Laser shaping device

A technology of laser shaping and laser beam, applied in the direction of optics, optical components, instruments, etc., can solve the problems of light transmittance reduction, edge ablation, burrs and large taper, etc., and achieve no thermal influence, enlarged application, and good slit The effect of cutting effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

[0026] The technical solution of the invention is: a laser shaping device.

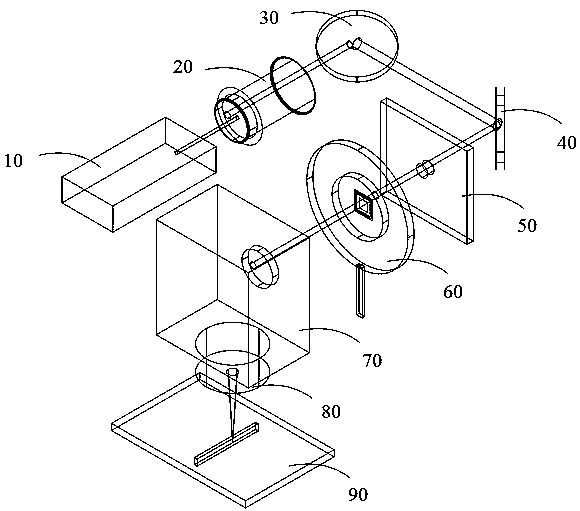

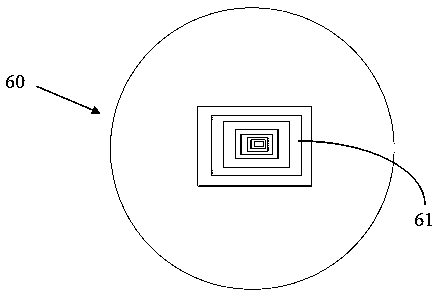

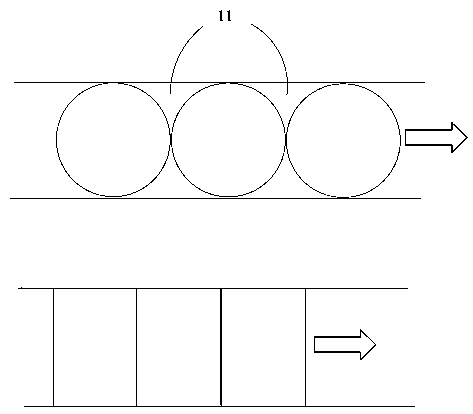

[0027] ginseng figure 1 As shown in a specific embodiment of the present invention, the laser shaping device is provided with a beam expander 20 at the output end of the laser transmitter 10, and two reflectors 30 and 40 are provided at the output end of the beam expander 20, The reflecting mirrors 30 and 40 are planar reflecting mirrors, a shaping mirror 60 is arranged at the reflection output end of the reflecting mirror 40, a spatial filter 50 is arranged between the reflecting mirror 40 and the shaping mirror 60, and a shaping mirror 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com