Novel non-leakage mechanical seal single-stage sliding valve vacuum pump

A sliding valve vacuum pump and mechanical seal technology, which is applied to mechanical equipment, piston pump sealing devices, pumps, etc., can solve problems such as poor reliability, oil leakage, and complex structure, and achieve the effect of small friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

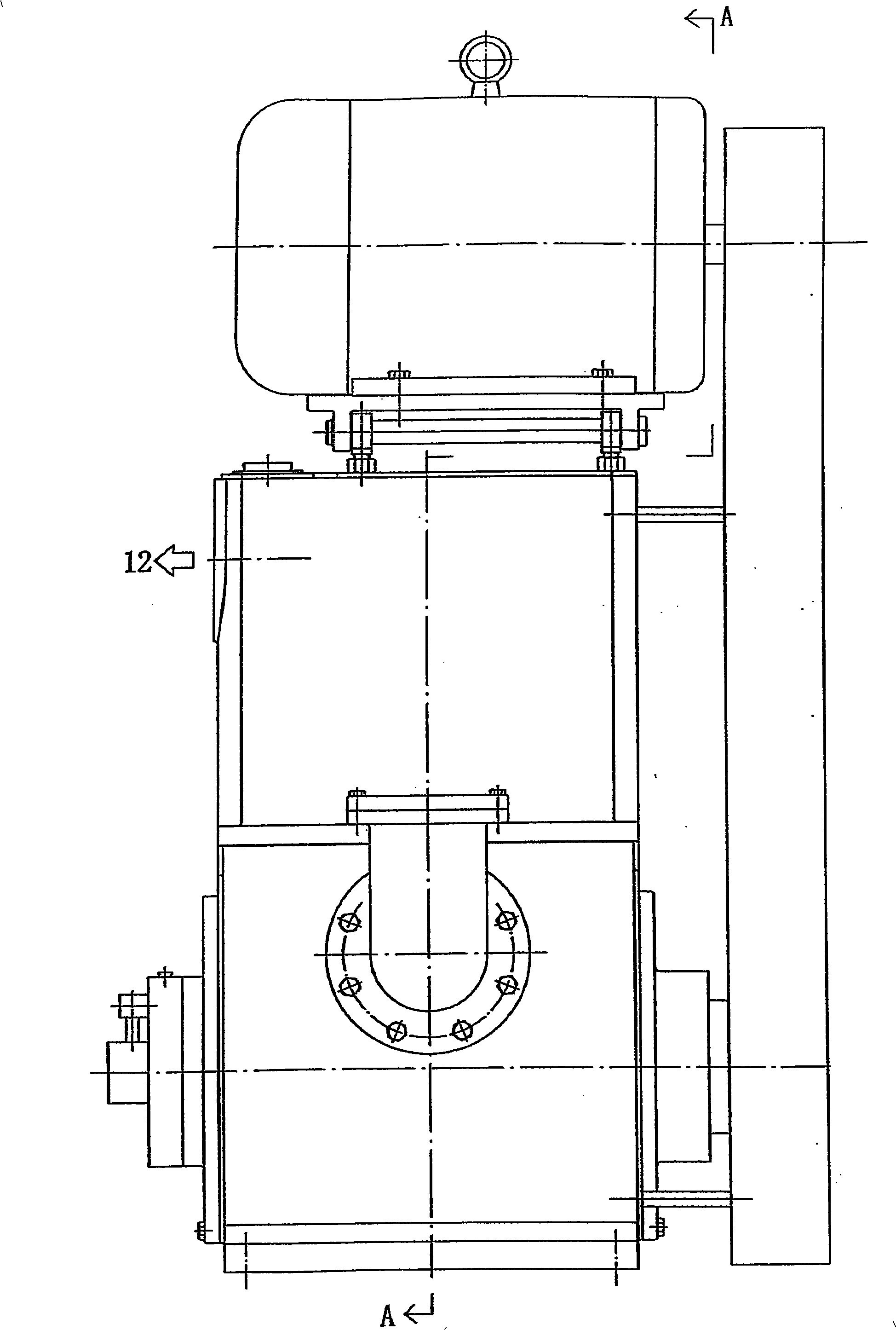

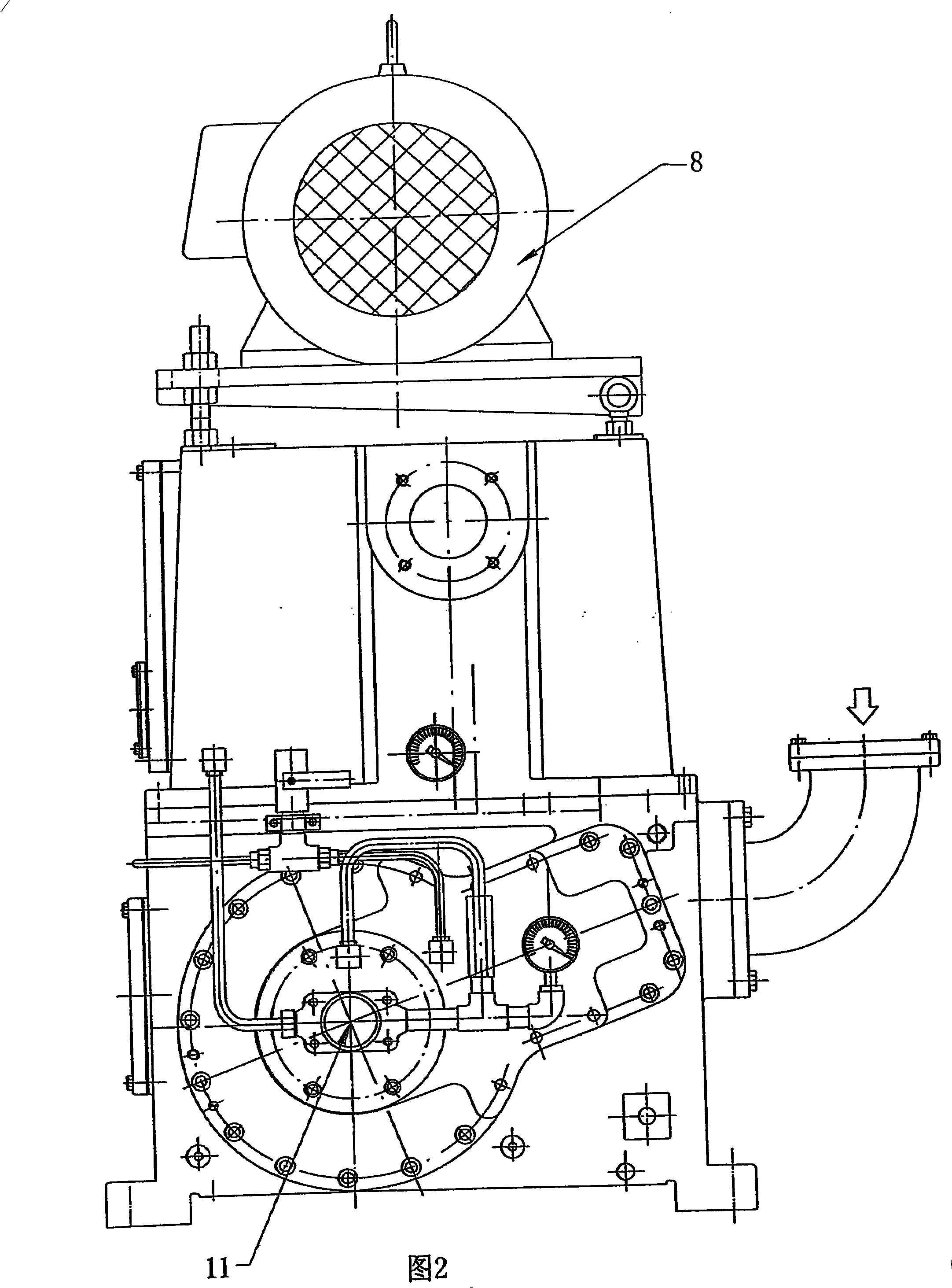

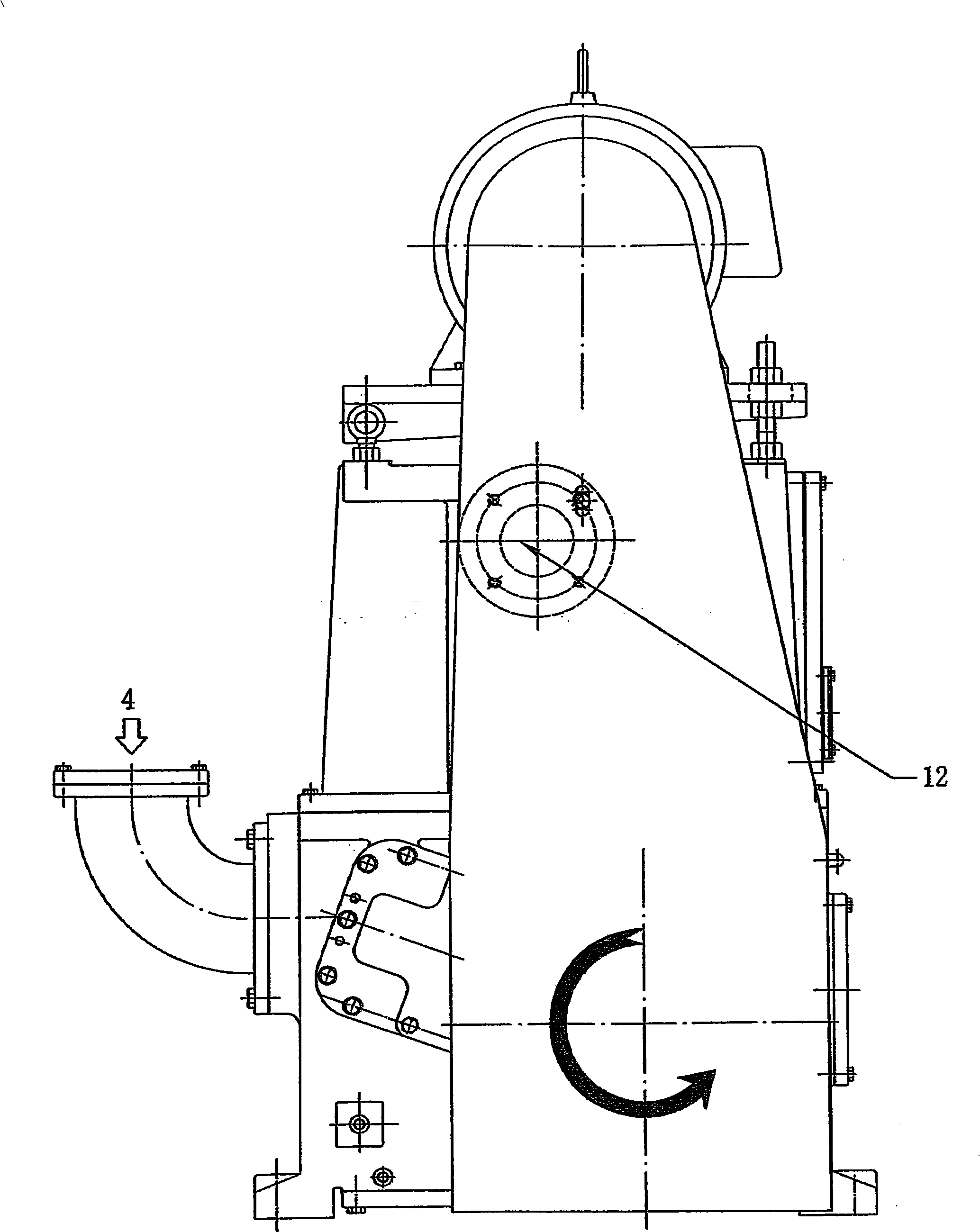

[0015] see figure 1 ~6. The new type non-leakage mechanical seal single-stage slide valve vacuum pump involved in the utility model includes a pump body 1, a guide rail 3 is arranged on the pump casing of the pump body 1, and a pump shaft 10 is arranged in the cavity of the pump body 1, There is a lubricating oil hole in the center of the pump shaft 10. The inner cavity of the pump body 1 is divided into two chambers, one close to the closed end of the pump shaft 10, called the closed end chamber, and the other close to the outlet of the pump shaft 10. The shaft end is called the shaft end chamber. There are two sets of spool valve eccentric wheel mechanisms 2 installed on the pump shaft 10, one of which is set in the closed end chamber and is called the closed end spool valve eccentric wheel. mechanism, the other set is set in the shaft end chamber, called the shaft end spool valve eccentric wheel mechanism, and the closed end spool valve eccentric wheel mechanism includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com