Porous ceramic atomizing core and preparation method thereof

A technology of porous ceramics and atomizing cores, applied in the field of ceramic materials, can solve the problems of affecting the taste of electronic cigarettes, oil leakage, low production process efficiency, etc., and achieve the effects of high dimensional stability, simple process flow and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

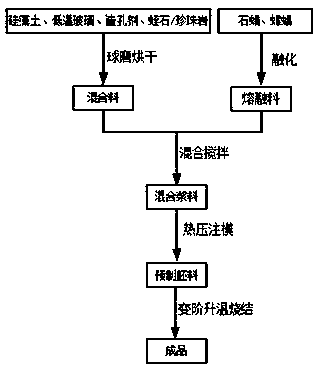

Method used

Image

Examples

Embodiment 1

[0020] According to the mass percentage, weigh 55% diatomite, 25% low-temperature glass, 19% PMMA, 1% vermiculite, and weigh 40% of the total mass of the above-mentioned diatomite, low-temperature glass, PMMA and vermiculite Paraffin wax and 5% beeswax, among them, the median particle size of diatomaceous earth is 20 μm, the median particle size of low temperature glass is 25 μm, the median particle size of PMMA is 15 μm, and the median particle size of vermiculite is 12 μm.

[0021] Mix diatomaceous earth, low-temperature glass powder, PMMA and vermiculite evenly, ball mill for 2 hours, and dry at 90°C for 5 hours to obtain a mixture. Melt paraffin and beeswax at 95°C into a liquid and mix with the mixture. Stir for 2 hours, pour the uniformly mixed slurry into the oil guide rod, and hot die-cast it to make a prefabricated green body. Heat the green body at a heating rate of 130°C / h to 160°C, and then at a heating rate of 145°C / h Raise the temperature to 340°C, then raise the...

Embodiment 2

[0023] According to mass percentage, take by weighing 60% diatomite, 25% low-temperature glass, 14% PMMA, 1% vermiculite, and weigh 42% of the total mass of diatomite, low-temperature glass, PMMA and vermiculite. % paraffin and 6% beeswax, among which, the median particle size of diatomaceous earth is 25 μm, the median particle size of low temperature glass is 30 μm, the median particle size of PMMA is 20 μm, and the median particle size of vermiculite is 15 μm .

[0024] Mix diatomaceous earth, low-temperature glass powder, PMMA and vermiculite evenly, ball mill for 3 hours, and dry at 85°C for 5 hours to obtain a mixture. Melt paraffin and beeswax at 95°C into a liquid and mix with the mixture. Stir for 2.5 hours, pour the uniformly mixed slurry into the oil guide rod, and hot die-cast it to make a prefabricated body. Raise the temperature of the green body to 180°C at a heating rate of 145°C / h, and then increase the temperature at a rate of 145°C / h The temperature was rais...

Embodiment 3

[0026] According to mass percentage, take by weighing 65% diatomite, 20% low-temperature glass, 13.5% PMMA, 1.5% vermiculite, and weigh 45% of the total mass of diatomite, low-temperature glass, PMMA and vermiculite. % paraffin and 7% beeswax, among them, the median particle size of diatomaceous earth is 30 μm, the median particle size of low temperature glass is 35 μm, the median particle size of PMMA is 25 μm, and the median particle size of vermiculite is 15 μm .

[0027] Mix diatomaceous earth, low-temperature glass powder, PMMA and vermiculite evenly, ball mill for 3 hours, and dry at 90°C for 5 hours to obtain a mixture. Melt paraffin and beeswax at 95°C into a liquid and mix with the mixture. Stir for 2.5 hours, pour the uniformly mixed slurry into the oil guide rod, and make a prefabricated green body by hot die-casting. The green body is heated up to 180°C at a heating rate of 130°C / h, and then heated at a rate of 145°C / h The temperature was raised to 340°C at a rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com