Glass pipe cutting device

A technology for cutting equipment and glass tubes, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of inconvenient cutting of glass tubes, easy to hurt hands, rough incision, etc., and achieve simple structure, high safety performance, Even cut effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

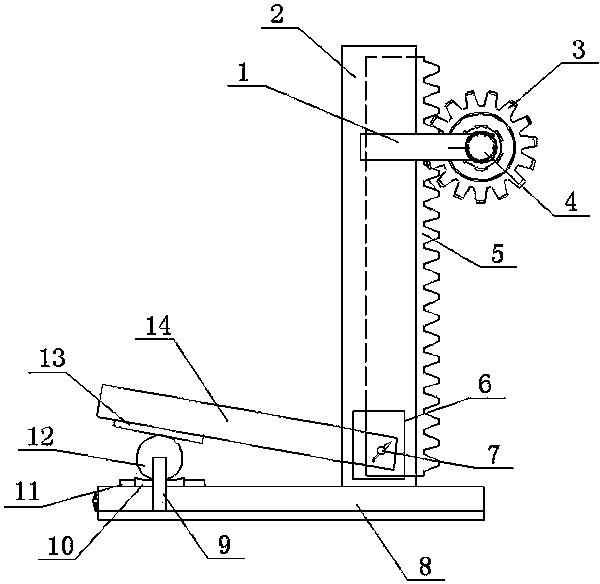

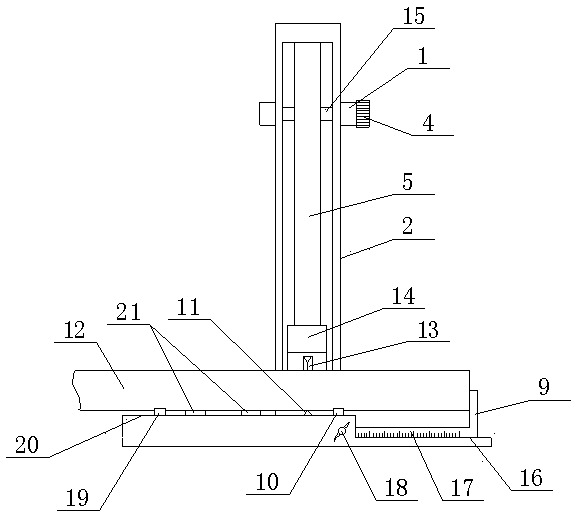

[0016] Glass tube cutting equipment, including a base 8, a rack 5, a gear 3, an upper blade 13, a lower blade 11 and a blade fixing rod 14, the rack 5 is fixed on the right side of the base 8 through the rack holder 2, and the gear 3. The gear fixing frame 1 is fixed on the upper part of the rack fixing frame 2 and meshes with the rack 5. The right end of the blade fixing rod 14 and the lower end of the rack 5 are fixed by the adjusting screw 7. The upper blade 13 is fixed on the blade fixing rod 14 The lower side of the left end of the rack 5 controls the up and down movement of the upper blade 13 to realize the cutting of glass tubes 12 of various sizes; the lower blade 11 is fixed on the left middle of the base 8 and aligned with the upper blade 13 , so that the incision of the glass tube is even after cutting, the glass tube 12 is between the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com