Treating agent for aluminum case of controller of electric bicycle and preparation method of treating agent

A technology for electric bicycles and controllers, applied in the field of chemical descaling, which can solve problems such as adverse environmental impact, increased production costs, and irritation of operators, and achieves no re-deposition of oil stains, long service life, and good descaling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

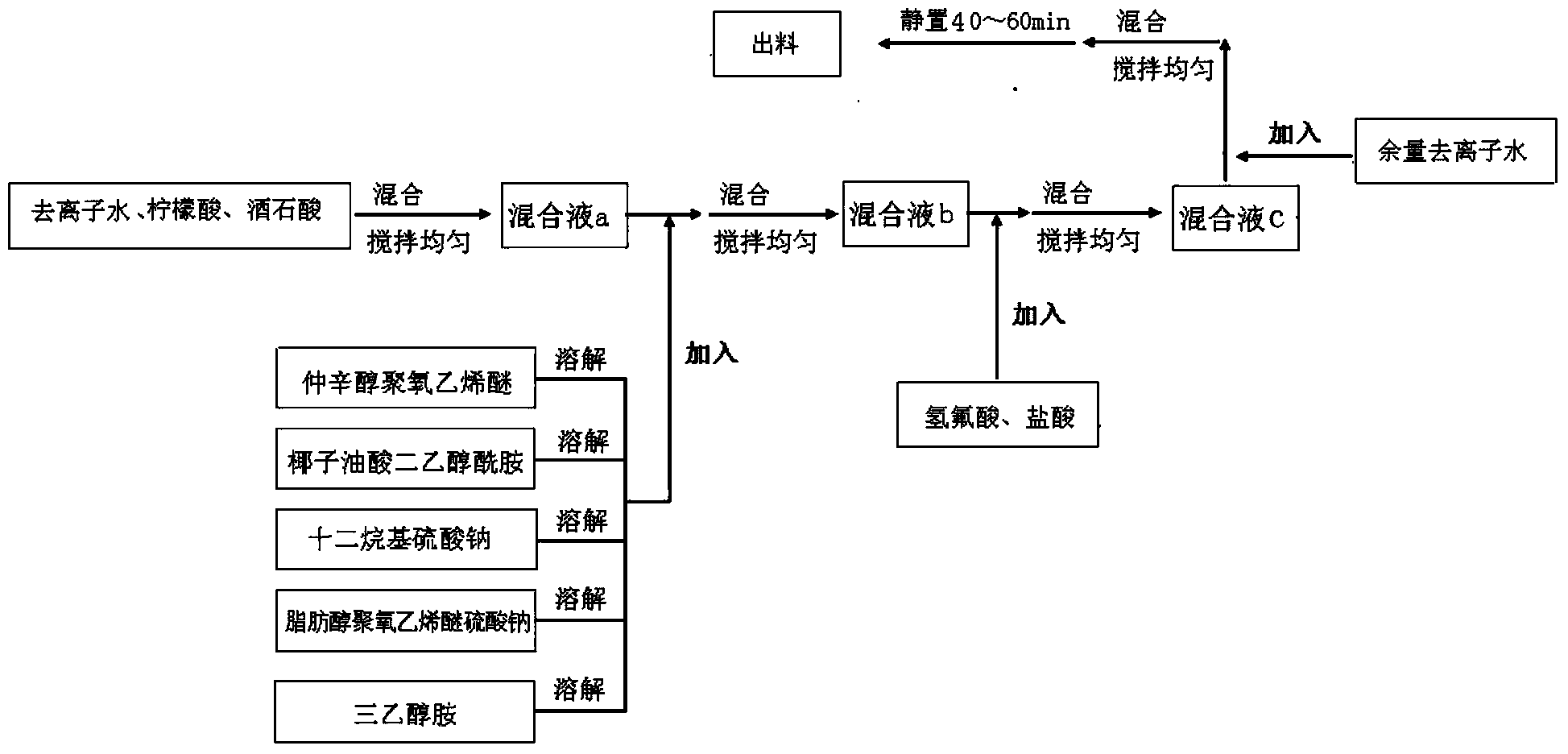

Method used

Image

Examples

Embodiment 1

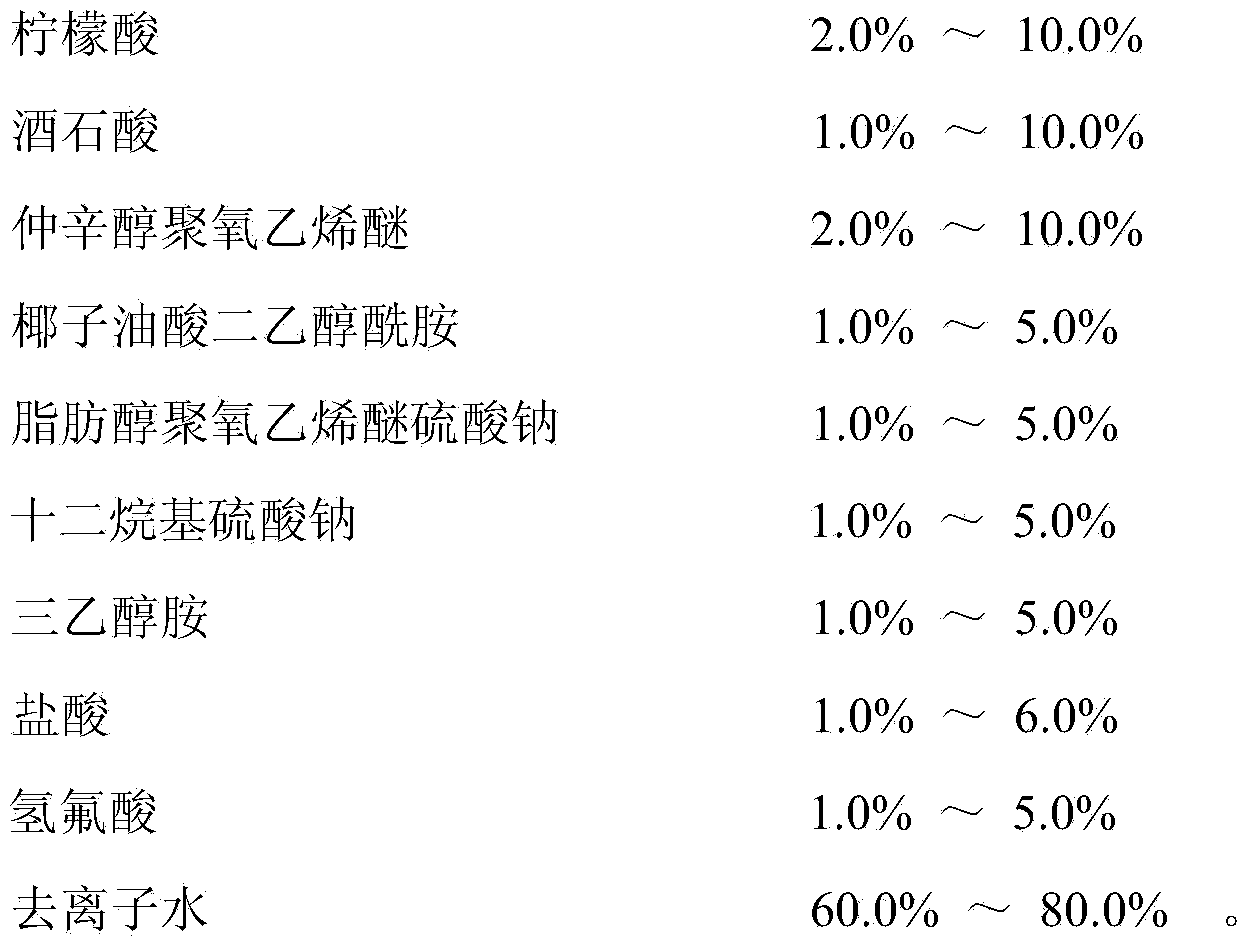

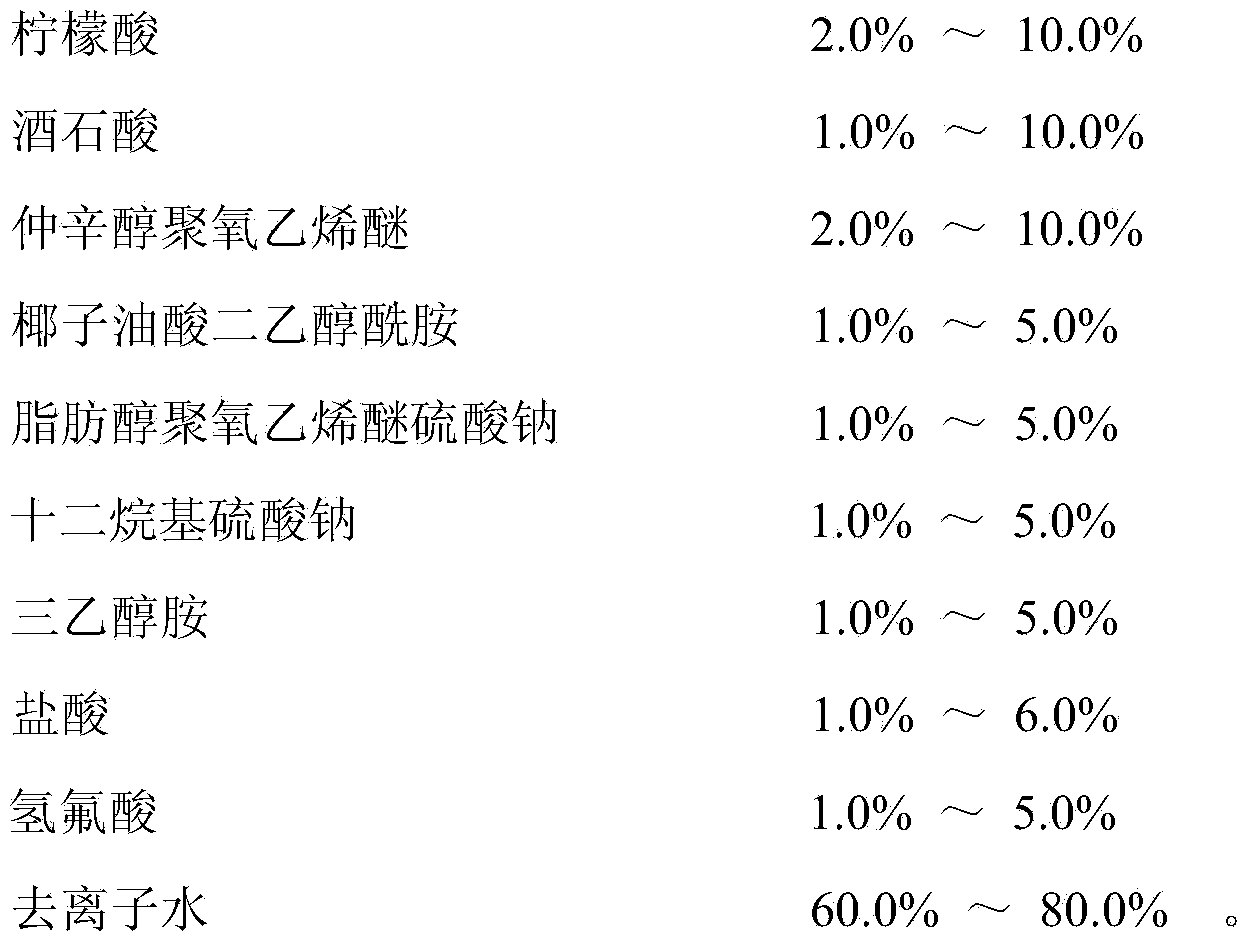

[0038] (1) Add 296kg of deionized water, 50kg of citric acid and 20kg of tartaric acid into the reaction kettle, and stir for 15min at a stirring speed of 60rpm to obtain a mixture a;

[0039] (2) Take 222kg of deionized water, add 50kg of 2-octyl alcohol polyoxyethylene ether, 20kg of coconut oleic acid diethanolamide, 40kg of fatty alcohol polyoxyethylene ether sodium sulfate, 10kg of sodium lauryl sulfate and 10kg of triethanolamine Dissolve, mix the dissolved components with the mixed solution a, and stir for 40 minutes at a stirring speed of 15 rpm to obtain the mixed solution b;

[0040] (3) Add 50kg of hydrochloric acid and 10kg of hydrofluoric acid into the mixed solution b respectively, and stir for 20 minutes at a stirring speed of 50 rpm to obtain the mixed solution c;

[0041] (4) Add the remaining amount of deionized water into the mixed solution c, stir for 50 minutes at a stirring speed of 30 rpm, let stand for 40 minutes after stirring, and discharge to obtain ...

Embodiment 2

[0051] (1) Add 306kg of deionized water, 20kg of citric acid and 30kg of tartaric acid into the reaction kettle, and stir for 10min at a stirring speed of 80rpm to obtain a mixture a;

[0052] (2) Take 229.5kg of deionized water, add 80kg of 2-octyl alcohol polyoxyethylene ether, 10kg of coconut oleic acid diethanolamide, 10kg of fatty alcohol polyoxyethylene ether sodium sulfate, 20kg of sodium lauryl sulfate and 10kg of three Dissolve the ethanolamine, mix the dissolved components with the mixed solution a, and stir for 30 minutes at a stirring speed of 25 rpm to obtain the mixed solution b;

[0053] (3) Add 35kg of hydrochloric acid and 20kg of hydrofluoric acid into the mixture b respectively, and stir for 10 minutes at a stirring speed of 70rpm to obtain the mixture c;

[0054] (4) Add the remaining amount of deionized water into the mixture c, stir for 30 minutes at a stirring speed of 50 rpm, let stand for 60 minutes after stirring, and discharge to obtain the finished ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com