Insulation paper forming machine

A technology of insulating paper and forming machine, which is applied in metal processing and other directions, can solve the problems of low production efficiency and poor dimensional accuracy of insulating paper products, and achieve the effects of improving production efficiency, good product consistency, and high product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

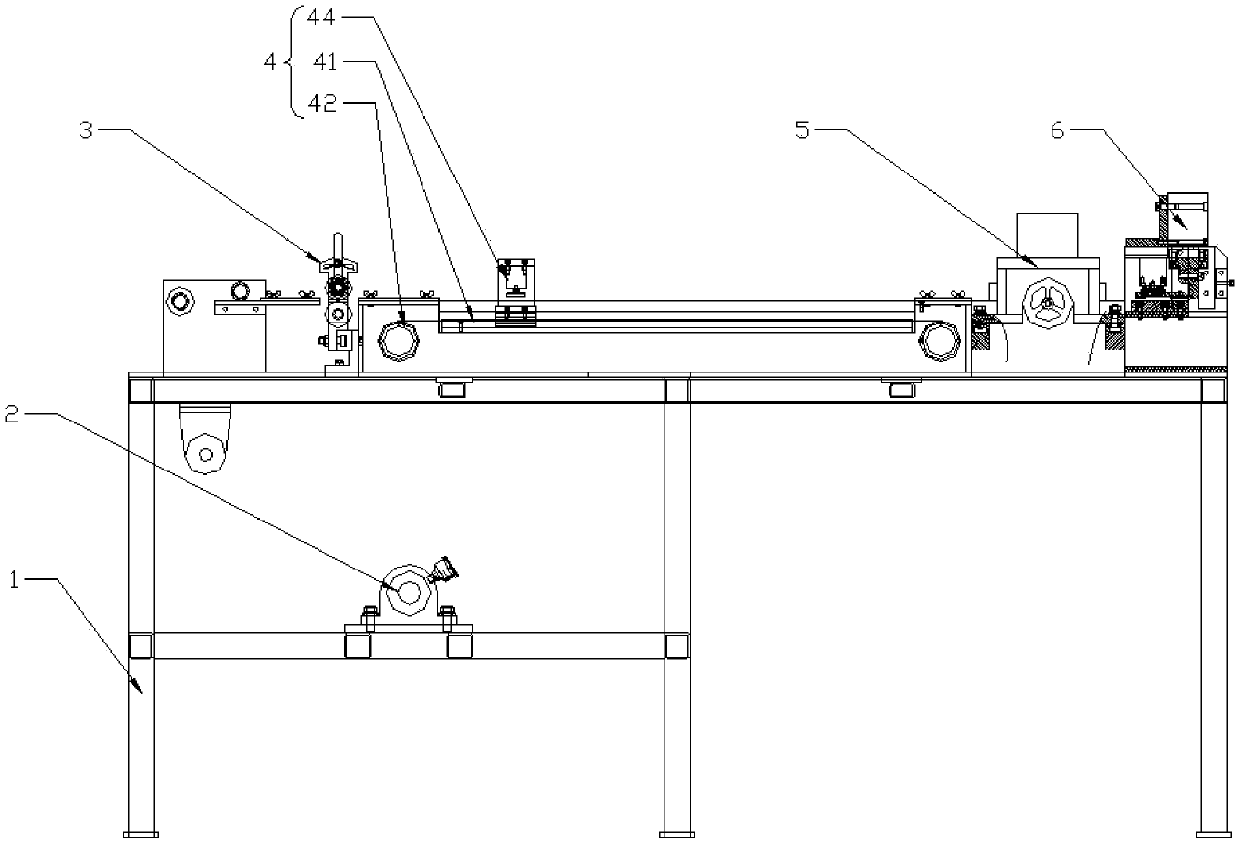

[0055] Such as figure 1 The insulating paper molding machine shown includes a frame 1, and a material shaft 2, an indentation mechanism 3, a conveying device 4, a corner cutting mechanism 5 and a cutting mechanism fixedly installed on the frame 1 in sequence along the direction of insulation paper travel 6. The material shaft 2 is used to place the insulating paper roll; the creasing mechanism 3 is used to squeeze out creases on the insulating paper; the conveying device 4 is used to provide power for the insulating paper to move forward; Cut the corners of the insulating paper according to the actual required shape; the cutting mechanism 6 is used to cut off the continuous insulating paper after indentation and corner cutting.

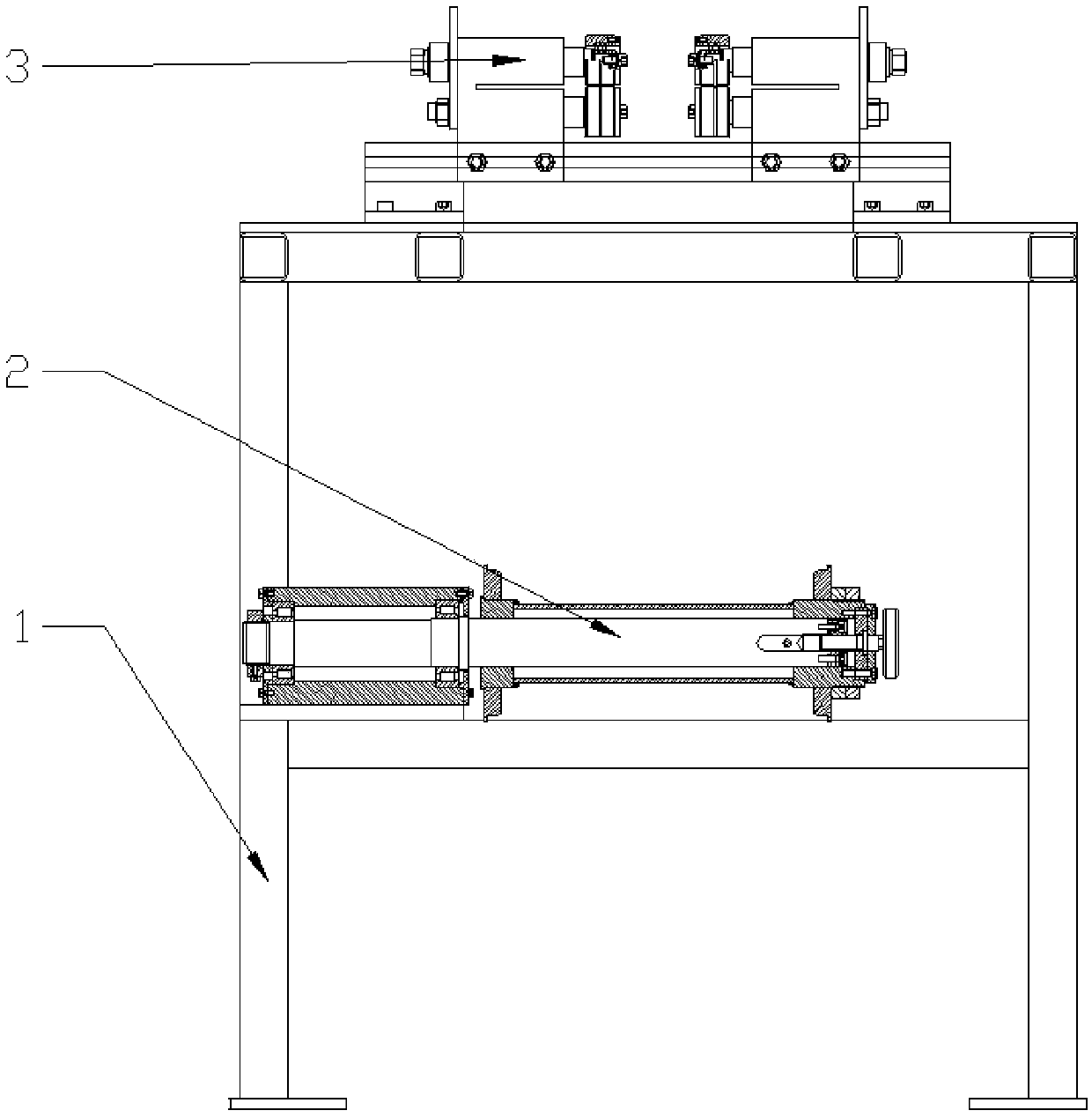

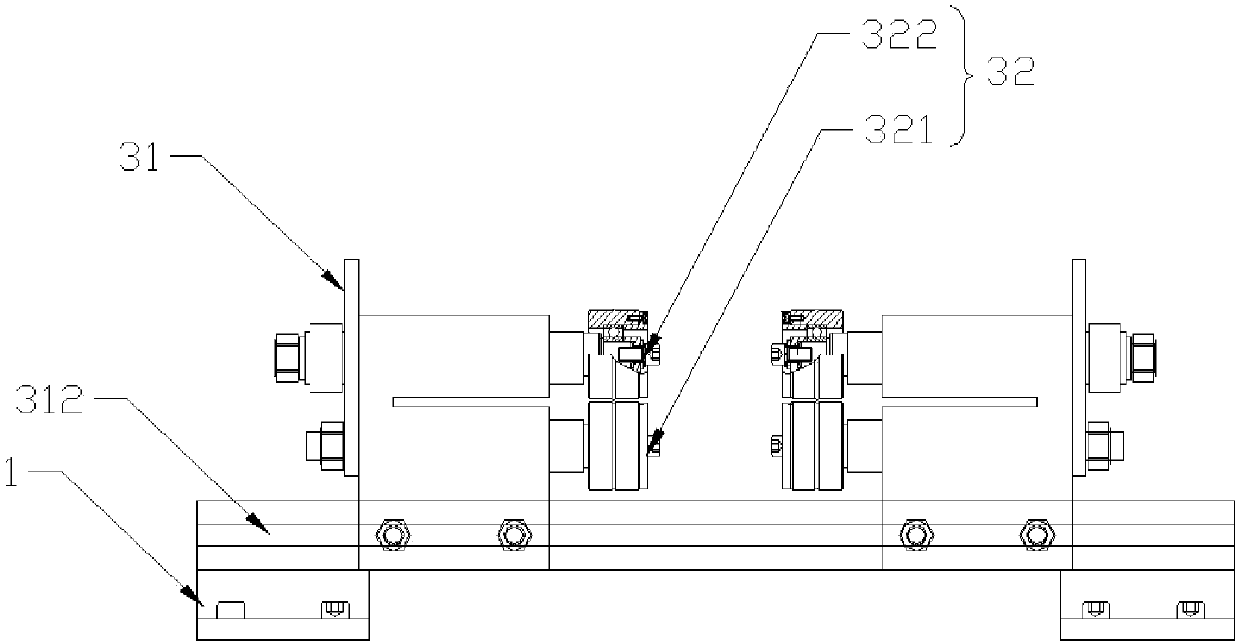

[0056] Such as figure 2 , image 3 , Figure 4As shown, the creasing mechanism 3 includes a positioning plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com