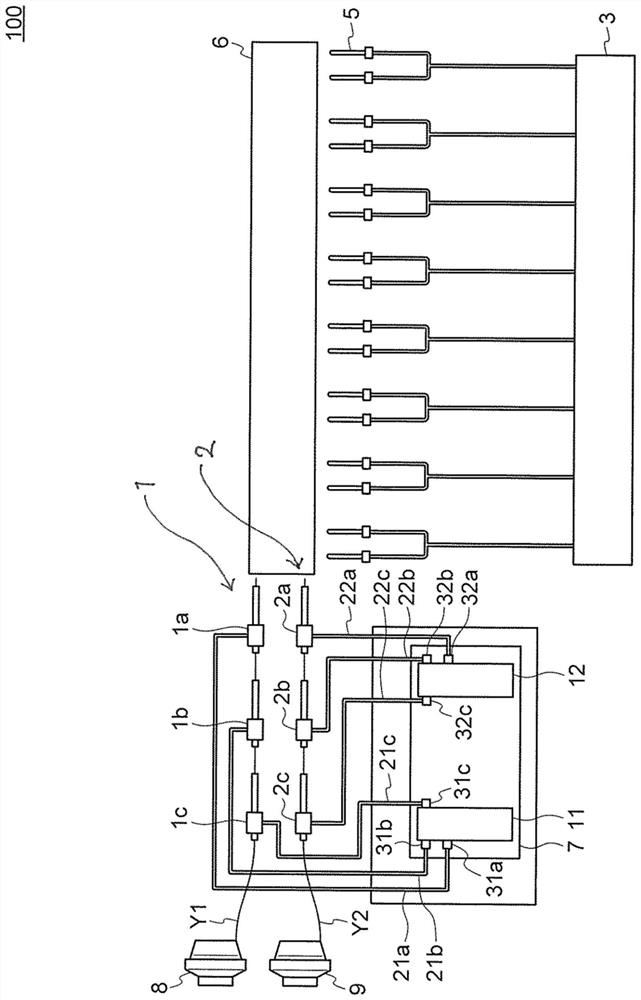

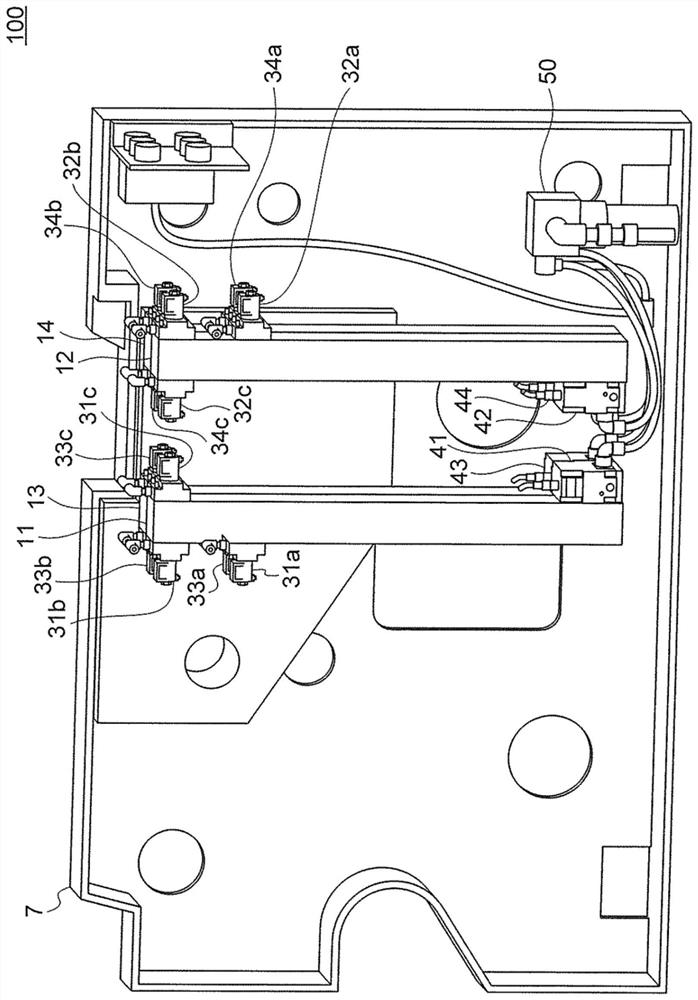

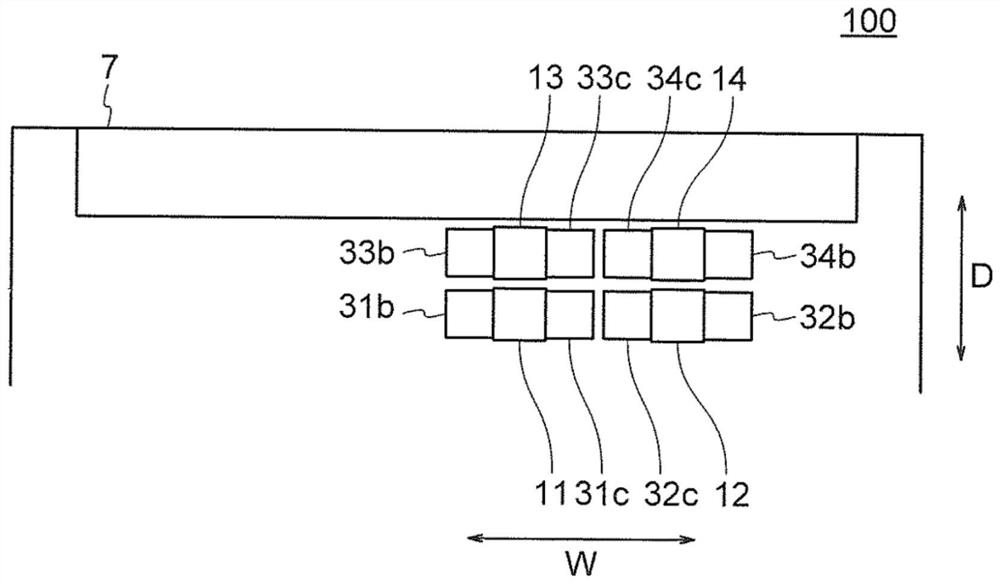

[0026] Furthermore, in this embodiment, the multi-color air-jet loom 100 has four weft insertion systems, but in figure 1 In , a part of the weft insertion system is omitted, and the arrangement of the main nozzles 1a, 1b, 1c, 2a, 2b, 2c and the main air tanks 11, 12 corresponding to the two weft insertion systems 1, 2 is schematically shown. The weft insertion system 1 has main nozzles 1a, 1b, 1c and a weft yarn length measuring and accumulating device 8 . The weft insertion system 2 has main nozzles 2a, 2b, 2c and a weft yarn length measuring and accumulating device 9 . A main air tank 11 is connected to the main nozzles 1a, 1b, and 1c. A main air tank 12 is connected to the main nozzles 2a, 2b, and 2c.

[0027] Additionally, with figure 1 The main nozzles and the main air tanks 13 and 14 corresponding to the not-shown weft insertion system are also arranged in the same manner....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com