Electrically controlled manipulation method of grader

A leveling, electromechanical technology, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of low transmission efficiency, low service life, inconvenient installation, etc., to achieve convenient system installation, long service life, and easy replacement and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

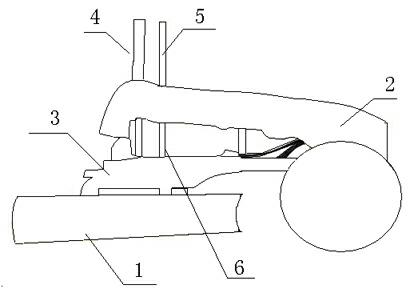

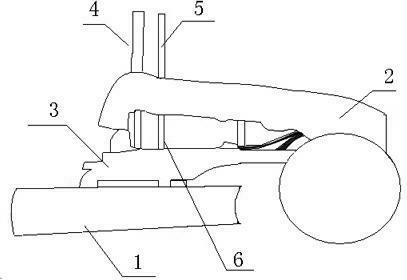

[0021] Such as figure 1 As shown, it at least includes the flat bucket 1 of the loader, the leveling body 2, the operating mechanism 15 and the operating mechanism 15. The flat bucket 1 is connected to the leveling body 2 through the leveling arm 3. The leveling arm 3 includes left and right arms, distributed At the left and right positions of the leveling body 2, movable joints are arranged on the left and right arms, and the left and right arms are respectively connected with electric cylinders 9 telescopic arm push rods 7, and the electric cylinders 9 cylinder bodies are fixed with the leveling body 2, left and right The electric cylinder 9 of the electric cylinder 9 is electrically connected with the operating mechanism 15 respectively, and the electric cylinder 9 of the left and right arms is controlled by the operating mechanism 15.

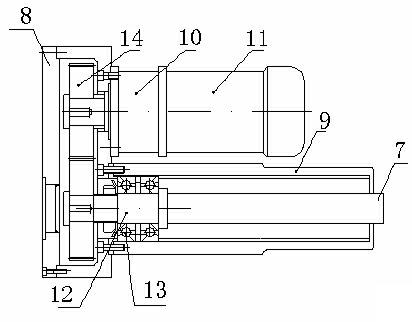

[0022] Such as figure 2 As shown, the electric cylinder 9 includes a motor 11, a gear pair 14, a gearbox 8, a transmission shaft 12, a t...

Embodiment 2

[0025] Electric cylinder 9 comprises motor 11, transmission shaft 12, transmission bearing 13 and push rod 7, and motor 11, transmission shaft 12, transmission bearing 13 and push rod 7 are on an axis, and motor 11 drives transmission shaft 12 to rotate through speed changer, transmission shaft 12 is fixed in the transmission bearing 13, and the push rod 7 extends or retracts with the rotation of the motor 11 shaft. When working, the electric cylinder 9 is connected with the operating mechanism 15 of the leveling body 2, and the push rod 7 is controlled to start and stop by the operating mechanism 15 , extend and retract, so that the leveling arm drives the leveling bucket to lift.

[0026] In the present invention, the electric cylinder 9 includes a left electric cylinder 4 and a right electric cylinder 5, and the left electric cylinder 4 and the right electric cylinder 5 are respectively on the left and right arms.

[0027] A complete electric cylinder should include a power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com