High-efficiency energy-saving forklift hoisting mechanism

An energy-saving, forklift technology, applied in the direction of lifting devices, etc., can solve the problems of high operating noise, low transmission efficiency, and low service life, and achieve the effects of low operating noise, convenient system installation and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

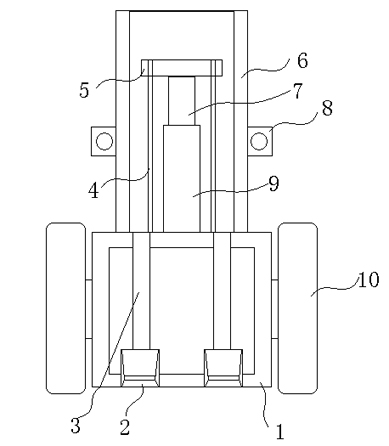

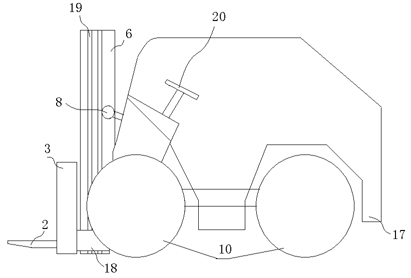

[0025] Such as figure 1 , figure 2 As shown, a high-efficiency and energy-saving forklift lifting mechanism, it at least includes a forklift body 17, a fork frame 1 connected to the front end of the forklift body 17, a fork 2 and a guide frame 6, the fork frame 1 and the guide frame 6 pass through the guide groove 19 sliding connection, the two horizontal forks 2 on the left and the right are slidingly connected to the fork frame 1 through the fork rod 3, the upper end of the guide frame 6 is connected to the upper end of the forklift body 17 through the left and right front big arm drive cylinders 8, and the guide frame 6. The lower end is fixed to the chassis of the forklift body 17. Fork head frame 1 has a fork head guide frame 18 at both ends. Driven by the transmission belt / chain 4, the fork head guide frame 18 slides and moves up and down along the guide frame 6 in the guide groove 19. The two transmission belts One end of the chain 4 is fixed to the fork head frame 1,...

Embodiment 2

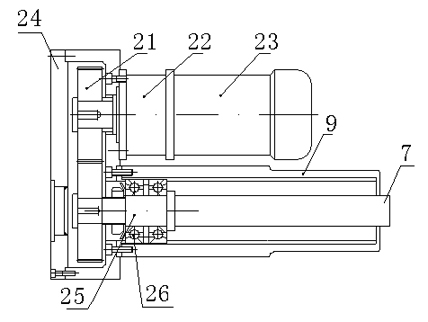

[0028] Such as image 3 As shown, in order to enhance the driving force and balance of the forklift, the electric cylinders 9 in the guide frame 6 are two groups, vertically erected between the left and right frames of the guide frame 6, the left electric cylinder 13 and the right electric cylinder 14 of the two groups of electric cylinders Balanced arrangement, one end of the left drive belt / chain 11 and right drive belt / chain 12 is fixed to the fork frame 1, the other end is fixed on the forklift body 17, there is a forklift moving wheel 10 under the forklift body 17, and the middle of the two drive belts / chains 4 passes through the horizontal The elevating rod 5 is transitionably connected, and the left push rod 15 and the right push rod 16 of the left electric cylinder 13 and the right electric cylinder 14 are vertically connected with the horizontal elevating rod 5 .

[0029] Both groups of electric cylinders include motor 23, gear pair 21, gearbox 24, transmission shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com