Bicycle double-brake mechanical disc-braking device

A dual-brake, bicycle technology, applied in the direction of bicycle brakes, bicycle accessories, etc., can solve the problems of easy deformation of discs, easy wear and tear of brake pads, dragging and other problems, and achieve the effect of simple and practical structure, good braking effect and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

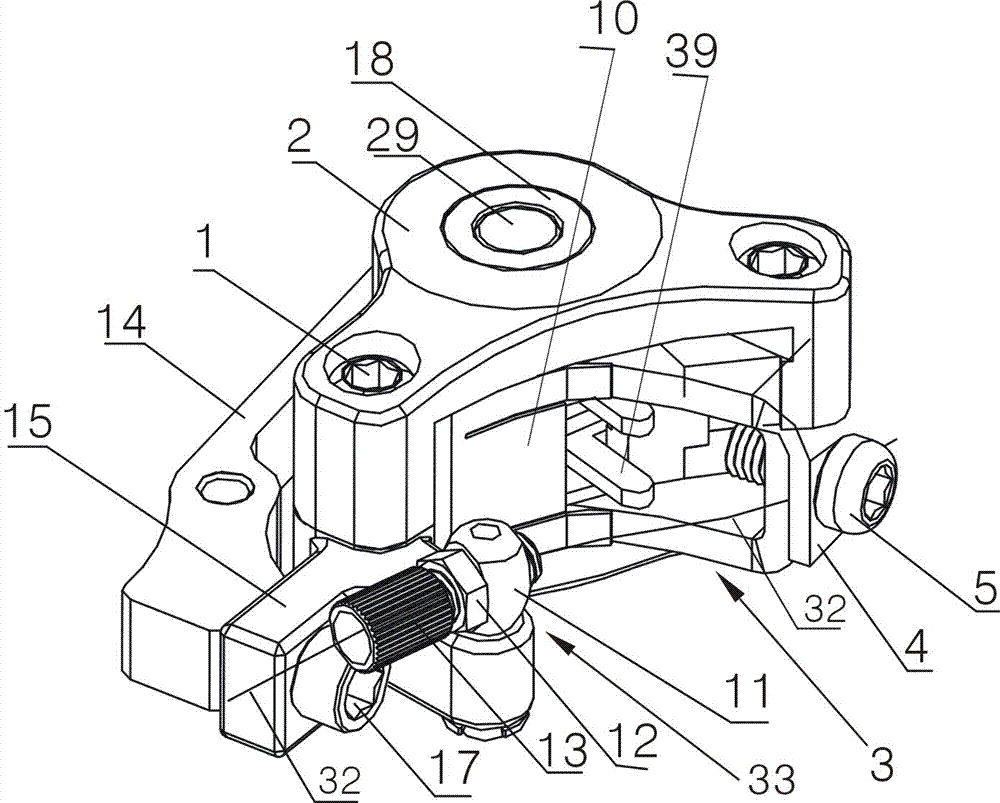

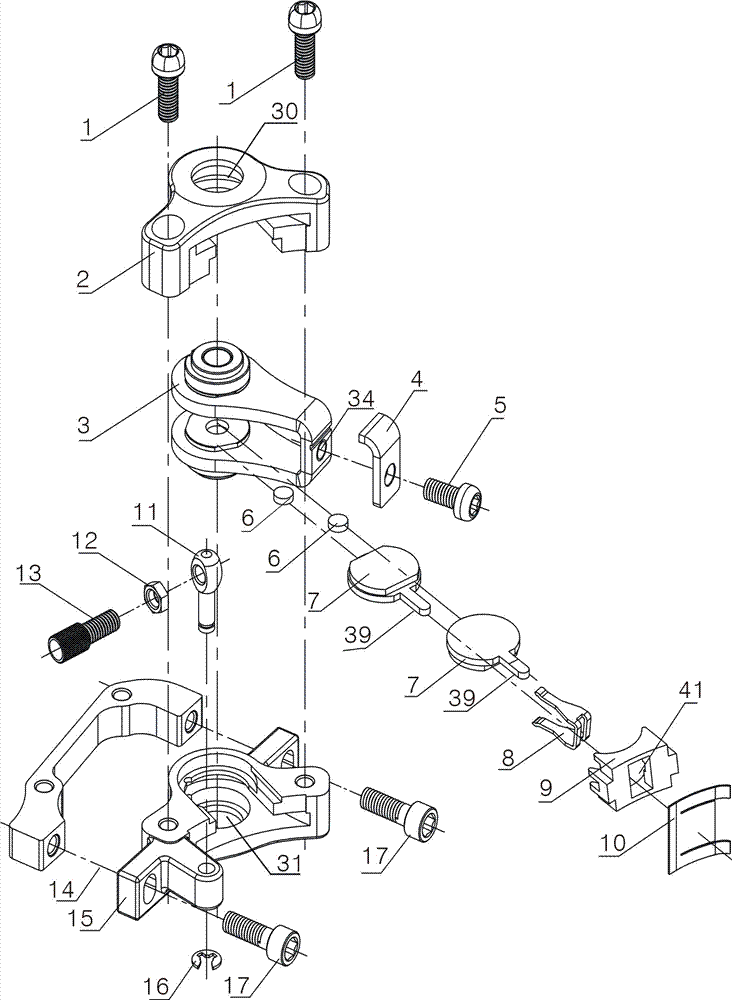

[0026] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

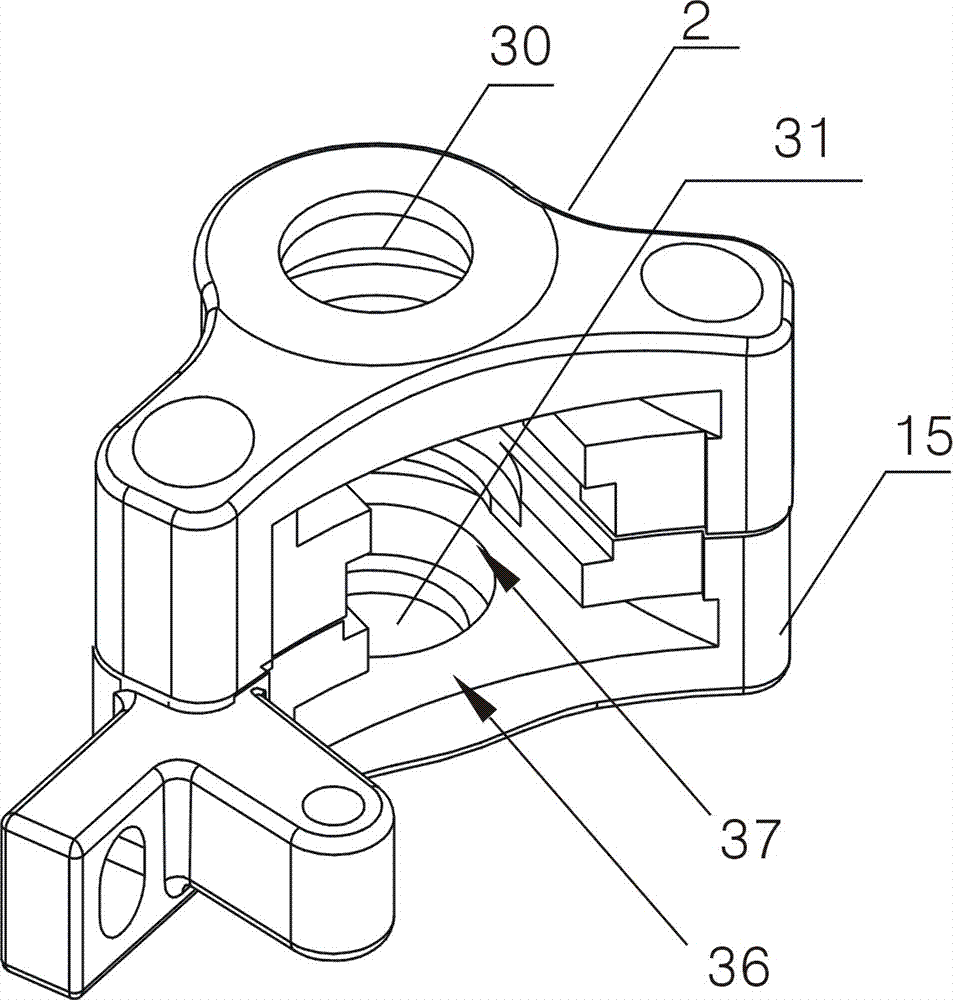

[0027] like Figure 1-8 As shown, a bicycle dual-brake mechanical disc brake device includes an upper cover 2 and a lower cover 15, and a power biaxial rotor group 3 is placed in an inner cavity 37 between the upper cover 2 and the lower cover 15. The power The biaxial rotor group 3 includes a biaxial connecting rod 21, a first stator 18, a first rotor 20, a second stator 22, a second rotor 23, and a ball 19. The biaxial connecting rod 21 has a first shaft arm 24 and a The second shaft arm 25 .

[0028] figure 1 , 2 , 3, 4, 5, for the convenience of explanation, Figure 5 2 parts of the middle and upper cover are cut off. The first rotor 20 is installed in the first shaft arm hole 26, the shaft hole 38 of the first stator 18 is penetrated in the rotating shaft 29 of the first rotor 20, the bead groove of the first stator 18 and the first rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com