A horizontal side-fired coil structure rapid steam generation system

A generation system and coil tube technology, applied in steam generation, control systems, steam boilers, etc., can solve the problems of large floor area, large steel consumption, low heat transfer efficiency, etc., and achieve small floor space and low raw material consumption , high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these specific implementations. Those skilled in the art will realize that the present invention covers all alternatives, modifications and equivalents as may be included within the scope of the claims.

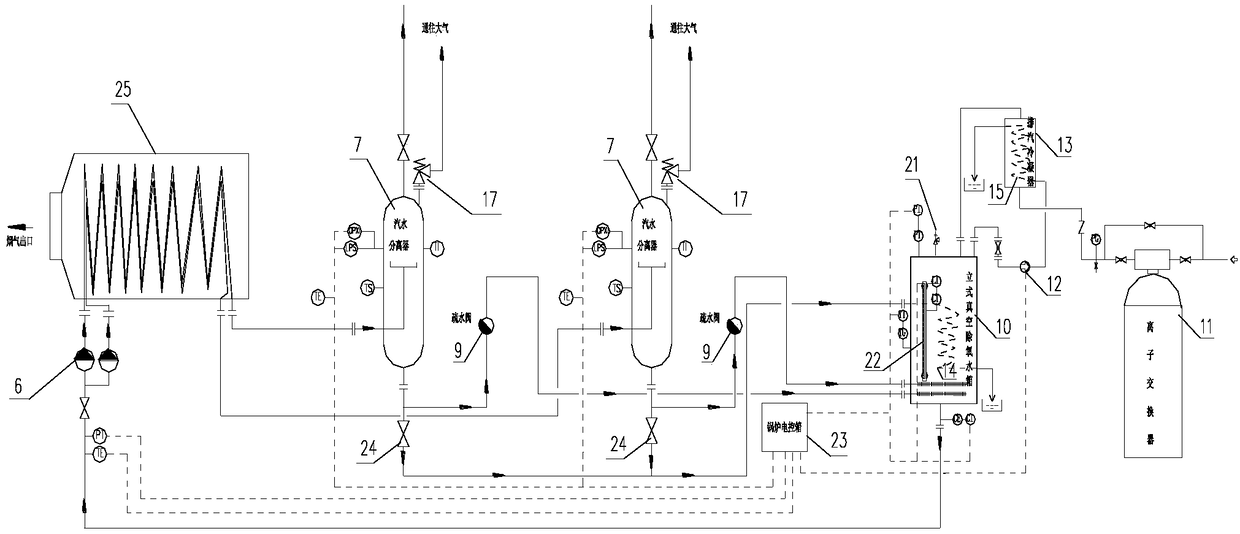

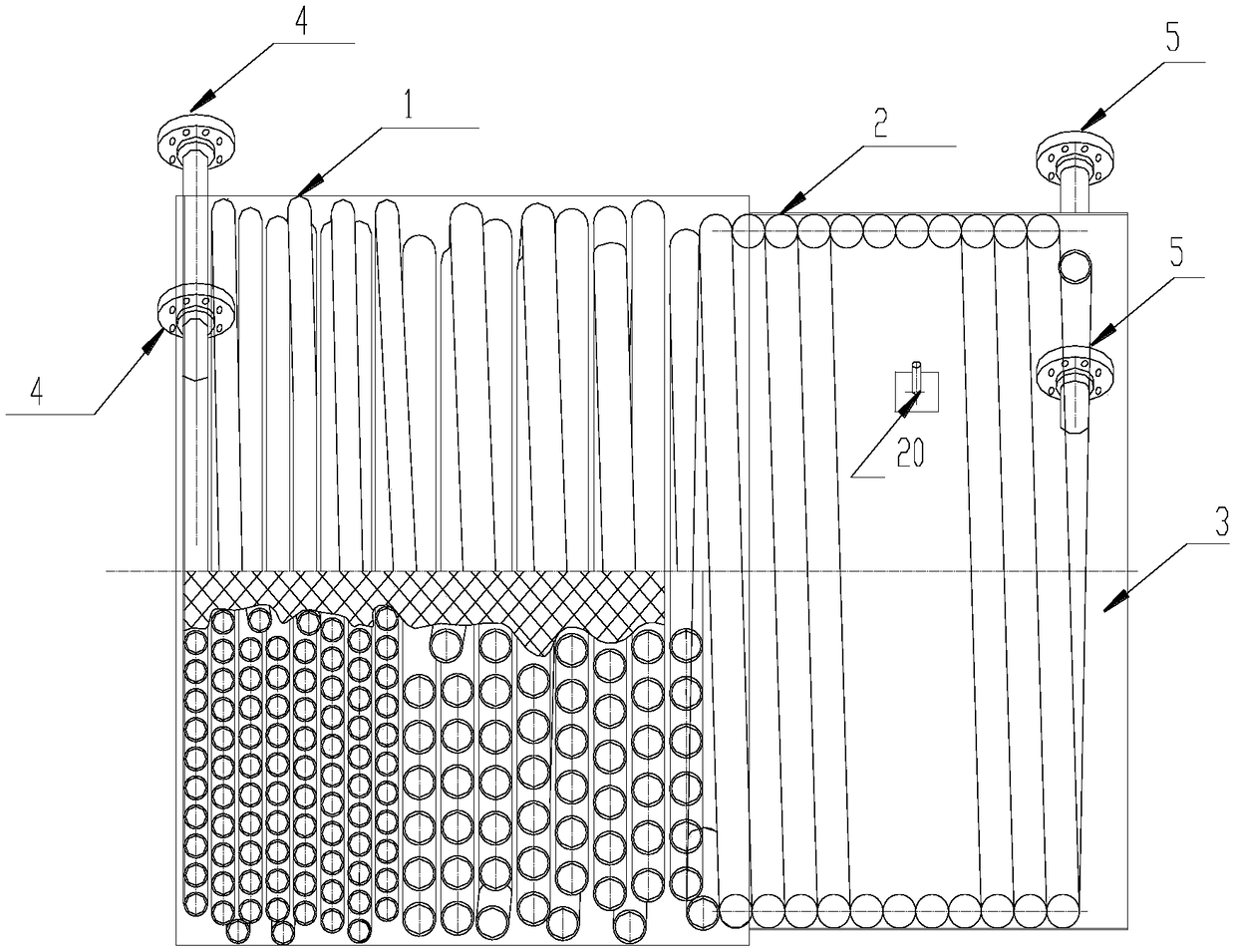

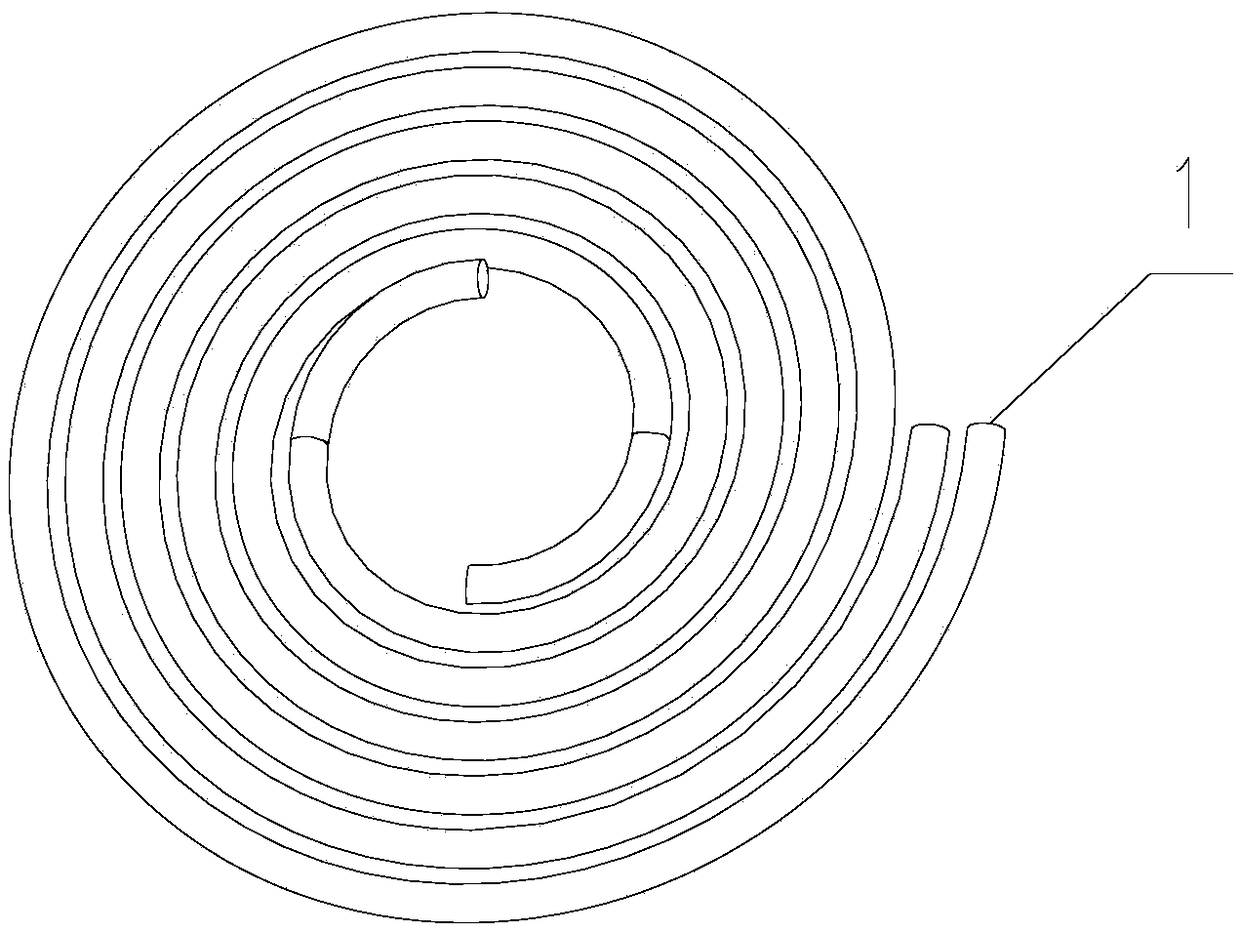

[0022] refer to Figure 1-5 , a horizontal side-fired coil structure rapid steam generation system, including a water treatment system, a heat exchanger, a steam-water separator, and a combustion system, the water treatment system is a sodium-magnesium ion exchanger 11, exhaust steam The vacuum deaeration water supply system that condenser 13, vacuum deaeration pump 12, vertical vacuum deaeration water tank 10 constitute, the water inlet of described sodium-magnesium ion exchanger 11 is connected with running water pipe, and its soft water outlet is connected with steam exhaust condenser 13 The water inlet is connected, the soft wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com