Online surface coating silicification wall treatment method for fusion device

A surface coating and treatment method technology, applied in fusion reactors, thermonuclear fusion reactors, coatings, etc., can solve problems such as impurity and fuel gas retention, steady-state operation interruption, film erosion or coverage, etc., and achieve oxygen spectrum peaks Effects of reduction, suppression of oxygen impurities, and strong adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

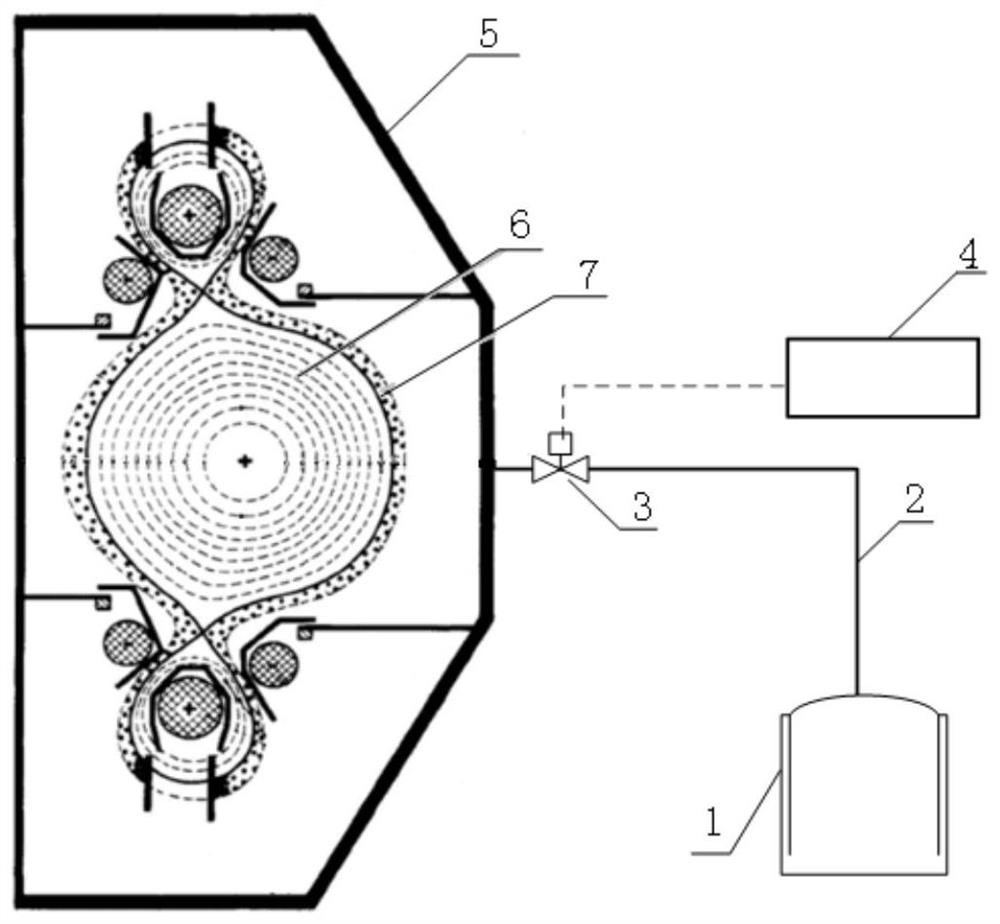

[0027] figure 1 As shown, the surge tank 1 is filled with working gas, and the working gas is sent into the vacuum chamber 5 through the piezoelectric crystal valve 3 and the gas supply pipeline 2 .

[0028] The main plasma region 6 and the scraping layer region 7 are formed in the vacuum chamber 5 , and the scraping layer 3 is formed outside the main plasma region 6 .

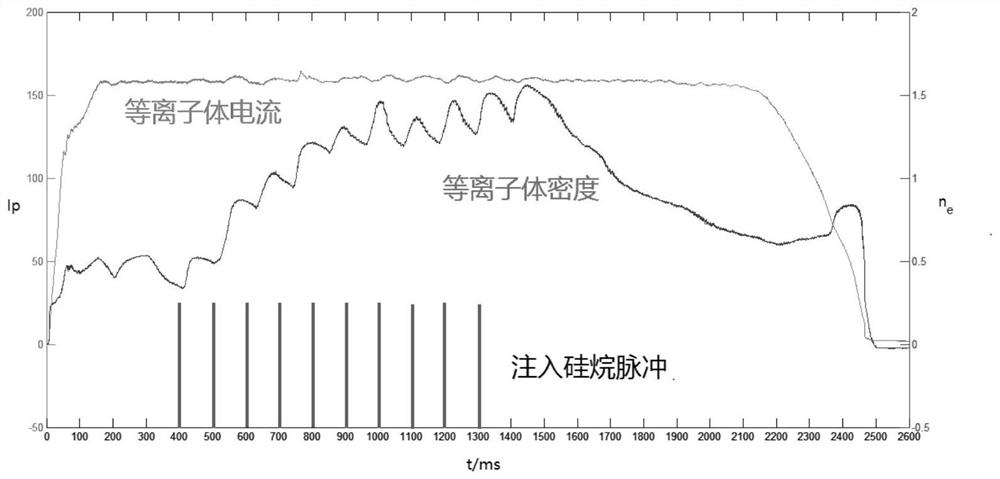

[0029] During the plasma operation, the mixed gas of deuterium silane and helium is injected into the vacuum chamber 2 through the voltage stabilizer 1, and the online surface coating silicide wall treatment is carried out, which is carried out in the ohmic heating stage of the plasma discharge of the HL-2A device. Steady-state operation of the fusion device plasma creates optimized wall conditions. The piezoelectric crystal valve 3 is connected to the power supply 4, and the power s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com